Camera calibration device based on diffractive optical element

A diffractive optical element and camera calibration technology, which is applied in the field of photogrammetry, can solve the problems of large space occupation, high cost, and large space required for arranging the control field, and achieve the effects of ensuring calibration accuracy, saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

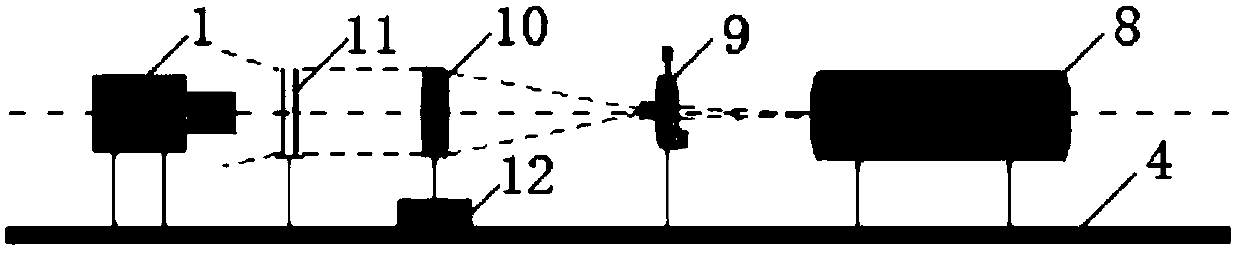

[0023] A camera calibration device based on a diffractive optical element, comprising: a laser 8, a spatial filter 9, a collimator 10, and a double-crossed one-dimensional DOE11; the beam emitted by the laser 8 is vertically incident on the spatial filter 9 and the collimator in turn 10 and double-crossed one-dimensional DOE11.

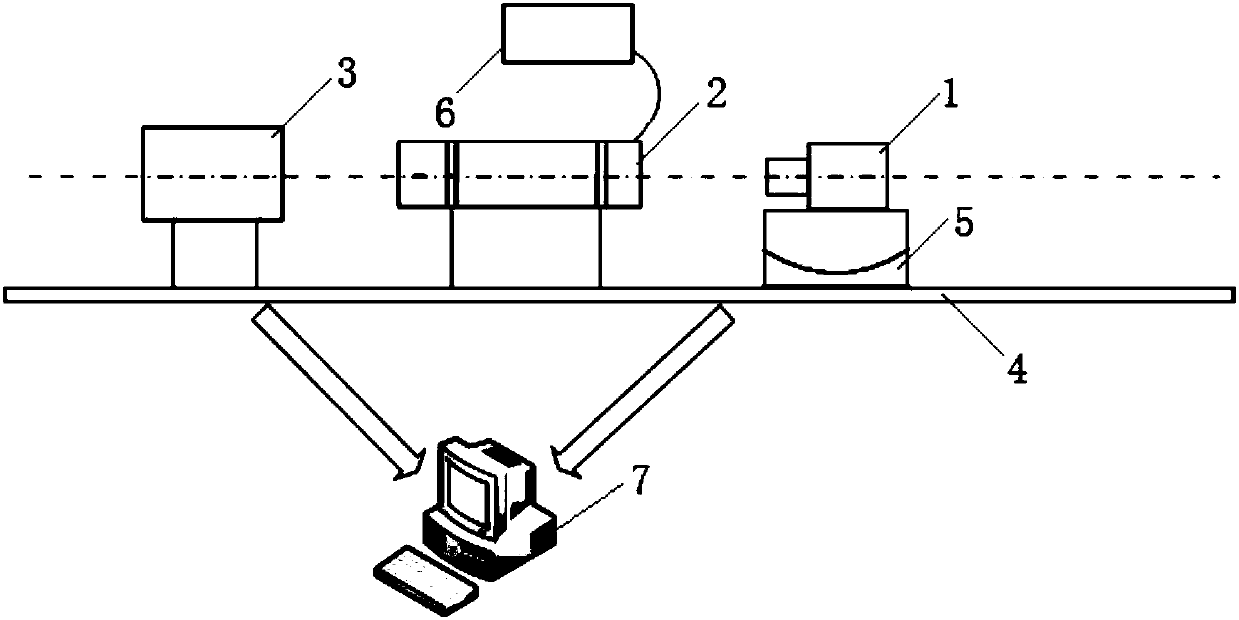

[0024] The layout diagram of a camera calibration device based on diffractive optical elements of the present invention can be found in figure 1 , using DOE to build an optical calibration platform. In this embodiment, the laser 8, the spatial filter 9, the collimating mirror 10, and the double-crossed one-dimensional DOE 11 are sequentially arranged along the same axis, and all devices are installed and fixed on the same line of holes on the optical table 4, along the same The axis arrangement simplifies the elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com