Gallium arsenide processing device and processing method

A technology of processing equipment and processing methods, applied in the direction of improving process efficiency, etc., can solve problems that are not conducive to operation and personnel safety, and achieve the effect of being conducive to operation and personnel safety and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

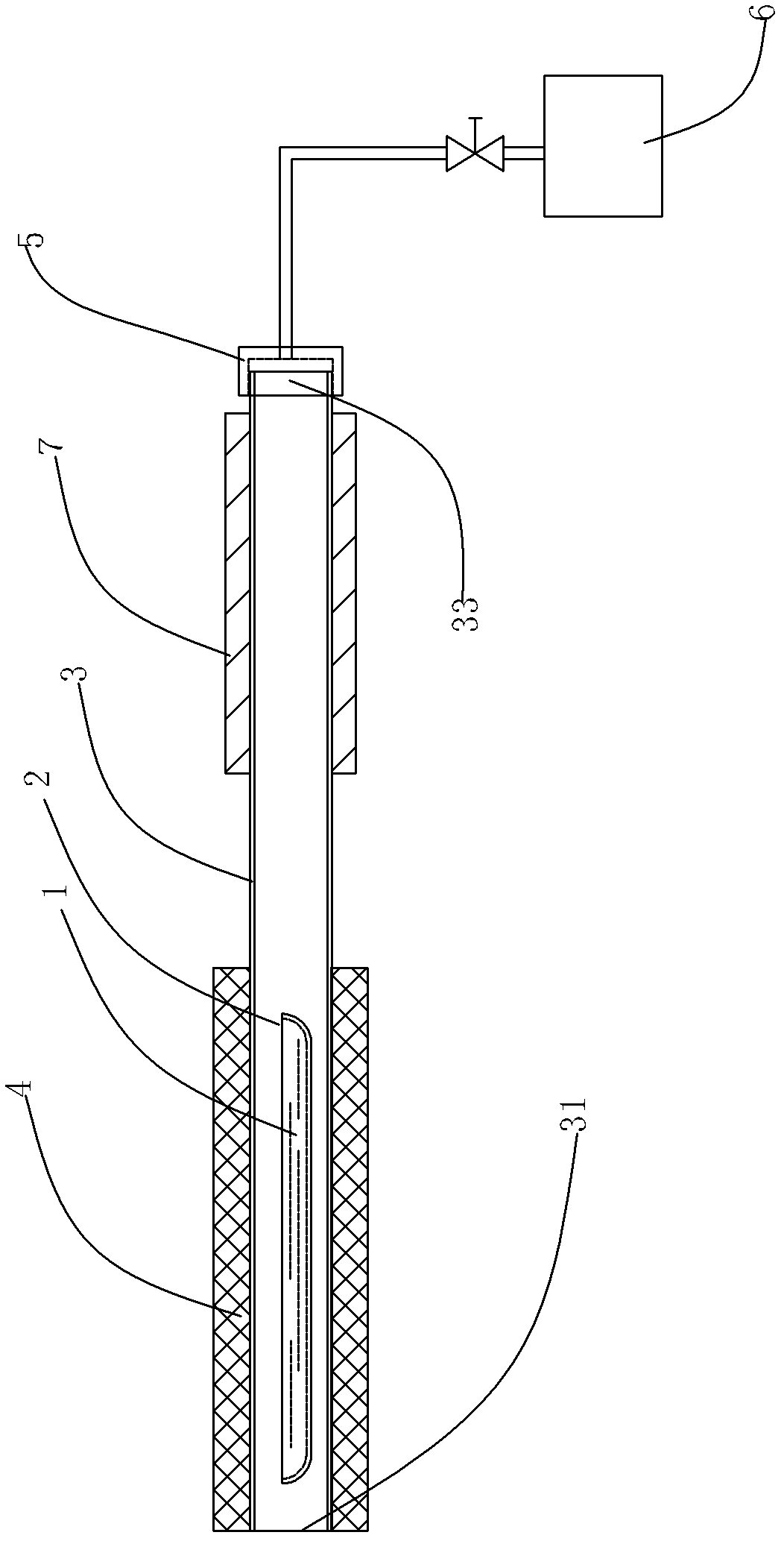

Method used

Image

Examples

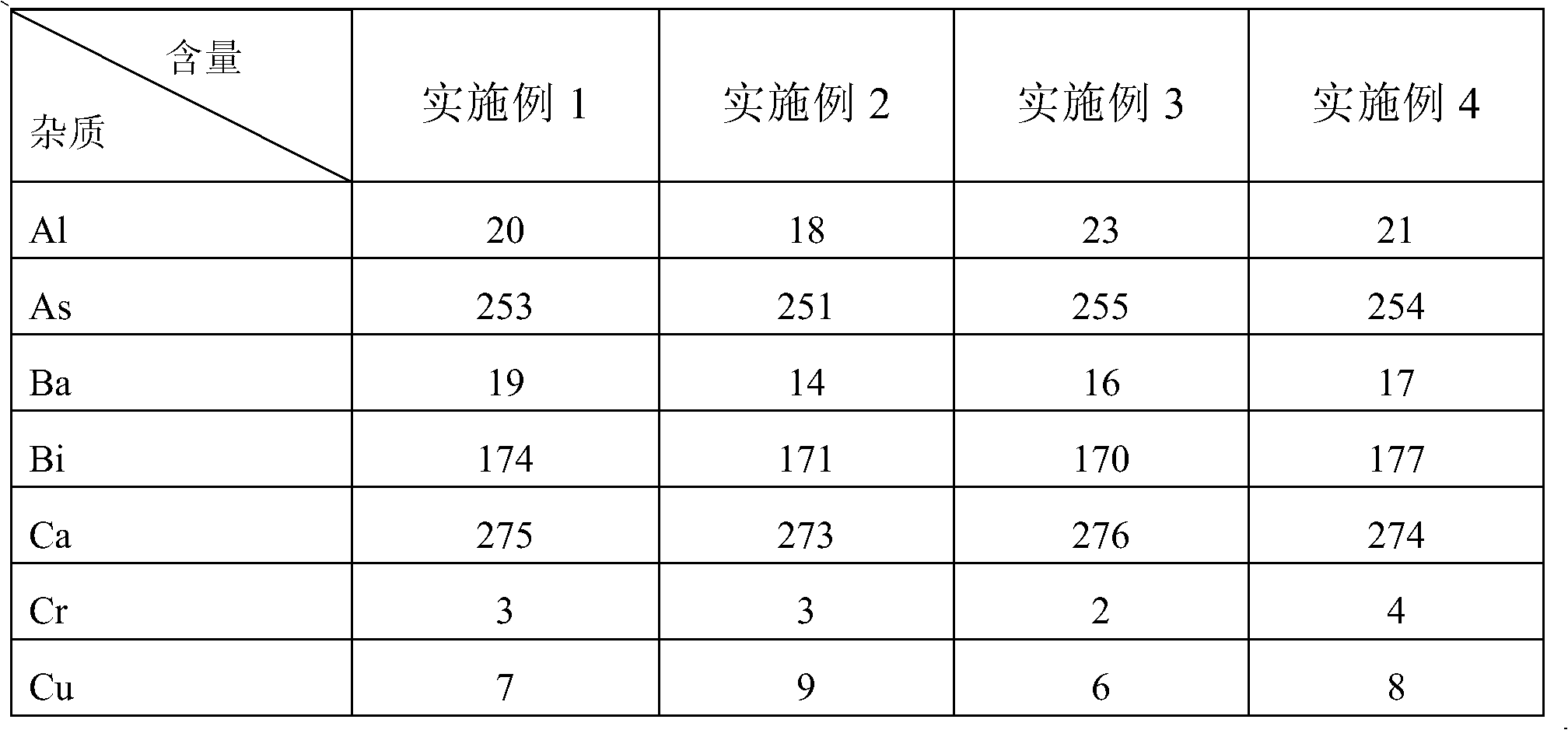

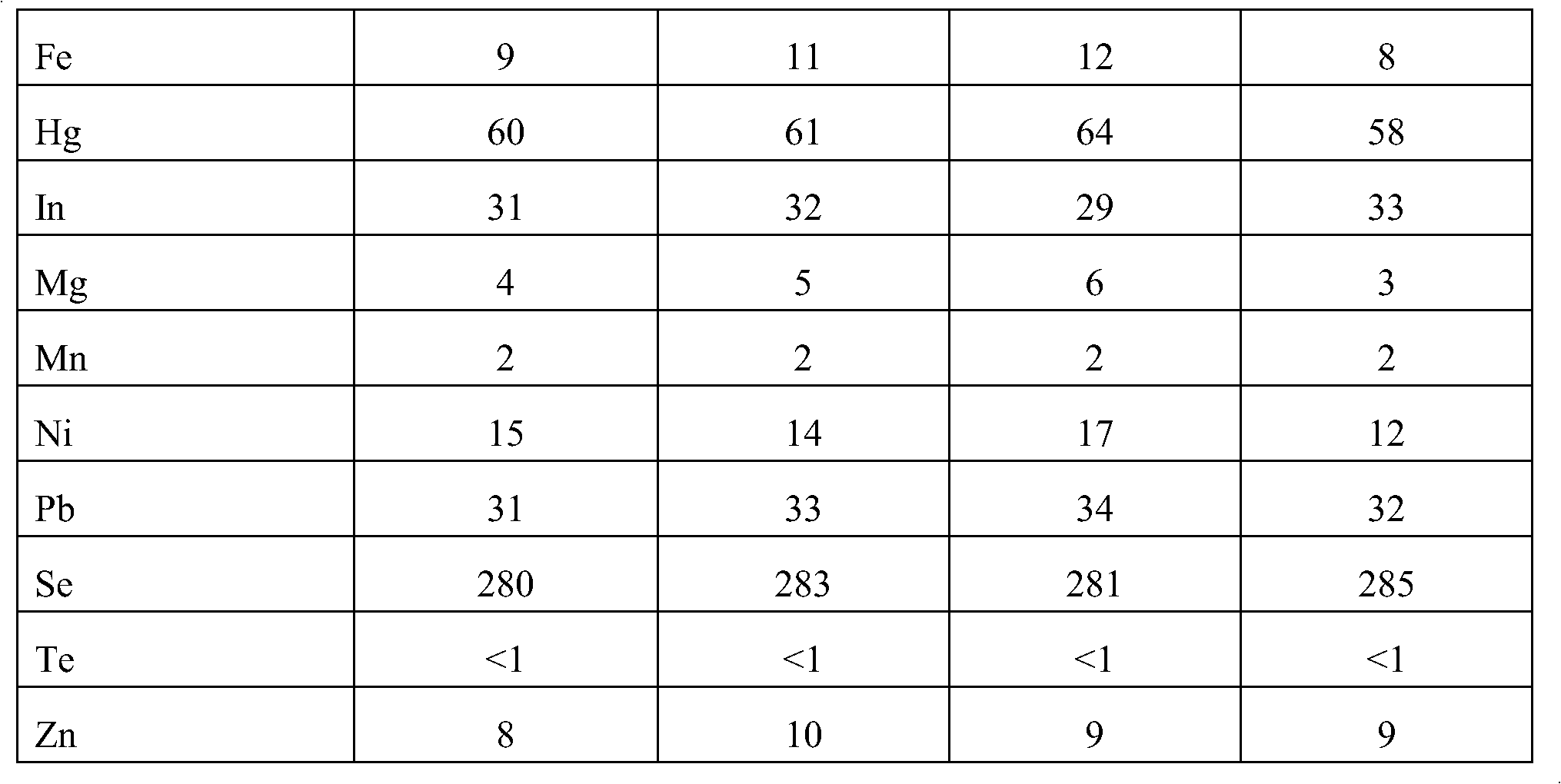

Embodiment 1

[0033] Gallium arsenide scrap is irregular flake and small particle powder with a thickness of about 2mm. Take 100g of gallium arsenide waste as a raw material, add it to the quartz boat, and put the quartz boat into the sealing end of the quartz tube. Put the quartz tube into the heating zone of the horizontal crystal growth furnace, and place the open end of the quartz tube in the air and connect with the vacuum unit. Turn