Calibration method of pose position-free constraint line laser monocular vision three-dimensional measurement sensor parameters

A technology of sensor parameters and three-dimensional measurement, applied in measuring devices, instruments, optical devices, etc., can solve the problems of complex target production, mechanical errors, and operation restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] The three-dimensional measurement sensor calibrated by the method of the invention is a line laser monocular vision three-dimensional measurement sensor used for on-line detection of industrial production lines. The sensor includes a monocular camera and a line laser projector.

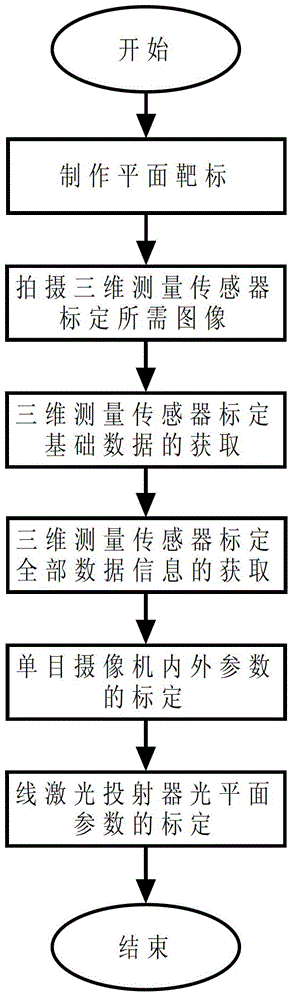

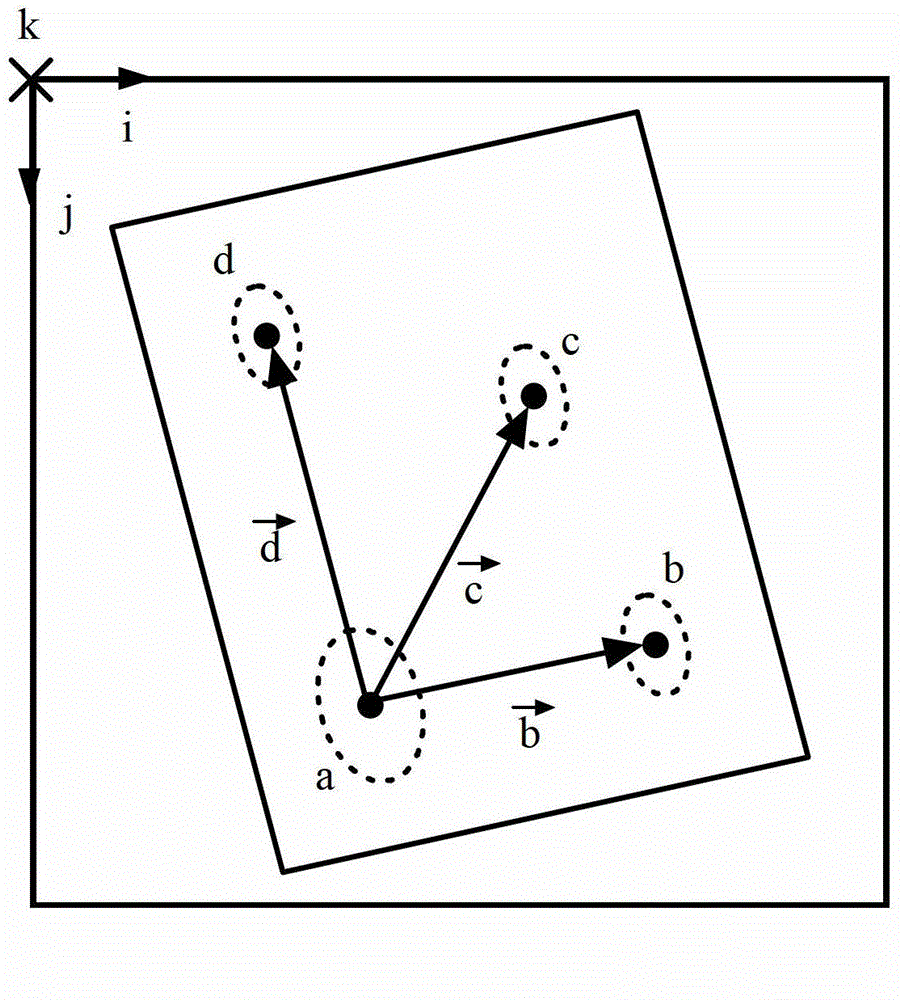

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the specific implementation steps of the calibration method of the present invention are as follows:

