Method and device for bending glass plate

A glass plate and bending technology, applied in glass forming, glass reshaping, glass production, etc., can solve the problem that the glass plate cannot be separated from the traces of the roller table, so as to simplify the processing process and equipment, save production costs, and eliminate rollers. The effect of the possibility of traces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The content of the present invention will be further described below with reference to the accompanying drawings.

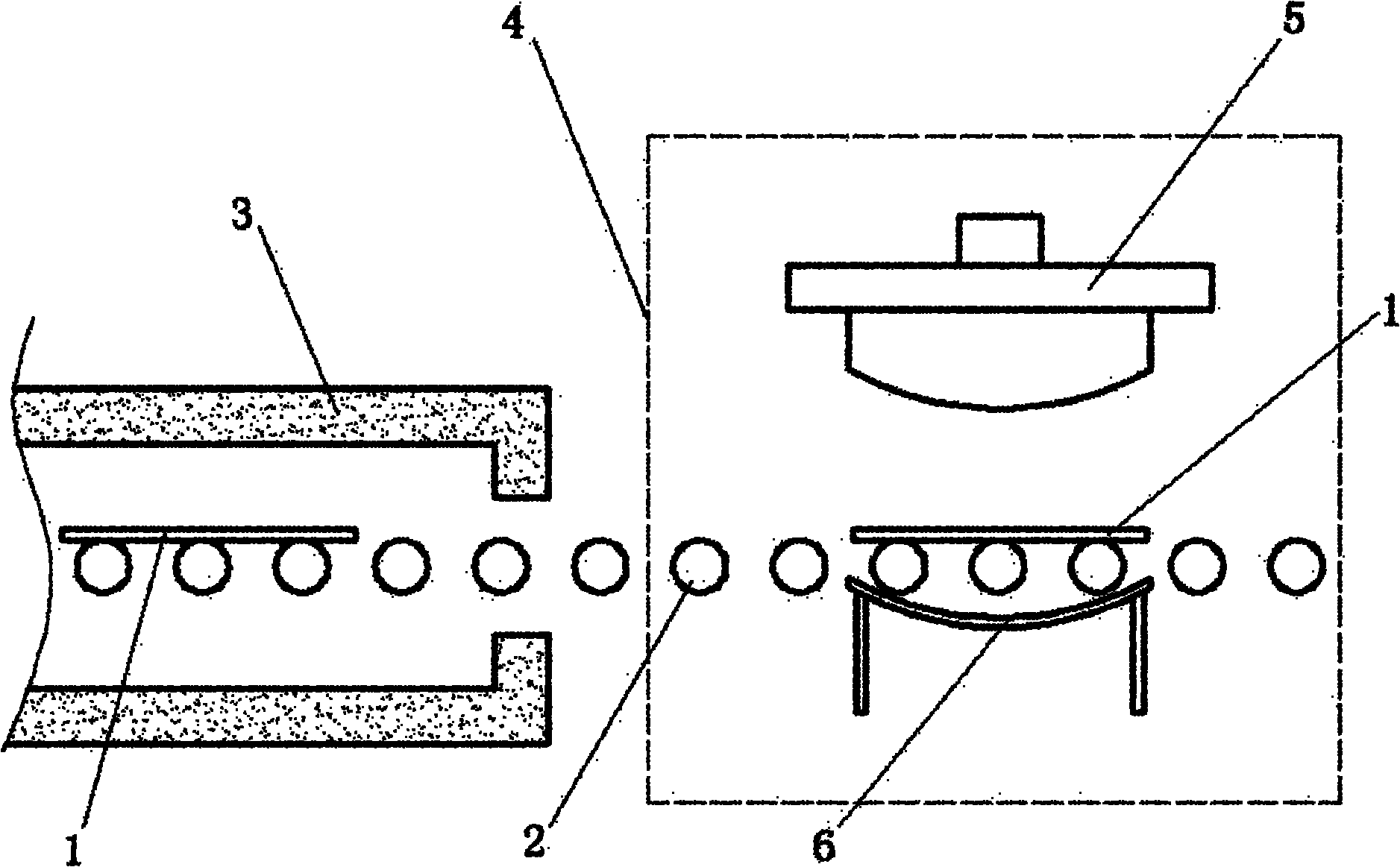

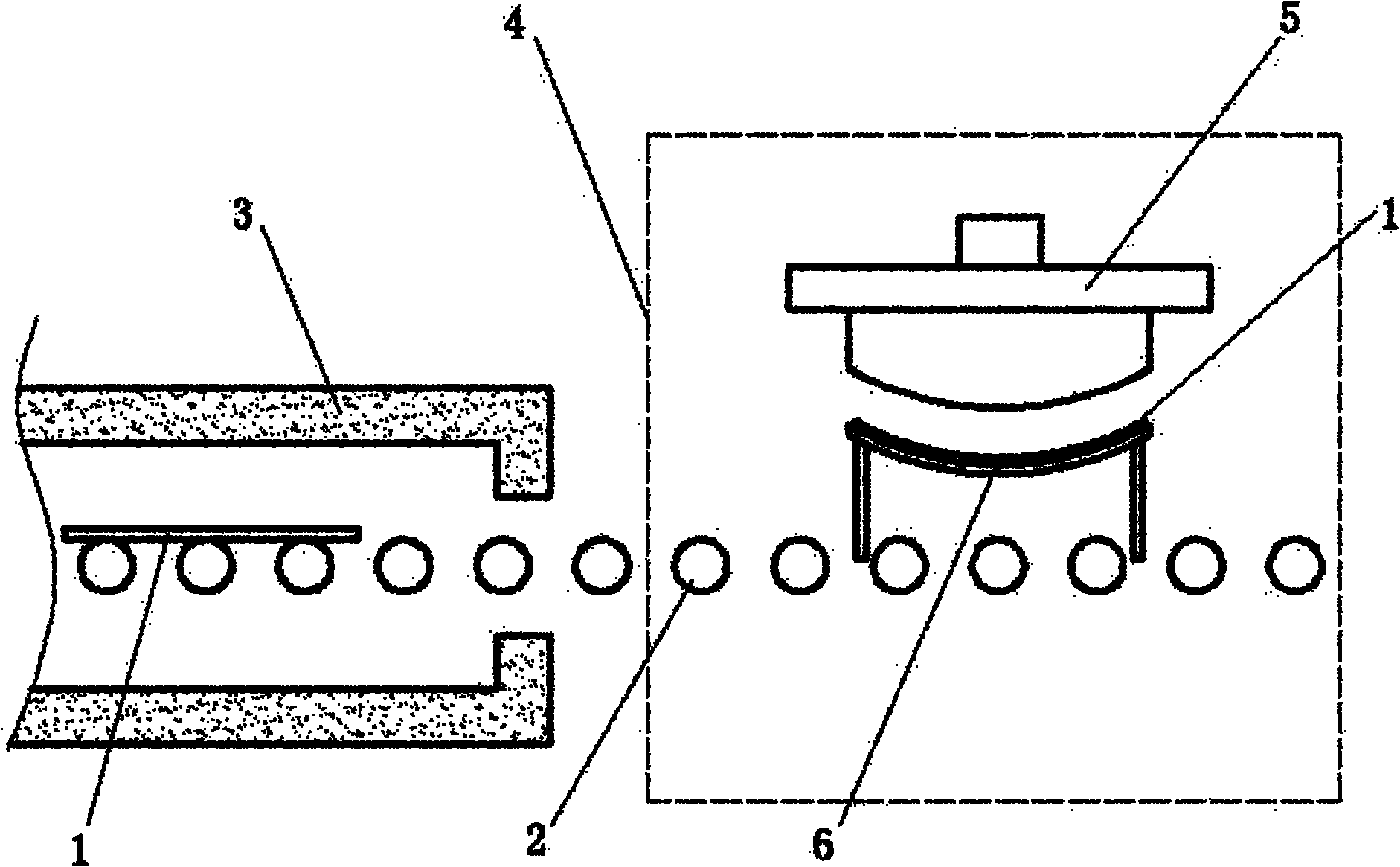

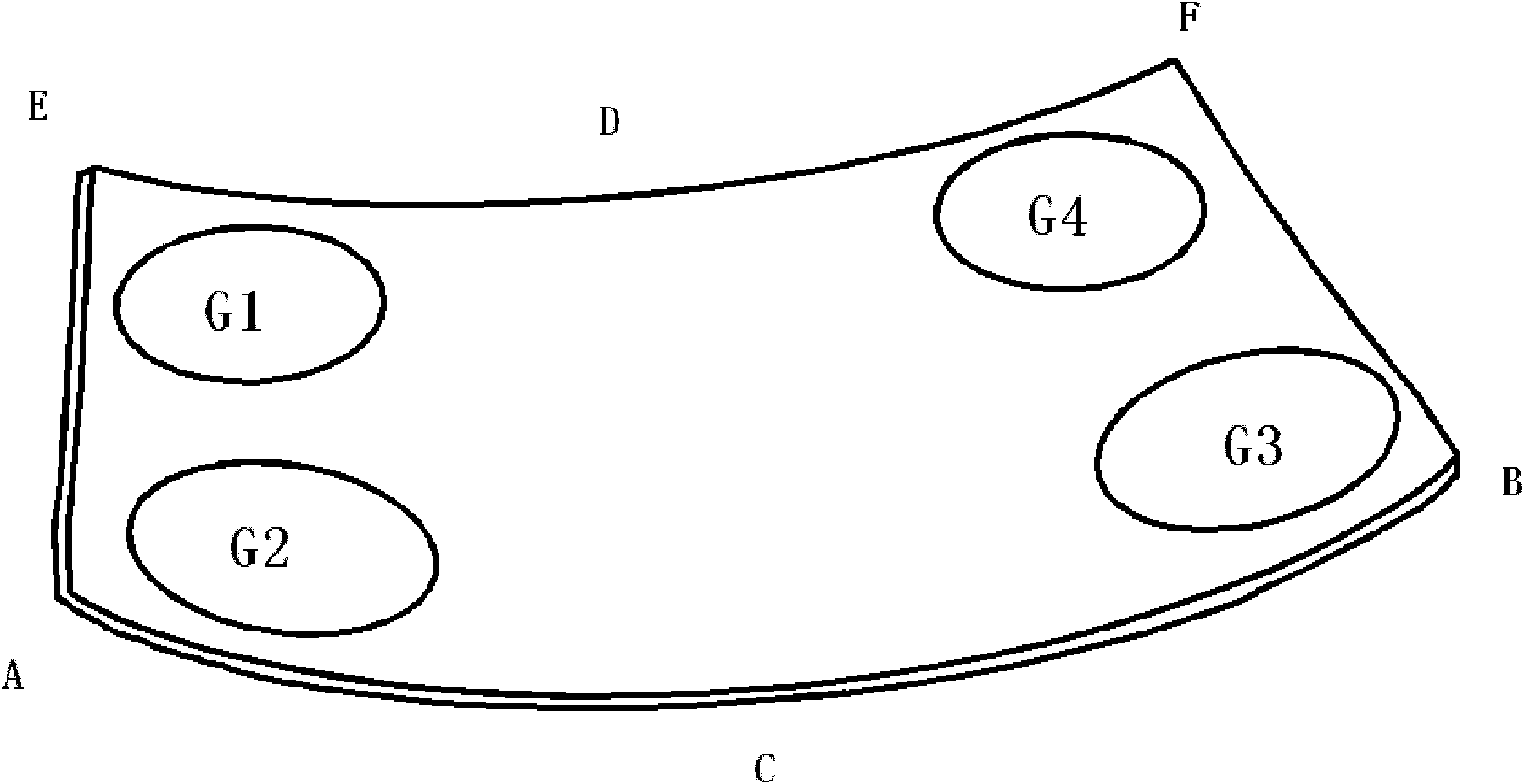

[0037] like Figure 4 As shown, the steps of glass plate 1 being heated and softened in the heating furnace 3 and the steps of transporting the heated and softened glass plate 1 out of the heating furnace 3 and into the forming area 4 through the horizontal conveying roller table 2 are simply shown with a frame structure As well as a component part of a device suitable for bending a glass sheet for applying the method of the invention. The device for bending glass sheets suitable for applying the method of the present invention includes a heating furnace 3 for heating and softening the glass sheets, a horizontal conveying roller table 2 for transporting the glass sheets and an upper pressing convex for pressing the glass sheets for final shaping. Die 5 and lower pressing die 6, said upper pressing punch 5 having a convex forming surface matching the concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com