Acetonitrile refining technology and device

A kind of acetonitrile and process technology, applied in the field of acetonitrile refining, can solve the problems of high energy consumption and complicated equipment, and achieve the effects of low energy consumption, equipment cost reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

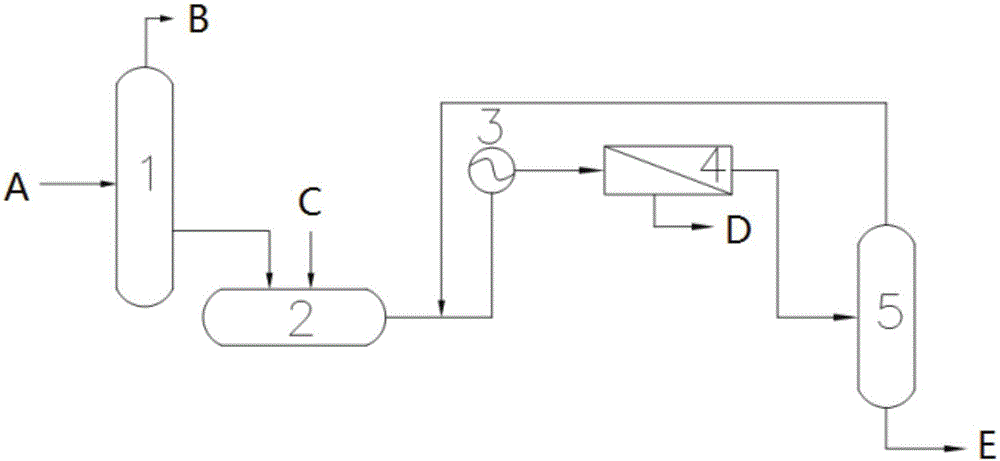

[0037] Embodiment 1: First, the crude acetonitrile solution A produced in the process of producing acrylonitrile by propylene ammoxidation is sent into the flash tank 1 for flash evaporation, and most of the hydrocyanic acid, oxazole and acrylonitrile including hydrocyanic acid, oxazole and acrylonitrile are removed from the top of the tower Low boiling point substance B, the main components of the tower bottom are acetonitrile, water and a small amount of high boiling point substance.

[0038] Then, the tower bottom liquid is sent to the chemical reaction kettle 2, and a strong oxidizing agent and alkali C are added into the chemical reaction kettle 2, the strong oxidizing agent is potassium permanganate, and the alkali is sodium hydroxide. The chemical reaction kettle 2 provides necessary heat, sufficient stirring and a certain residence time, and utilizes the principle that cyanohydrin has poor thermal stability and is easily decomposed in alkaline medium at a higher tempera...

Embodiment 2

[0041] Embodiment 2: First, the crude acetonitrile solution A produced in the process of producing acrylonitrile by propylene ammoxidation is sent into the flash tank 1 for flash evaporation, and most of the hydrocyanic acid, oxazole and acrylonitrile including hydrocyanic acid, oxazole and acrylonitrile are removed from the top of the tower Low boiling point substance B, the main components of the tower bottom are acetonitrile, water and a small amount of high boiling point substance.

[0042] Then, the tower bottom liquid is sent to the chemical reaction kettle 2, and a strong oxidizing agent and alkali C are added into the chemical reaction kettle 2, the strong oxidizing agent is potassium permanganate, and the alkali is potassium hydroxide. After chemical treatment a mixture of acetonitrile, water and heavy components was obtained.

[0043] Next, when the mixture is preheated to 20°C by the heat exchanger 3, it is directly sent into the preferentially permeable organic mat...

Embodiment 3

[0045] Embodiment 3: First, the crude acetonitrile solution A produced in the process of producing acrylonitrile by propylene ammoxidation is sent to the flash tank 1 for flash evaporation, and most of the hydrocyanic acid, oxazole and acrylonitrile including hydrocyanic acid, oxazole and acrylonitrile are removed from the top of the tower Low boiling point substance B, the main components of the tower bottom are acetonitrile, water and a small amount of high boiling point substance.

[0046] Then, the tower bottom liquid is sent to the chemical reaction kettle 2, and a strong oxidizing agent and alkali C are added into the chemical reaction kettle 2, the strong oxidizing agent is sulfuric acid, and the alkali is sodium hydroxide. After chemical treatment a mixture of acetonitrile, water and heavy components was obtained.

[0047] Next, when the mixture is preheated to 50°C by the heat exchanger 3, it is sent directly into the preferentially permeable organic matter membrane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com