Patents

Literature

43results about How to "Calibration is easy to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

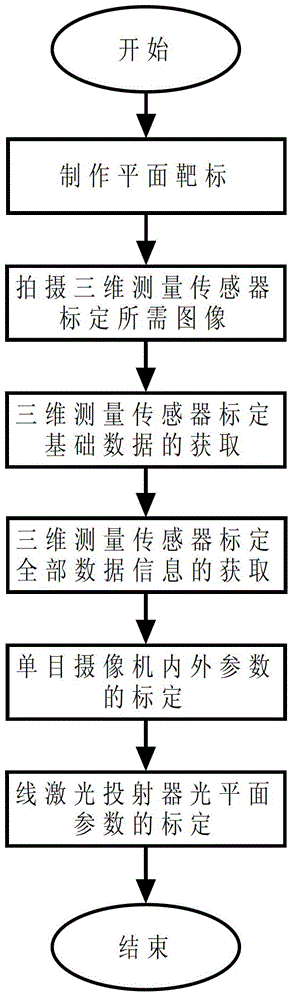

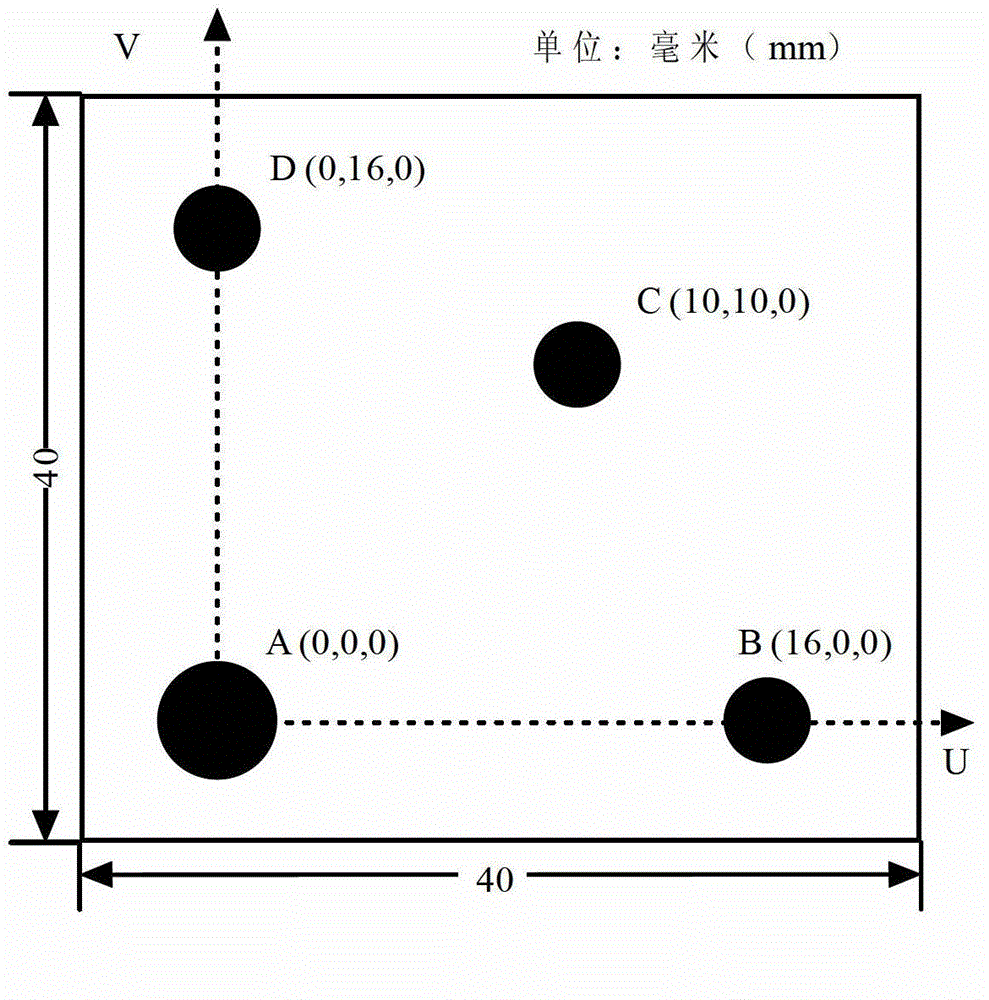

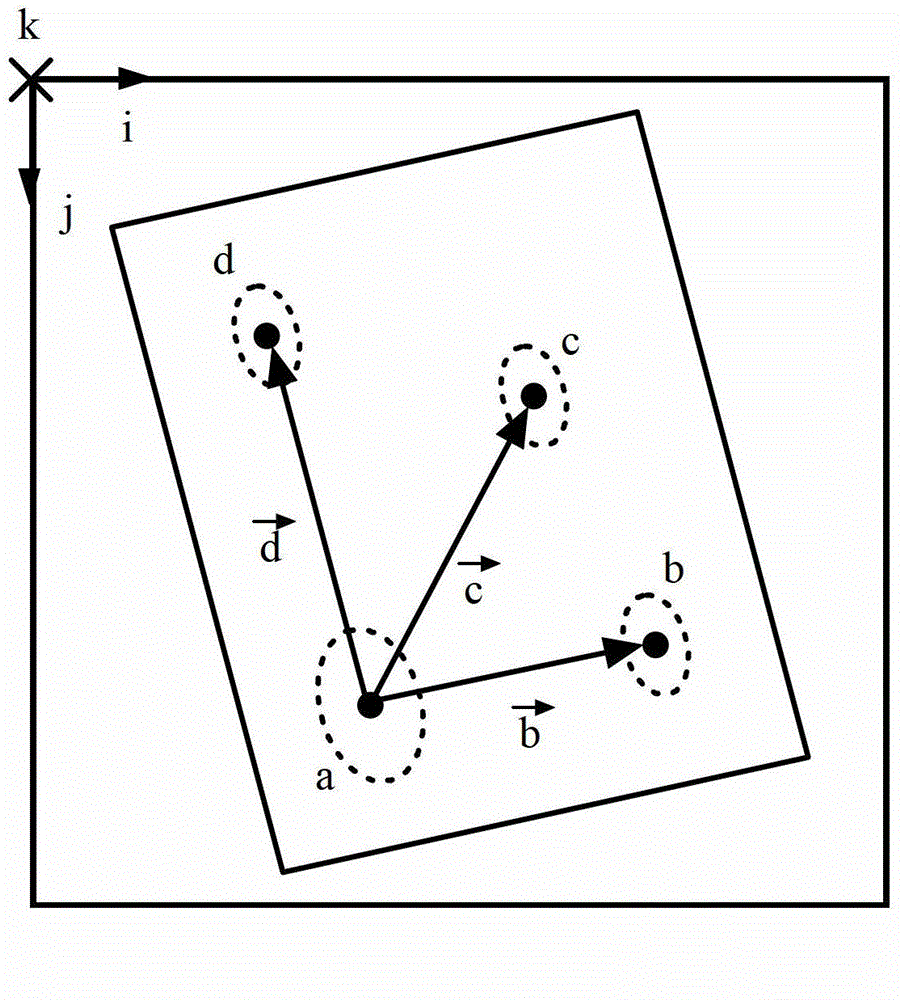

Calibration method of pose position-free constraint line laser monocular vision three-dimensional measurement sensor parameters

ActiveCN102980528AGuaranteed Calibration AccuracyCalibration is easy to operateUsing optical meansMechanical engineering technologyThree dimensional measurement

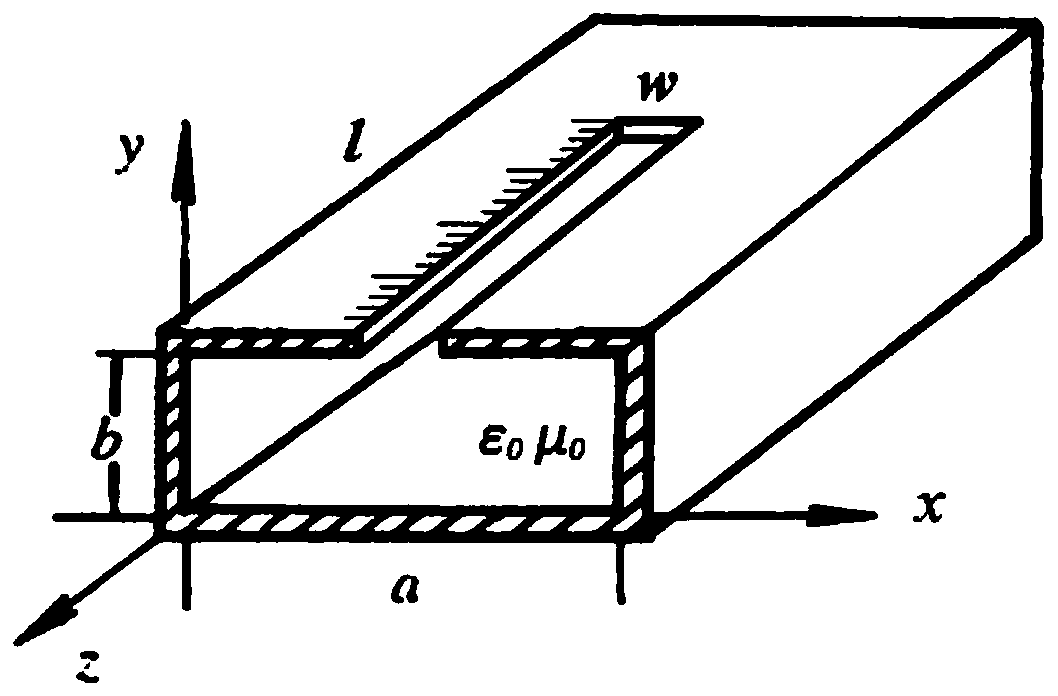

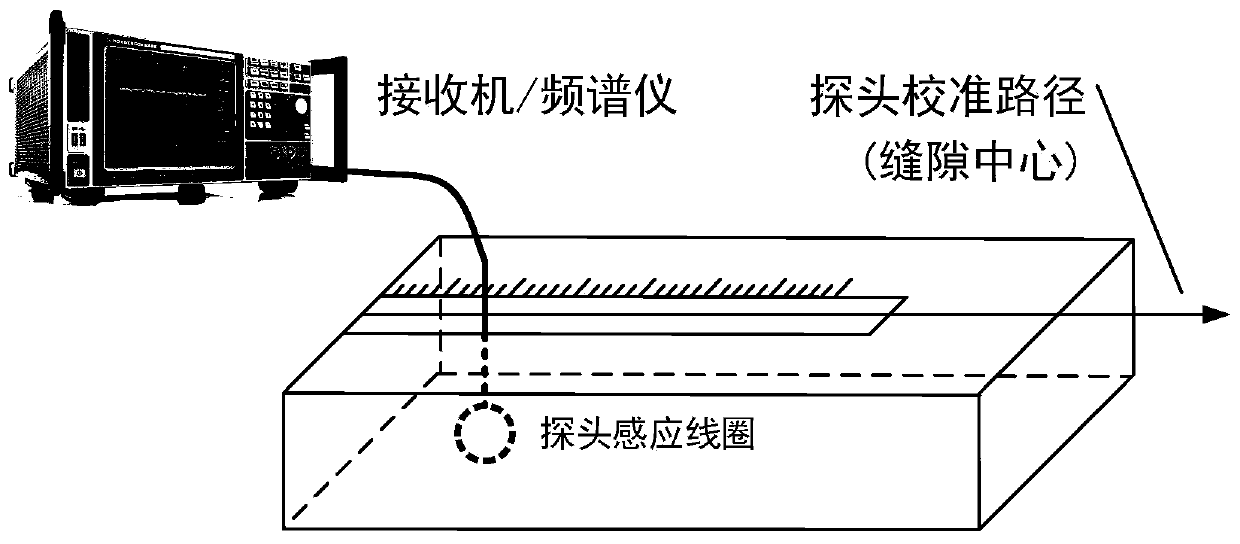

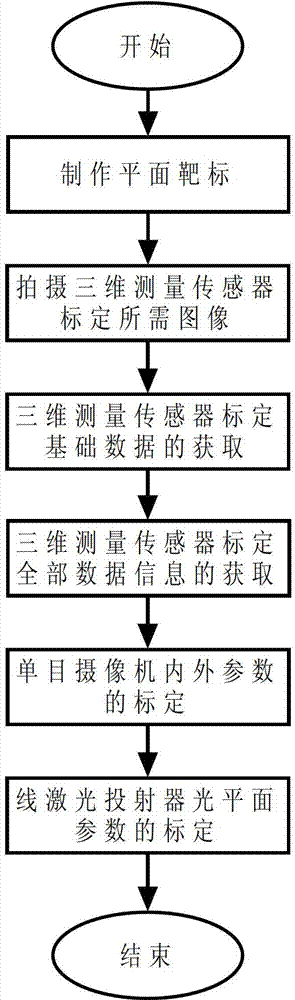

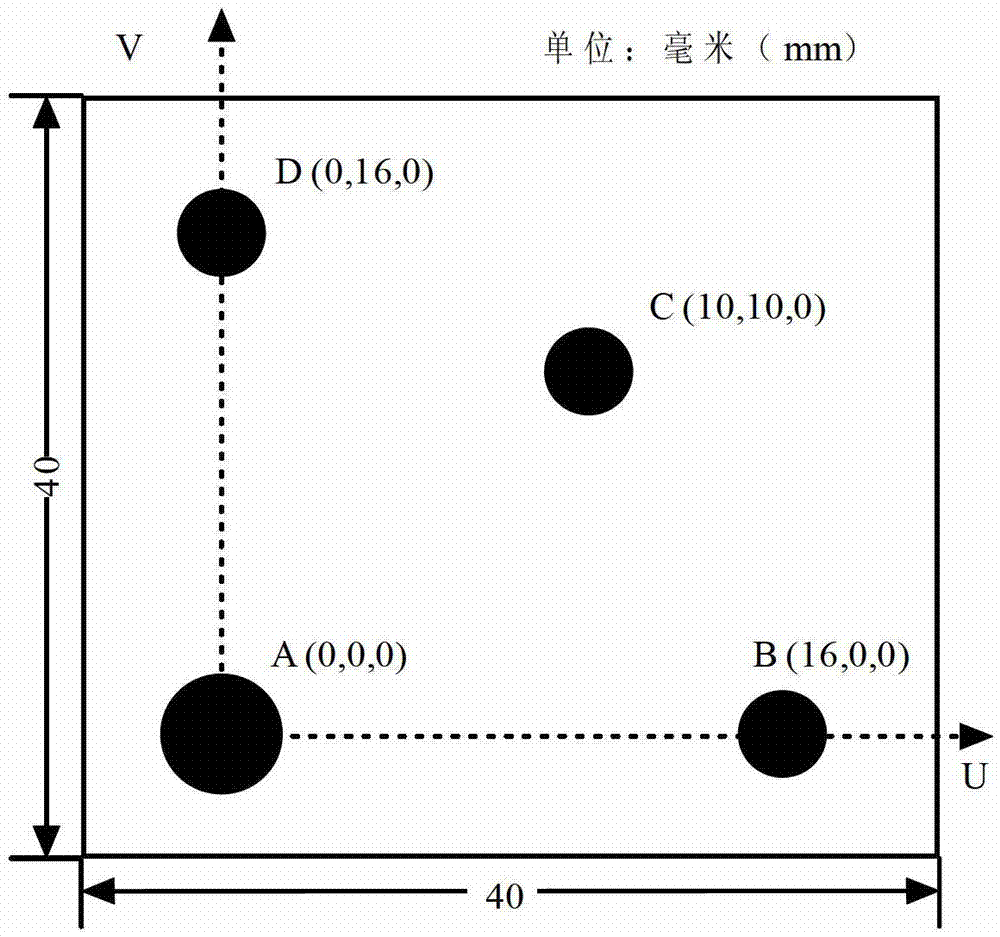

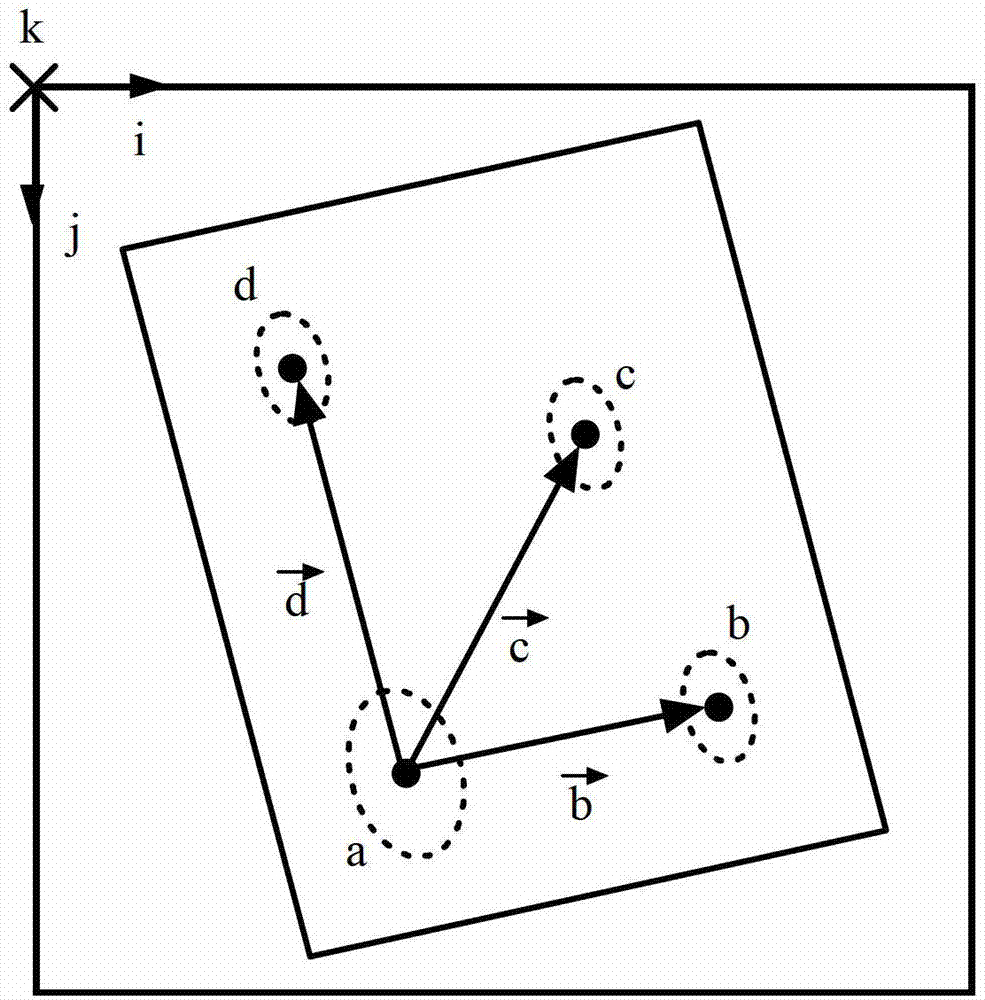

The invention provides a calibration method of pose position-free constraint line laser monocular vision three-dimensional measurement sensor parameters and belongs to the technical fields of optical measurement and mechanical engineering technologies. After basic data are extracted, imaging points are sequenced according to the invariance of a vector quantity cross product direction set composed of the imaging points of target feature points in any shooting pose position, and corresponding relation between the target feature points and the imaging points is built. Light plane feature points are extracted through quadrilateral intersection composed of a light knife central point set fitting straight lines and the target feature points, and a three-dimensional coordinate is calculated according to an intersection invariance principle. Inner and outer diameters in a monocular vidicon and light plane diameters of a line laser projector are optically fitted and calculated, and accurate calibration of the line laser monocular vision three-dimensional measurement sensor parameters is achieved. In calibration, a target can freely move and rotate completely, pose position placing is free of restraint, the same group of calibration images is shared for calibration of two parts of diameters, the calibration accuracy of a three-dimensional measurement sensor is ensured, and simultaneously calibration steps are simplified.

