Method for non-destroyed real time continuously testing concrete carbonization depth

A carbonation depth and concrete technology, which is applied in mechanical depth measurement, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem that the limit of reagent discoloration is not easy to determine, and it is not conducive to the establishment of carbonization model. and inspection, limited sampling times, etc., to achieve the effect of facilitating multiple sampling tests, facilitating long-term testing, and simplifying processes and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

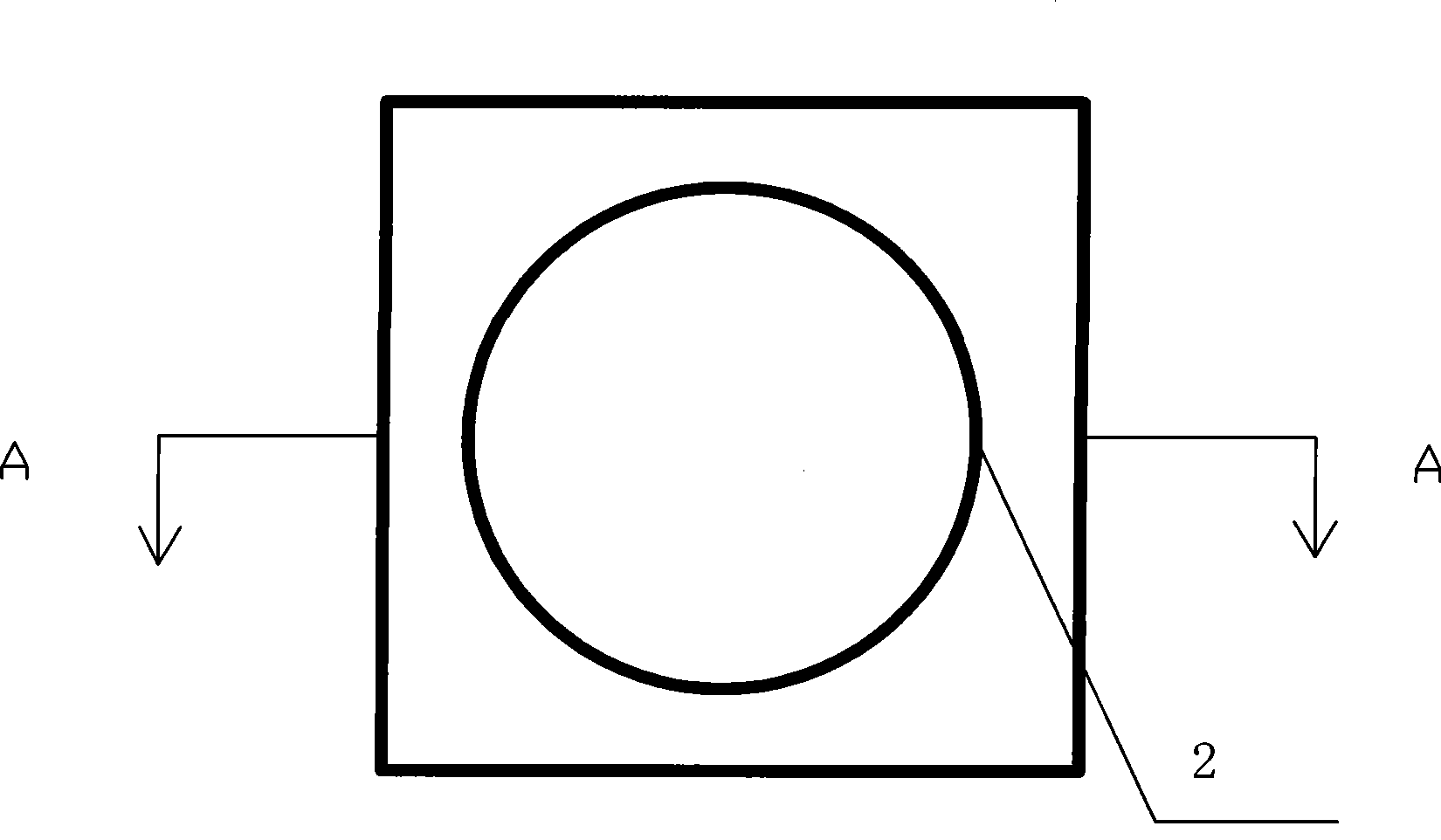

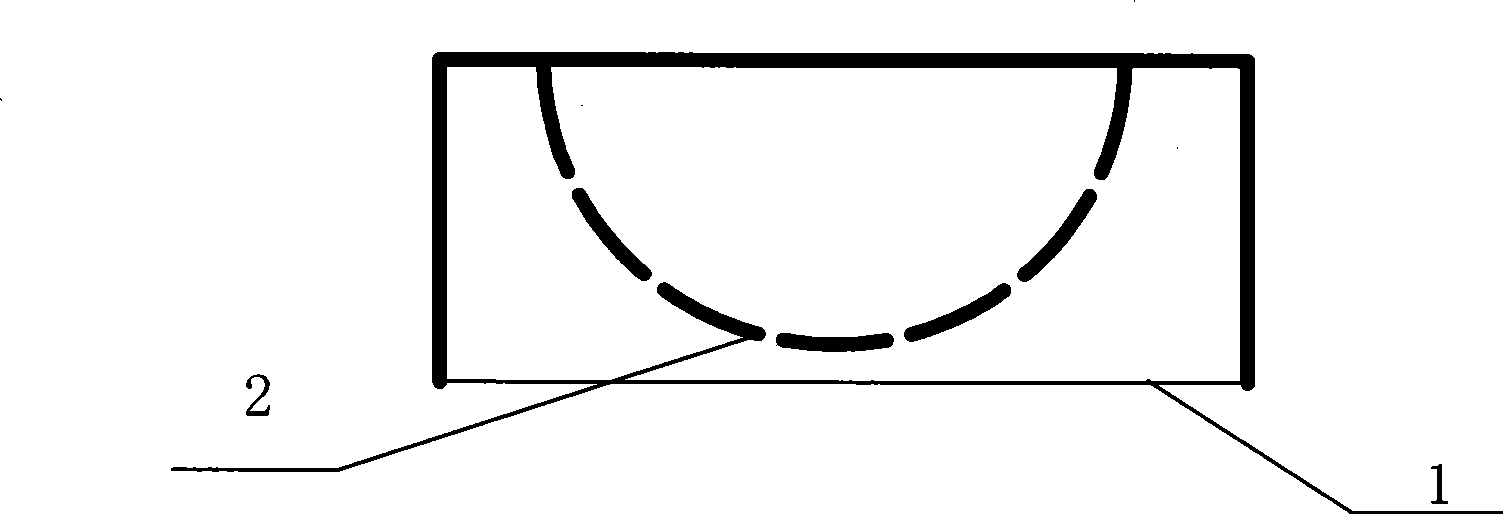

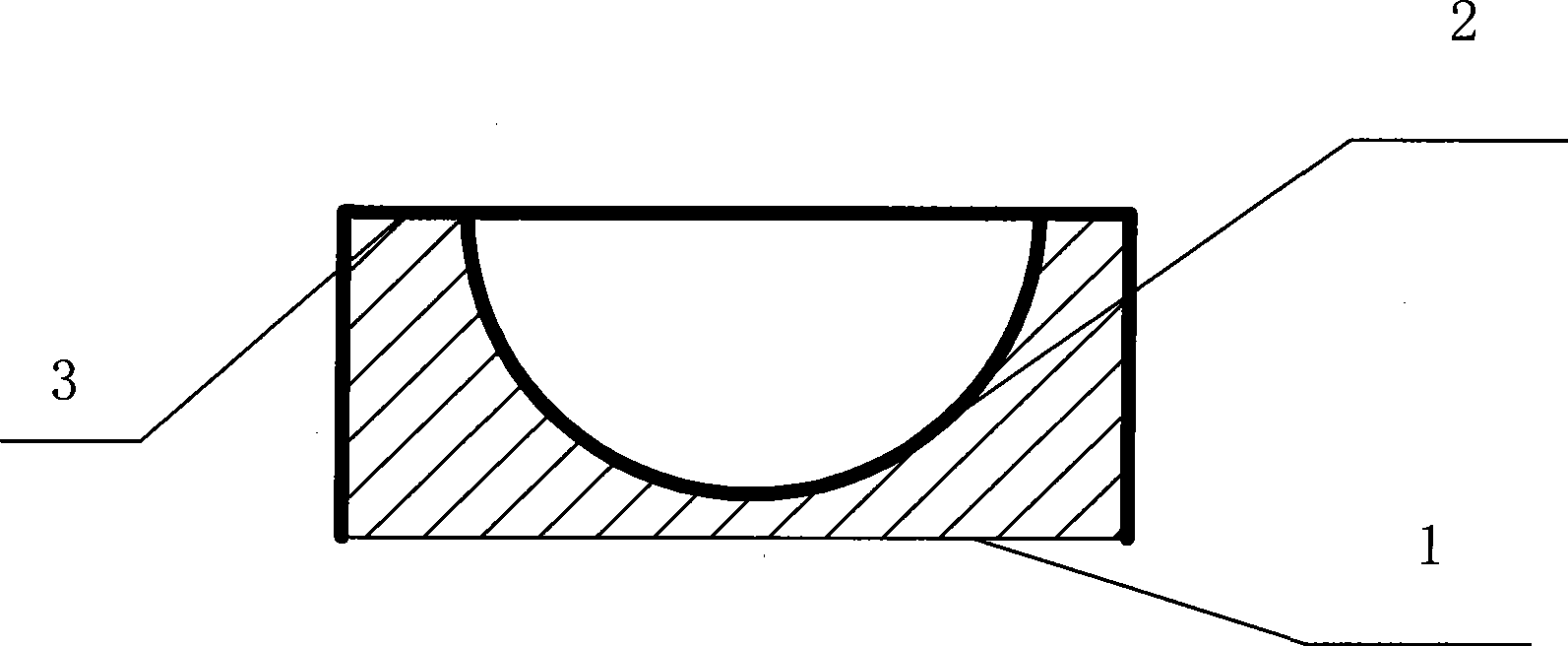

Embodiment 1

[0019] Select the following raw materials and mix ratio: 525 ordinary Portland cement; artificial limestone crushed stone, the maximum particle size is 20mm, and the apparent density is 2680kg / m 3 ;Natural river sand, fineness modulus 2.9, apparent density 2610kg / m 3 ; Class II fly ash. The mix ratio is 0.30 water-binder ratio, 30% fly ash, and 385kg / m cement 3 , gravel 1030kg / m 3 , sand 687kg / m 3 , tap water 165kg / m 3 . Manufacture the test block to be tested; the size of the test block is 160×160×55 mm, the test block has a hemispherical concave surface from the upper surface, and the radius of the hemispherical concave surface is 50 mm. After curing the test piece to the age of 28 days, carry out drying treatment, except for a bottom surface, the rest of the surface is sealed with heated paraffin; the test piece is put into the carbonization box, and the CO in the box is 2 The concentration is kept at 20% ± 3%, the relative humidity is 75% ± 5%, and the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com