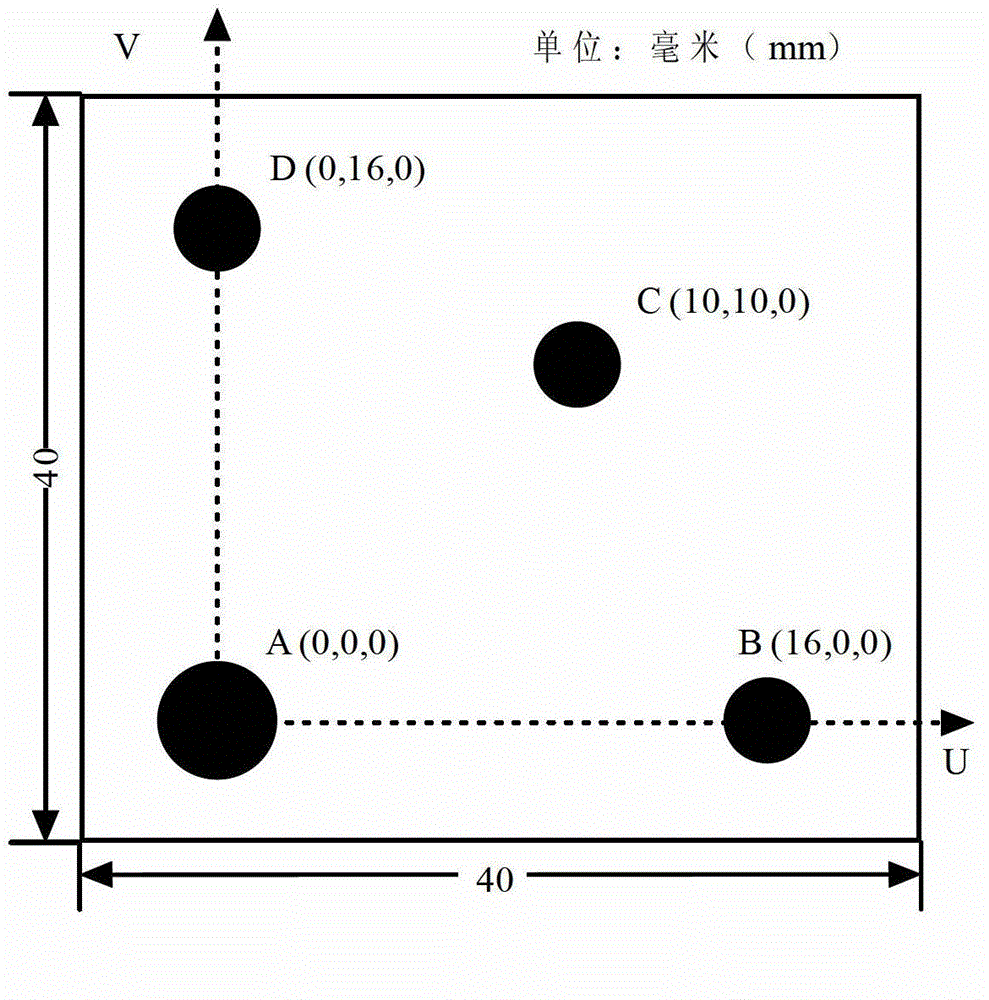

[0034] 1) Make a planar target. Make a flat target with white as the background color, the target size is 40×40mm, and four black mark circle patterns are distributed on the target according to the marked positions, one large diameter mark circle has a diameter of 5mm, and three small diameter mark circles of the same diameter The diameter is 3mm; the centroid B is located 16mm to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com