Owner:SHANGHAI JIAO TONG UNIV

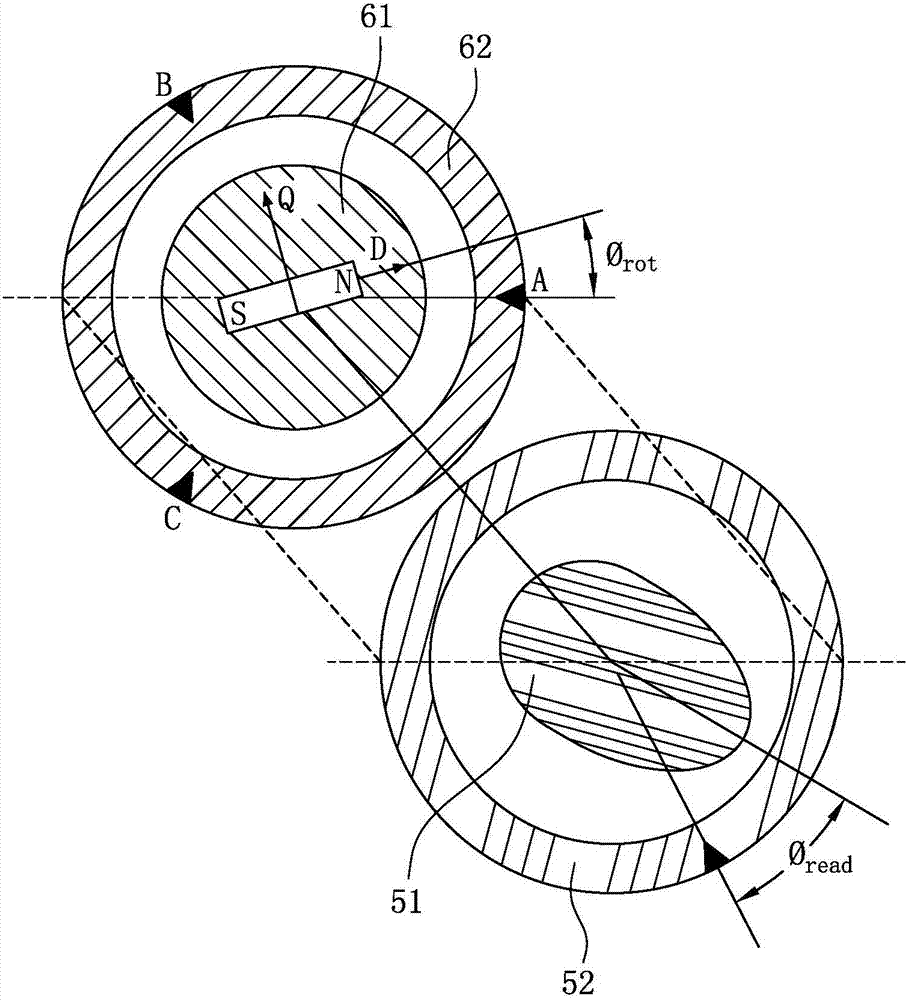

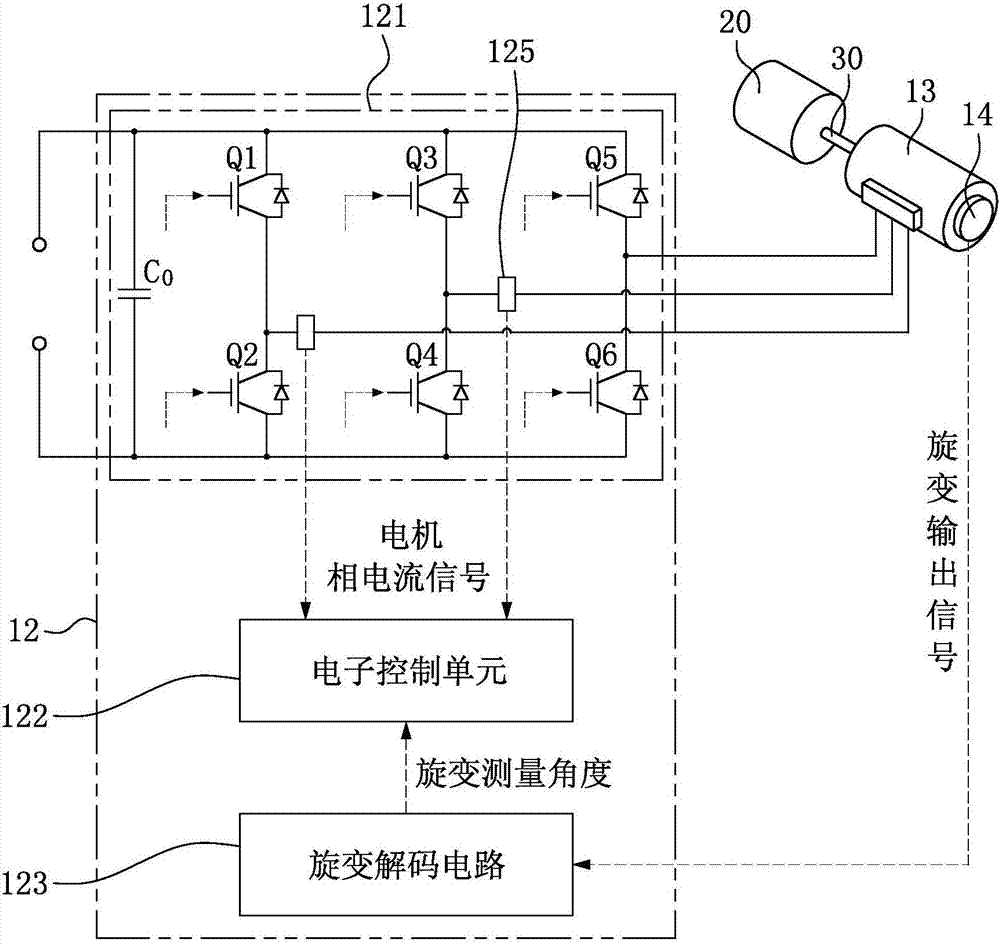

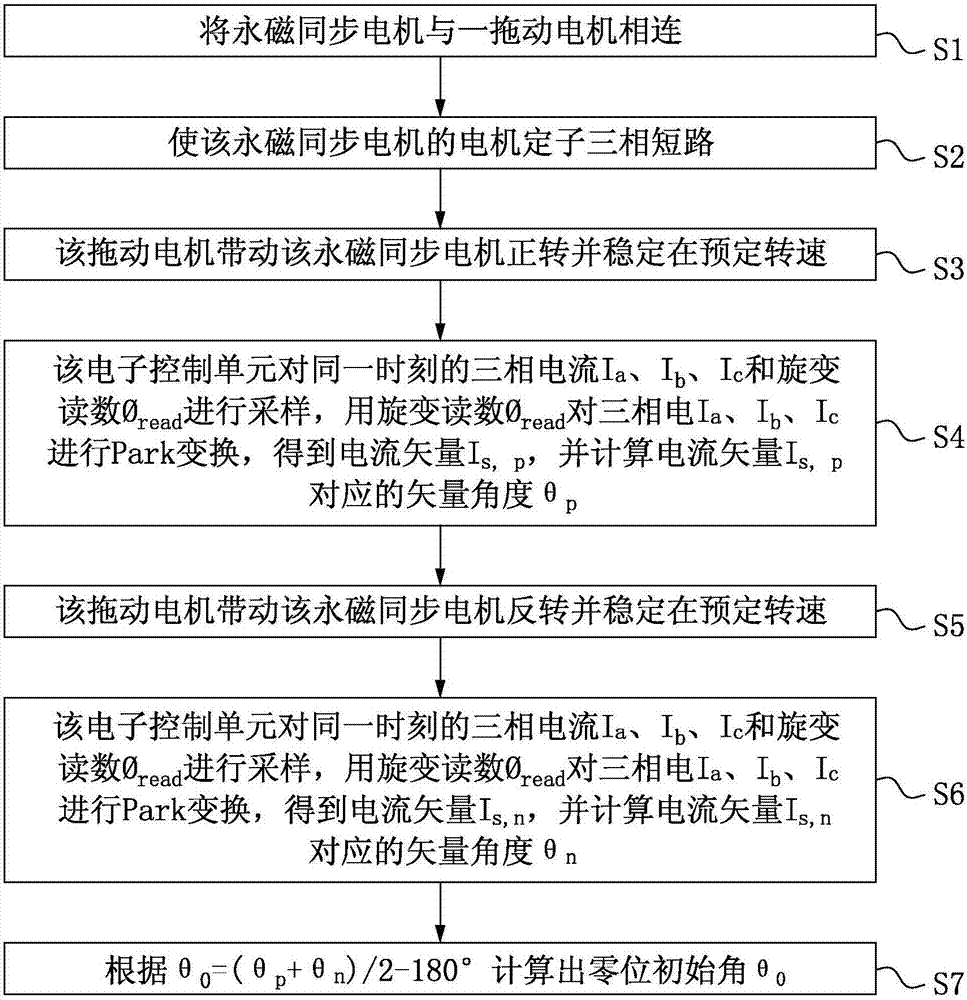

PMSM rotary transformer zero position initial angle calibration method and calibration system

ActiveCN107404272ACalibration is easy to operateCalculation method is simpleAC motor controlVector control systemsThree-phaseDrive motor

The invention discloses a PMSM rotary transformer zero position initial angle calibration method and calibration system. The PMSM rotary transformer zero position initial angle calibration method comprises steps of connecting an PMSM, on which a rotary transformer is installed, to a driving motor, enabling a motor stator of the PMSM to perform three-phase short circuit, using the driving motor to drive the PMSM to rotate forward and maintain at a preset rotation speed, using an electronic control unit to perform sampling on three phase current Ia, Ib and I c and a rotary transformer reading phi read at a same moment, using the rotary transformer reading phi read to perform Park conversion on three phase current Ia, Ib and Ic to obtain current vectors Is,p, calculating a vector angle theta p corresponding the current vector Is,p, using the driving motor to drive the PMSM to rotate backwards and maintaining the rotation at a preset rotation speed, using the electronic control unit to record a vector angle theta n corresponding to a current vector Is,n when the motor is rotated backwards, and calculating that a practical electric rotation angle theta 0 corresponding to the rotary transformer reading zero point angle is a zero position initial angle according to a formula theta 0=(thetap+thetan) / 2-180 degree.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

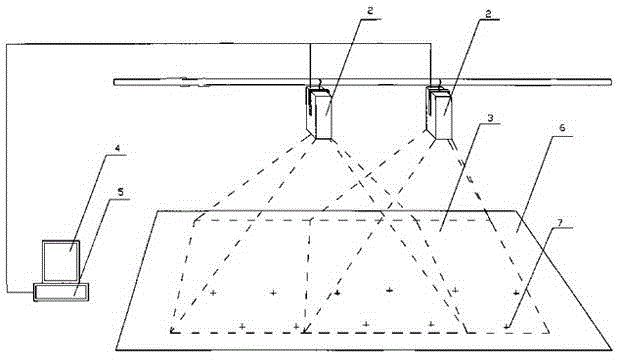

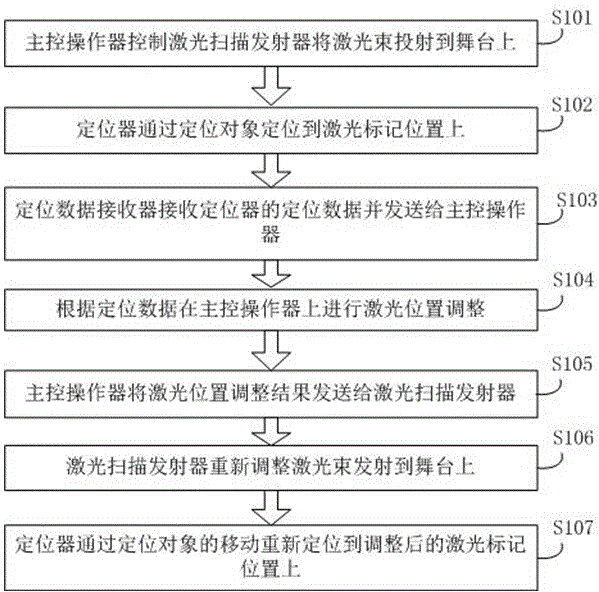

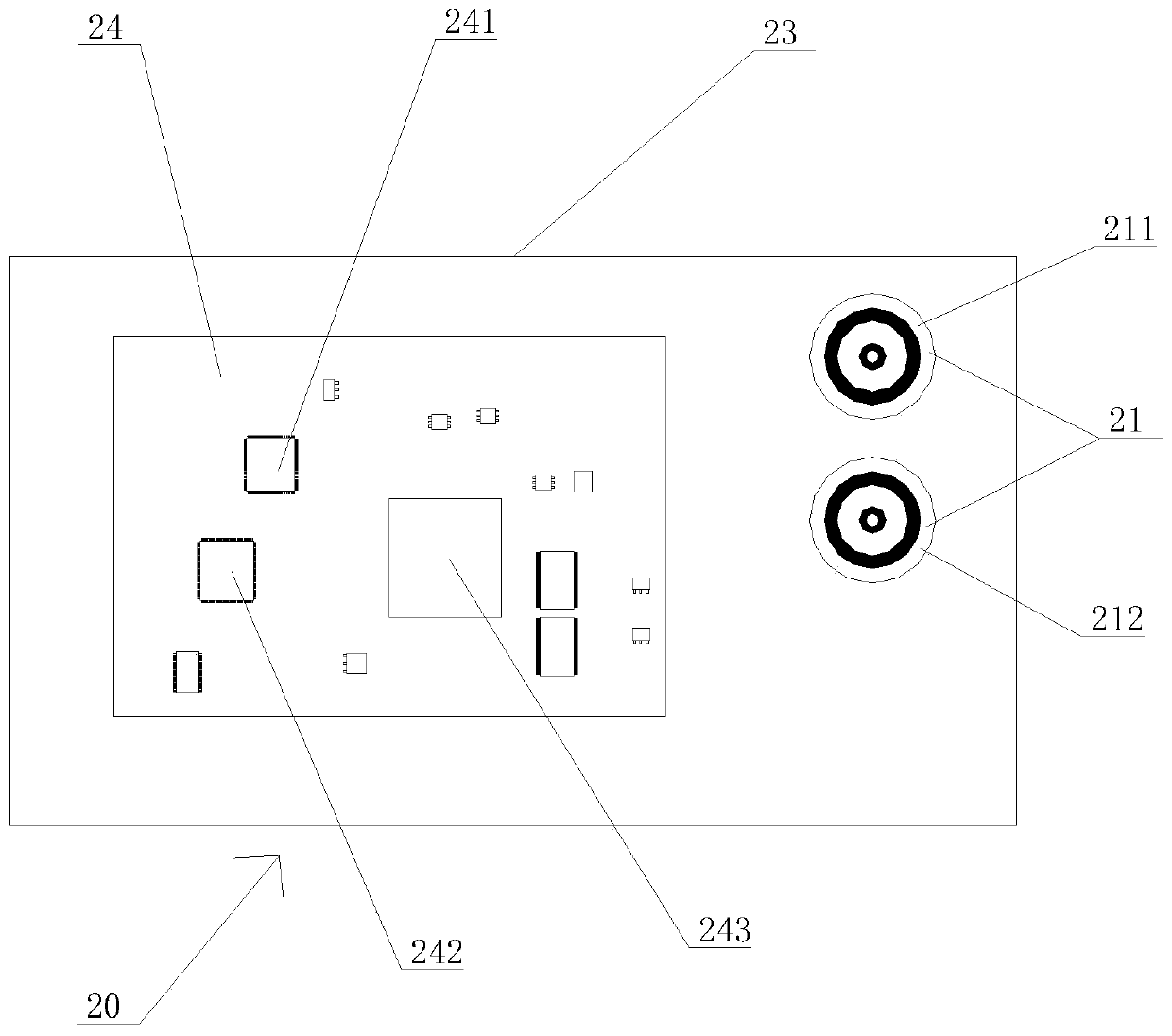

Stage laser positioning calibration device and stage laser positioning calibration method

InactiveCN104613957AImprove positioning accuracyImprove accuracySurveying instrumentsNavigation instrumentsImaging analysisDisplay device

The invention relates to the field of positioning, and particularly relates to a stage laser positioning calibration device and a stage laser positioning calibration method. The device comprises a master control manipulator, a display and a laser scanning transmitter installed above a stage, wherein the master control manipulator is connected with the display and the laser scanning transmitter respectively. The device also comprises a positioner arranged on a positioning object and a positioning data receiver in wireless connection with the positioner, wherein the positioning data receiver is connected with the master control manipulator. According to the stage laser positioning calibration device and the stage laser positioning calibration method provided by the invention, the defect that a laser projection effect is affected by stage light when a camera is adopted for shooting the stage can be overcome, the high cost of the camera is saved and an image analysis step which is needed after the camera is used for shooting images is omitted, and the entire calibration device is simple in structure, convenient for calibration operation, high in positioning and calibration speeds, and low in cost.

Owner:GUANGDONG VTRON TECH CO LTD

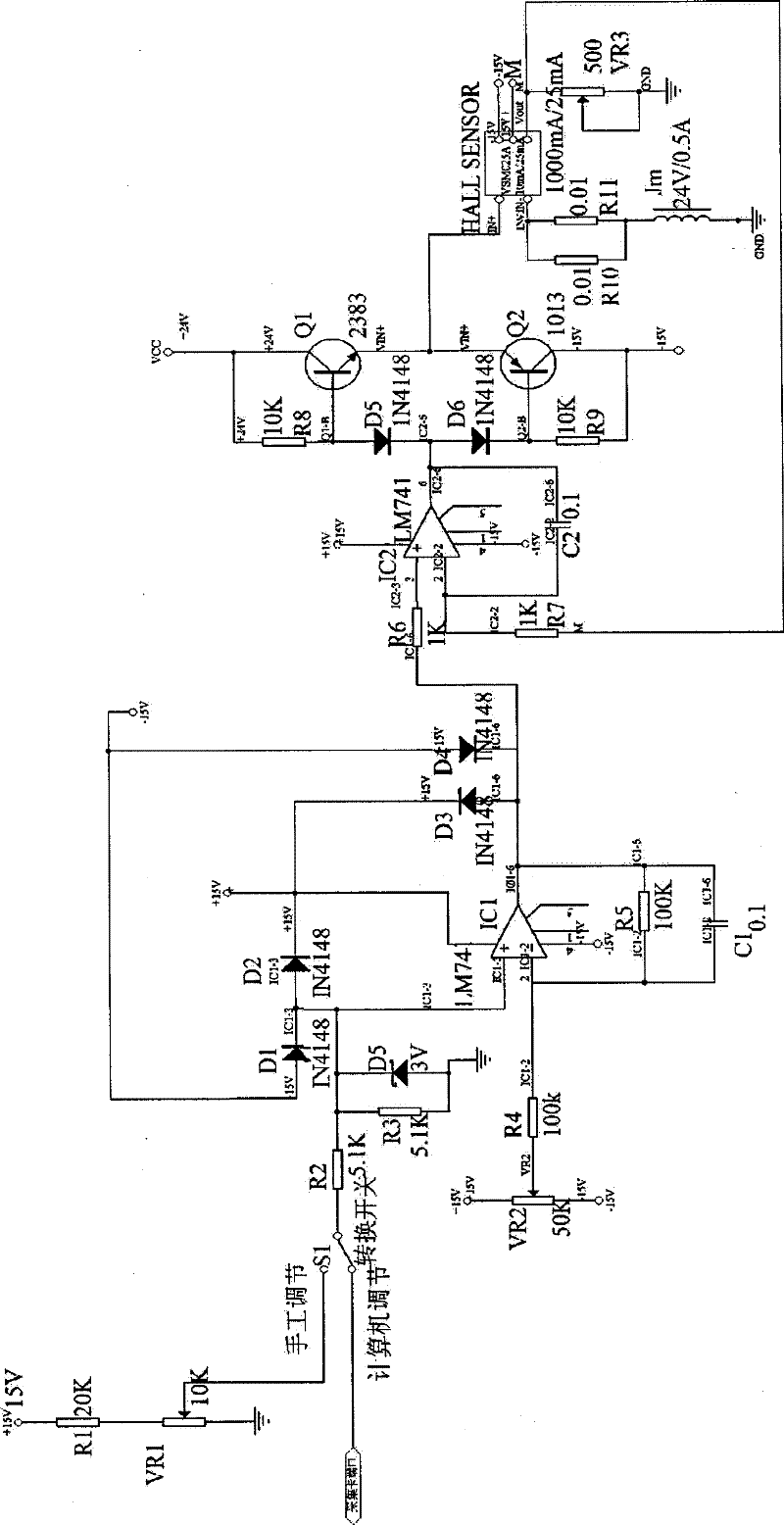

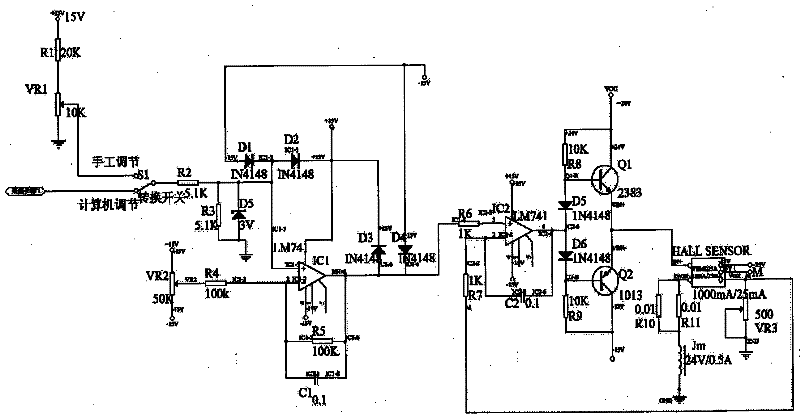

A solenoid valve control circuit

InactiveCN102287566ASimple designLow costOperating means/releasing devices for valvesControl systemClosed loop

The invention discloses an electromagnetic valve control circuit which comprises an electromagnetic valve, regulating devices and a main control circuit; the main control circuit and the regulating devices are connected through a change-over switch; the regulating devices control the electromagnetic valve through the main control circuit; and the main control circuit comprises an external closed loop control system circuit and an internal reference circuit. The electromagnetic valve control circuit has the beneficial effects that: a plurality of regulating devices are connected with the main control circuit, so that the different levels of operation of an operator are convenient, and the circuit has a simple design, low cost and reliable performance. The design of the reference circuit ismore convenient to calibrate and operate by the operator. Due to the design of the external closed loop control circuit, the control circuit has strong anti-interference capability, good stability and high reaction speed.

Owner:江苏茶花电气股份有限公司

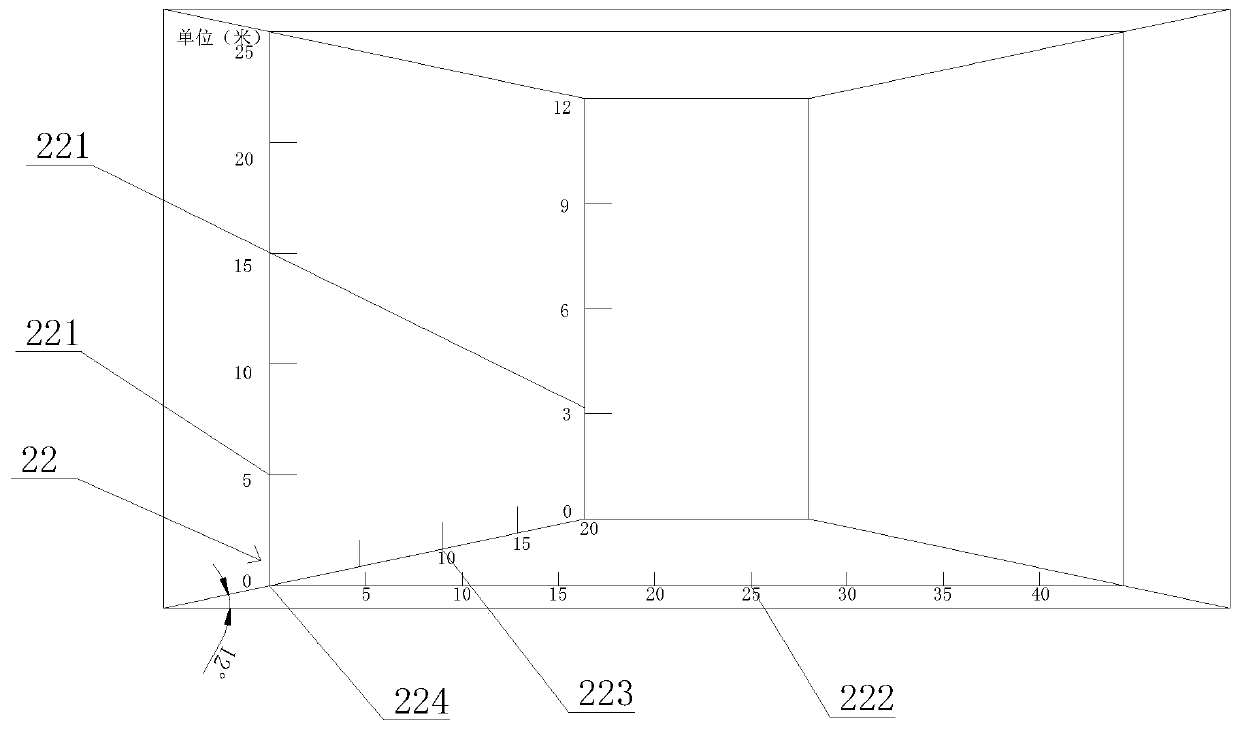

Height limit detection method and device based on machine vision recognition

InactiveCN110940319AMeet real-time requirementsEasy to detectPicture interpretationMachine visionEngineering

The invention discloses a height limit detection method and device based on machine vision recognition, and the method comprises the following steps: adjusting the focal length of a camera of a photographing mechanism, and calibrating an image coordinate system of the camera; acquiring a vehicle image; acquiring height information of the target vehicle according to the longitudinal scale corresponding to the depth scale line of the target vehicle in the vehicle image; acquiring an image of a height limiting rod in front of the target vehicle; obtaining height information of a target height limiting rod according to a longitudinal scale corresponding to a scene depth scale line of the height limiting rod image where the target height limiting rod is located in the height limiting rod image;comparing the height information of the target height limiting rod with the height information of the target vehicle; obtaining a height difference. According to the detection method, vehicle overallheight detection and height limiting rod height detection can be realized, analysis is performed by comparing the heights of the detection vehicle and the height limiting rod, and whether the heightis ultrahigh is judged according to the analysis result.

Owner:广东互动电子有限公司

Method for camera self-calibration based on orthogonal vanishing points

ActiveCN105046691AHigh precisionEliminate the influence of false detection resultsImage analysisPattern recognitionCalibration result

The invention discloses a method for camera self-calibration based on orthogonal vanishing points, including the following steps: carrying out line detection on a calibration scene image to obtain a plurality of parallel line segments; for any n (n>=4) line segments, calculating the orthogonal vanishing point and camera focal length of the n line segments, and calculating a corresponding intrinsic parameter matrix according to the camera focal length and the orthogonal vanishing point; and acquiring a final intrinsic parameter matrix according to all the intrinsic parameter matrixes and based on a random sampling consistency approach. According to the method for camera self-calibration of the invention, all the line segments obtained through line detection are grouped. Through multiple groups of detection, the influence of error detection results in line detection can be effectively eliminated, and the accuracy of self-calibration results can be improved. Grouping facilitates parallel calculation and is beneficial to the improvement of self-calibration rate.

