A tubular compact electrostatic coalescer for w/o emulsion electric field demulsification

An electrostatic coalescence and emulsification technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of increased difficulty in manufacturing and fixed installation of large-scale spiral blades, small processing capacity, and large volume, and achieves improvement The distribution of dwell time, the extension of dwell time, and the effect of ensuring the safety of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

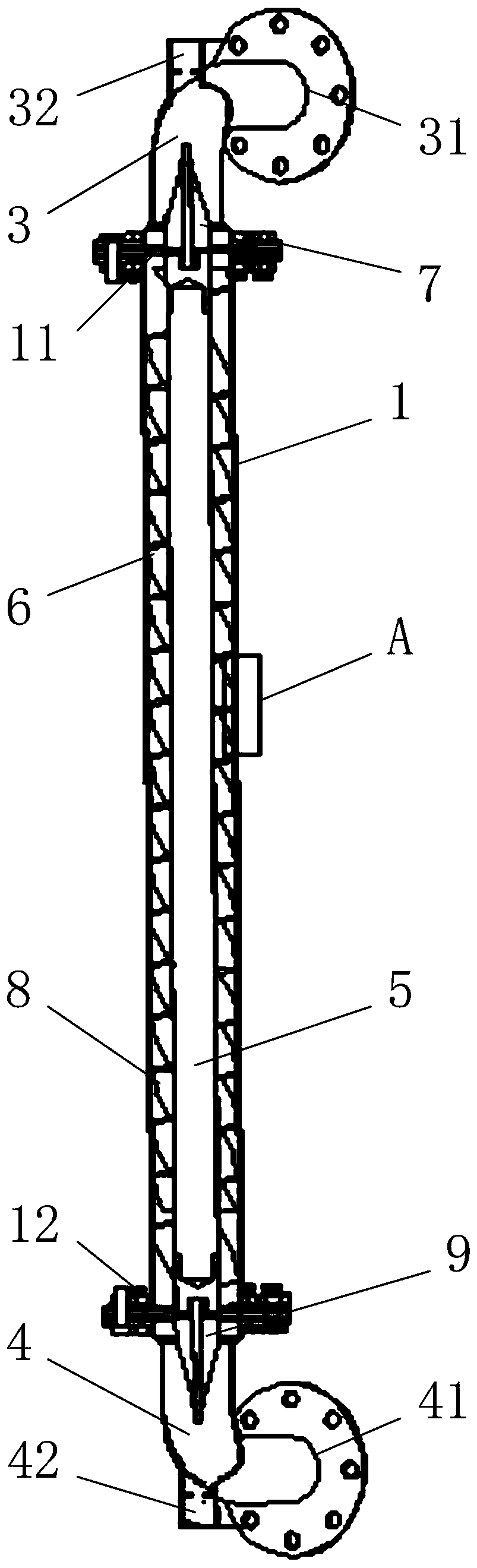

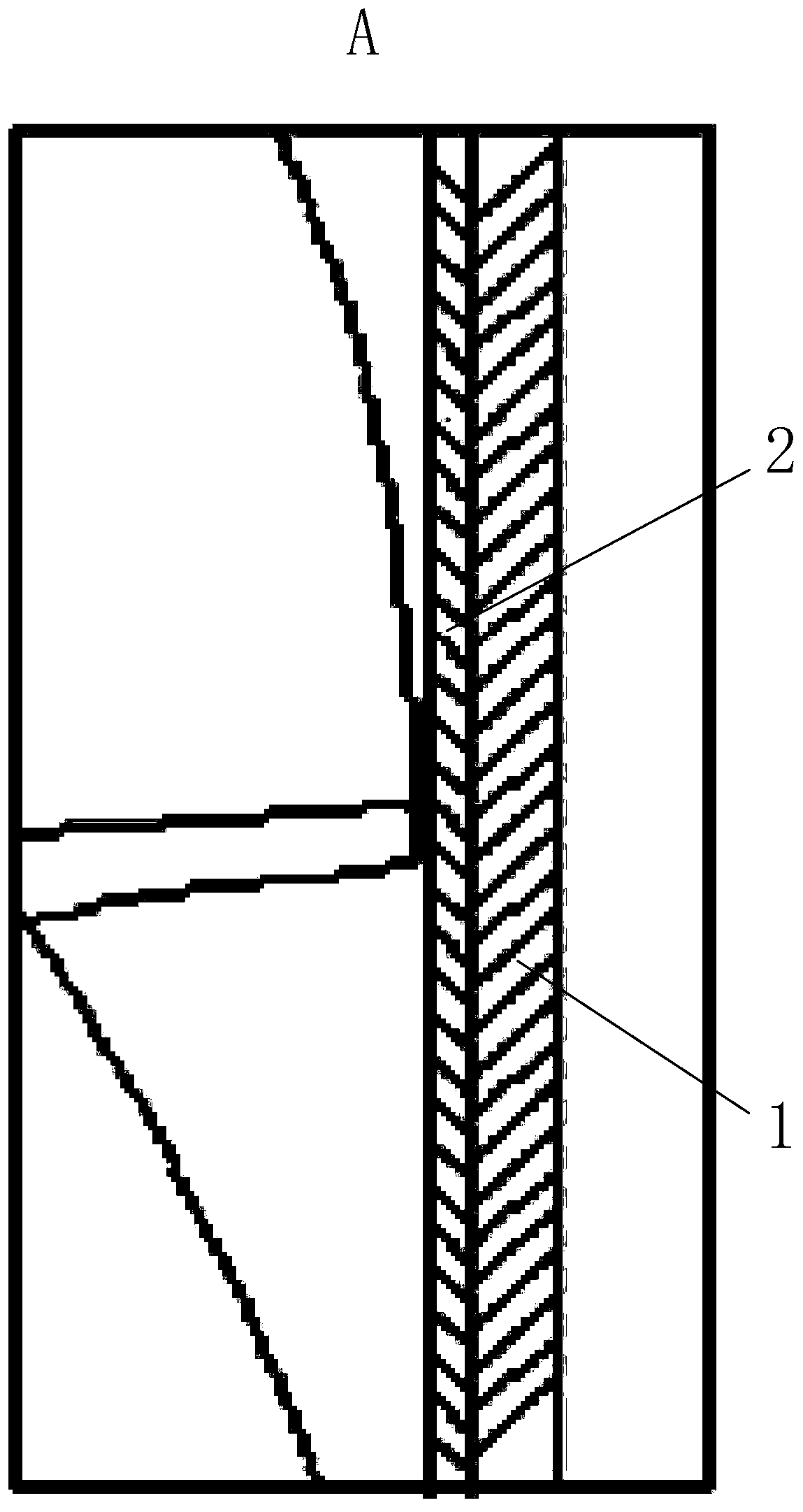

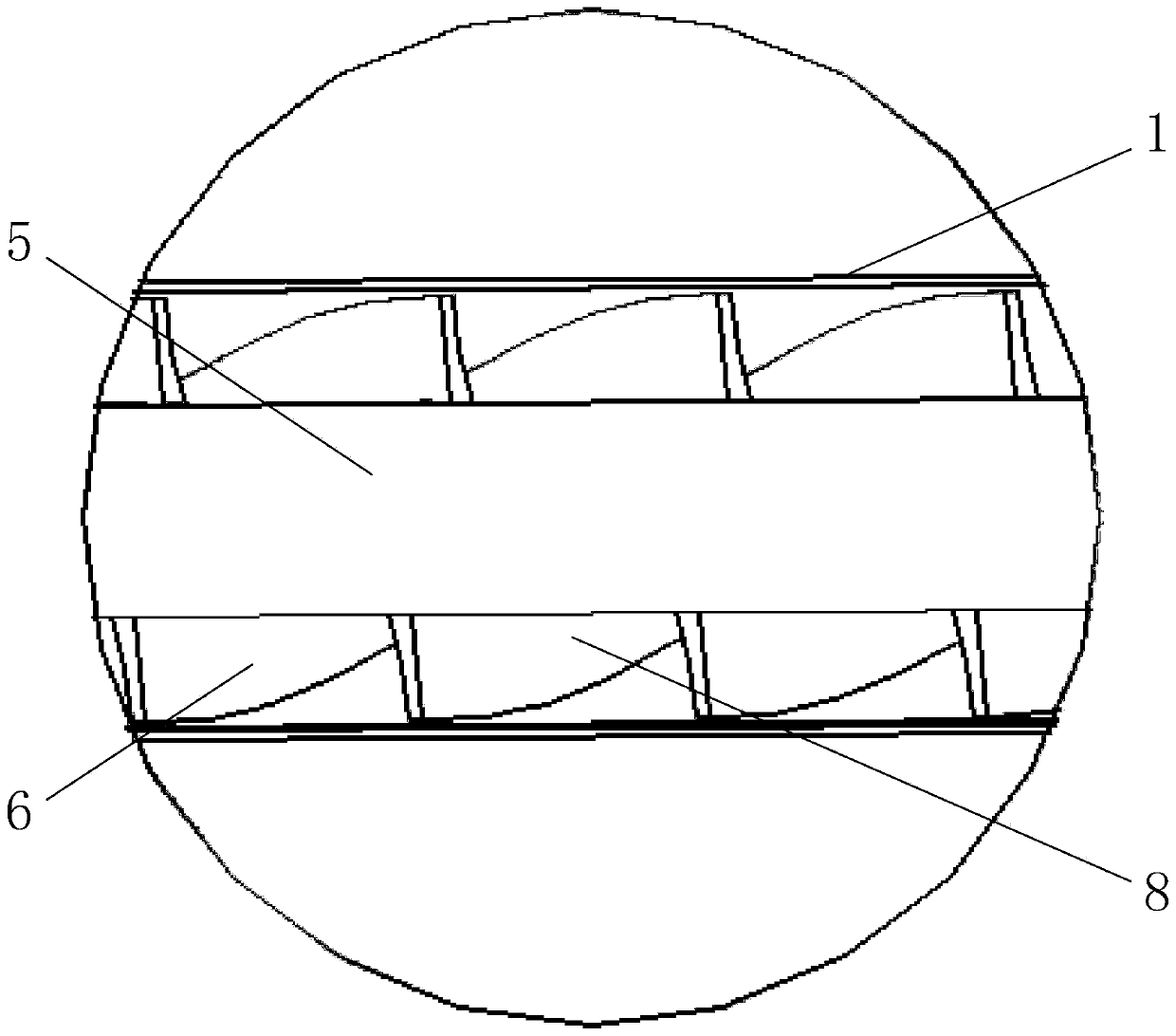

[0030] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a tubular compact electrostatic coalescer for W / O emulsion electric field demulsification, which is mainly used for electric field demulsification and coalescence of W / O emulsions such as crude oil emulsions. Due to the difference in electrical conductivity between the phase oil and the dispersed phase water particles, the dispersed phase water particles with smaller particle sizes coalesce and grow up through the action of the electric field, which facilitates the subsequent oil-water separation process such as gravity sedimentation or centrifugal separation and improves the oil-water separation process. Separation efficiency; it includes tubular shell 1, insulating sleeve 2, front end cover 3, rear end cover 4, central shaft 5, high voltage electrode spiral b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com