on the vacuum unit, and when the pressure inside the quartz tube is 2pa, start the heating program of the horizontal crystal growth furnace to raise the temperature to 1000°C and keep it for 3h. The vacuum state is naturally cooled to obtain 46g gallium and 40g arsenic.

[0034] In terms of mass, the recovery rate of gallium and arsenic is 86%.

Embodiment 2

[0036] Gallium arsenide scrap is irregular flake and small particle powder with a thickness of about 2mm. Take 100g of gallium arsenide waste as a raw material, add it to the quartz boat, and put the quartz boat into the sealing end of the quartz tube. Put the quartz tube into the heating zone of the horizontal crystal growth furnace, and place the open end of the quartz tube in the air and connect with the vacuum unit. Turn on the vacuum unit, and when the pressure inside the quartz tube is 5pa, start the heating program of the horizontal crystal growth furnace to heat up to 1050°C and keep it for 2.5h. Naturally cooled in a vacuum state, 46.8g gallium and 41.2g arsenic are obtained.

[0037] In terms of mass, the recovery rate of gallium and arsenic is 88%.

Embodiment 3

[0039] Gallium arsenide scrap is irregular flake and small particle powder with a thickness of about 2mm. Take 100g of gallium arsenide waste as a raw material, add it to the quartz boat, and put the quartz boat into the sealing end of the quartz tube. Put the quartz tube into the heating zone of the horizontal crystal growth furnace, and place the open end of the quartz tube in the air and connect with the vacuum unit. Turn on the vacuum unit, when the pressure inside the quartz tube is 9pa, start the heating program of the horizontal crystal growth furnace to raise the temperature to 1100°C and keep it for 2h. Naturally cooled in a vacuum state, 46.2g gallium and 40g arsenic are obtained.

[0040] In terms of mass, the recovery rate of gallium and arsenic is 86.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com