Owner:ZHEJIANG UNIV

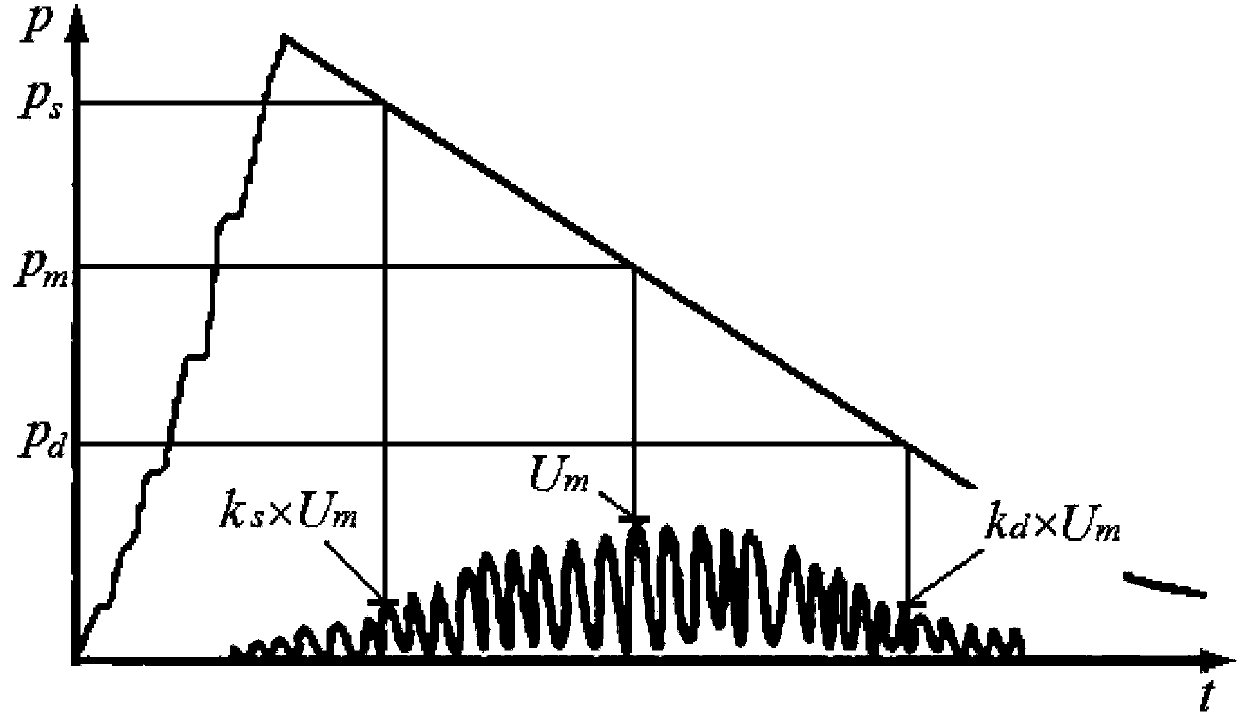

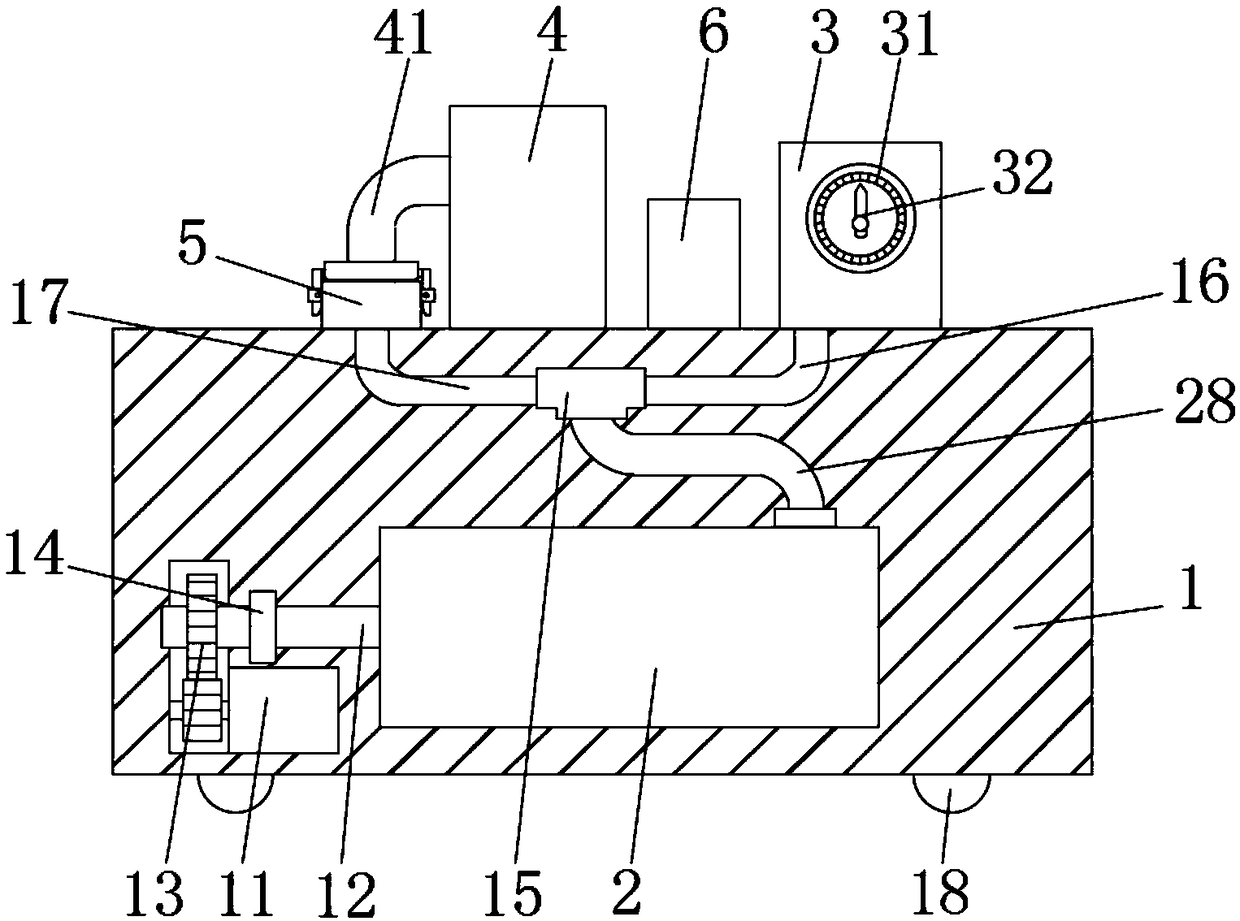

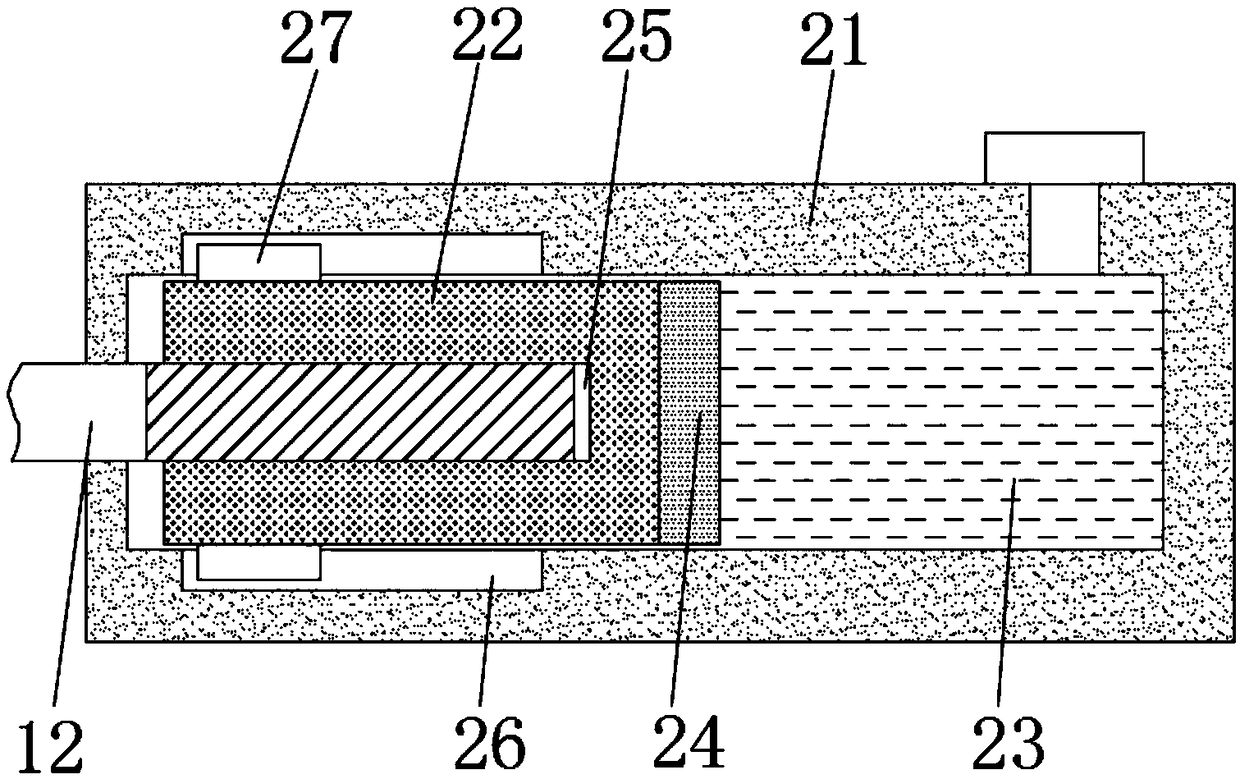

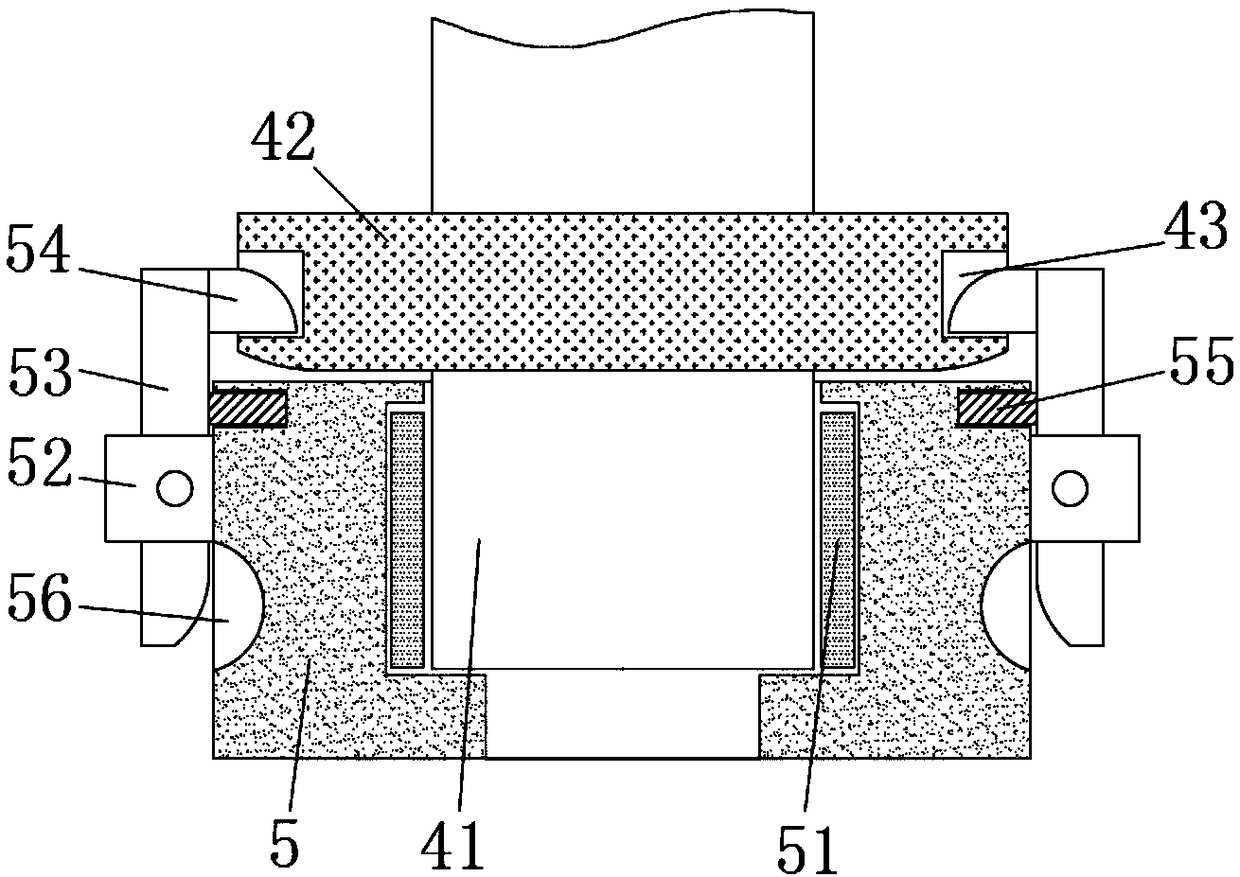

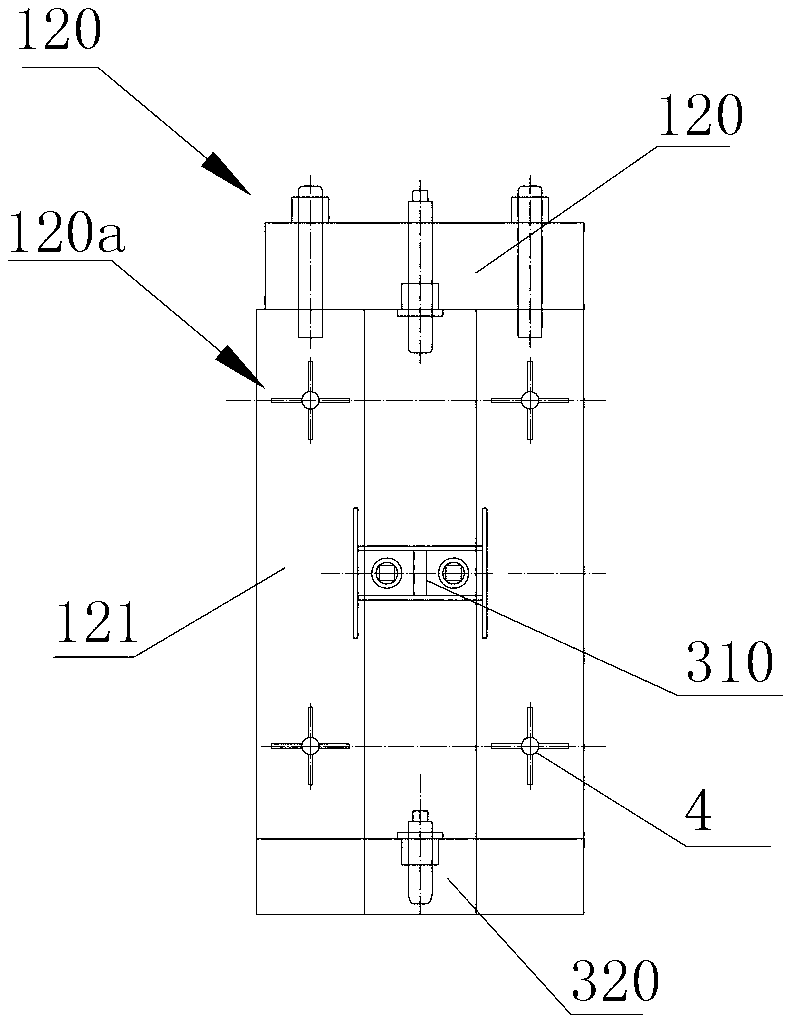

Human body simulation and calibration device of oscilloscope electronic sphygmomanometer

The invention relates to a human body simulation and calibration device of an oscilloscope electronic sphygmomanometer. The device comprises a pressure vessel assembly, wherein the pressure vessel assembly is connected with the electronic sphygmomanometer, the output end of the pressure vessel assembly is connected with a control and processing assembly, the control and processing assembly is connected with a power amplifying assembly, and the power amplifying assembly is connected with the driving end of the pressure vessel assembly. The detected pressure value is transmitted into the control and processing assembly by the pressure vessel assembly, and the control and processing assembly controls the power amplifying assembly to generate a power amplifying driving signal according to the pressure value of the pressure vessel assembly, so as to simulate and generate the pulse wave in the pressure vessel assembly through the power amplifying driving signal. The control and processing assembly determines the systolic pressure Ps and diastolic pressure Pd of the electronic sphygmomanometer connected with the pressure vessel assembly according to a pressure signal with the pulse wave generated by the pressure vessel assembly. The device has the advantages that the structure is compact, the oscilloscope electronic sphygmomanometer can be calibrated, the calibration precision is high, the calibration operation is convenient, the applicable range is wide, and the safety and the reliability are realized.

Owner:WUXI MEASUREMENT & TESTING CENT

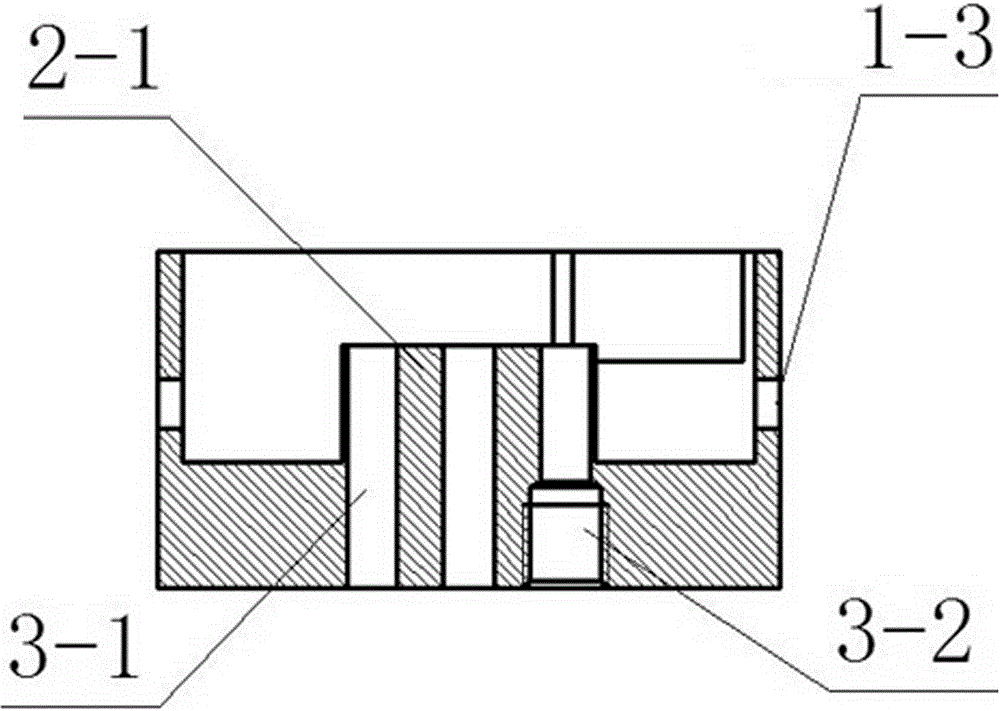

Pressure sensor calibration device

InactiveCN108918027AAvoid damageCalibration is easy to operateFluid pressure measurementHydraulic cylinderMeasurement device

The invention discloses a pressure sensor calibration device, and relates to the technical field of the pressure sensor. The pressure sensor calibration device comprises a base and a hydraulic outputdevice; a motor and a lead screw are arranged in the base, and a transmission gear is sleeved at the outside of one end of the lead screw; the hydraulic output device comprises a hydraulic cylinder, apiston and hydraulic oil; the piston and the hydraulic oil are located in the hydraulic cylinder, a thread groove is formed at the other end of the piston, one side of the top end of the hydraulic cylinder is fixedly connected with a mainstream pipe, one end of the mainstream pipe is fixedly connected with a T-joint, one end of the T-joint is fixedly connected with a first shunt. Through the pressure sensor calibration device disclosed by the invention, the pressure sensor is calibrated by using the hydraulic principle by arranging the hydraulic output device, the precision of the calibrationis improved; by arranging the measurement device, one the one hand, the phenomenon that the pressure sensor is damaged due to excessive pressure is avoided, on the other hand, the calibration operation is performed on the pressure sensor.

Owner:LONGYAN UNIV

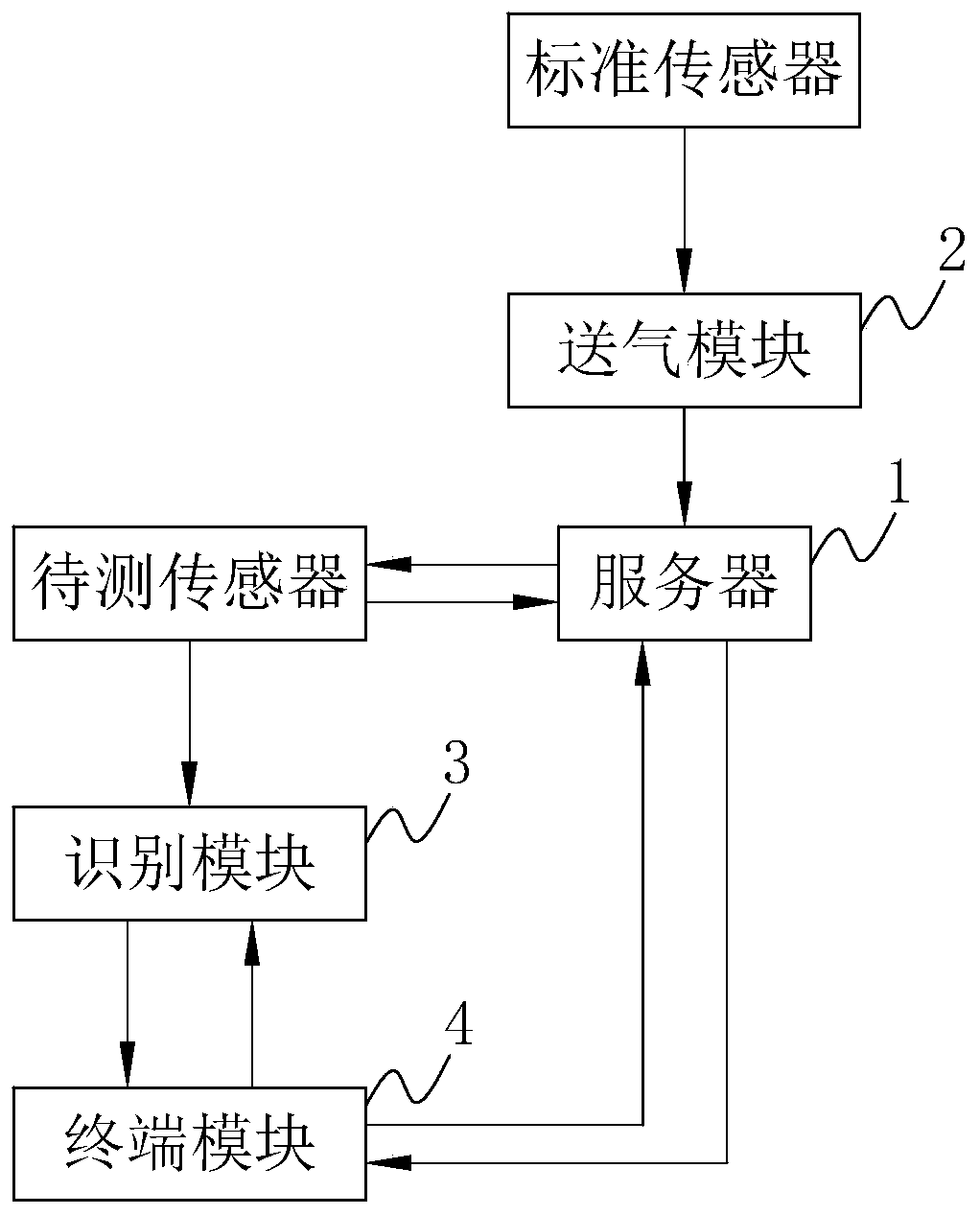

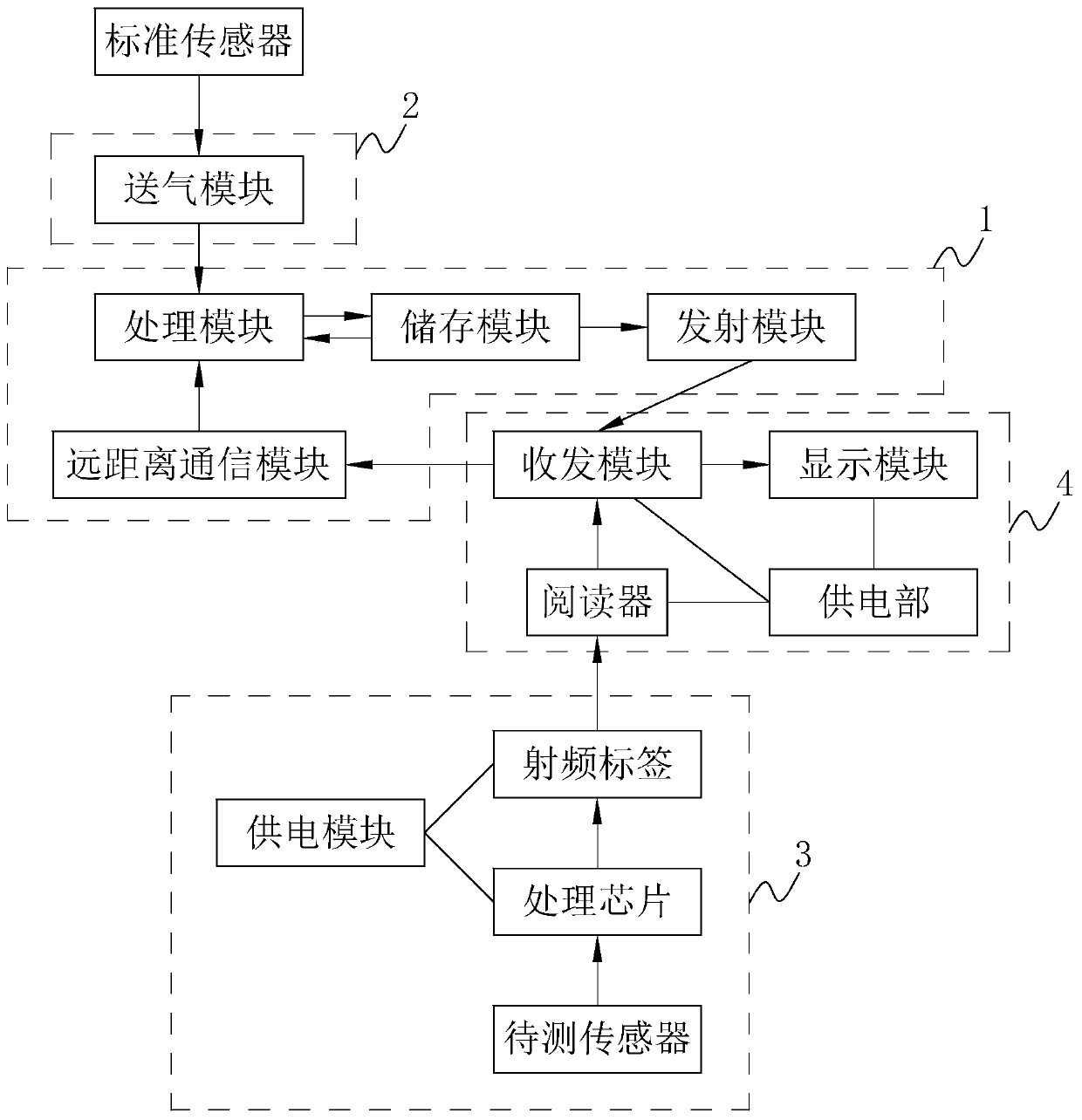

Management system and method for gas sensor

InactiveCN109813847ACalibration is easy to operateEasy maintenance and managementMaterial analysisData connectionComputer terminal

The invention relates to the technical field of gas sensors, and discloses a management system for a gas sensor. Based on a server, a to-be-tested sensor in data connection with the server, a standardsensor in data connection with the server, a gas supplying module in data connection with the server and the standard sensor, a recognition module in data connection with the to-be-tested sensor, anda terminal module in data connection with the server, the server generates calibration parameters used for calibrating the to-be-tested sensor according to state information and standard parameters,the calibration parameters are sent to the terminal module, and the gas supplying module supplies testing gas of the same concentration to the standard sensor and the to-be-tested sensor; the terminalmodule reads the output amount of the to-be-tested sensor, the gas supplying module reads standard parameters output by a standard module, and then the server processes the output amount according tothe standard parameters and outputs the calibration parameters to a display module for displaying; a worker can conveniently calibrate the to-be-tested sensor, and management and maintenance are convenient.

