Method and device for preparing high-purity pyridine series products from crude pyridine by refining

A series of products, pyridine technology, applied in the field of coal chemical industry, can solve the problems that the production process cannot be carried out smoothly, trace moisture cannot be removed, plugging packing and reboiler, etc., so as to reduce equipment investment and process energy consumption, reduce investment and Effect of energy consumption, simplification of processes and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

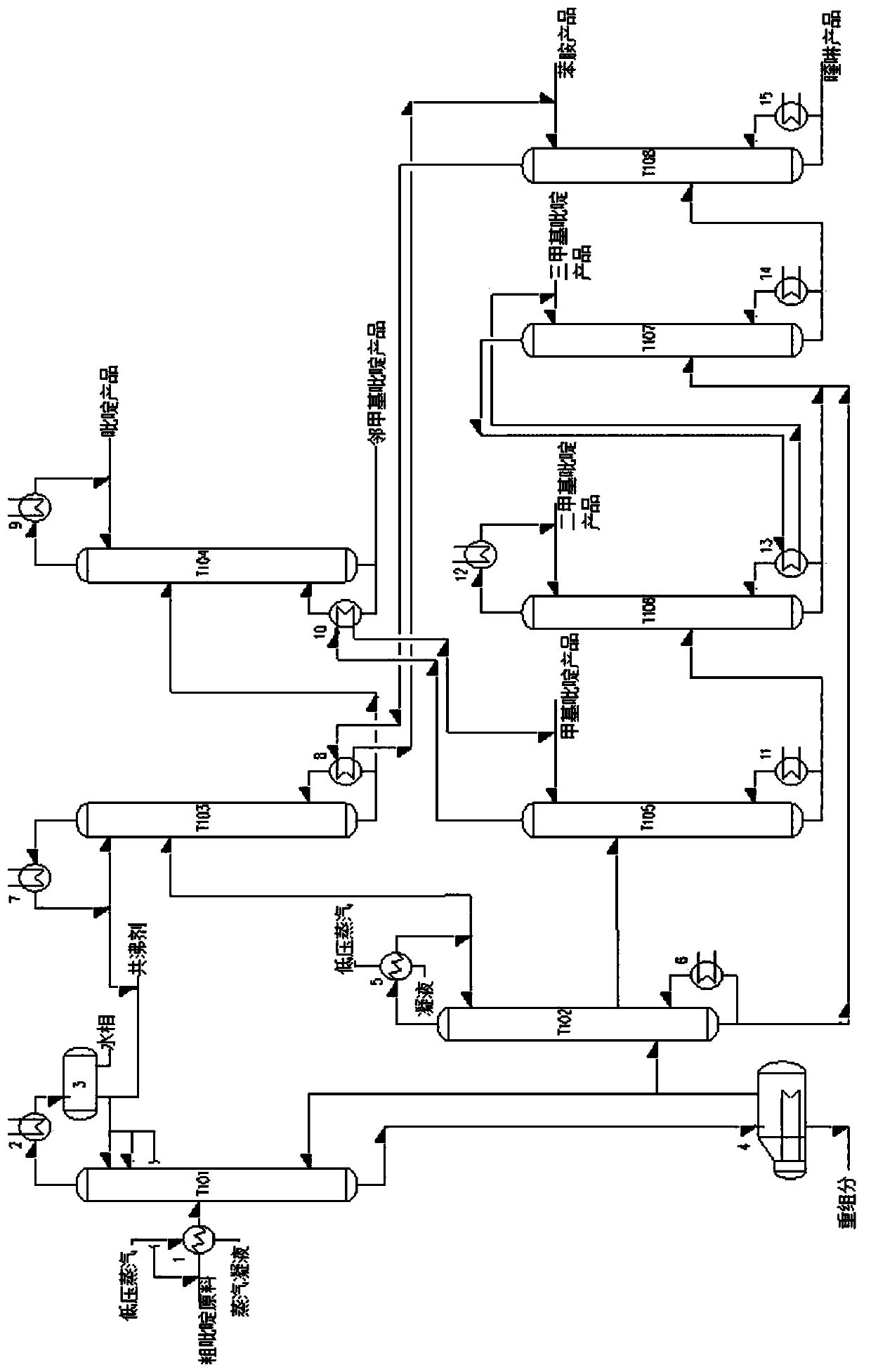

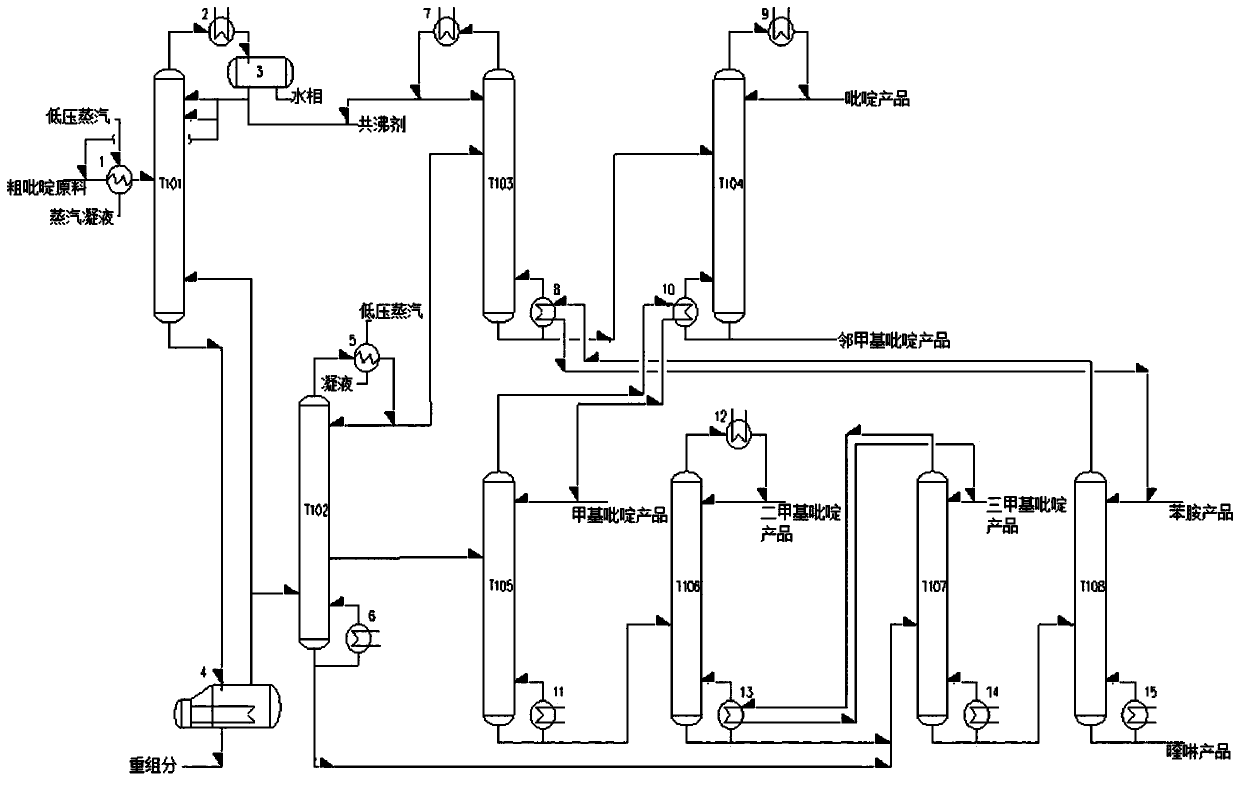

[0031] Embodiment 1: a kind of method for crude pyridine refining high-purity pyridine series products, comprises the following steps:

[0032] S1. Mix the crude pyridine raw material from medium and low temperature coal tar with part of the entrainer, and use low-pressure steam or other low-temperature heat sources to enter the drying tower T101 after being preheated by the feed preheater 1 of the drying tower T101; in this embodiment, the crude The flow rate of pyridine raw material is 8421kg / h, the pressure is 0.4MPa and the temperature is 40℃, its mass composition is water 6.5%, benzene 15.0%, pyridine 40.5%, o-picoline 3.7%, 2,6-lutidine 3.5% %, m-picoline 7%, o-ethylpyridine 0.3%, 2,4-lutidine 7%, 2,3,6-collidine 6%, indane 0.1%, aniline 5.8%, benzyl Amine 2.4%, m-methylaniline 2% and quinoline 0.2%.

