Interactive turbulent flow reaction device

A reaction device and interactive technology, applied in the petroleum industry, liquid carbon-containing fuel, fatty acid esterification, etc., can solve the problems of oil and methanol incompatibility, high cost of biodiesel, and non-continuous production, etc. Effects of stacking, improving residence time distribution, and increasing automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

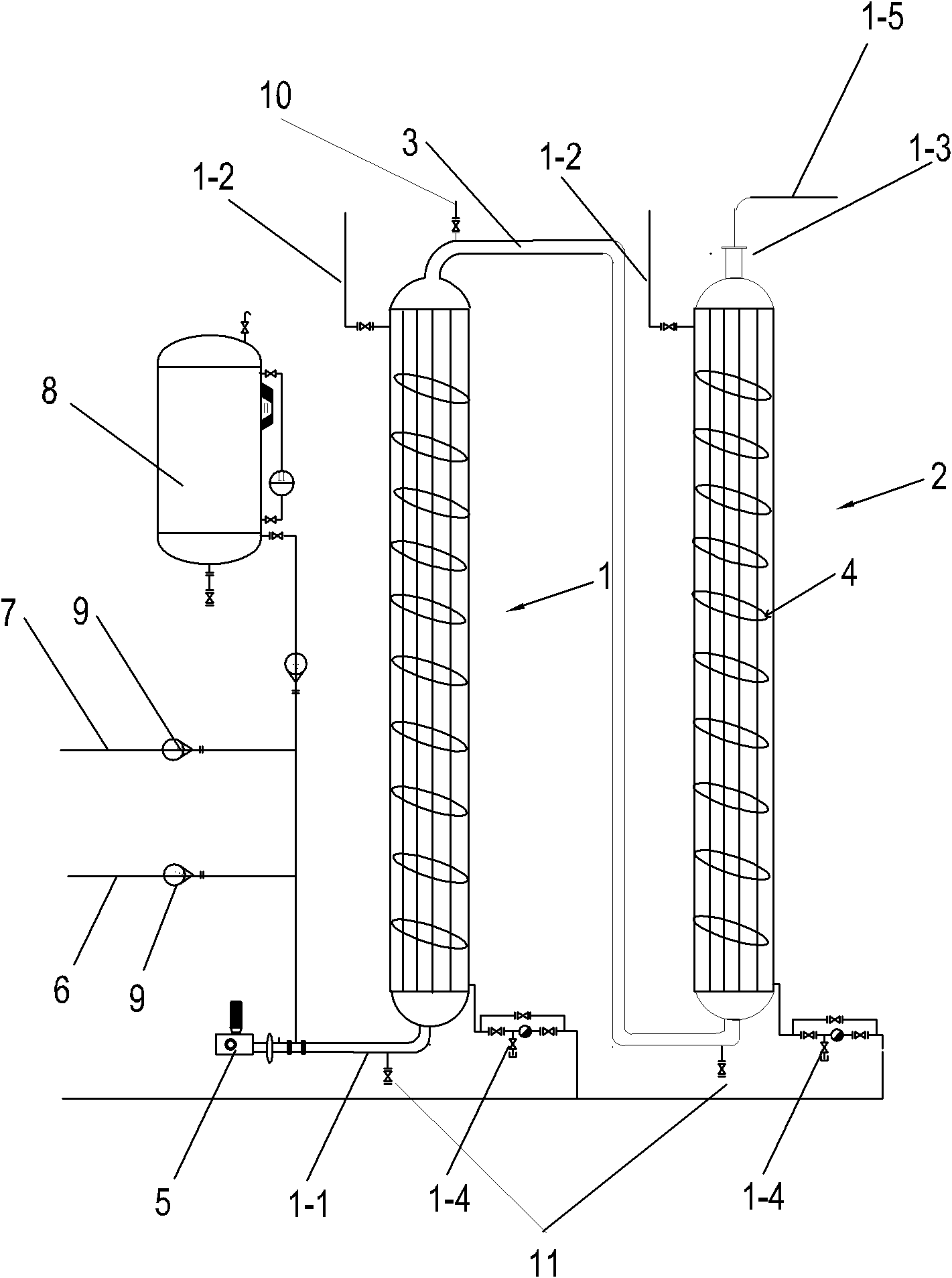

[0024] For specific embodiments of the present invention, refer to figure 1 , an interactive turbulent reaction device, including two reactors 1 and 2 connected in series, the two reactors are vertical or horizontal to the ground, and an elbow is used between the top of the reaction tube 1 and the lower end of the reactor 2 3 are connected, and the outside is respectively equipped with a heat exchange jacket or an external heater (not shown in the figure). An exhaust port 10 is provided at the top of the elbow 3 . In this embodiment, the reaction device is a tube type or a tower type, and in other embodiments, the reaction device can be in other forms.

[0025] The bottom of the reactor 1 is provided with a feed inlet 1-1 and a steam trap 1-4, and the top is provided with a steam inlet 1-2. A turbulent flow pump 5 and a discharge port 11 are arranged at the feed inlet 1-1, and the feed inlet 1-1 is respectively connected with the methanol inlet 6, the catalyst inlet 7 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com