Owner:上海源安安全科技有限公司

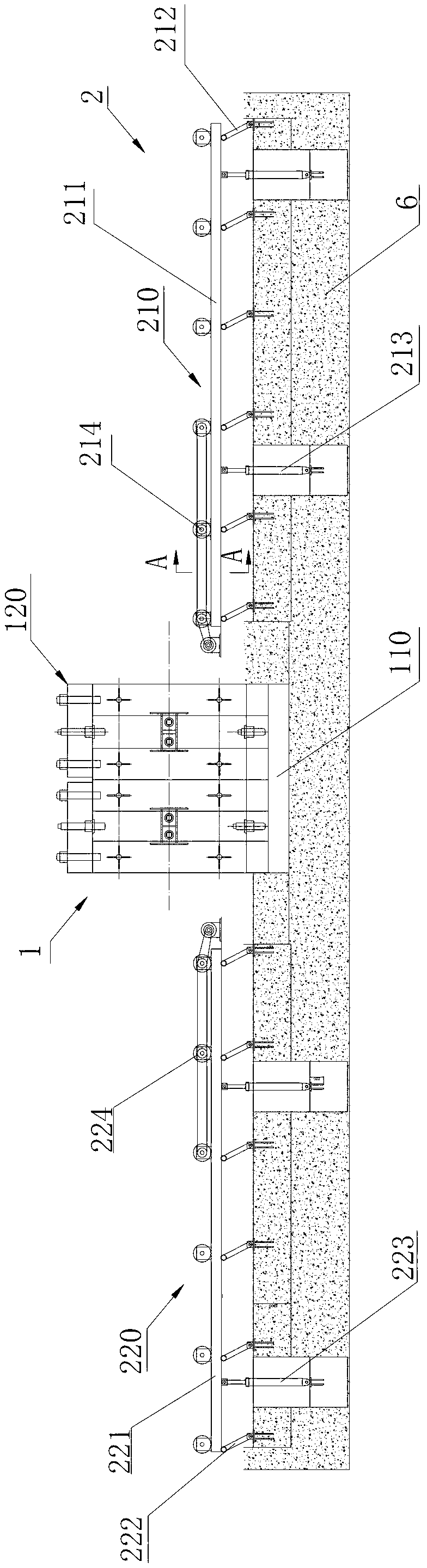

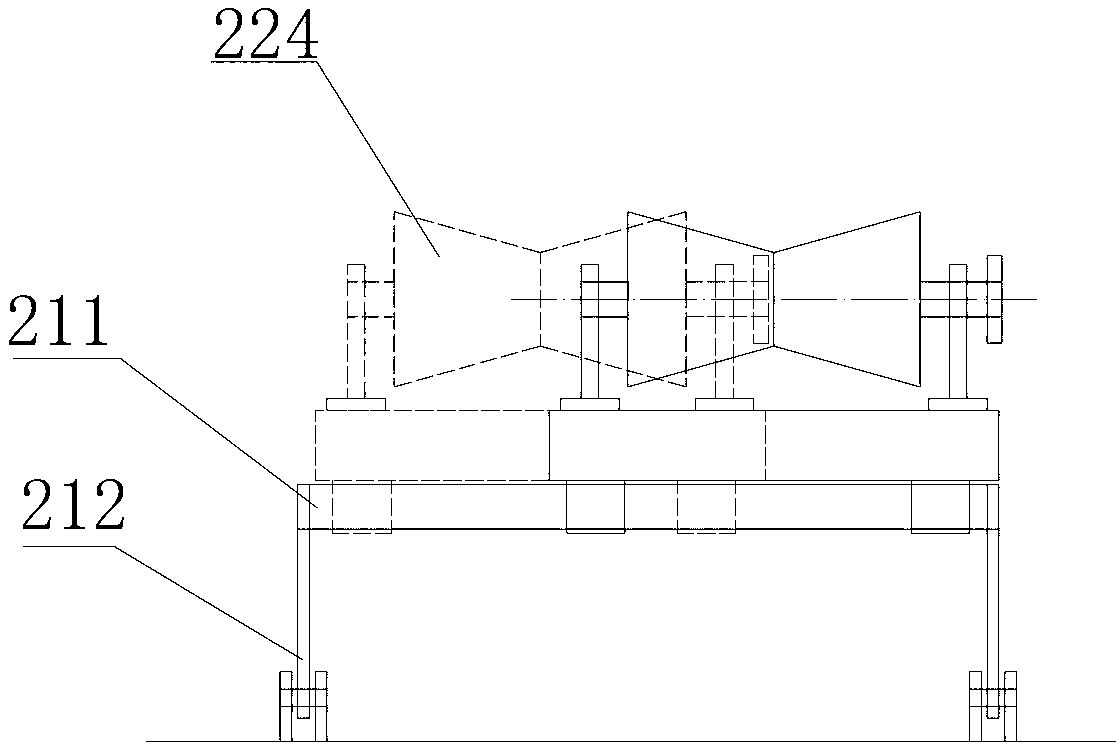

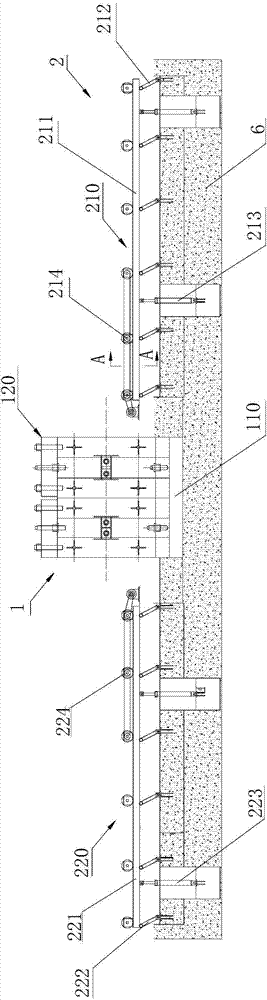

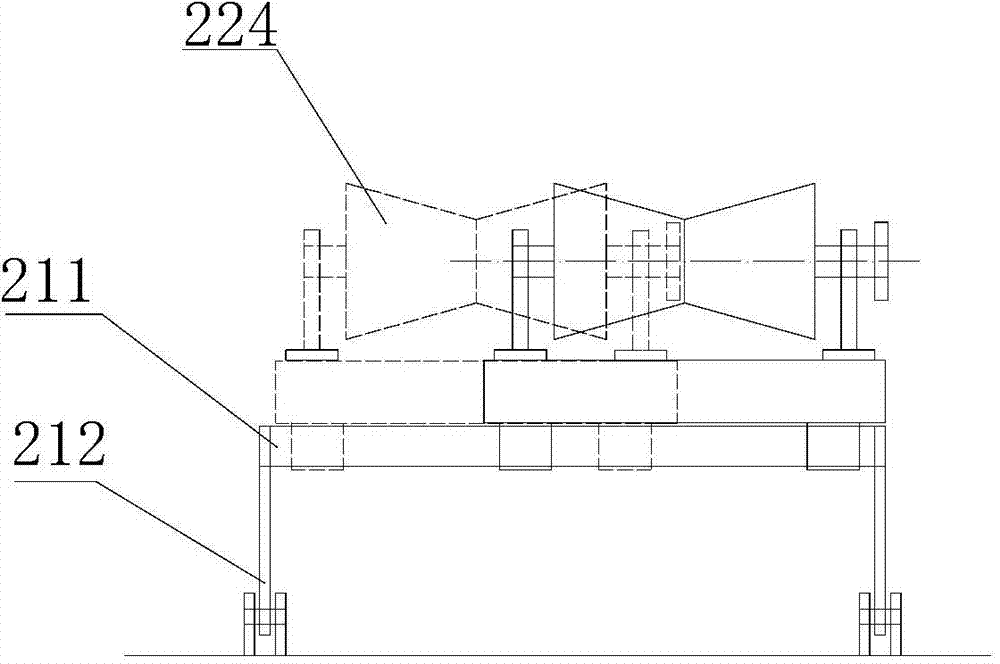

Multi-caliber roundness-correcting set

The invention relates to a multi-caliber roundness-correcting set. The multi-caliber roundness-correcting set is characterized by comprising a roundness-correcting device and a carrier roller device, wherein the roundness-correcting device comprises a base, at least one set of symmetrical roundness-correcting unit is installed on the base, a framework is installed on the roundness-correcting unit, the roundness-correcting unit mainly comprises two sets of vertical columns which are parallelly arranged, one set of vertical column of the two sets of vertical columns which are parallelly arranged is a fixed structure, the other set of vertical column of the two sets of vertical columns which are parallelly arranged is a relative-moving structure, and a guiding mechanism and a horizontal moving device are arranged between the two sets of vertical columns which are parallelly arranged. In actual operation, the multi-caliber roundness-correcting set is also convenient to operate, the locating and guiding mechanism just needs to be loosened, the horizontal moving device is started, the distance between the two sets of vertical columns which are parallelly arranged can be enlarged or shrunk, and roundness-correcting work of round pipes with different pipe diameters can further be completed; the multi-caliber roundness-correcting set also has the advantages of being simple in structure, reasonable in design, low in cost, easy to operate, safe, reliable and the like.

Owner:天津厚重科技有限公司

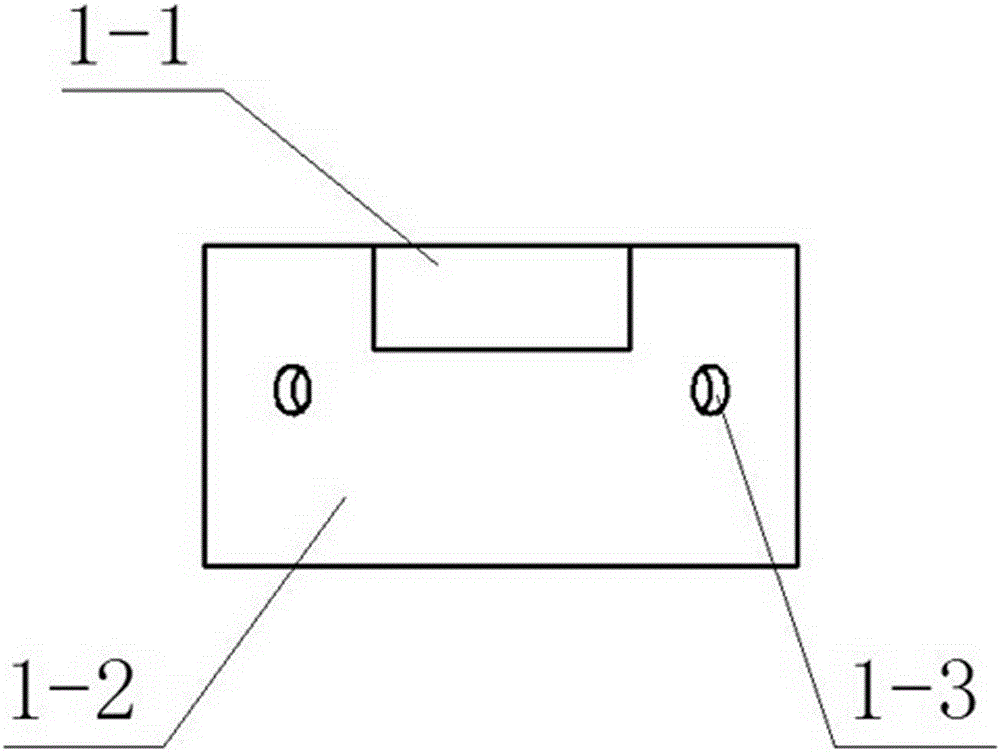

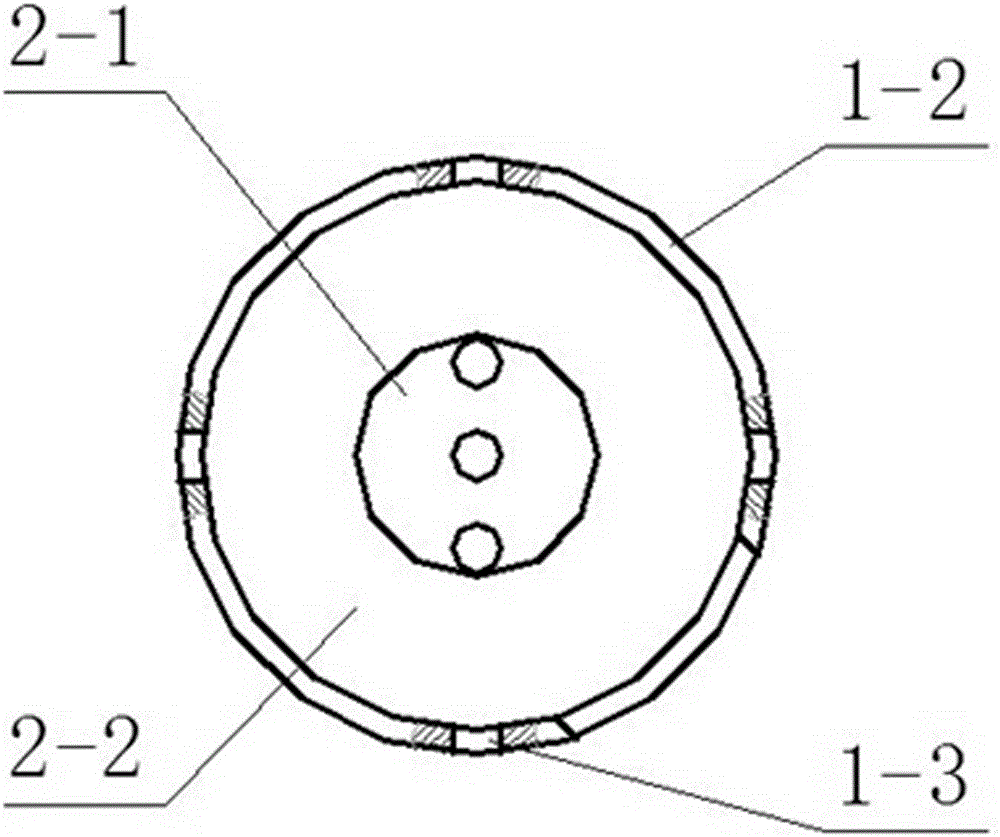

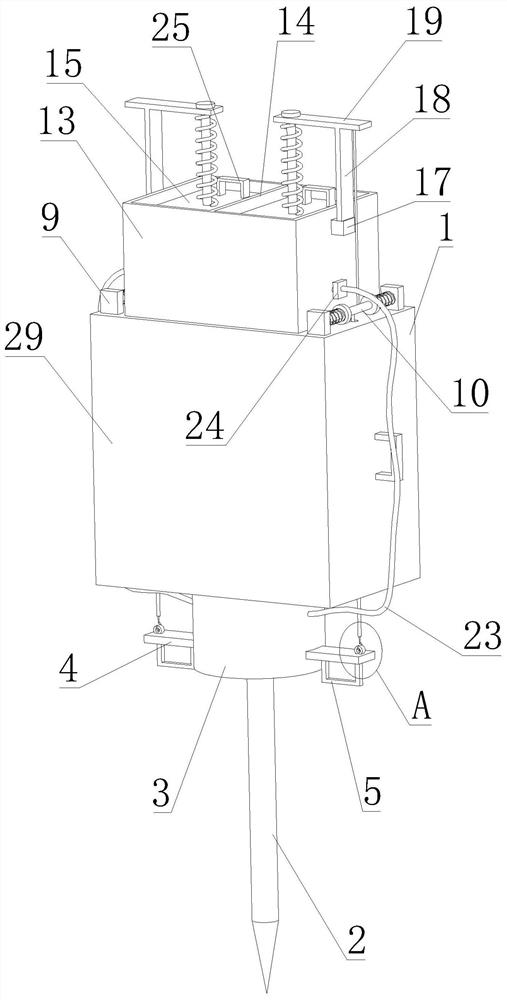

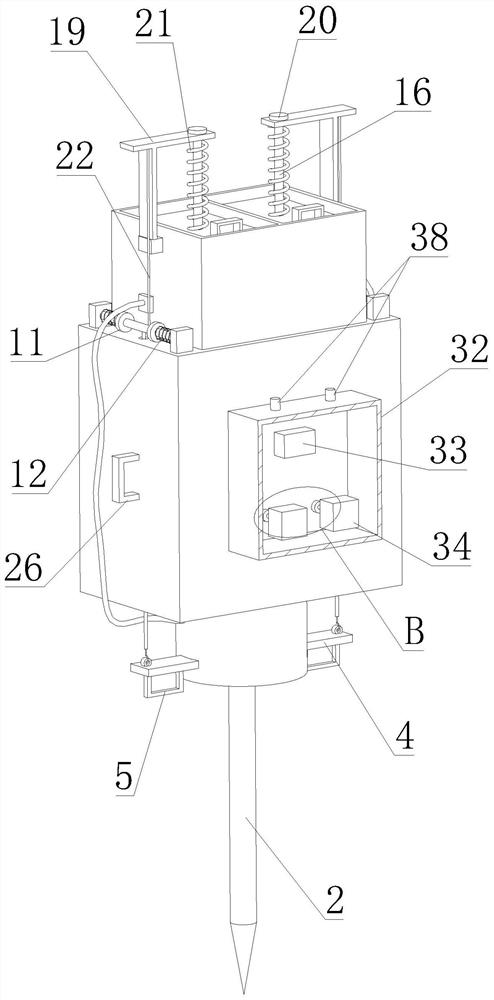

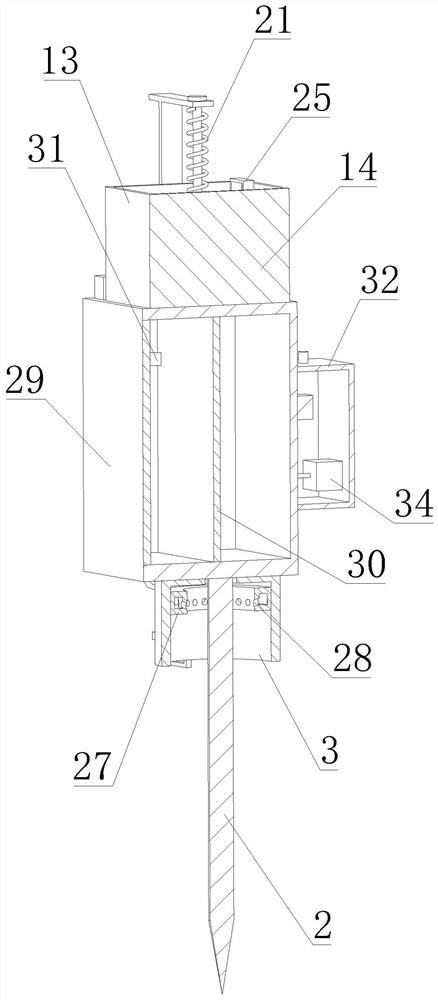

Sensor calibration device

InactiveCN105181901AImprove adsorption capacitySimple structureMaterial analysisMechanical engineeringThin walled

The invention discloses a sensor calibration device which comprises a cylindrical bottom face, a boss and a cylindrical thin-walled ring. The sensor calibration device is characterized in that the top of the cylindrical bottom face is connected with the cylindrical thin-walled ring and the boss, the boss is located inside the cylindrical thin-walled ring, bottom exhaust holes and an air inlet hole are formed in the cylindrical bottom face, and exhaust holes and an air inlet which correspond to the cylindrical bottom face are formed in the boss. The sensor calibration device has the advantages that the sensor calibration device is simple in structure, calibration operation is convenient, and the response time for calibration of gas T90 having good adsorption capacity reaches a standard value.

Owner:HARBIN EAST ALARM EQUIP DEV

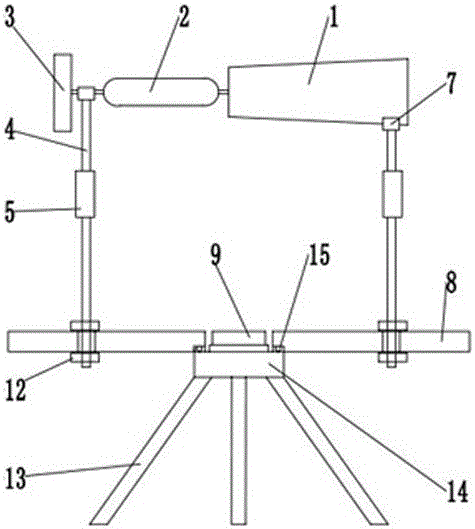

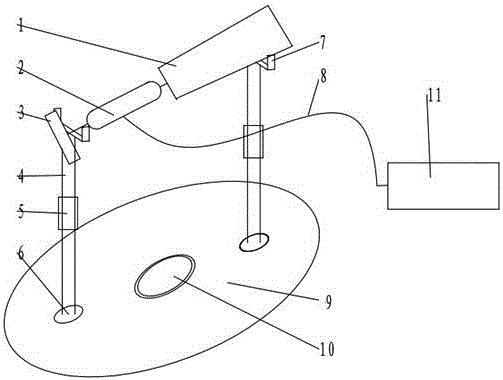

Method and device for calibrating current meter flow direction

InactiveCN106526236AImprove accuracyIncrease flexibilityTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterMeasurement point

The invention relates to a method and a device for calibrating a current meter flow direction. The device comprises a compass, a tray, a support and a test table, wherein the test table comprises a supporting frame and a table plate; the compass is fixedly arranged in the center of the table plate; the support is connected onto the tray; and the tray is connected onto the table plate in a rotating mode. The calibration method comprises steps: (1) the current meter is placed on the current meter flow direction calibration device; (2) the level of the current meter is adjusted, and a detector is started; (3) the flow direction degree of the current meter is detected, and the reading of the current meter and the scale on the compass at the corresponding position are recorded; (4) the tray is rotated to a next position, and the calibration operation is repeated; and (5) the differences between the flow direction degrees at measurement points and scales on the compass are compared, if the average value of the differences is no smaller than + / -4 DEG, the measurement parameters of the current meter are adjusted, and the test operation is repeated until the average value of the differences is smaller than + / -4 DEG. The structure is simple and easy to carry, calibration operation at any time is facilitated, the method and the device are suitable for flow direction calibration on various current meters, the calibration process is optimized, and the current meter flow direction accuracy and the flexibility are improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

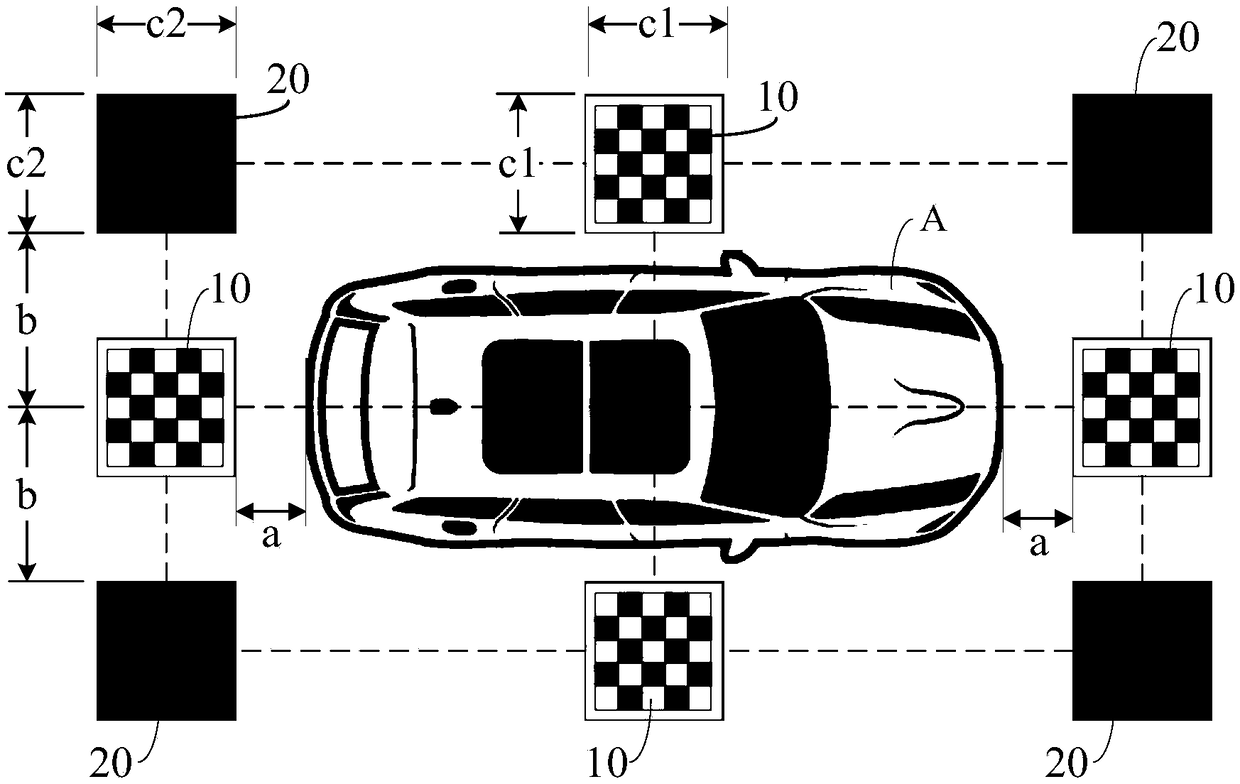

Vehicle round-looking system calibration scene

PendingCN108537850ASimple sceneEasy to buildImage enhancementImage analysisPattern recognitionRight triangle

Provided is a vehicle round-looking system calibration scene. The vehicle round-looking system calibration scene comprises first calibration blocks and second calibration blocks, wherein the first calibration blocks are symmetrically distributed on central axes of the vehicle length direction and vehicle width direction of a to-be-calibrated vehicle, a second calibration block is arranged betweeneach pair of adjacent first calibration blocks, a center point of each second calibration block and center points of two first calibration blocks arranged adjacently form a right triangle, and the center point of each second calibration block is a right angle vertex. The vehicle round-looking system calibration scene has the advantages that the construction of the scene can be completed by arranging the calibration blocks in parallel around the vehicle body, the scene is simple, and the construction is convenient; the calibration blocks are divided into two groups according to the content of picture blocks and separately arranged in a visual overlapping area and a non-overlapping area, so that a computer can analyze and judge the orientation according to a real-scene picture taken by the calibration scene, an image can be automatically spliced and verified after feature points are extracted, and the calibration operation is fast and convenient.

