Stainless steel for heat exchanger welded pipe and manufacturing method thereof

A technology of stainless steel and heat exchanger, applied in the field of stainless steel, to achieve the effects of improving comprehensive mechanical properties, simplifying the production process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

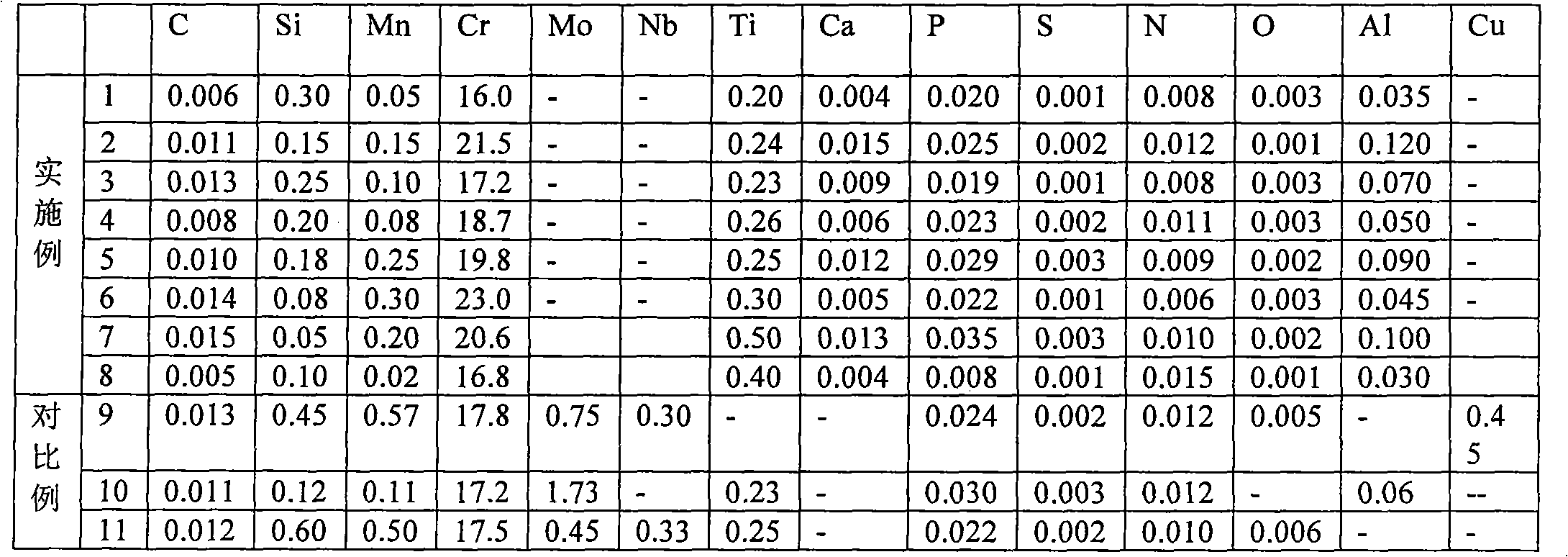

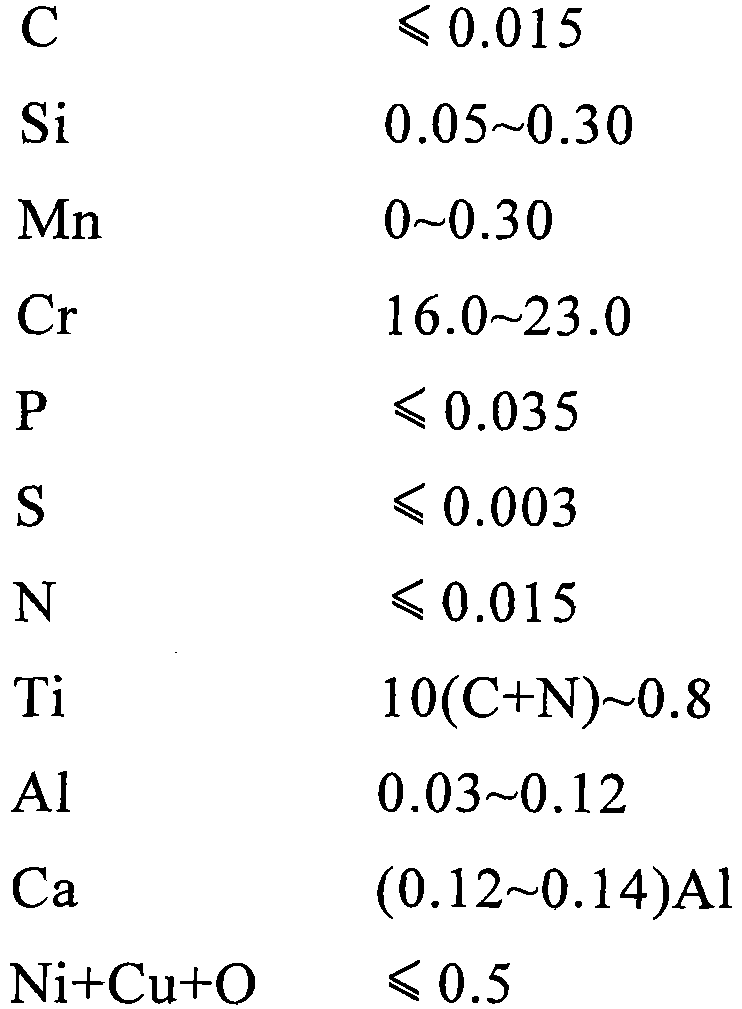

[0036] According to the chemical composition requirements of the steel grade of the present invention, the billet undergoes electric furnace smelting, AOD smelting and VOD smelting, adding aluminum and calcium, soft stirring for a period of time, and then adding titanium for continuous casting and grinding. The slab is rough-rolled