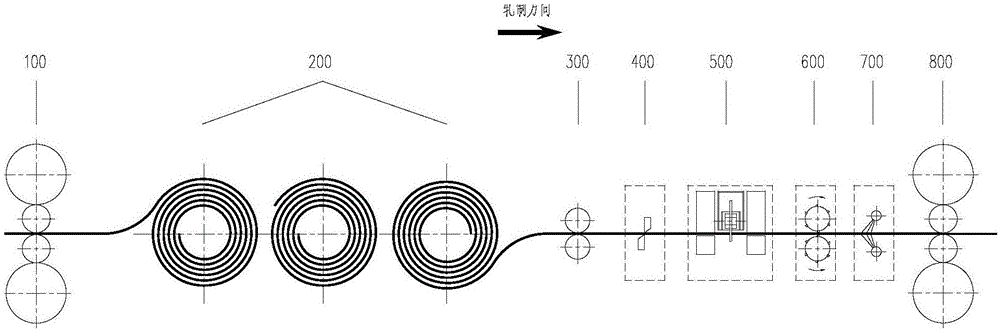

Connecting method and system for endless rolled intermediate slabs

A technology of endless rolling and connecting method, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high equipment investment and maintenance cost, low connection strength of intermediate billets, influence of strength of connection area, etc. Achieve the effect of improving the mechanical properties of the joint, shortening the welding time, simplifying the process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this example, the front-back direction is the rolling direction as the front.

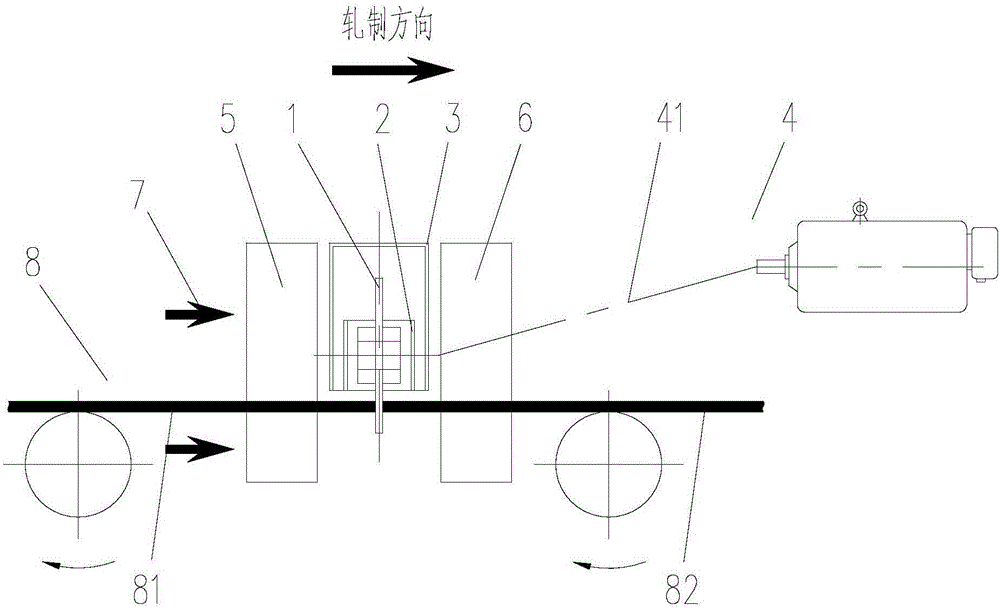

[0066] The invention provides a method for connecting intermediate blanks. Specifically, the head and tail ends of the front and rear intermediate blanks are aligned, and the tail end face of the front intermediate blank and the head end face of the rear intermediate blank are rubbed. The forward frictional pressure is exerted on the middle billet, so that the connecting end face and the surrounding area of the front and rear middle billets rapidly heat up to a viscoplastic state, and the head of the rear middle billet is connected forward with the tail of the front middle billet Together. The friction method can be rotational friction or vibration friction.

[0067] Using the solid state welding method, the material to be welded does not melt, the metal in the welding zone is forged structure, and there is no defect of melting welding; under the action of upsetting force, some mechani...

Embodiment 2

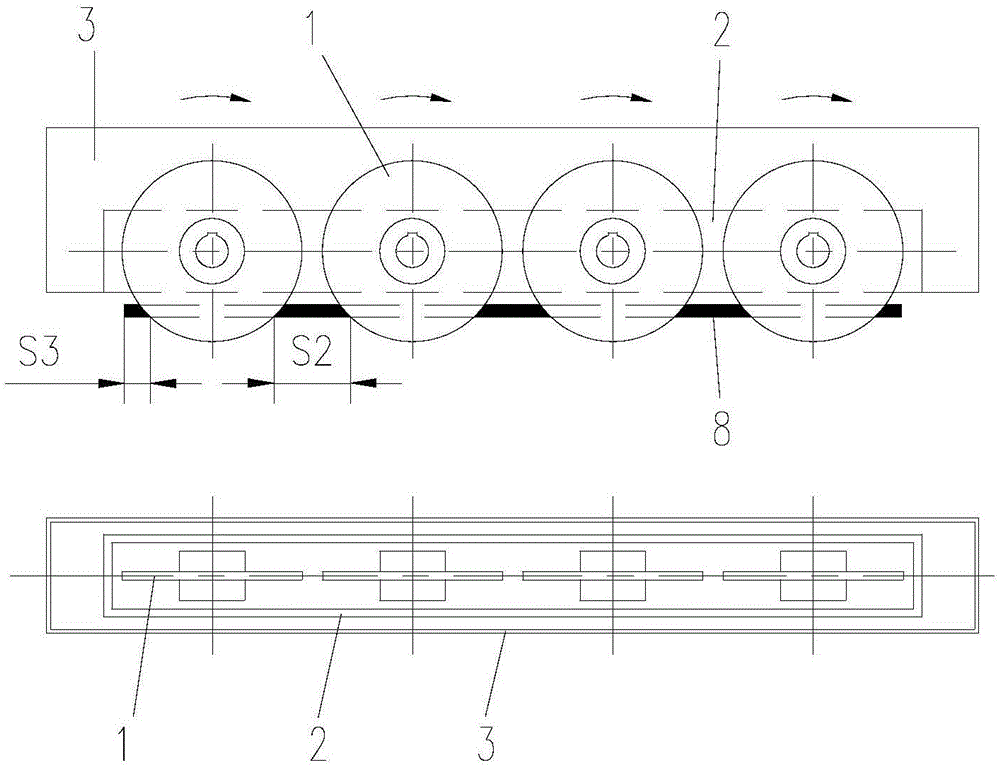

[0077] The difference between this example and Embodiment 1 is that the structure of the intermediate blank connecting device 500 is different, such as Image 6 with Figure 7 As shown, this example adopts the mode of vibration friction, that is, the friction mechanism 1 is a friction blade, and also includes a friction blade vibrating tool holder 91, a friction blade pressing tool holder 92, a friction blade vibration device 93, an inlet clamping device 5, an outlet clamp Holding device 6 and upsetting device 7. The inlet clamping device 5, the outlet clamping device 6 and the upsetting device 7 are the same as those in the first embodiment.

[0078] Wherein, the entrance clamping device 5 is used for clamping the rear block intermediate blank 81, and the outlet clamping device 6 is used for clamping the front block intermediate blank 82, and the friction blade is installed on the friction blade vibrating knife rest 91, and the friction blade vibrating knife rest 91 Install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com