Owner:HEFEI SOFTEC AUTO ELECTRONICS

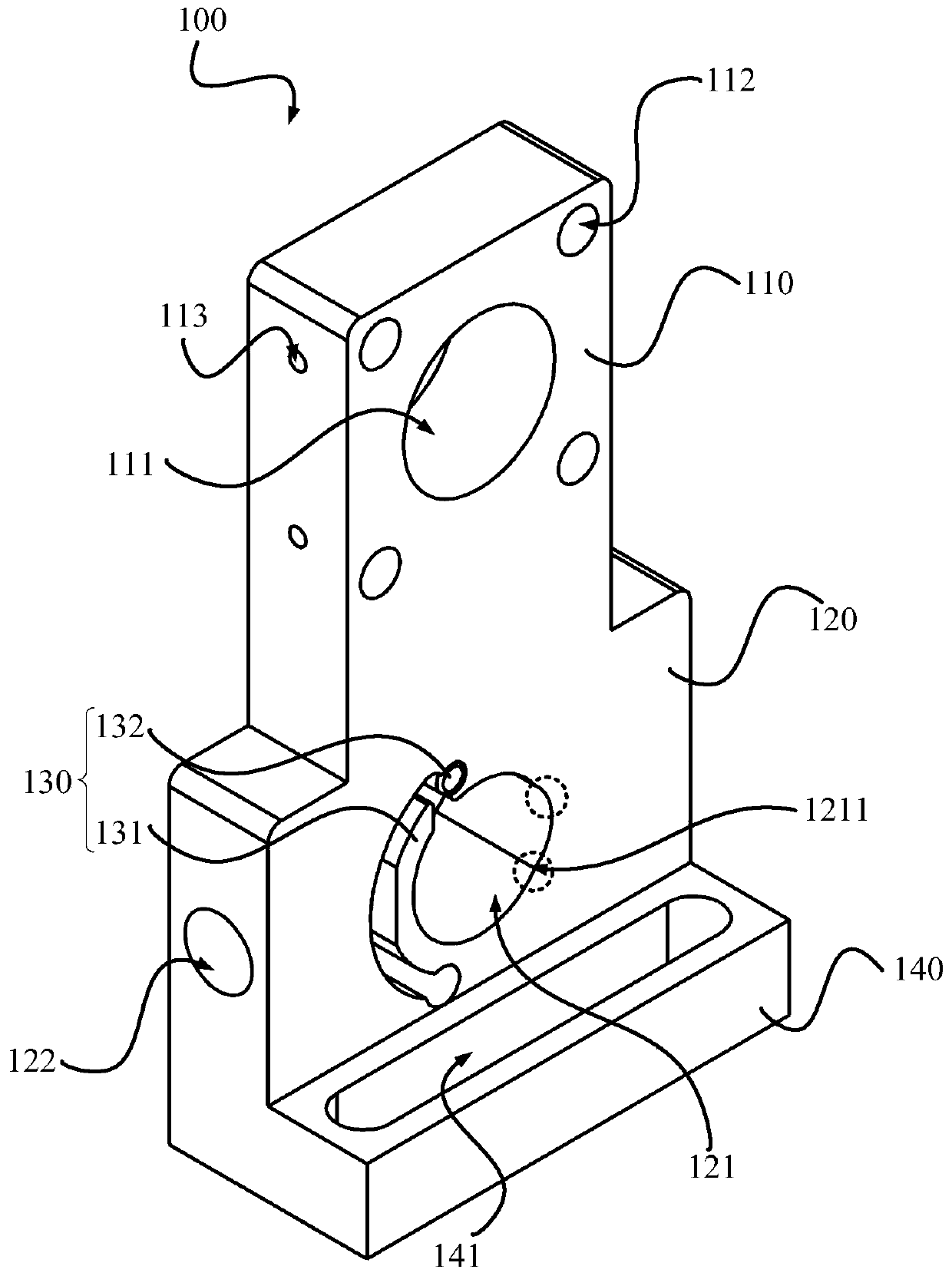

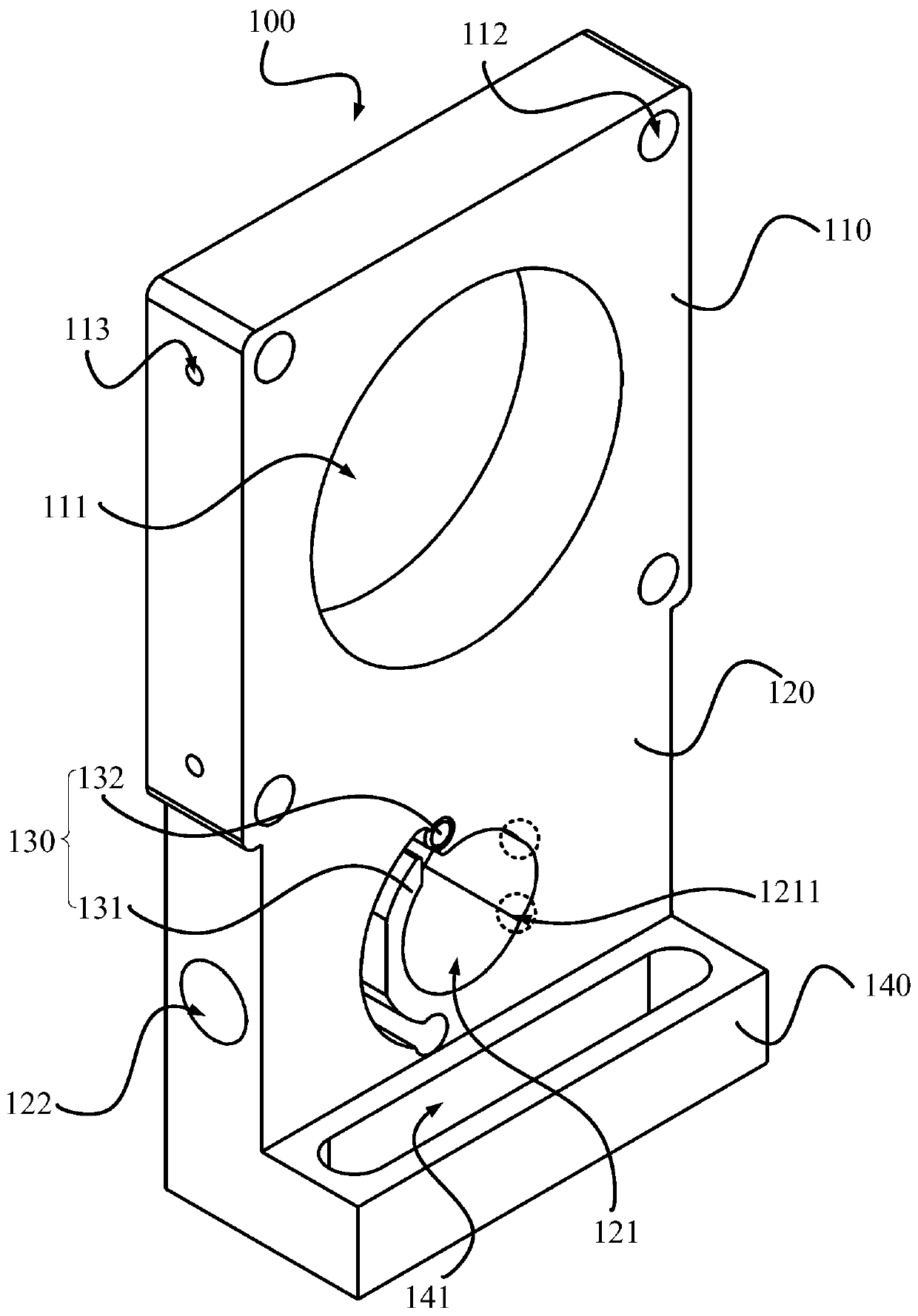

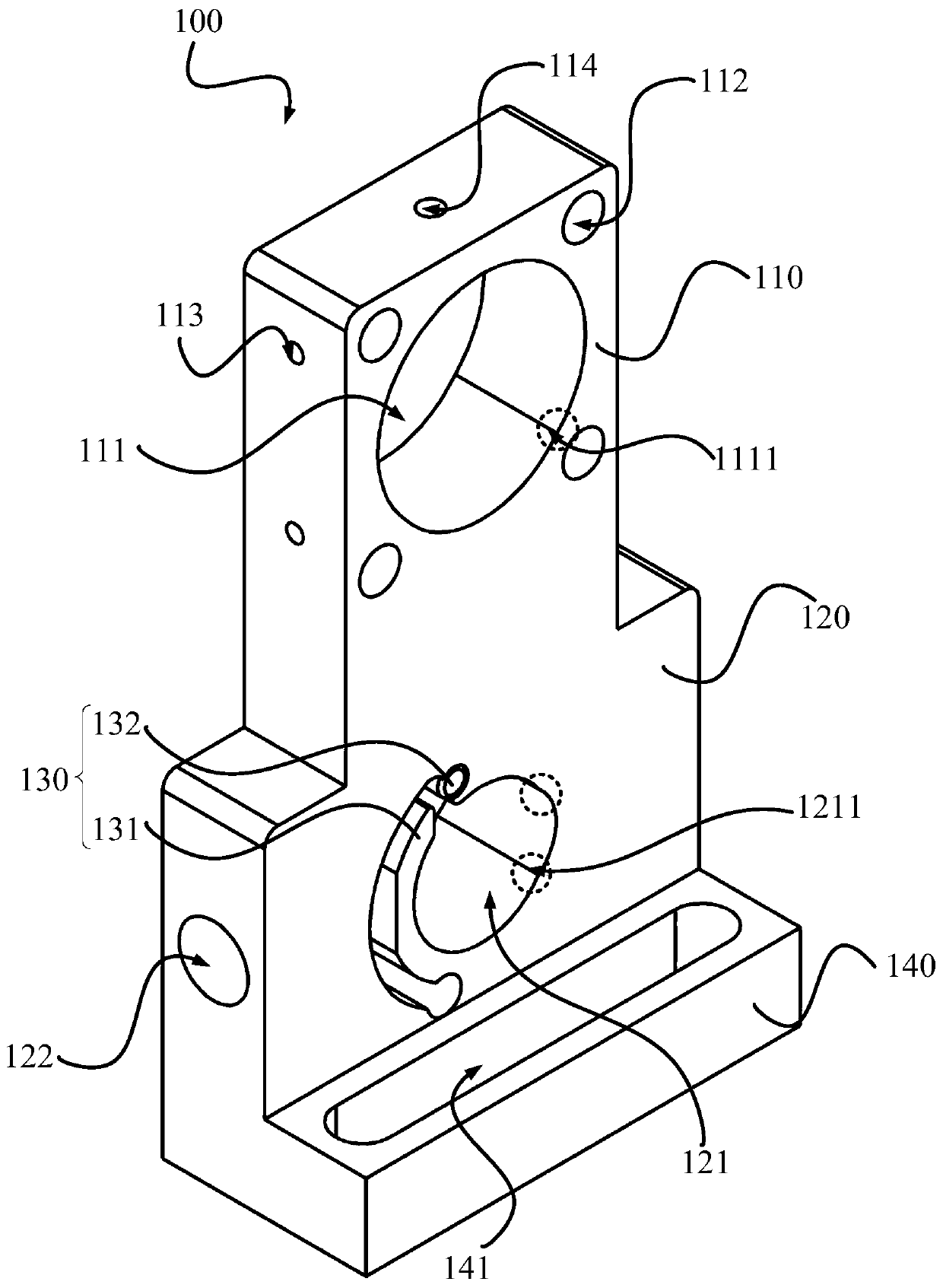

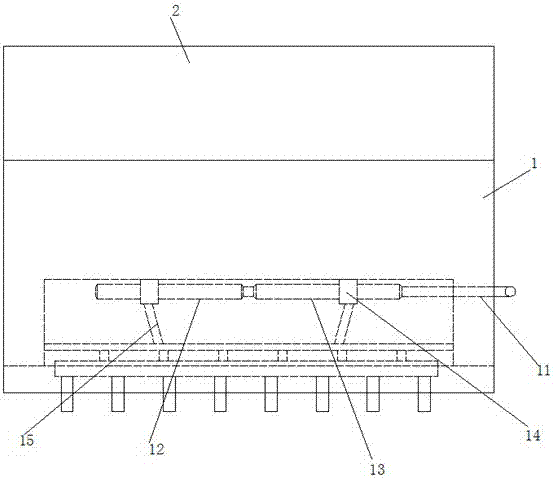

Mounting bracket for coaxial optical system and coaxial optical system with same

PendingCN110244424AImprove installation accuracyCalibration is easy to operateMountingsEngineeringOptical table

The present invention provides a mounting bracket for a coaxial optical system, and a coaxial optical system with the same. The mounting bracket comprises: a base body mounted on an optical platform of the coaxial optical system, wherein the base body has a positioning hole for mounting a positioning rod; a clamping assembly which is arranged on the positioning hole and is configured to fix the positioning rod; and a mounting plate arranged on the base body, wherein the mounting plate has a mounting hole for mounting an optical component. The clamping assembly is configured to position, clamp and fix the positioning rod to ensure a unique positional relationship between the positioning rod and the mounting bracket; and a plurality of mounting brackets can be connected and positioned by using the positioning rod to ensure collimation, and the coaxial precision of the mounting bracket can be improved, so that the mounting precision of the coaxial optical system is improved, the calibration accuracy of the optical path is improved, the stability of the optical path is improved, and the calibration operation of the coaxial optical system is facilitated.

Owner:唐云青 +2

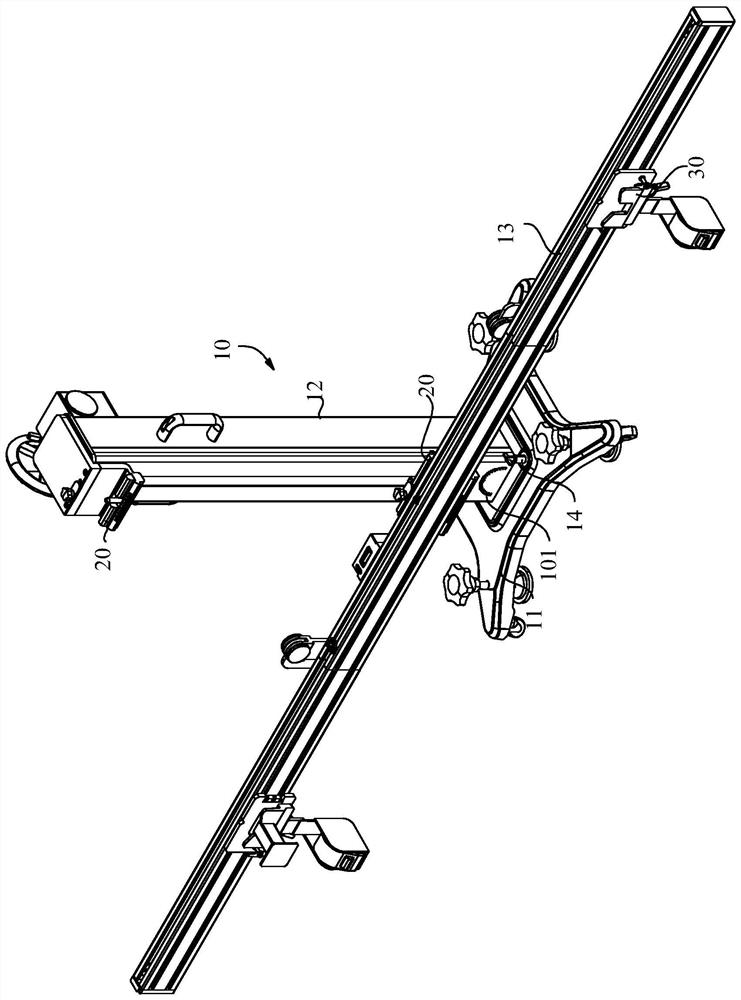

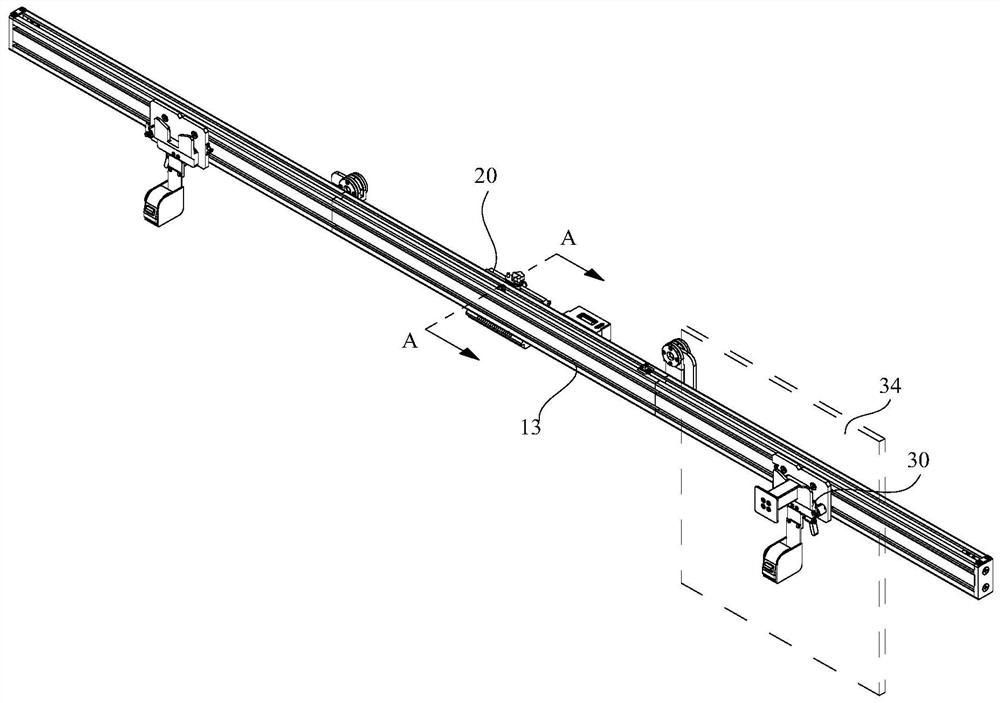

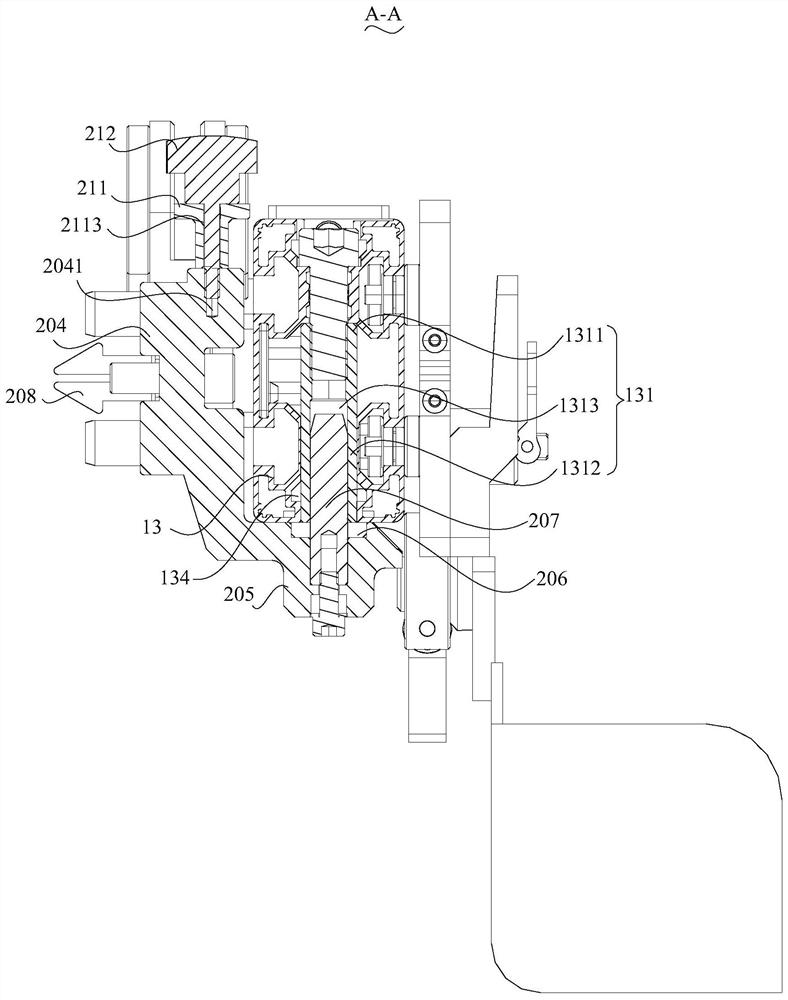

Calibration support and calibration equipment

PendingCN112578348ACalibration is easy to operateCalibration operations are fast and accurateWave based measurement systemsStands/trestlesEngineeringErbium lasers

The invention discloses a calibration support and calibration equipment. The calibration support comprises a main frame and calibration seats. The number of the calibration seats is two, and the calibration seats are arranged on the main frame at intervals along the vertical direction. Each calibration seat is provided with a light receiving surface used for receiving a plane laser beam emitted bya laser along the longitudinal direction of a vehicle, the light receiving surface is provided with a centering mark, and the centering mark is located at the middle position of the calibration seat;the centering marks on the at least two calibration seats jointly define a centering plane, the centering plane is perpendicular to the light receiving face, the light receiving face intersects withthe center line of the main frame, the center line of the main frame is located on the centering plane, and the center line of the main frame extends in the height direction of the main frame. According to the invention, the calibration operation in the calibration process is convenient, rapid and accurate.

Owner:SHENZHEN XTOOLTECH INTELLIGENT CO LTD

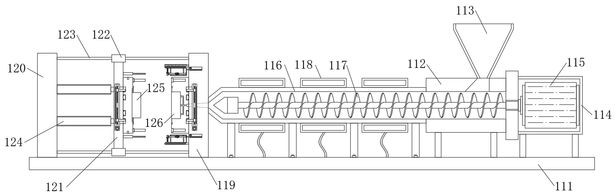

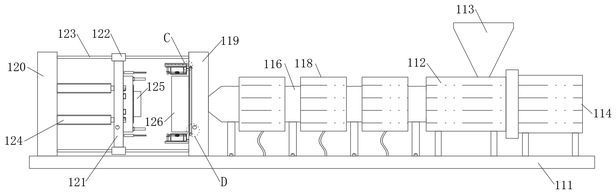

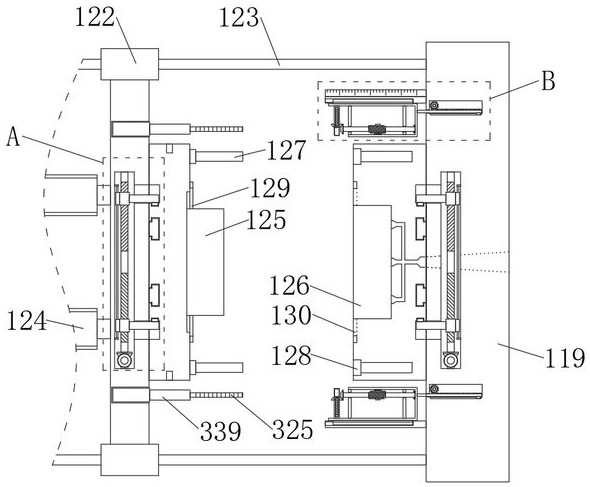

Packaging plastic injection molding machine with injection mold calibration function

PendingCN112659486AAvoid offsetCalibration is easy to operatePlastic injection moldingPlastic packaging

The invention relates to the technical field of injection molding machines, in particular to a packaging plastic injection molding machine with an injection mold calibration function. The packaging plastic injection molding machine with the injection mold calibration function comprises a base, wherein the other side of a hydraulic push rod is fixed to the outer wall of a movable frame; the sides, close to each other, of a first fixed frame and the movable frame are connected with a first mold and a second mold through calibration mechanisms correspondingly; the calibration mechanisms comprise positioning cavities; two-way threaded lead screws are arranged in the positioning cavities; the upper ends and the lower ends of the outer sides of the two sets of two-way threaded lead screws are in threaded connection with lead screw sleeves; and locking mechanisms are arranged at the upper ends and the lower ends of the first mold and the second mold. According to the packaging plastic injection molding machine with the injection mold calibration function provided by the invention, the problems that the first mold and the second mold fall down during long-time production, deviation is likely to be generated during positioning, secondly, loosening and deviation can be generated due to insufficient locking force between the first mold and the second mold, and the internally-machined plastic packaging box is damaged are effectively solved.

