Method for improving isometric crystal ratio of high-carbon steel billet

A technology of equiaxed grain rate and billet, which is applied in the field of metallurgy, can solve the problems of low equiaxed grain rate, etc., and achieve the effects of improving production efficiency, improving loose shrinkage defects, and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

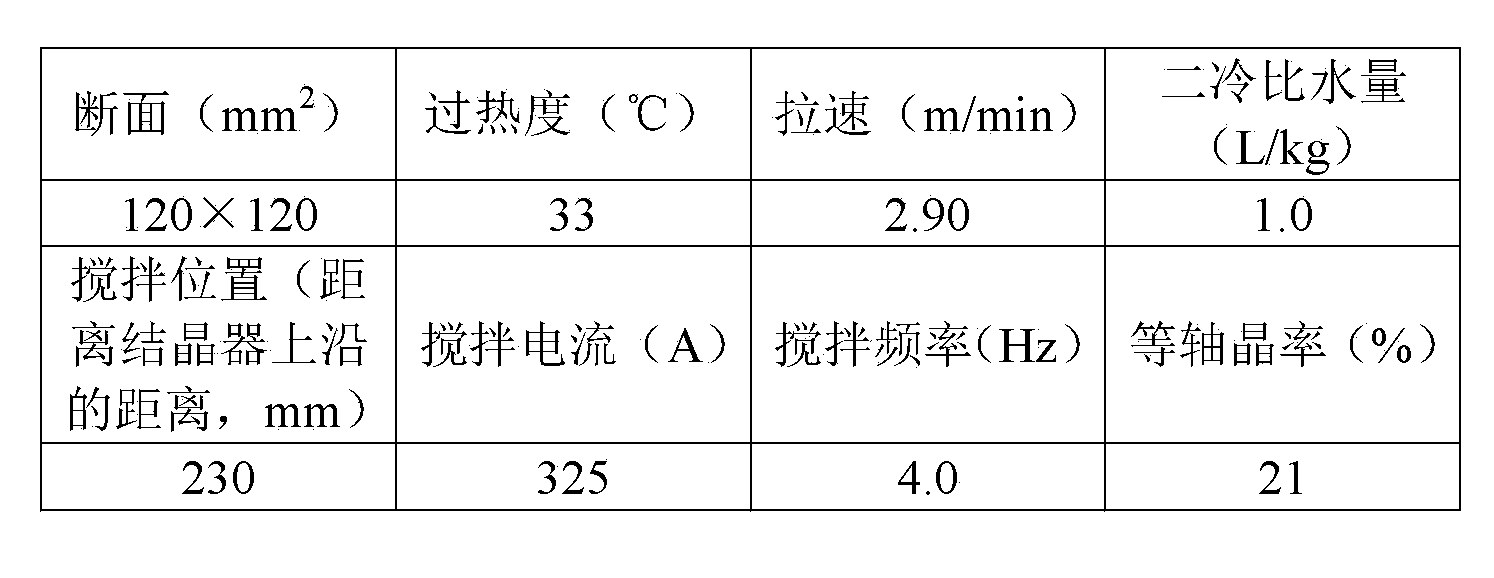

[0017] An electromagnetic stirring method for increasing the equiaxed grain rate of high carbon steel billet, producing 60 # High carbon steel 120×120mm billet, the specific steps are as follows:

[0018] (1) During the continuous casting process, the pouring is protected throughout the process, and the superheat is 33°C.

[0019] (2) The average casting speed corresponding to each crystallizer is 2.90 m / min, the cooling ratio of the secondary cooling water in the secondary cooling section of each crystallizer is 1.0 L / kg, and the whole process is air mist cooling,

[0020] (3) The electromagnetic stirrer is 20mm away from the lower edge of the crystallizer, and the electromagnetic stirring of the crystallizer under the conditions of 325A and 4.5Hz is used.

[0021] Table 1 Chemical composition of steel grades (%)

[0022] C

Si

mn

P

S

0.60

0.24

0.58

0.018

0.009

[0023] Table 2 Implementation process and effect

[0024...

Embodiment 2

[0026] An electromagnetic stirring method for increasing the equiaxed grain rate of high carbon steel billet, producing 60 # High carbon steel 120×120mm billet, the specific steps are as follows:

[0027] (1) During the continuous casting process, the pouring is protected throughout the process, and the superheat is 30°C.

[0028] (2) The average casting speed corresponding to each crystallizer is 2.83m / min, the cooling ratio of the secondary cooling water in the secondary cooling section of each crystallizer is 0.9L / kg, and the whole process is air mist cooling,

[0029] (3) The electromagnetic stirrer is 22mm away from the lower edge of the crystallizer, and the electromagnetic stirrer of the crystallizer under the condition of 295A and 4.0Hz is used.

[0030] Table 3 Chemical composition of steel grades (%)

[0031] C

Si

mn

P

S

0.58

0.26

0.56

0.019

0.007

[0032] Table 4 Implementation process and effect

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com