Multi-caliber roundness-correcting set

A multi-caliber and circle-calibrating technology, which is applied in the field of multi-caliber circle-calibrating units, can solve the problems of single function and space occupation in the workshop, and achieve the effects of low cost, easy operation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

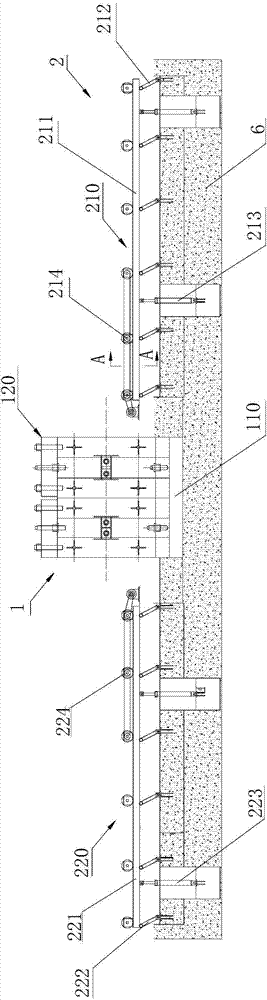

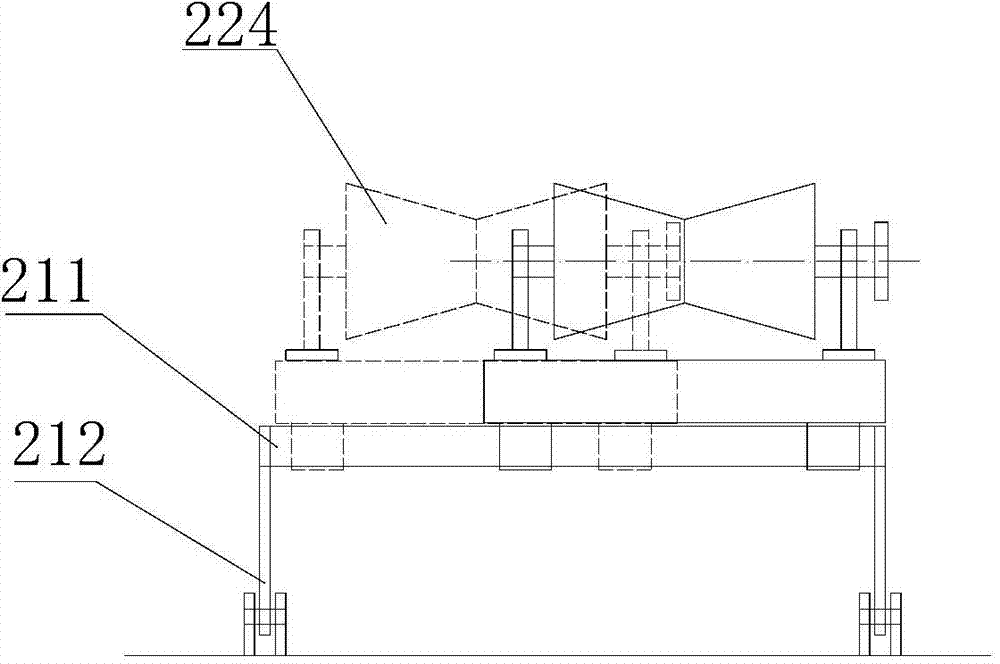

[0020] see Figure 1 to Figure 2 , a multi-diameter circle correction unit, including a circle correction device 1 and a roller device 2, the roller device includes a feeding idler 210 and a discharge idler 220, and the feeding idler and the discharge idler are respectively arranged on The two ends of the circle calibration device 1;

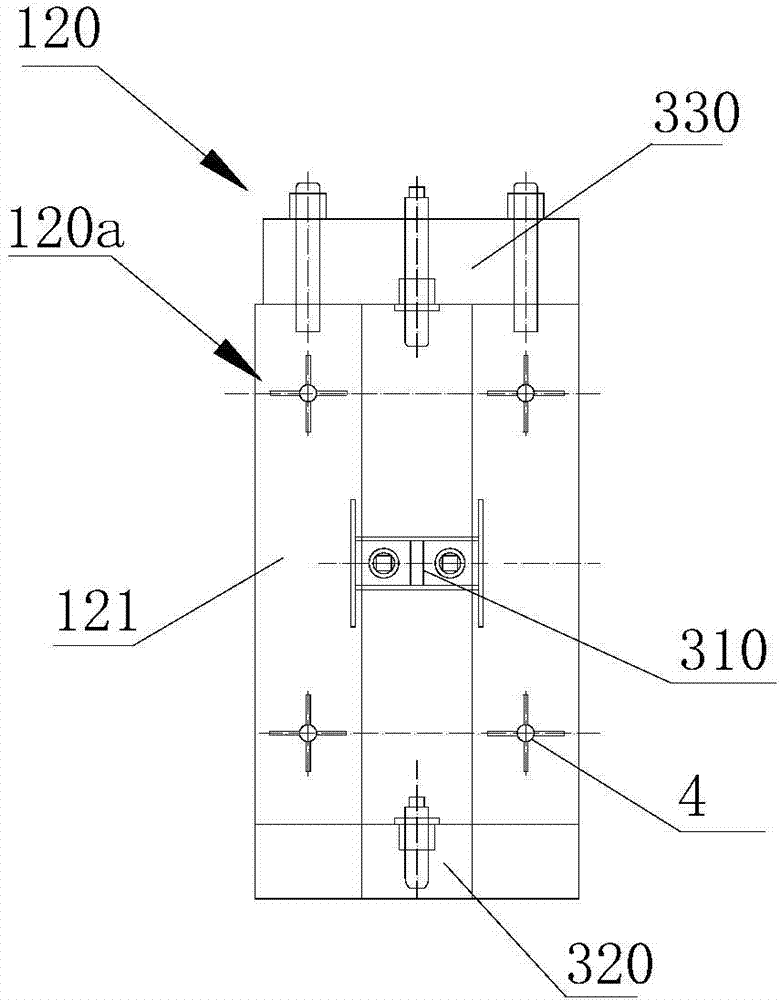

[0021] Wherein the circle calibration device 1 includes a base 110, on which at least one group of symmetrical circle calibration units 120 is installed, and the setting of the circle calibration units can be set according to the circle calibration accuracy. In this embodiment, two sets of circle calibration units are provided. , one for rough calibration, and another for fine calibration, a mold base is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com