Owner:郭德镇

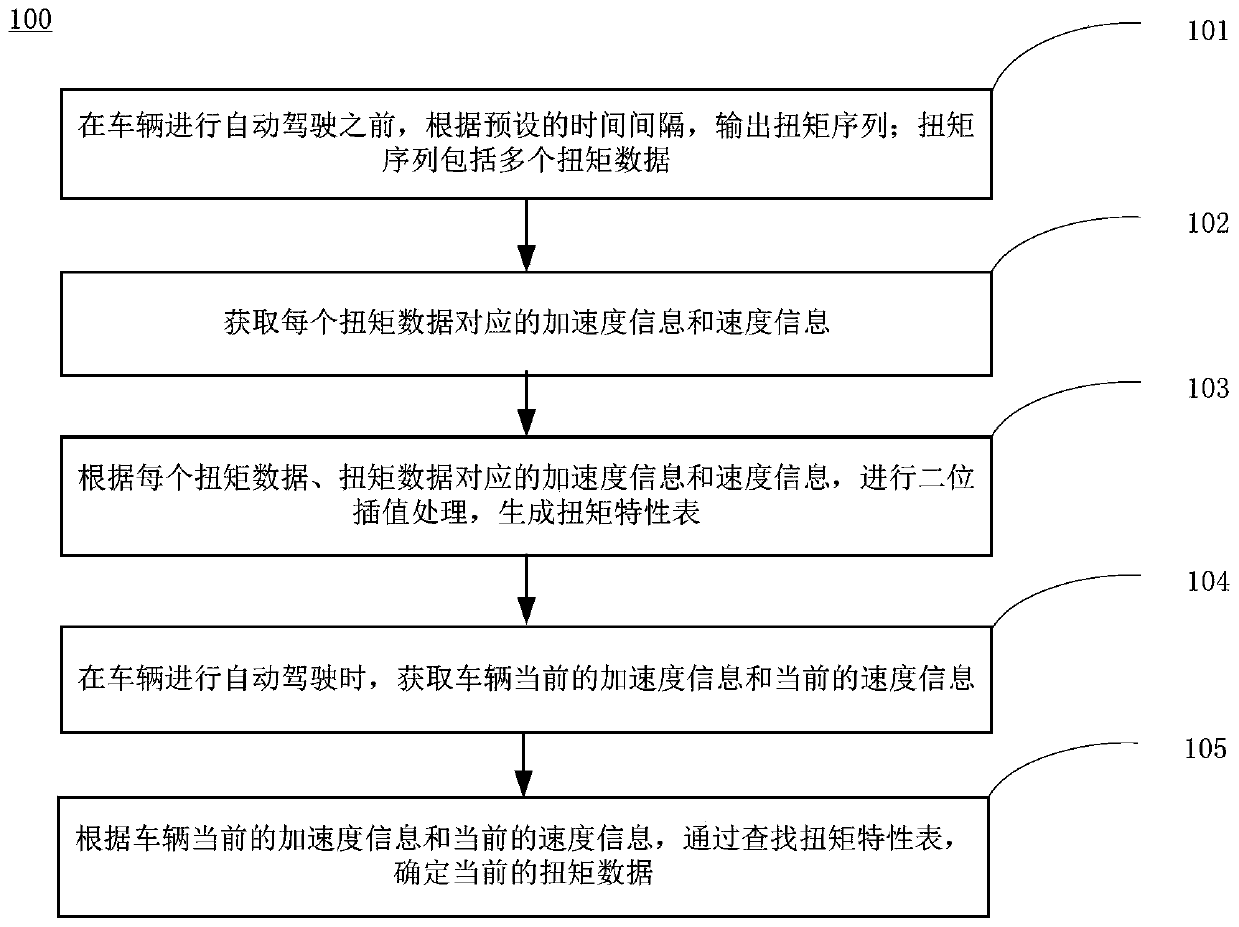

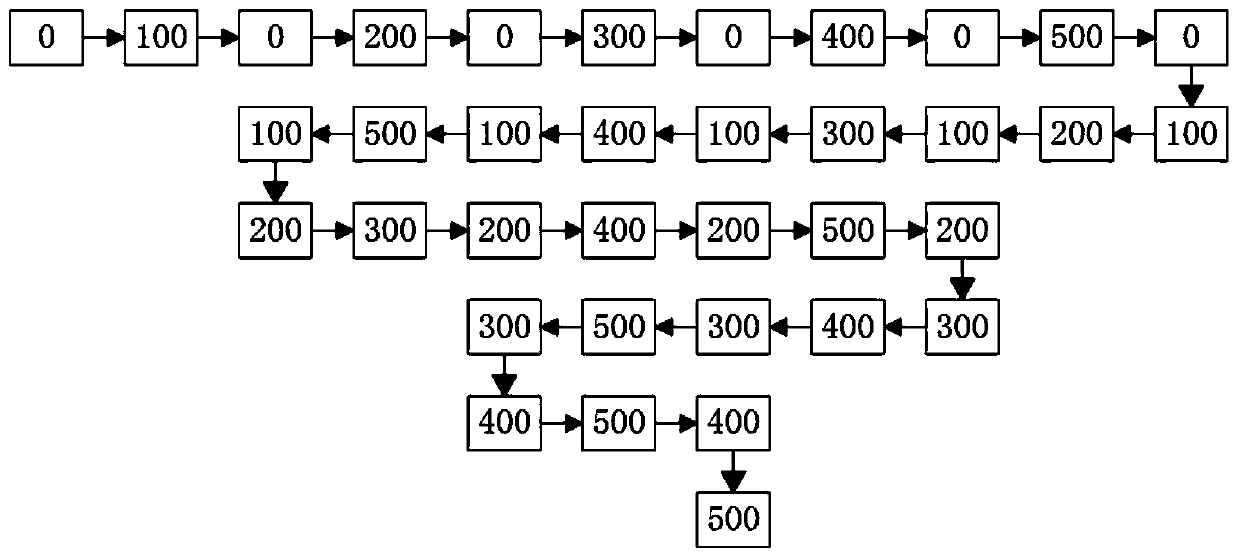

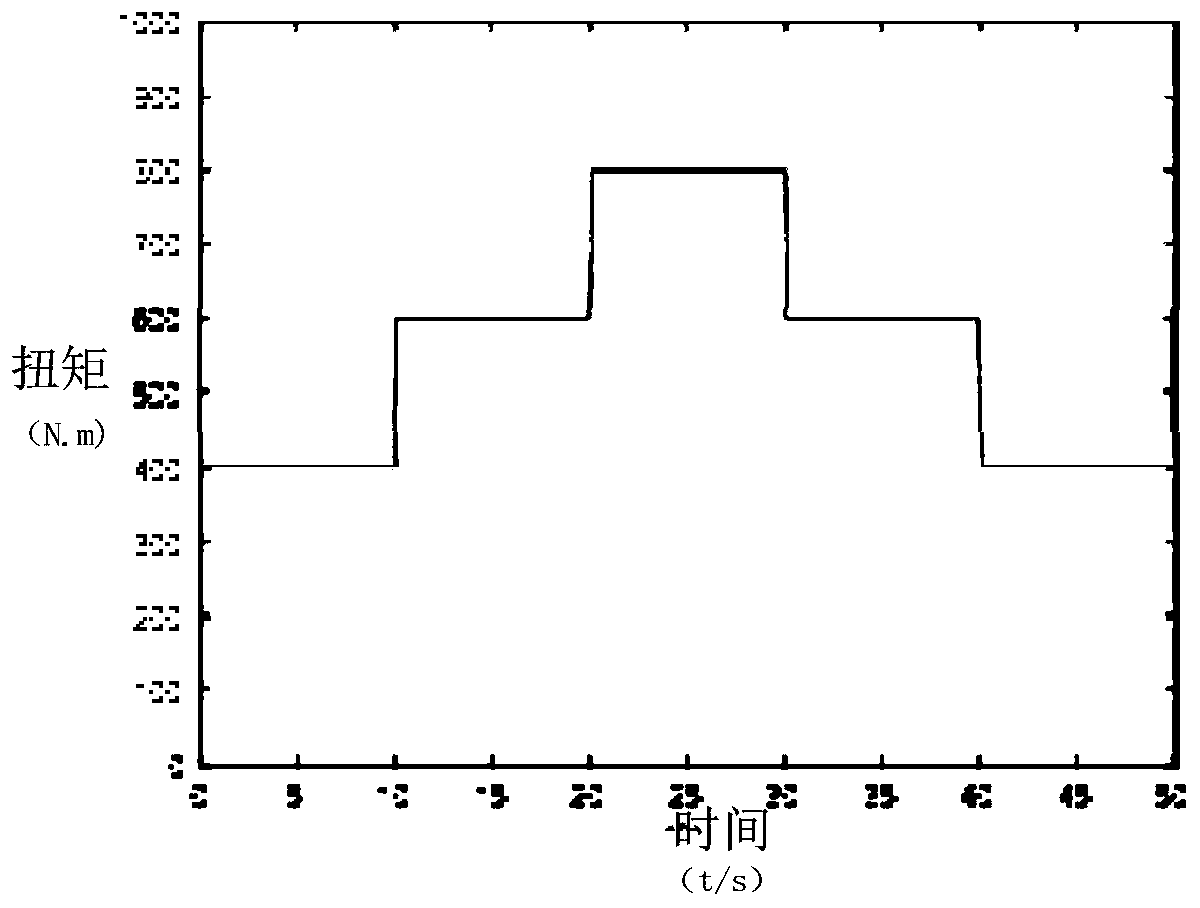

Driving and braking parameter automatic calibration method and device

InactiveCN110375994AEasy to operateSave labor costVehicle testingRegistering/indicating working of vehiclesTime costControl theory

The invention provides a driving and braking parameter automatic calibration method, which comprises the steps of: outputting a driving / braking control sequence according to a preset time interval before a vehicle enters automatic driving, wherein the driving / braking control sequence comprises a plurality of pieces of torque data; acquiring acceleration information and speed information corresponding to each piece of the torque data; performing two-bit interpolation processing according to each piece of the torque data and the acceleration information and the speed information corresponding tothe torque data, and generating a torque characteristic table; acquiring current acceleration information and current speed information of the vehicle when the vehicle performs automatic driving; anddetermining the current torque data through looking up the torque characteristic table according to the current acceleration information and the current speed information of the vehicle. Therefore, the labor and time costs are saved, the calibration operation is simple and convenient, and the calibration personnel can start to operate the device easily.

Owner:BEIJING ZHIXINGZHE TECH CO LTD

Calibration support and calibration equipment thereof

PendingCN112578347ACalibration is easy to operateCalibration operations are fast and accurateWave based measurement systemsStands/trestlesEngineeringProjection plane

The invention discloses a calibration support and calibration equipment thereof. The calibration support comprises an adjustable main frame and a calibration disc. The calibration disc is arranged onthe adjustable main frame, the calibration disc is provided with a projection plane for projection of laser rays emitted in the longitudinal direction of a vehicle, and calibration lines are arrangedon the projection plane. The calibration line is located in the middle of the adjustable main frame, and the extension line of the calibration line intersects with the center line of the adjustable main frame. According to the invention, the calibration operation of the calibration support is convenient, rapid and accurate.

