PMSM rotary transformer zero position initial angle calibration method and calibration system

A technology of permanent magnet synchronous motor and calibration method, which is applied in control systems, control generators, vector control systems, etc., can solve the problems of complex calibration process and high hardware requirements, achieve simple calibration operation, reduce equipment dependence, and calculation method Simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation methods, structures, features and functions proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

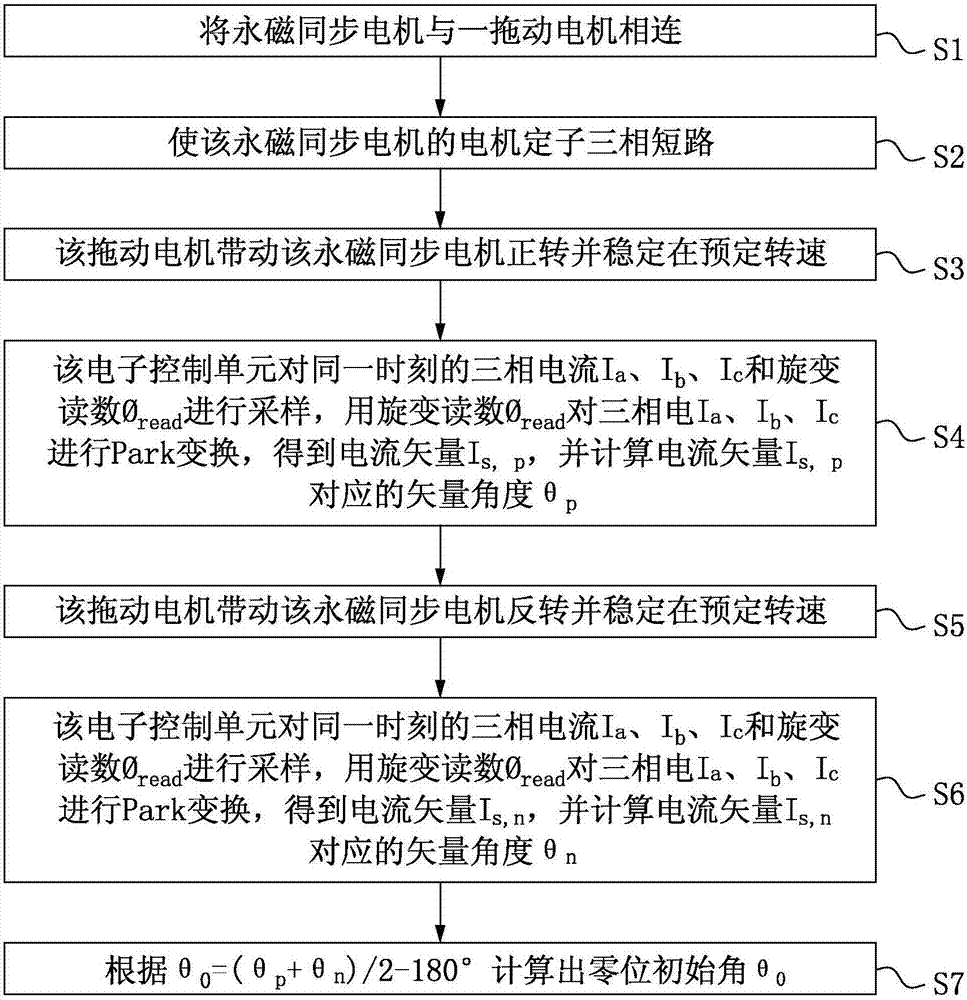

[0031] The embodiment of the present invention provides a method for calibrating the zero position of the resolver suitable for permanent magnet synchronous motors. The calibration method only needs an ordinary motor test bench to drive the permanent magnet synchronous motor to run at a given speed and constant speed without other For any additional circuits and auxiliary sensors, the zero position calibration of the resolver can be realized by using the phase current sensor of the motor controller itself and the resolver decoding circuit.

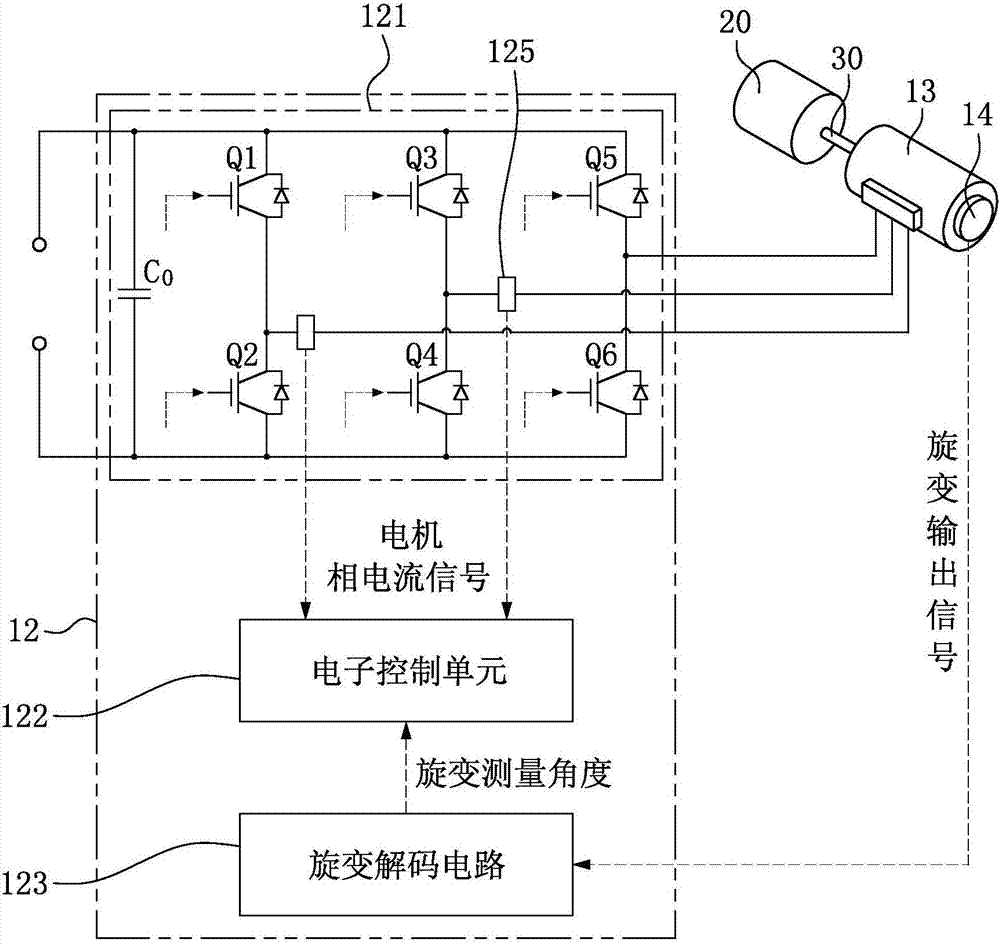

[0032] Such as figure 2 As shown, the calibration system of the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com