Process method for increasing low-temperature heat utilization efficiency of arene device and low-temperature heat utilization system of arene device

A process method and low-temperature heat technology, applied in the field of aromatics industry, can solve the problems of indirect use of heat and low efficiency, and achieve the effects of saving investment and production and operation costs, low energy consumption, and energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

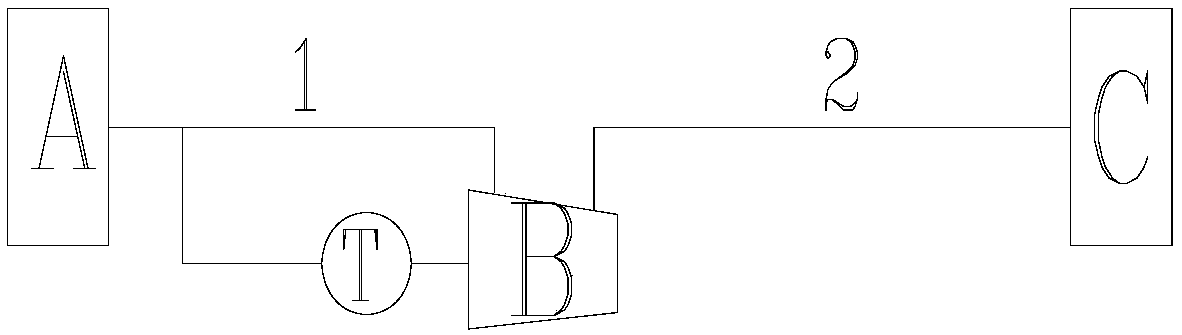

[0033] Such as figure 1 As shown, the low-pressure steam produced by the aromatics plant is boosted by the screw compressor to prepare boosted steam. The screw compressor is used for boosting the pressure. For steam heating equipment. This process can produce 130t / h of boosted steam.

Embodiment 2

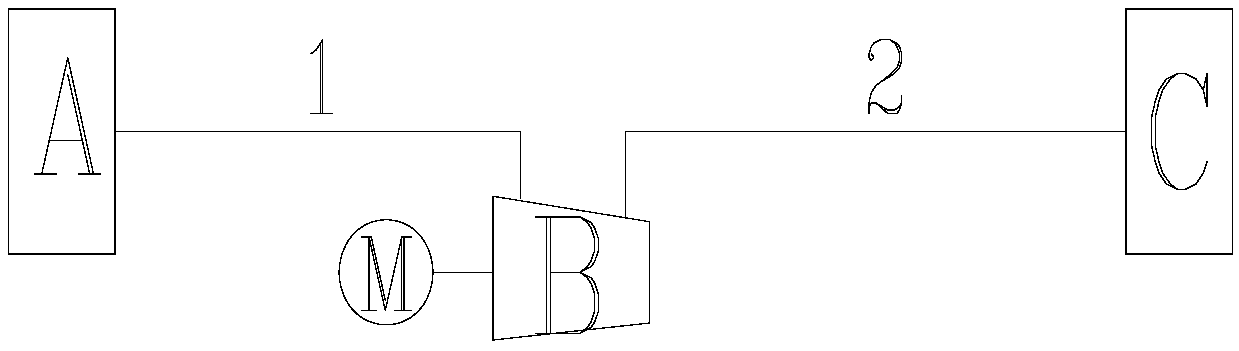

[0035] Such as figure 2 As shown, the low-pressure steam generated by the aromatics plant is boosted by the screw compressor to prepare boosted steam, and the boost uses a screw compressor, and the driving form is electric drive. Condensed water is sprayed into the compressor inlet to eliminate the superheat at the compressor outlet. After the boost is completed, the steam is merged into the steam pipe network of the factory. This process can produce 220t / h of boosted steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com