Owner:SHENZHEN XTOOLTECH INTELLIGENT CO LTD

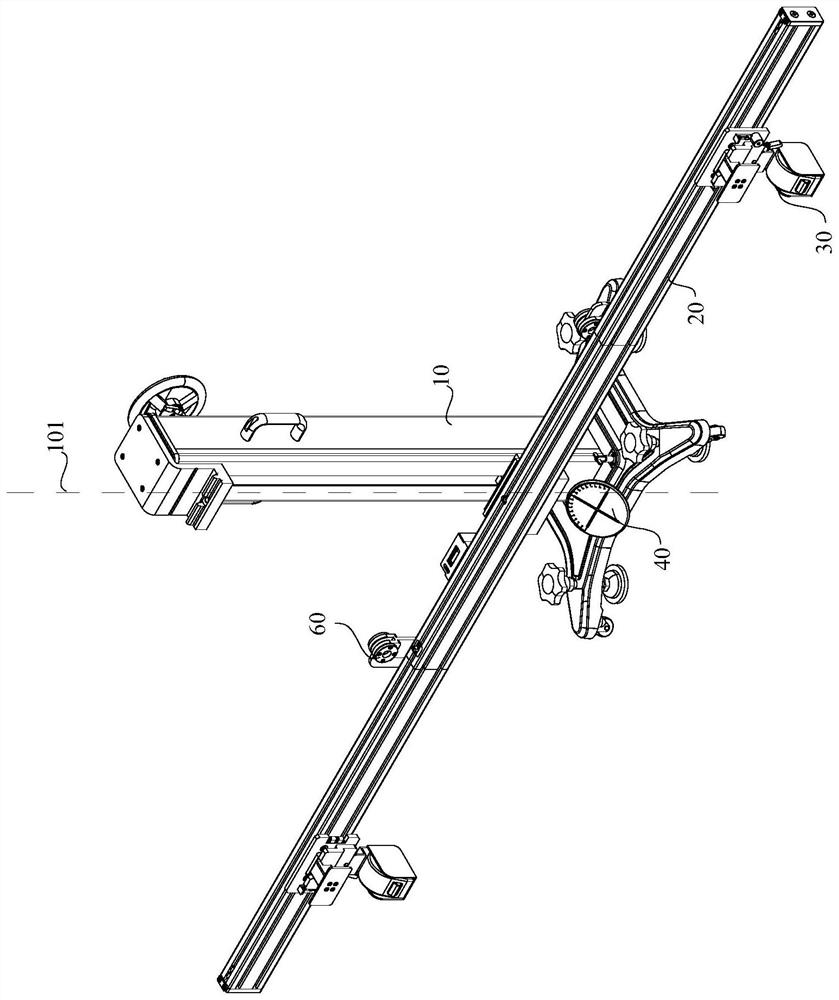

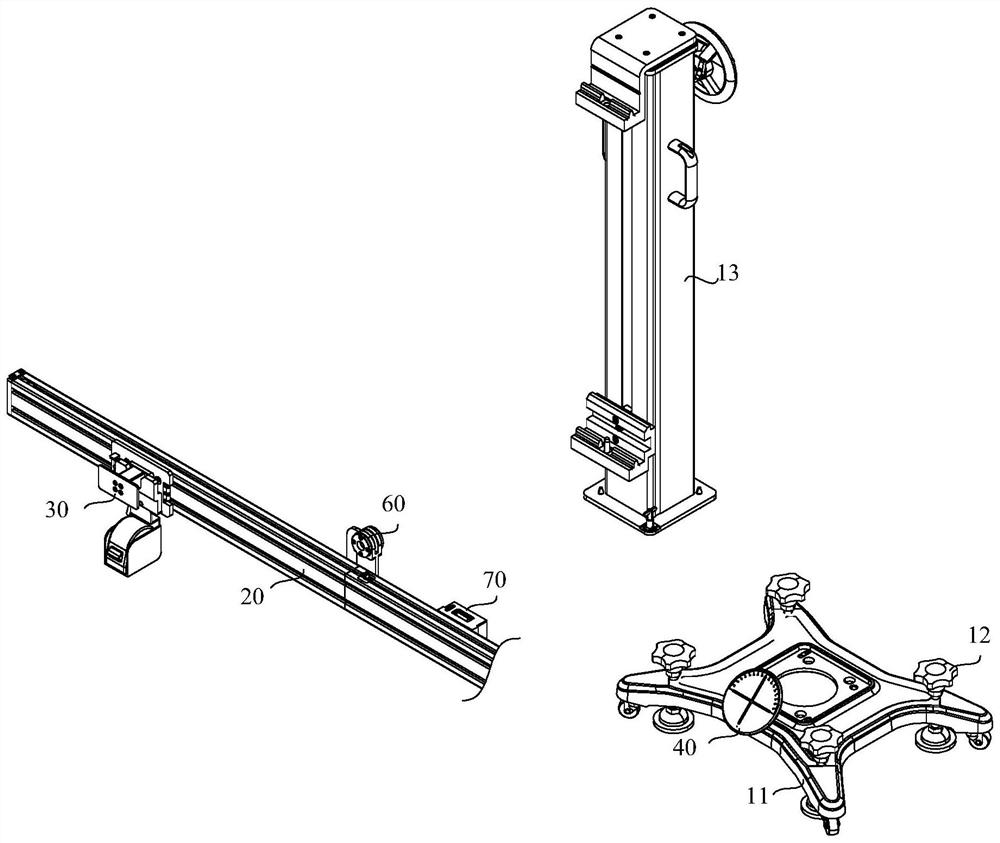

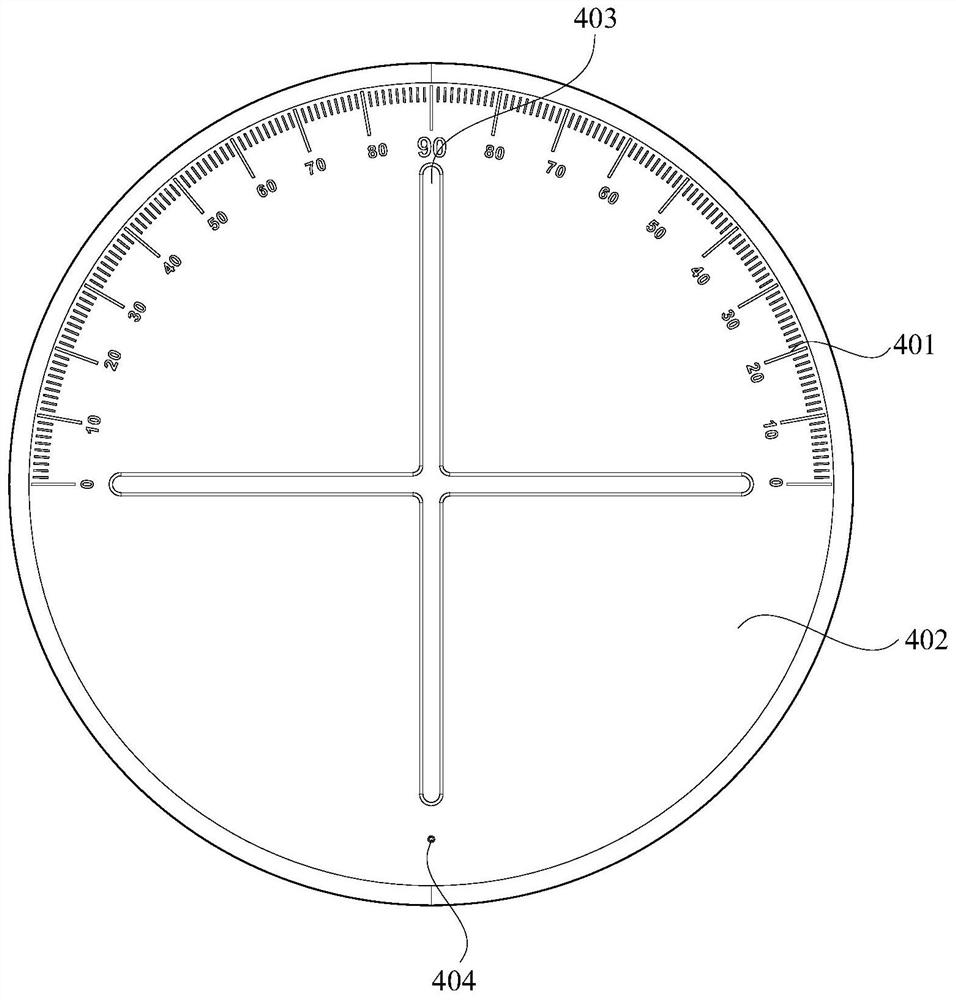

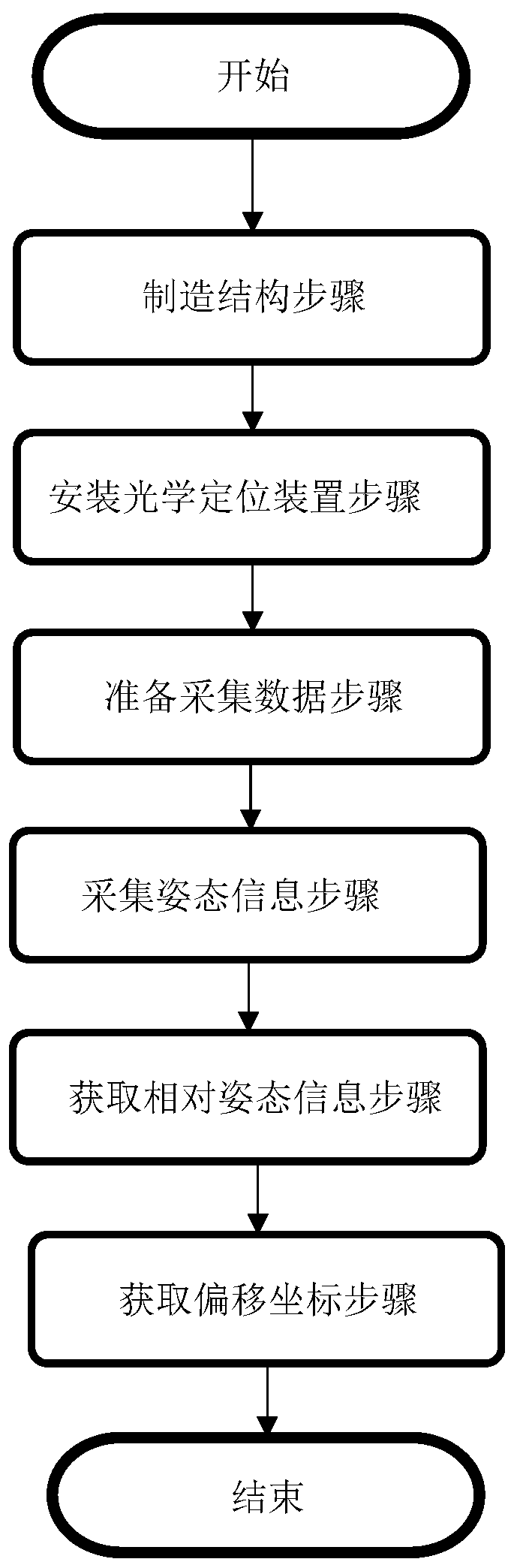

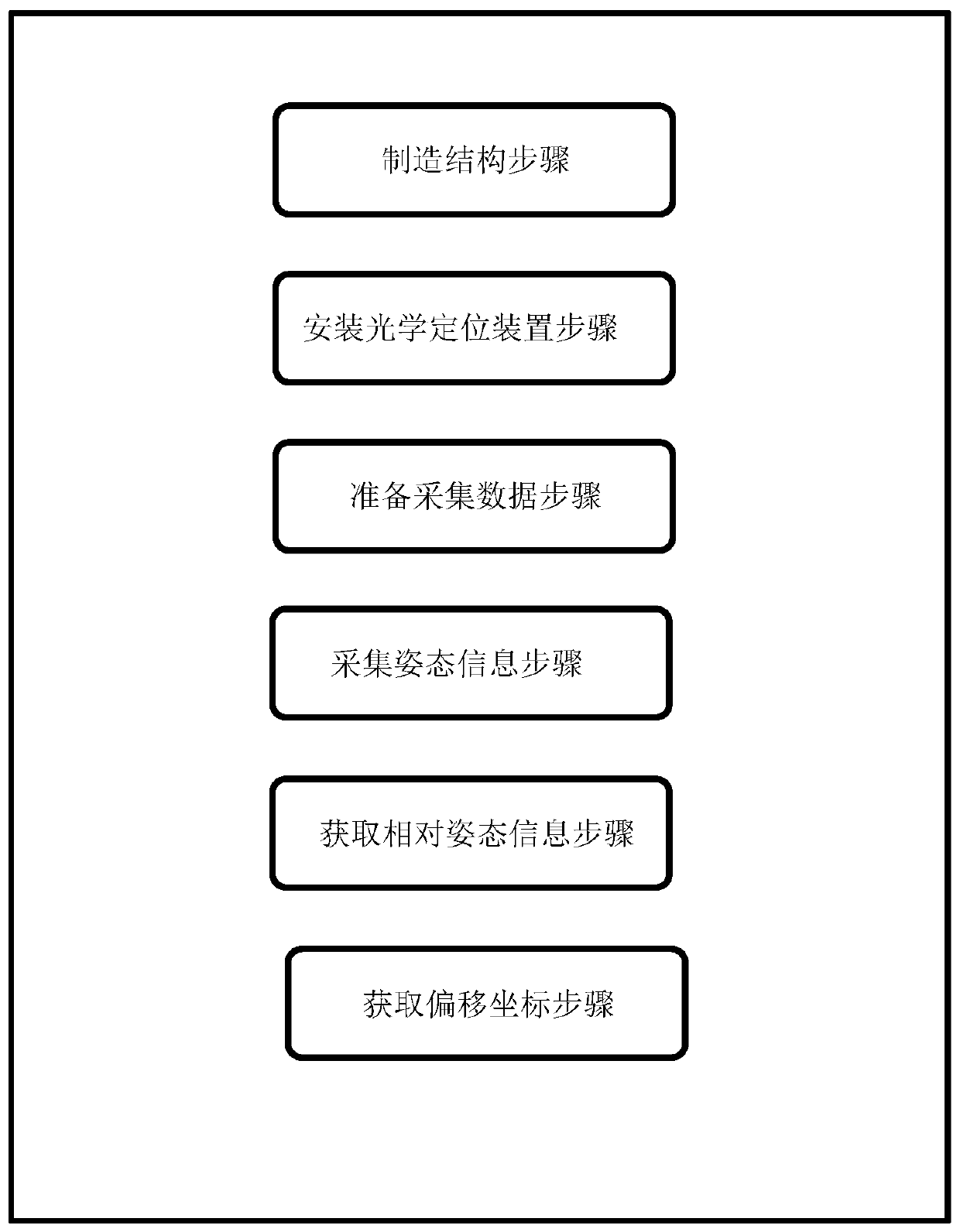

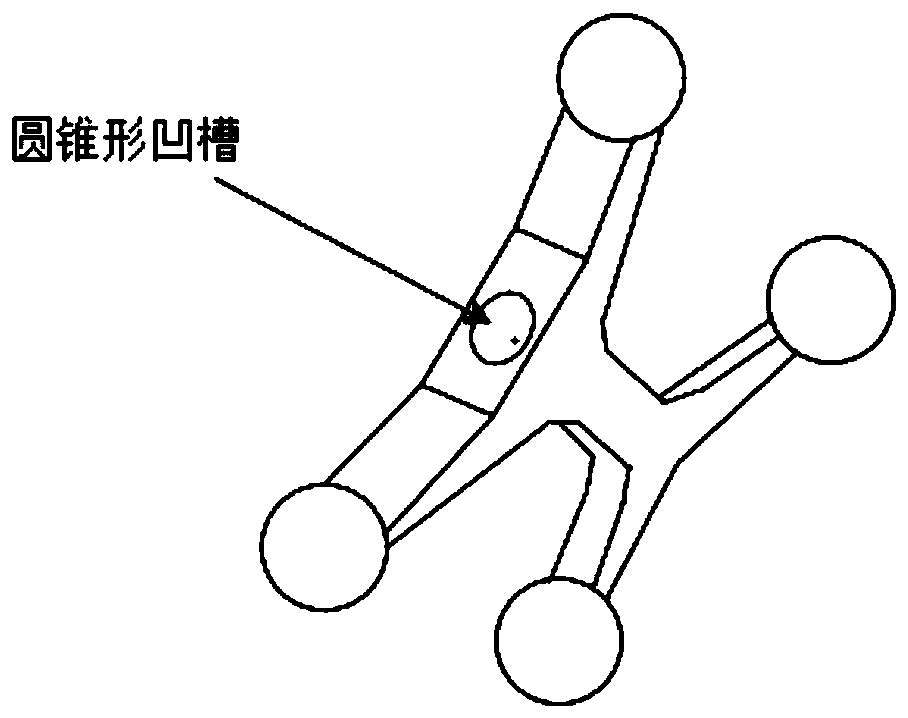

Dynamic tool tip position calibration method and system based on optical locator, medium and equipment

InactiveCN111043959ACalibration operation is simpleReasonable designUsing optical meansComputer visionEngineering

The invention provides a dynamic tool tip position calibration method and system based on an optical locator, a medium and equipment. The method comprises the steps of constructing a structure; mounting an optical positioning device by forming a conical groove in a specific surface position of a reference block, and mounting the optical locater in a specific position; preparing for data collectionby tightly jacking the tool tip against the groove of the reference positioning block, and preparing to acquire data; acquiring attitude information by rotating a tool around the tool tip , and acquiring the attitude information of the tool and the attitude information of the reference positioning block through the optical locator; and acquiring relative attitude information by transmitting the acquired information to a conversion algorithm, transmitting the attitude information of the tool relative to the reference positioning block into a spherical fitting algorithm, and obtaining the offset coordinates of the tool tip phase under a tool coordinate system. According to the invention, the purpose of obtaining accurate tool tip offset data can be achieved, and meanwhile calibration operation becomes more convenient.

Owner:上海嘉奥信息科技发展有限公司

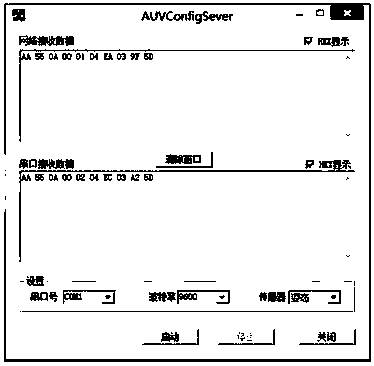

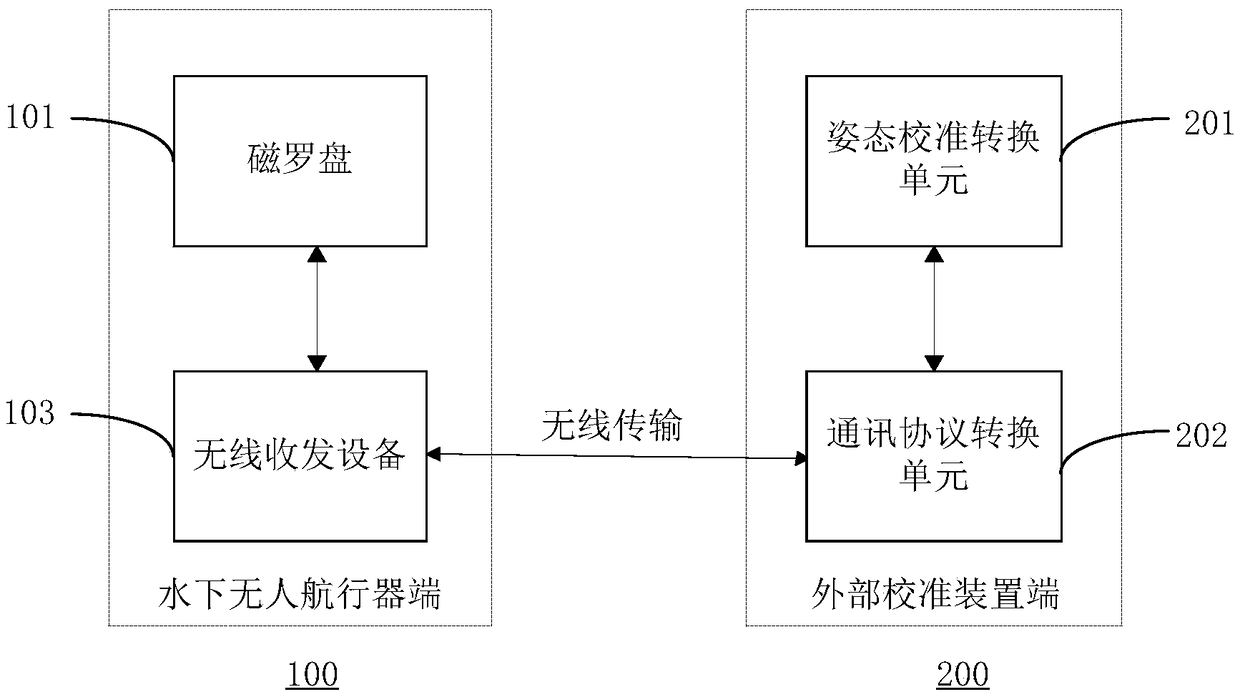

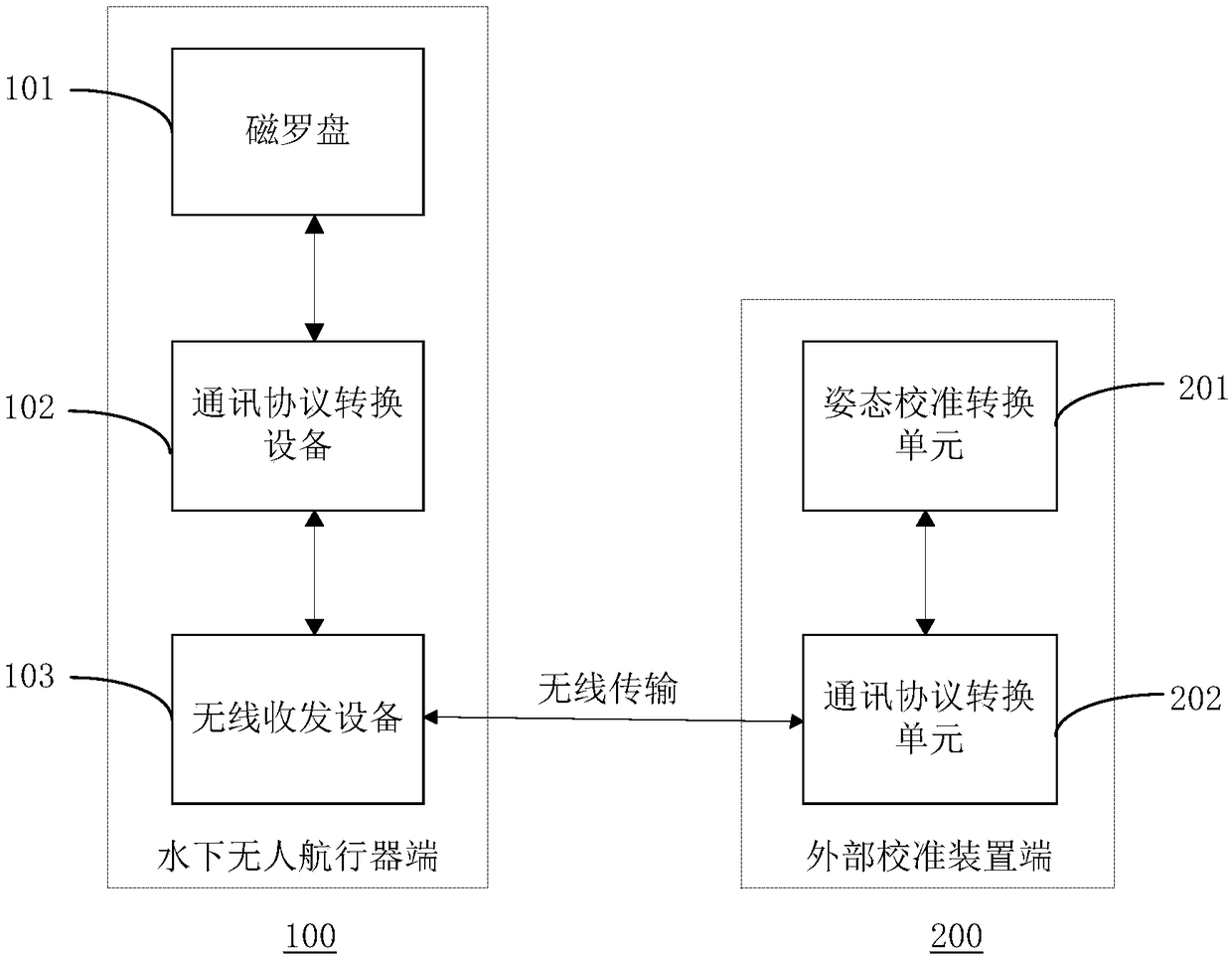

Calibration system and method for magnetic compass of underwater unmanned vehicle

PendingCN108775897AImprove securityCalibration is easy to operateCompassesUnderwaterWireless transmitter

The invention discloses a calibration system and method for a magnetic compass of an underwater unmanned vehicle. The calibration system for the magnetic compass of the underwater unmanned vehicle mainly comprises a wireless transmitter-receiver and an external calibration device. The calibration method for the magnetic compass of the underwater unmanned vehicle comprises the following steps thatthe wireless transmitter-receiver transmits the preset magnetic field information of the magnetic compass to the external calibration device; the external calibration device receives the preset magnetic field information of the magnetic compass, processing the preset magnetic field information to generate calibration data and returns the calibration data to the wireless transmitter-receiver; and the wireless transmitter-receiver transmits the received calibration data to the magnetic compass to complete wireless calibration of the magnetic compass. The calibration system and method of the invention make the calibration operation more convenient and faster, and improve the safety performance of the underwater unmanned vehicle.

Owner:西安特种飞行器工程研究院有限公司

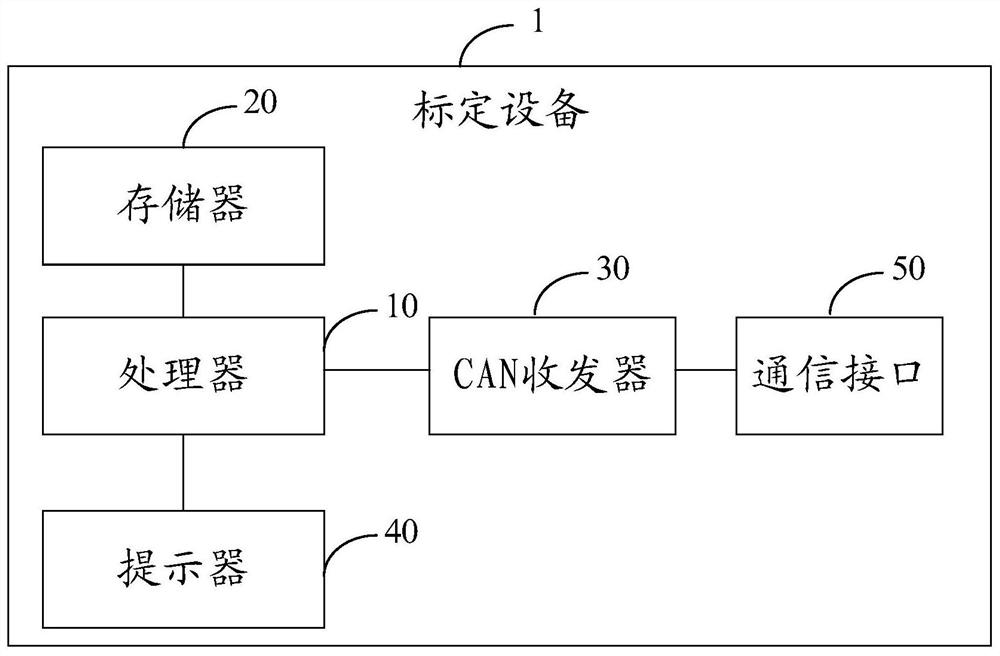

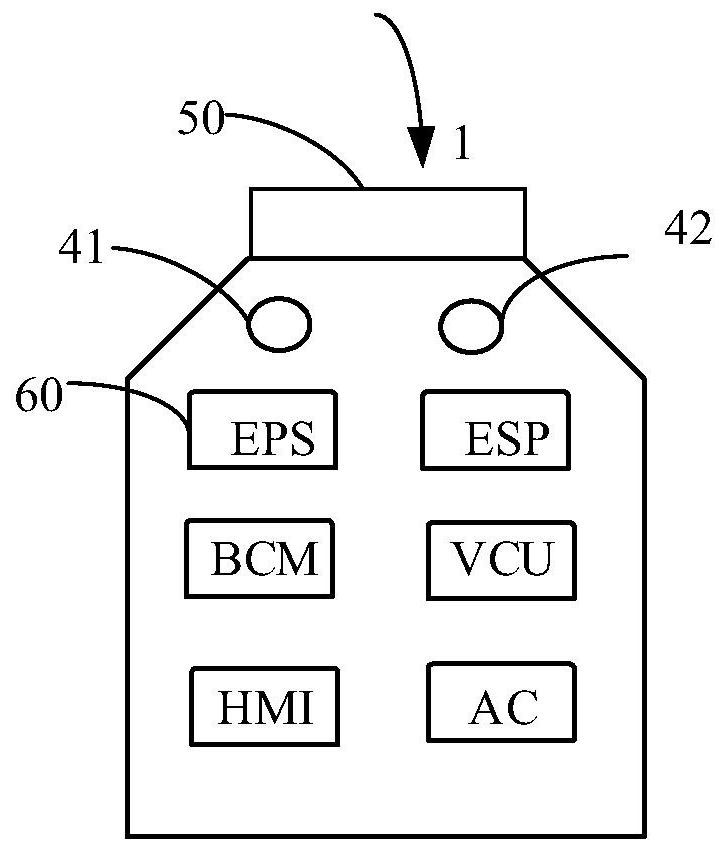

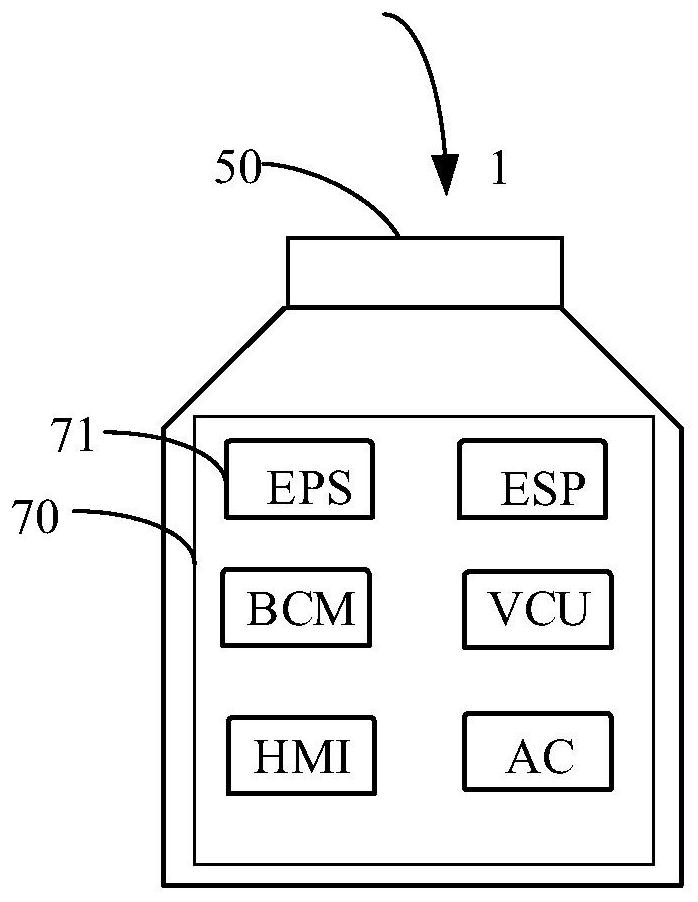

Calibration equipment and vehicle controller calibration method and device

InactiveCN112039742ACalibration is easy to operateElectric/fluid circuitBus networksCommunication interfaceCalibration result

The invention provides calibration equipment and a vehicle controller calibration method and device. The calibration equipment comprises a processor; a memory electrically connected with the processorand storing a calibration instruction corresponding to a vehicle controller; a CAN transceiver electrically connected with the processor and used for sending the calibration instruction to the vehicle controller and receiving response information sent by the vehicle controller; a prompter electrically connected with the processor and used for prompting a calibration result; and a communication interface, wherein one end of the communication interface is electrically connected with the CAN transceiver, and the other end of the communication interface is connected with a vehicle. Through the calibration equipment provided by the invention, the calibration operation is relatively simple and convenient.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

