Technique for producing ceramic yellow color of bismuth vanadate clad by compound of silicate class

A technology of coating bismuth vanadate and silicon dioxide, which is applied in the fields of vanadium compounds, inorganic pigment treatment, inorganic chemistry, etc., can solve problems such as obstruction and health pollution, and achieve the effect of loose structure, elimination of harm, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

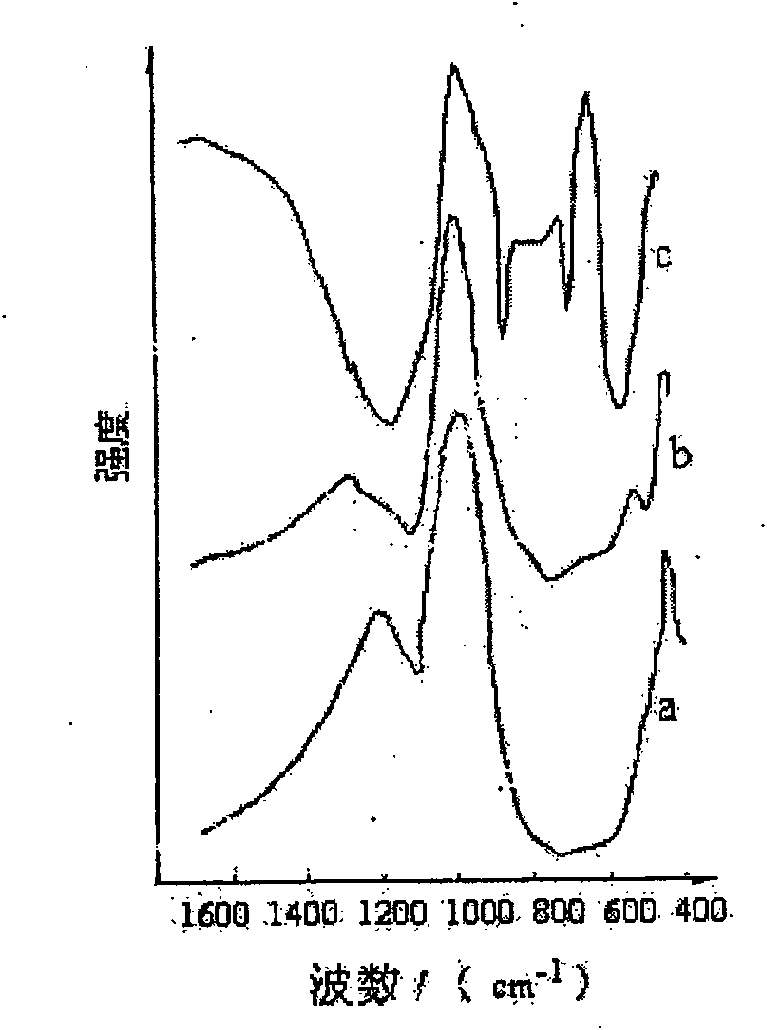

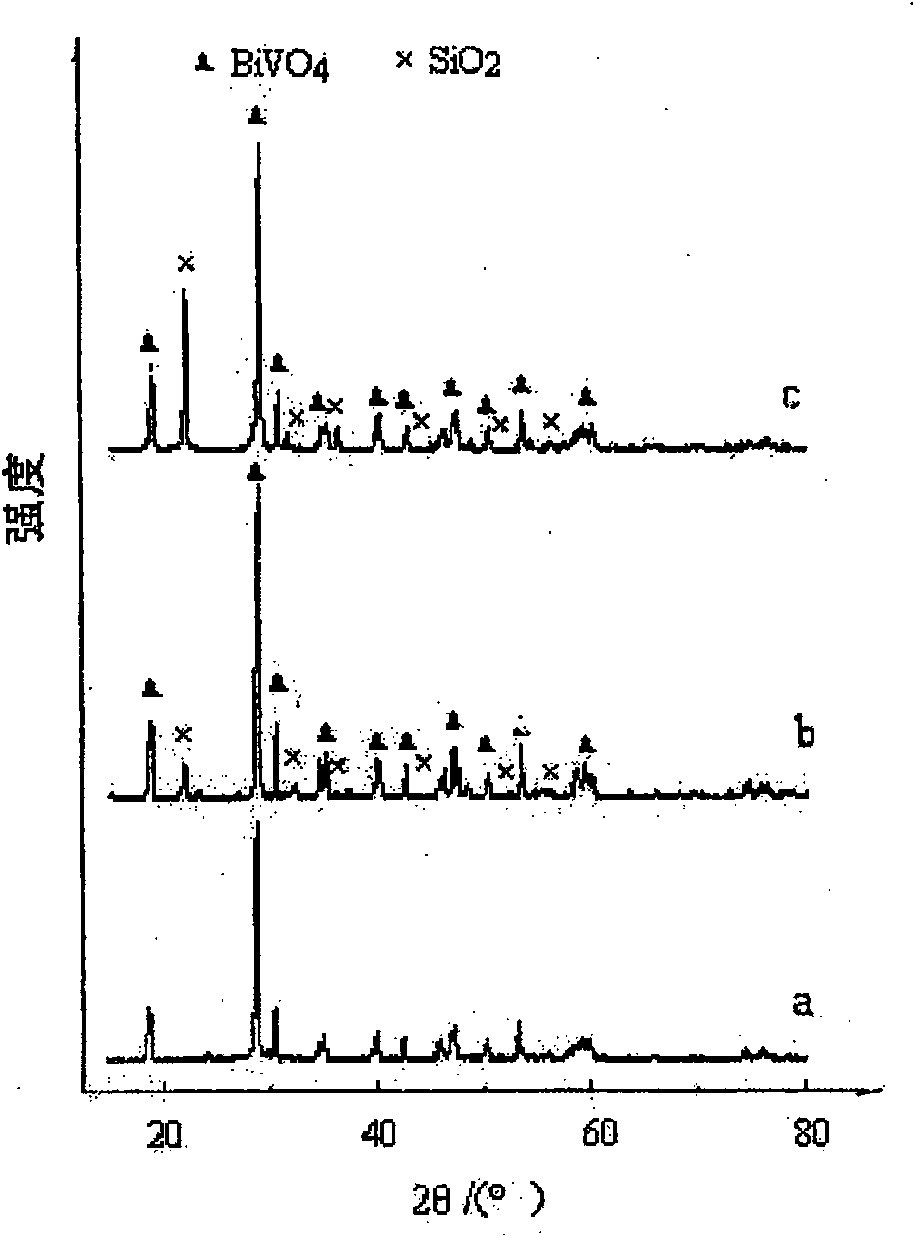

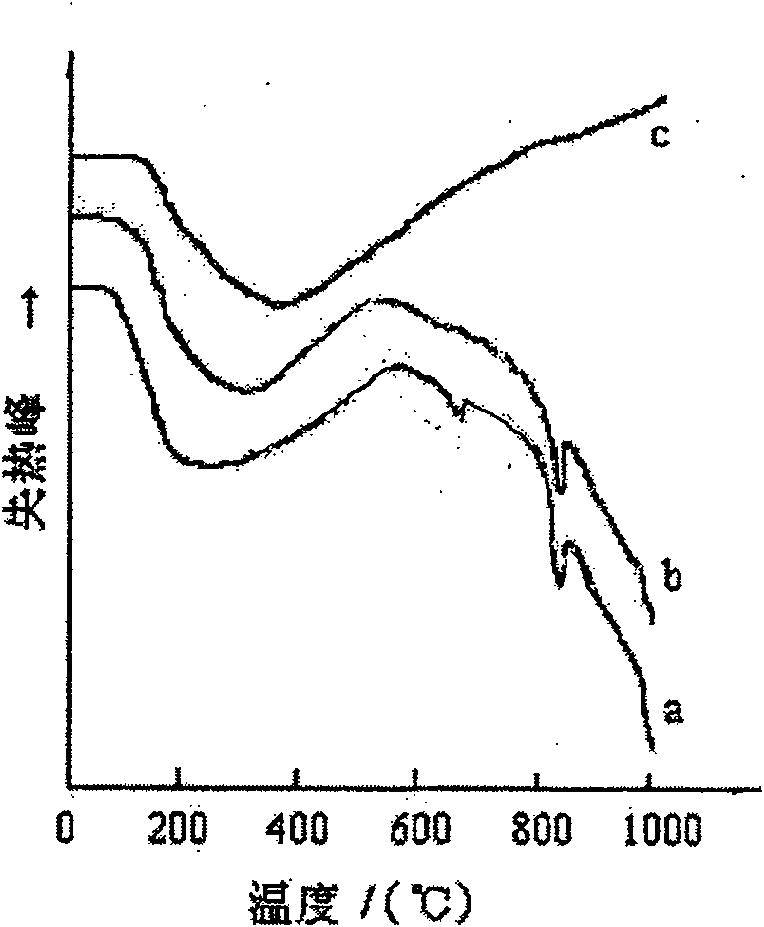

Examples

preparation example Construction

[0021] (1) Yellow pigment BiVO 4 preparation of

[0022] Prepare 0.5-2.0mol / L concentration of Bi(NO 3 ) 3 Solution 100-1000mL, need to add 5-200mL concentrated HNO when preparing 3 to inhibit Bi(NO 3 ) 3 The hydrolysis; simultaneously 100-1000mL ammonium metavanadate is dissolved in the NaOH solution of 1-8mol / L to obtain and Bi(NO 3 ) 3 Solution isotropic NH 4 VO 3 Solution 100-1000mL. Under stirring, 100-1000mL NH 4 VO 3 The solution was added dropwise to the same volume of Bi(NO 3 ) 3 In the solution, adjust the pH to 4.5-7.5, and at the same time raise the temperature of the