Electromagnetic stirring water-cooled mold and method for pouring steel ingot

A technology of electromagnetic stirring and electromagnetic stirrer, which is applied in the field of iron and steel smelting, can solve the problems of low equiaxed crystal rate of steel ingots and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

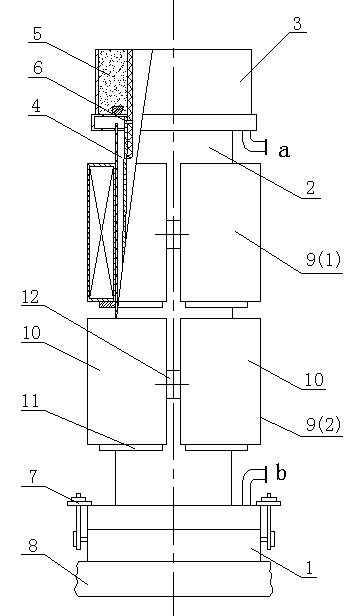

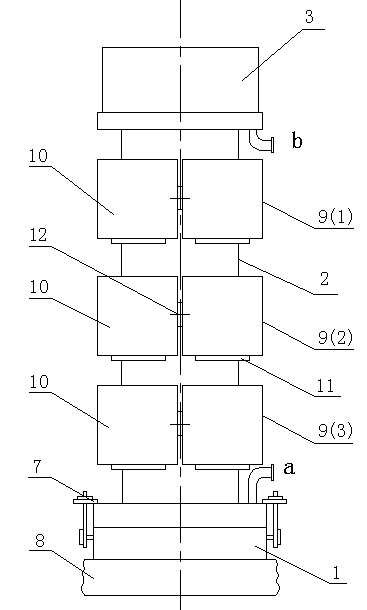

[0024] The electromagnetic stirring water-cooled mold of the present invention is composed of an attached plate 1 , a mold body 2 and a thermal insulation cap 3 , the mold body 2 is fixed on the attached plate 1 by clamps 7 , and the attached plate 1 is installed on the chassis 8 . There is only a first-level mold body on the attached plate, and the upper opening of the mold body 2 is embedded with a heat preservation cap 3. The inner wall of the mold body 2 is a cylindrical structure with a top diameter slightly smaller than the bottom diameter. Cooling water jacket 4, the gap of the jacket wall is 5-30mm and the gap of the cavity gradually increases from bottom to top, the cooling water in the cooling water jacket is high-level water, the outlet water pressure of the jacket is greater than 0.05MPa, the water quality for soft water. And the two ends of the cooling water jacket 4 are provided with inlets a and b for cooling water. An electromagnetic stirrer 9 is closely attac...

Embodiment 2

[0041] The method for pouring steel ingots with electromagnetic stirring water-cooled molds of the present invention utilizes water-cooled casting molds to carry out the following steps:

[0042] (1) Put mold powder at the bottom of the mold;

[0043] (2) Turn on the cooling water system and check whether the outlet water pressure is greater than 0.05MPa;

[0044] (3) When pouring, the superheat of molten steel is controlled at (50-80) ℃, the pouring speed of the ingot body is controlled at (10-50) cm / min, and the speed of the cap mouth is smaller than that of the ingot body. When the liquid level rises above the reinforcement hole and the pendant Stop pouring under the structure, and then put heat insulating agent and heating agent on the liquid surface;

[0045] (4) When the liquid level rises to more than 2 / 3 of the height, turn on the electromagnetic stirrer (9). by figure 1 For example, first open the lower electromagnetic stirrer 9 (2), the electromagnetic stirrer 9 (...

Embodiment 3

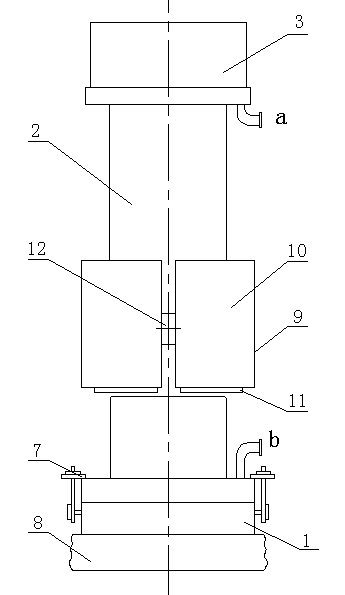

[0049] Such as figure 2 As shown, a steel ingot below 10 tons is poured with an electromagnetic stirrer, and a typical mold steel H13 is poured, and a 10-ton water pours one. The molten steel is H13 which has been refined by 10 tons of LF and treated by VD. The choice of the chassis for the masonry of the flow steel channel, the materials used, and the technical requirements are equivalent to the technical literature with the patent name: New steel ingot water-cooled casting mold and method, and patent number: 201210180527.8. The bottom brick of the mold attached to the plate is inlaid with the chassis, and the insulation cap is installed with the same name. The name is: new steel ingot water-cooled casting mold and method, and the patent number is: 201210180527.8. T. Turn on the cooling water system before pouring. The water supply system is provided by the high-level water tank, and the water quality is soft water. It is pumped into the high-level water tank by the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com