CrNiMo round steel for wind power gear and preparation method

A round steel and gear technology, applied in the field of CrNiMo round steel for wind power gears and its production process, can solve problems such as pits and pits on the material, affecting product surface quality, etc., reduce component segregation, and optimize continuous casting parameter settings , Realize the effect of constant pulling speed casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

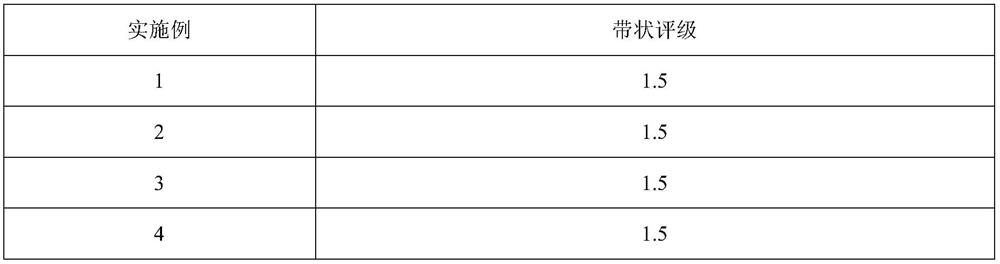

Examples

Embodiment 1

[0058] (1) The steelmaking raw materials used in the electric furnace are steel scrap and molten iron, and the steel scrap accounts for 10% of the total weight of the steelmaking raw materials, and the molten iron accounts for 90% of the total weight of the steelmaking raw materials, and the total charge is 102t / furnace.

[0059] The electric furnace uses the molten iron tipping device to adopt the online molten iron loading mode, combined with the foam slag operation process, to achieve the purpose of removing P and controlling temperature, tapping [C] 0.08%, tapping [P] 0.009%, residual [Cu] 0.040%, [B] 0.0002%, tapping temperature 1635°C, adding aluminum block 0.80kg / t, ferrosilicon 0.75kg / t, low-carbon ferromanganese 5.5kg / t, low-carbon ferrochrome 27.5kg / t in sequence with the steel flow t. Lime 500kg / furnace, slagging agent 550kg / furnace, the tapping process adopts eccentric furnace bottom tapping, and slag removal is strictly prohibited.

[0060] (2) LF uses 1.5kg / t of ...

Embodiment 2

[0065] Compared with Example 1, the difference is that molten iron accounts for 93% of the total weight of the steelmaking raw materials, the total charging capacity is 108t / furnace, the tapping temperature is 1650°C, the refining white slag time is 31min, the total refining time is 60min, and the refining slag Binary alkalinity 4.0, all the other operations are identical with embodiment 1.

Embodiment 3

[0067] In step (1), electric furnace tapping [C] 0.09%, tapping [P] 0.010%, residual [Cu] 0.037%, [B] 0.0002%, tapping temperature 1630 ° C, and the rest of the operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com