reaction solution to 60-100° C. and then keep it warm for 0.5-2.0 hours. During this process, NaOH solution needs to be added dropwise to maintain a constant pH value. Then, carry out suction filtration, wash the precipitate with a large amount of distilled water to wash away impurity ions, and then wash with organic solvent absolute ethanol to prevent the agglomeration of particles durin...

Embodiment 1

[0042] The production technology of bismuth vanadate yellow ceramic pigment coated with silicate compound is characterized in that it comprises the following process:

[0043] (1) Yellow pigment BiVO 4 Preparation of:

[0044] A. Prepare 0.5mol / L concentration of Bi(NO 3 ) 3 Solution 100mL, need to add 5mL concentrated HNO when preparing 3 to inhibit Bi(NO 3 ) 3 hydrolysis;

[0045] B. Add NH 4 VO 3 Dissolved in 2mol / L NaOH solution to obtain Bi(NO 3 ) 3 Solution isotropic NH 4 VO 3 Solution 100mL;

[0046] C. Under stirring, 100mL NH 4 VO 3 The solution was added dropwise to the same volume of Bi(NO 3 ) 3 In the solution, adjust the pH to 4.5 with sodium hydroxide or ammonia water, heat up to 100° C. and then keep it warm for 1.0 hour, then perform suction filtration, wash with distilled water, and dry at 80° C. to obtain loose powdery bismuth vanadate yellow pigment;

[0047] (2) High temperature resistant yellow pigment BiVO 4 / SiO 2 Preparation of:

[0...

Embodiment 2

[0050] The production technology of bismuth vanadate yellow ceramic pigment coated with silicate compound is characterized in that it comprises the following process:

[0051] (1) Yellow pigment BiVO 4 Preparation of:

[0052]A. Prepare 2.0mol / L concentration of Bi(NO 3 ) 3 Solution 1000mL, need to add 200mL concentrated HNO when preparing 3 to inhibit Bi(NO 3 ) 3 hydrolysis;

[0053] B. Add NH 4 VO 3 Dissolved in 5mol / L NaOH solution to obtain the same Bi(NO 3 ) 3 Solution isotropic NH 4 VO 3 Solution 1000mL;

[0054] C. Under stirring, 1000mL NH 4 VO 3 The solution was added dropwise to the same volume of Bi(NO 3 ) 3 In the solution, adjust the pH to 6.2 with sodium hydroxide or ammonia water, heat it up to 80°C and then keep it warm for 2.0 hours, then perform suction filtration, wash with distilled water, and dry at 100°C to obtain loose powdery bismuth vanadate yellow pigment;

[0055] (2) High temperature resistant yellow pigment BiVO 4 / SiO 2 Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com