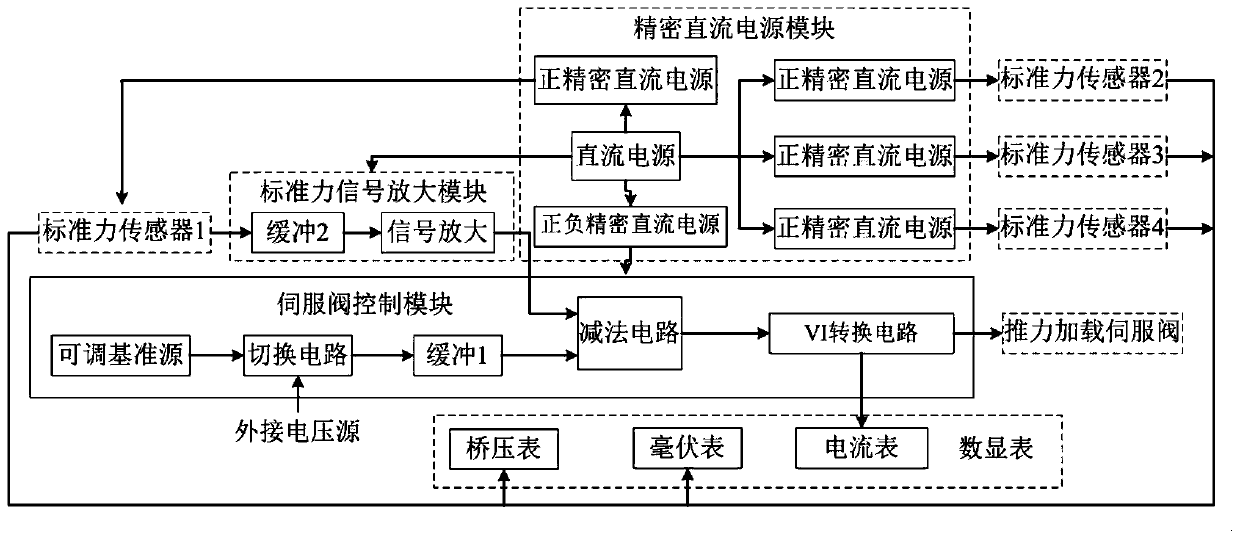

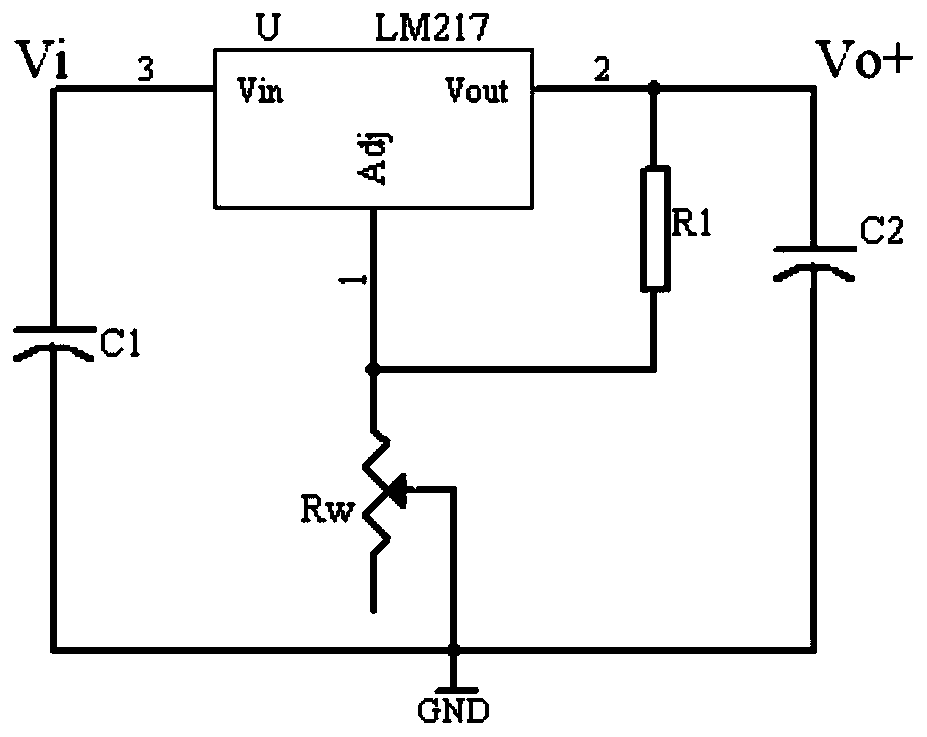

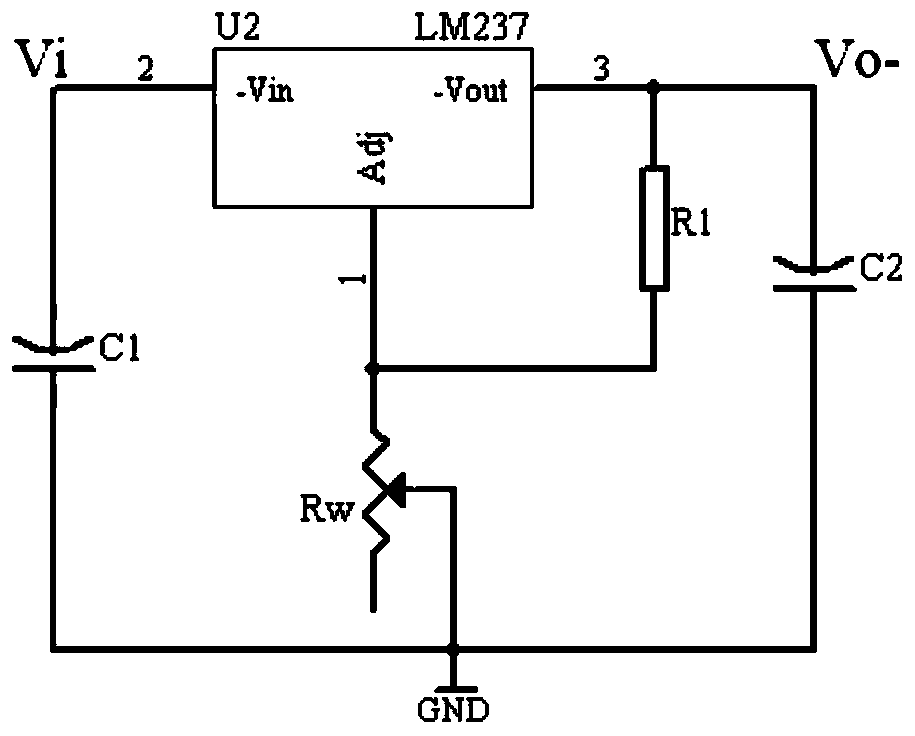

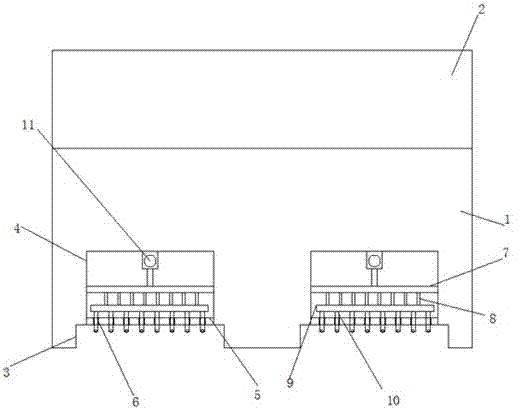

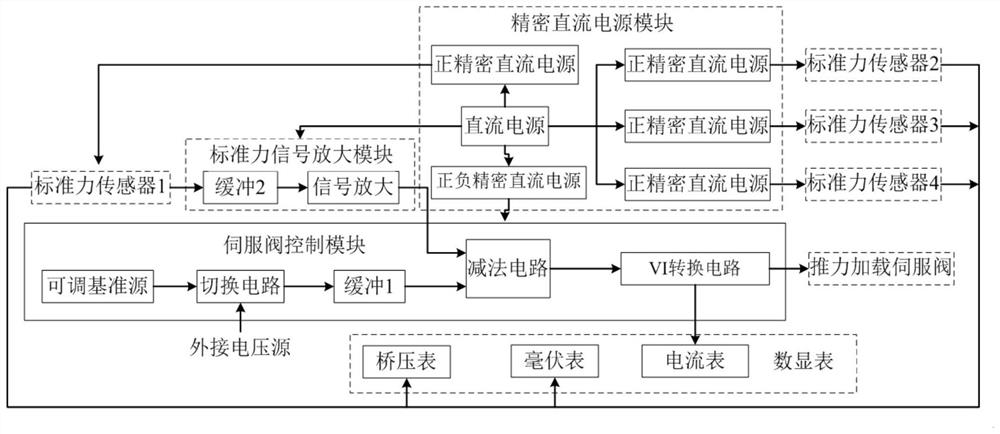

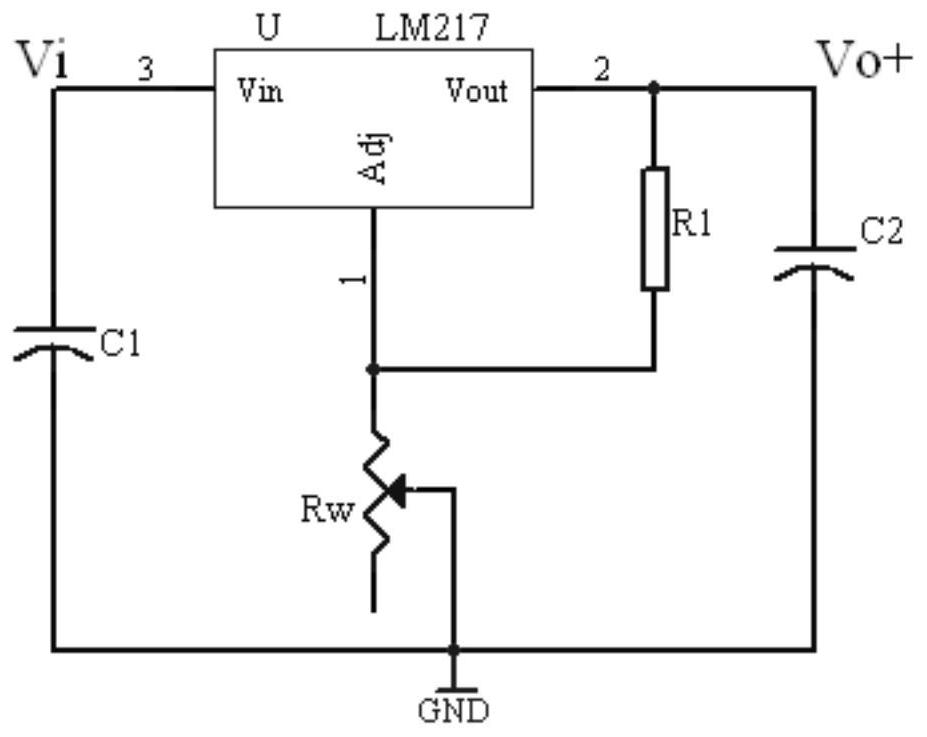

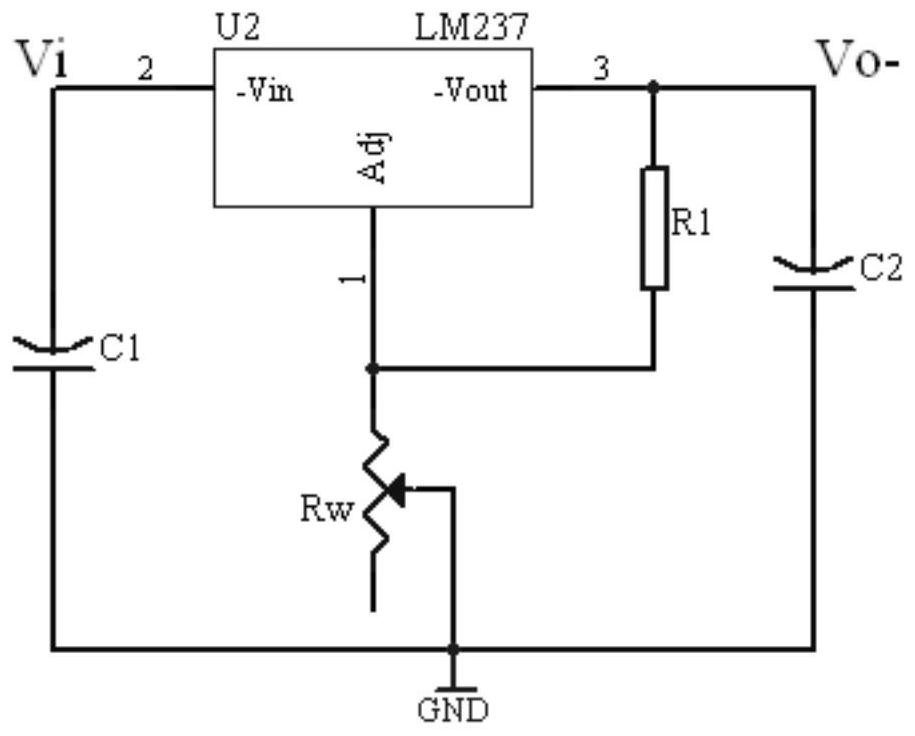

High-precision thrust servo controller

ActiveCN110716503AImprove stabilityImprove output stabilityNumerical controlHemt circuitsForce sensor

The invention discloses a high-precision thrust servo controller, and solves the problems that a high-precision servo controller of a field thrust calibration system is high in cost, complex in structure and poor in stability of an excitation power supply and a servo control current, and cannot meet the use requirements of high-accuracy thrust calibration. The controller comprises a precision direct-current power supply module, a standard force signal amplification module, a servo valve control module and a digital display meter, wherein the precision direct-current power supply module is connected with a standard force sensor, the standard force signal amplification module, the servo valve control module and the digital display meter, and is used for providing a stable power supply for the standard force sensor, the standard force signal amplification module, the servo valve control module and the digital display meter; the input end of the standard force signal amplification module is connected with an output signal of the standard force sensor, and the output end of the standard force signal amplification module is connected with the input end of the servo valve control module;and the output end of the servo valve control module is connected with an external thrust loading servo valve. The digital display meter is used for circuit parameter visualization, and facilitates operation and control of a calibration process.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Air conditioner shell stamping structure convenient to move

ActiveCN107321853AReduce difficultyCalibration is easy to operateShaping toolsMechanical engineeringEngineering

The invention discloses an air conditioner shell stamping structure convenient to move. The structure comprises a lower stamping die body and an upper stamping die body mounted above the lower stamping die body. Two parallel sets of forklift fork pockets are formed in the bottom of the lower stamping die body; long-strip-shaped accommodating grooves communicating with the forklift fork pockets are formed in the bottoms of the forklift fork pockets correspondingly; a partition plate flush with the inner wall of the bottom of each forklift fork pocket is mounted at an opening of the corresponding accommodating groove; through holes are formed in each partition plate in an array mode; a mounting plate is mounted in each accommodating groove and is in sliding connection with the side wall of the accommodating groove; connecting rods are vertically mounted on the side, close to the opening of the corresponding accommodating groove, of each mounting plate; and one ends of the connecting rods are connected with the mounting plates, and movable plates are perpendicularly mounted at the other ends of the connecting rods. According to the air conditioner shell stamping structure, the mode that when a traditional stamping die is mounted, knocking is adopted for calibration is changed, the moving difficulty during calibration of the stamping die is reduced, calibration operation of the stamping die is facilitated, and the mounting efficiency of the stamping die is improved.

Owner:滁州华宇机件有限公司

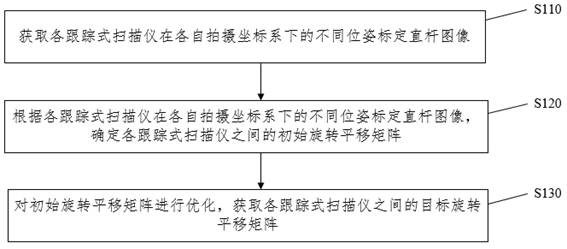

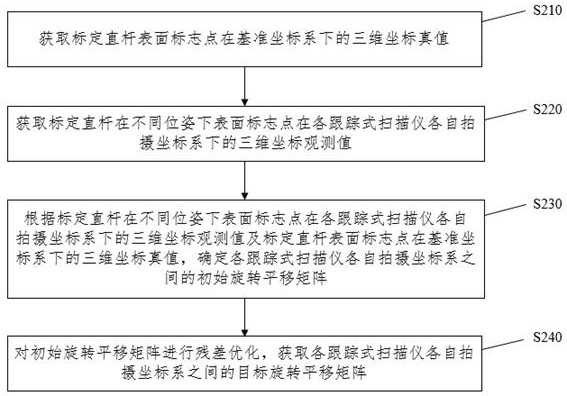

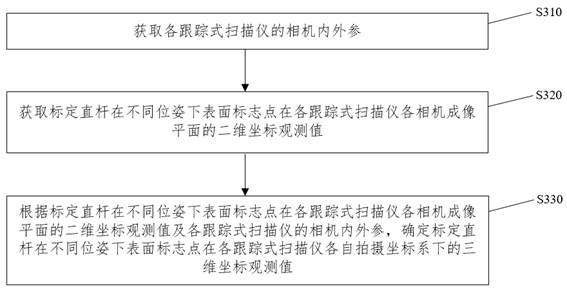

Method and device for joint calibration of multiple tracking scanners

InactiveCN114037768AImprove scanning efficiencyCalibration is easy to operateImage enhancementImage analysisComputer graphics (images)Radiology

The invention relates to a method and a device for joint calibration of multiple tracking scanners. The method comprises the following steps: acquiring different pose calibration straight rod images of each tracking scanner in a respective shooting coordinate system; determining an initial rotation translation matrix between the tracking scanners according to different pose calibration straight rod images of the tracking scanners under respective shooting coordinate systems; and optimizing the initial rotation translation matrix to obtain a target rotation translation matrix between the tracking scanners. According to the technical scheme, the unique advantage that scanning can be carried out without pasting mark points in the tracking type scanning technology is inherited, in the process that multiple sets of photographing type scanners are combined to scan and measure the measured workpiece, and superposition and expansion of scanning view fields of the multiple sets of tracking type scanners can be obtained without moving the scanners, so the scanning range and the scanning efficiency of the tracking scanner are effectively improved, and the method and the device are particularly suitable for the field of automatic detection of large-size workpieces.

Owner:TENYOUN 3D(TIANJIN)TECH CO LTD

Multi-caliber roundness-correcting set

The invention relates to a multi-caliber roundness-correcting set. The multi-caliber roundness-correcting set is characterized by comprising a roundness-correcting device and a carrier roller device, wherein the roundness-correcting device comprises a base, at least one set of symmetrical roundness-correcting unit is installed on the base, a framework is installed on the roundness-correcting unit, the roundness-correcting unit mainly comprises two sets of vertical columns which are parallelly arranged, one set of vertical column of the two sets of vertical columns which are parallelly arranged is a fixed structure, the other set of vertical column of the two sets of vertical columns which are parallelly arranged is a relative-moving structure, and a guiding mechanism and a horizontal moving device are arranged between the two sets of vertical columns which are parallelly arranged. In actual operation, the multi-caliber roundness-correcting set is also convenient to operate, the locating and guiding mechanism just needs to be loosened, the horizontal moving device is started, the distance between the two sets of vertical columns which are parallelly arranged can be enlarged or shrunk, and roundness-correcting work of round pipes with different pipe diameters can further be completed; the multi-caliber roundness-correcting set also has the advantages of being simple in structure, reasonable in design, low in cost, easy to operate, safe, reliable and the like.

Owner:天津厚重科技有限公司

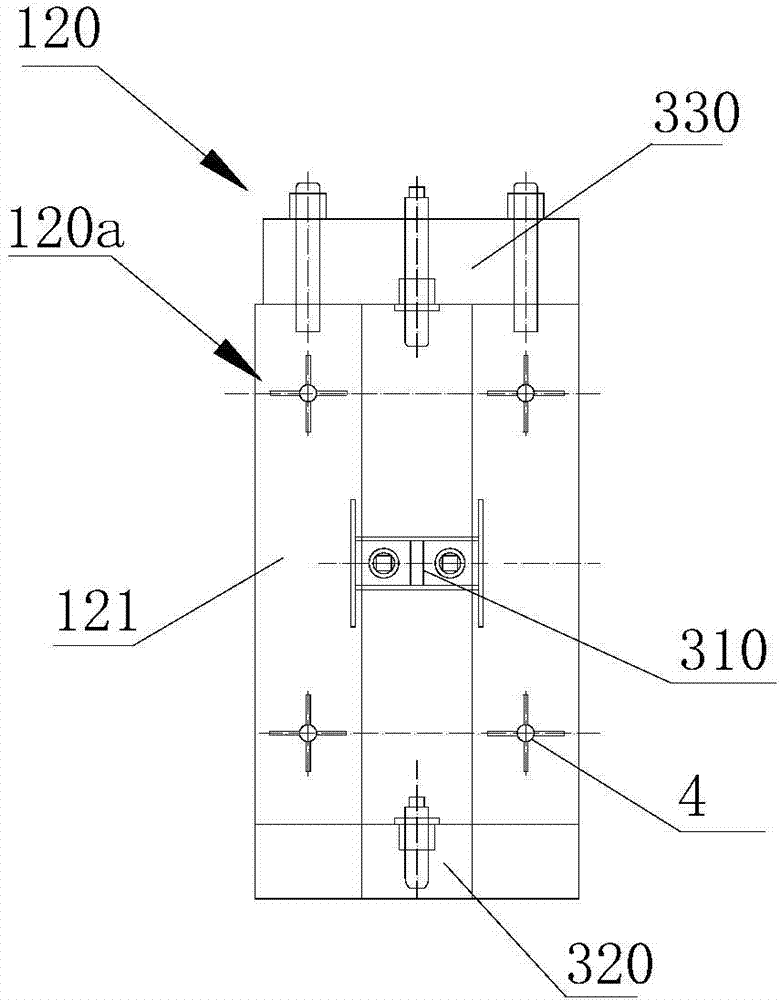

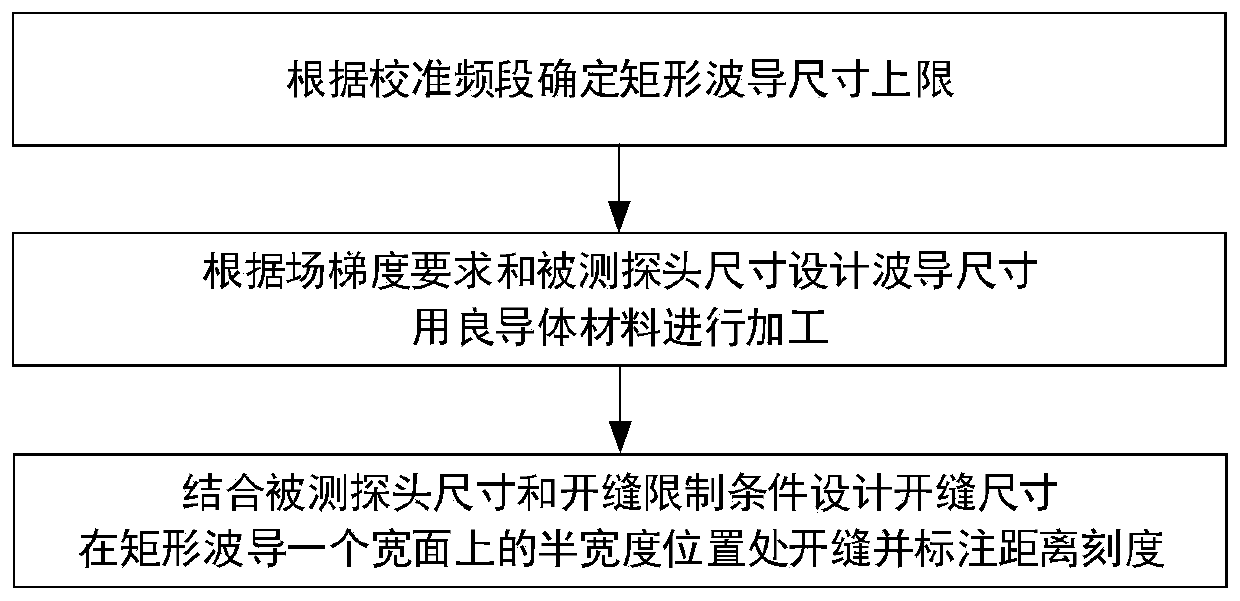

Rectangular waveguide evanescent mode based electromagnetic field probe spatial resolution calibration device

ActiveCN109975732AWide Calibration BandwidthMeeting Calibration NeedsElectrical measurementsEvanescent modeElectromagnetic field

The invention discloses a rectangular waveguide evanescent mode based electromagnetic field probe spatial resolution calibration device. The device includes a rectangular waveguide connected to a matching load; the rectangular waveguide has a width a, a height b and a length l, wherein a <= 0.4c / f<max>, b < a, l > 8[lambda]c10, the c is the light velocity in vacuums, f<max> is the highest calibration frequency, and [lambda]c10 is the cut-off wavelength of a dominant mode TE10 mode of the rectangular waveguide; the half position on the upper broad wall of the rectangular waveguide is provided with a slit so as to form a calibration area; a probe can be completely stretched into the slit and move in the slit through the configuration of the width w of the slit and the height b of the rectangular waveguide; and the disturbance of the slit on a waveguide internal field structure can be in the allowed range of calibration precision through the configuration of the width w of the slit. The device is flexible and plastic in design and wide in calibration band, and can obtain large electromagnetic field gradients, so that the device is convenient in calibration operation and high in calibration precision.

Owner:BEIHANG UNIV

Calibration method of pose position-free constraint line laser monocular vision three-dimensional measurement sensor parameters

ActiveCN102980528BGuaranteed Calibration AccuracyCalibration is easy to operateUsing optical meansMechanical engineering technologyThree dimensional measurement

The invention provides a calibration method of pose position-free constraint line laser monocular vision three-dimensional measurement sensor parameters and belongs to the technical fields of optical measurement and mechanical engineering technologies. After basic data are extracted, imaging points are sequenced according to the invariance of a vector quantity cross product direction set composed of the imaging points of target feature points in any shooting pose position, and corresponding relation between the target feature points and the imaging points is built. Light plane feature points are extracted through quadrilateral intersection composed of a light knife central point set fitting straight lines and the target feature points, and a three-dimensional coordinate is calculated according to an intersection invariance principle. Inner and outer diameters in a monocular vidicon and light plane diameters of a line laser projector are optically fitted and calculated, and accurate calibration of the line laser monocular vision three-dimensional measurement sensor parameters is achieved. In calibration, a target can freely move and rotate completely, pose position placing is free of restraint, the same group of calibration images is shared for calibration of two parts of diameters, the calibration accuracy of a three-dimensional measurement sensor is ensured, and simultaneously calibration steps are simplified.

Owner:SHANGHAI JIAOTONG UNIV

Multi-port wireless communication tester calibration method

PendingCN107612632ACalibration results are accurate and reliableImprove efficiencyTransmission monitoringTester deviceCalibration result

The invention relates to the technical field of tester calibration, and particularly relates to a multi-port wireless communication tester calibration method. The invention adopts the technical schemethat the multi-port wireless communication tester calibration method is characterized by comprising a signal transmitting function calibration step and a signal receiving function calibration step, wherein the signal transmitting function calibration step consists of a Tx / DLRF OUT output port calibration step and a MPA RFIO Port 0-7 output port calibration step; and the signal receiving functioncalibration step consists of an Rx / UL RF IN input port calibration step and a MPA RFIO Port 0-7 input port calibration step. The multi-port wireless communication tester calibration method has the advantages that a multi-port wireless communication tester calibration result can be guaranteed to be more reliable; in the calibrating process, efficiency is higher; and the multi-port wireless communication tester calibration method is more convenient in the process of carrying out the calibration operation.

Owner:泰州赛宝工业技术研究院有限公司

A High Precision Thrust Servo Controller

ActiveCN110716503BImprove stabilityImprove output stabilityNumerical controlControl engineeringHemt circuits

The invention discloses a high-precision thrust servo controller, which solves the problems of high cost, complex structure, poor stability of the excitation power supply and servo control current, and cannot meet the requirements of high-precision thrust in the on-site thrust calibration system. Calibration usage requirements issue. The controller includes a precision DC power supply module, a standard force signal amplification module, a servo valve control module and a digital display meter; the precision DC power supply module is connected with a standard force sensor, a standard force signal amplification module, a servo valve control module and a digital display meter respectively, It is used to provide stable power supply to the standard force sensor, standard force signal amplification module, servo valve control module and digital display; the input terminal of the standard force signal amplification module is connected to the output signal of the standard force sensor, and the output terminal is connected to the input terminal of the servo valve control module Connection, the output end of the servo valve control module is connected with the external thrust loading servo valve. The digital display meter is used to visualize the circuit parameters, which is convenient for the operation and control of the calibration process.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Intelligent monitoring pH meter

PendingCN114062466ACalibration is easy to operateEasy to operateMaterial analysis by electric/magnetic meansStructural engineeringElectrical and Electronics engineering

The invention relates to the field of pH meters, in particular to an intelligent monitoring pH meter which comprises a pH meter body, a cleaning cylinder and cleaning assemblies. The cleaning cylinder sleeves the outer side of a measuring electrode; a supporting plate a is arranged on the peripheral wall of the cleaning cylinder, and a pull ring is arranged on the supporting plate a; a hook is arranged at the bottom of the pull rope a and hung on the pull ring, and the top of the pull rope a is wound on the supporting rod a; a supporting rod a is rotationally arranged between the two sets of fixing blocks, a limiting ring a is arranged on the supporting rod a, and the supporting rod a is sleeved with a torsional spring; a piston is arranged in the box body and provided with a supporting rod b; the supporting rod b is sleeved with the spring; the sliding block is slidably arranged on the outer wall of the box body; one end of the pull rope b is connected with the bottom of the supporting plate c, and the other end of the pull rope b is wound on the supporting rod a; the inner cavity of the box body communicates with the inner cavity of the cleaning cylinder through a hose. There are two cleaning assemblies. According to the invention, the calibration operation is convenient and fast, the measuring electrode cleaning operation is simple, and the cleaning effect is good.

Owner:温州环科环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com