at 900-1100°C, then finish-rolled at 800-1000°C, the hot-rolled steel sheet is annealed and pickled and then cold-rolled to ensure a reduction rate of 60-80%. Finally, the cold-rolled steel sheet is annealed, pickled and divided into coils at 850-1000°C to manufacture stainless steel of different specifications. The comparative steel grades are mainly used in automobile exhaust systems. They must withstand temperatures of 700-900°C during use and undergo cold working deformation during production. The specific ingredients are as follows:

[0037] Table 1 Chemical composition of Examples and Comparative Examples (wt%)

[0038]

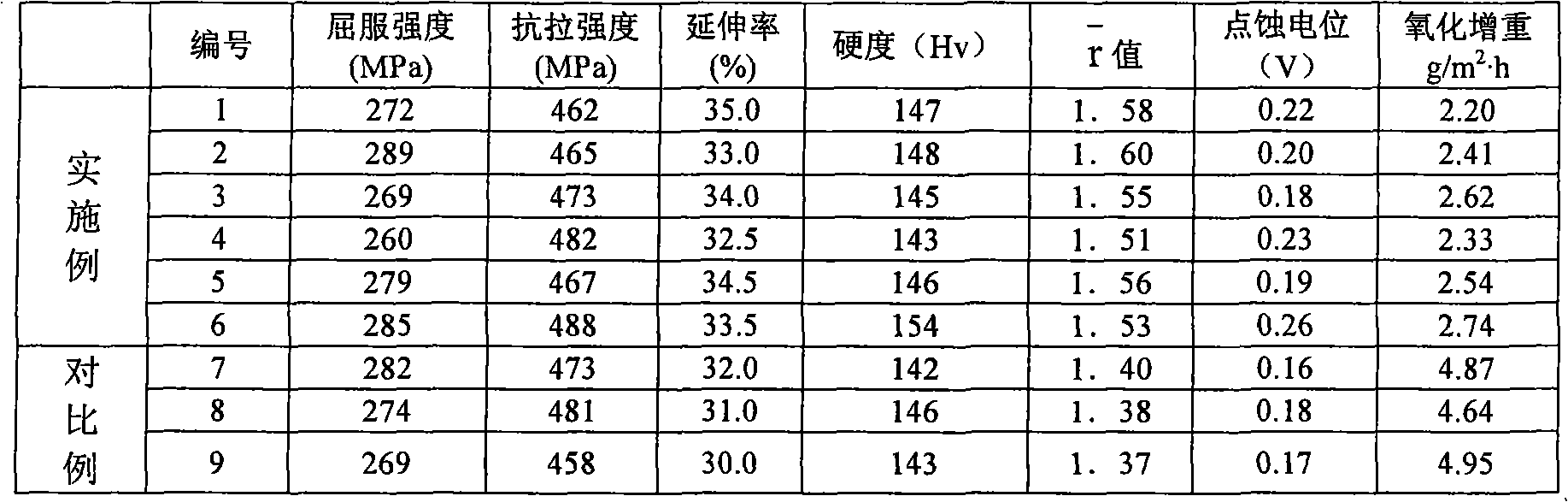

[0039] Table 2 shows the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com