Method for improving internal quality of casting blank by composite intervention

An internal quality and billet technology, applied in the field of composite intervention to improve the internal quality of the billet, can solve the problems of poor molten steel fluidity, difficult to float inclusions, and reduced molten steel temperature, so as to improve the pulling speed and reduce operation and maintenance costs. , The effect of reducing the superheat and temperature gradient of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

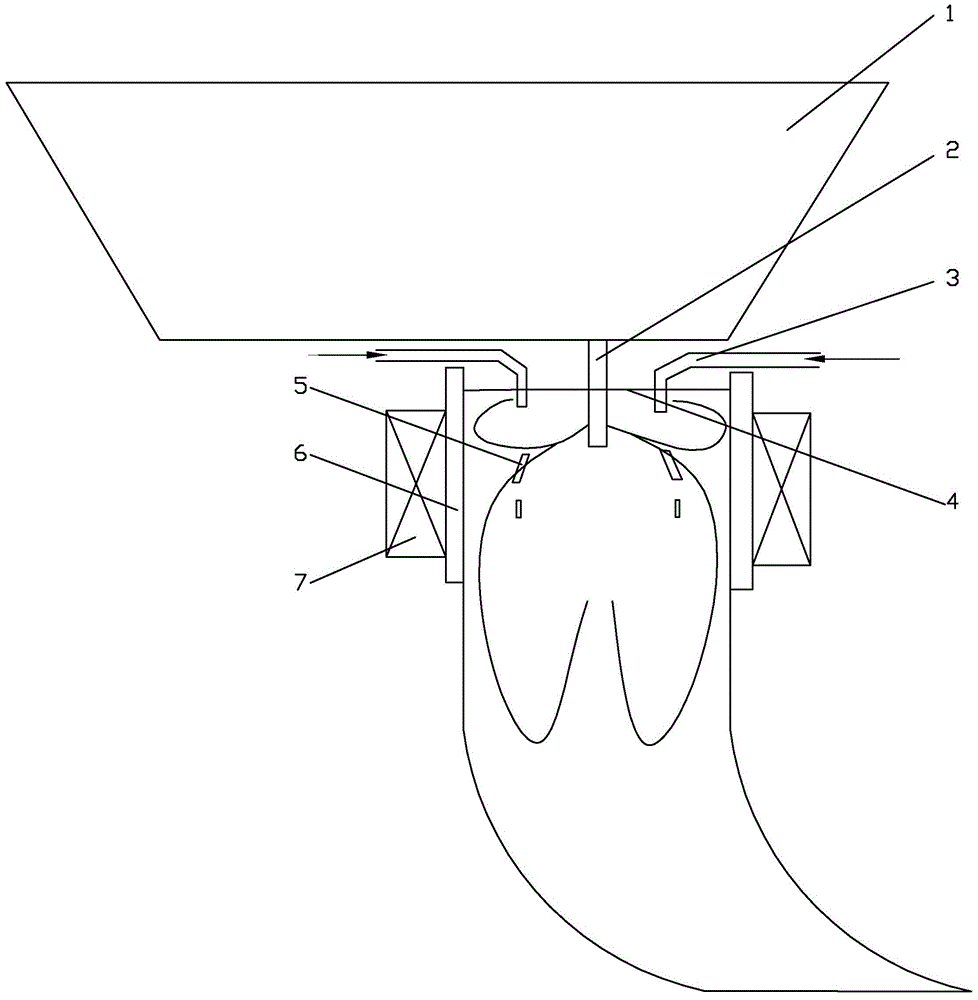

Image

Examples

Embodiment

[0035] Take the casting machine with a casting section of 250*2100mm as an example, the superheat is 20-40°C, and the casting speed is 0.8-1.2m / min. First, pure iron or steel with a composition close to that of cast steel is processed into a smaller cold body, and then dried. The cold body adopts a hollow circular tube with a cross-sectional diameter of less than 30mm, a hole diameter of not less than 8mm, and a length of not more than 150mm. Then, the feed conduit is baked and submerged under the molten steel surface of the mold. For the slab, two conduits can be used, which are distributed on both sides of the wide surface of the crystallizer, and the distance from the submerged nozzle can be adjusted. Next, the above-mentioned dried cold body is continuously injected into the predetermined position of the molten pool of the crystallizer through the conduit, and the injection device can be a pneumatic or electric injection device, and the injection speed is 30-60 rounds / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com