Method for preparing copper barrier layer-seed crystal layer film

A kind of thin film preparation, barrier layer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

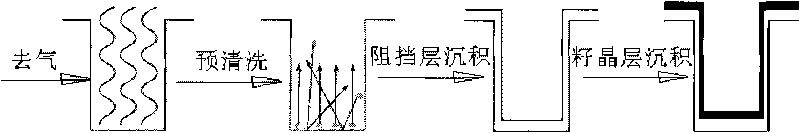

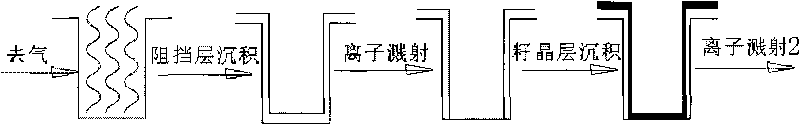

[0032] The production process of the copper barrier layer / seed layer film is: degassing => barrier layer deposition => ion sputtering => seed layer deposition => secondary ion sputtering 2.

[0033] First, carry out the degassing process;

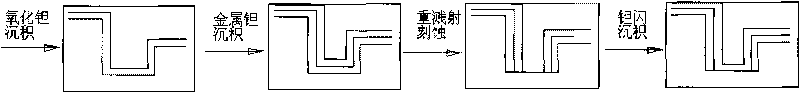

[0034] Next, a barrier layer deposition process is performed: first depositing a tantalum nitride film, and then depositing a metal tantalum film. After the tantalum nitride / tantalum double-layer barrier film deposition process is performed, there are impurity layers such as copper oxide and a tantalum nitride / tantalum double-layer barrier layer on the surface of the lower copper metal at the bottom of the through hole in sequence;

[0035] Subsequently, the ion sputtering process step is carried out. By sputtering, the above two layers of substances will be removed at the same time, exposing the underlying metal surface; moreover, ion sputtering will play the role of heavy sputtering technology, which will have a positive effect on the met...

specific Embodiment 2

[0040] The production process of the copper barrier layer / seed layer film is: degassing => barrier layer deposition => ion sputtering => seed layer deposition. Wherein, the process conditions of the ion sputtering process steps are: the power of the upper radio frequency is 300-800W, the power of the lower radio frequency is 200-700W, and the flow rate of argon gas is 20-150 sccm.

[0041] Compared with the specific embodiment 1, the process steps are simplified, and the dual effects of pre-cleaning and optimizing the pore filling coverage of the barrier film can be satisfied.

[0042] The invention adopts simplified barrier layer chamber design and barrier layer deposition process, which reduces the cost; at the same time, it avoids the problem of particle increase caused by the addition of tantalum heavy sputtering coils;

[0043] Using low-cost ion sputtering pre-cleaning technology, through the optimization of the process flow, the equipment and chip manufacturing costs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com