[0033] S2. Using azeotropic distillation technology, azeotropic distillation is carried out through the drying tower T101. The gas phase at the top of the drying tower T1...

Embodiment 2

[0043] Embodiment 2: In this embodiment, the crude pyridine raw material flow rate is 8421kg / h, the pressure is 0.4MPa and the temperature is 40°C, and its mass composition is water 8%, benzene 10.0%, pyridine 46%, o-picoline 3 %, 2,6-lutidine 3.2%, m-picoline 5%, o-ethylpyridine 0.3%, 2,4-lutidine 8%, 2,3,6-collidine 6% , indane 0.1%, aniline 5.8%, benzylamine 2.4%, m-methylaniline 2% and quinoline 0.2%; other technological process is identical with embodiment 1, and pyridine tower T104 tower top obtains 3874kg / h purity and is 99.5wt% Pyridine product, pyridine tower T104 tower kettle obtains 232kg / h purity is the o-picoline product of 99.8wt%; The picoline tower T105 obtains 711kg / h content exceeds 96.5wt% picoline product mixture material, dimethyl Pyridine tower T106 was refined to obtain 671kg / h of 2,4-lutidine product with a purity of 99.8wt%, and 498kg / h of 2,3,6-trimethylpyridine with a purity of 98.3wt% was extracted from the top of colloidal tower T107 A picoline pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com