Substrate cleaning method

A technology for substrates and cleaning fluids, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as leakage, inability to fit well, insufficient cleaning of the substrate surface, etc., and achieve reduction Effects of reverse contamination, improved cleaning performance, and reduced number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

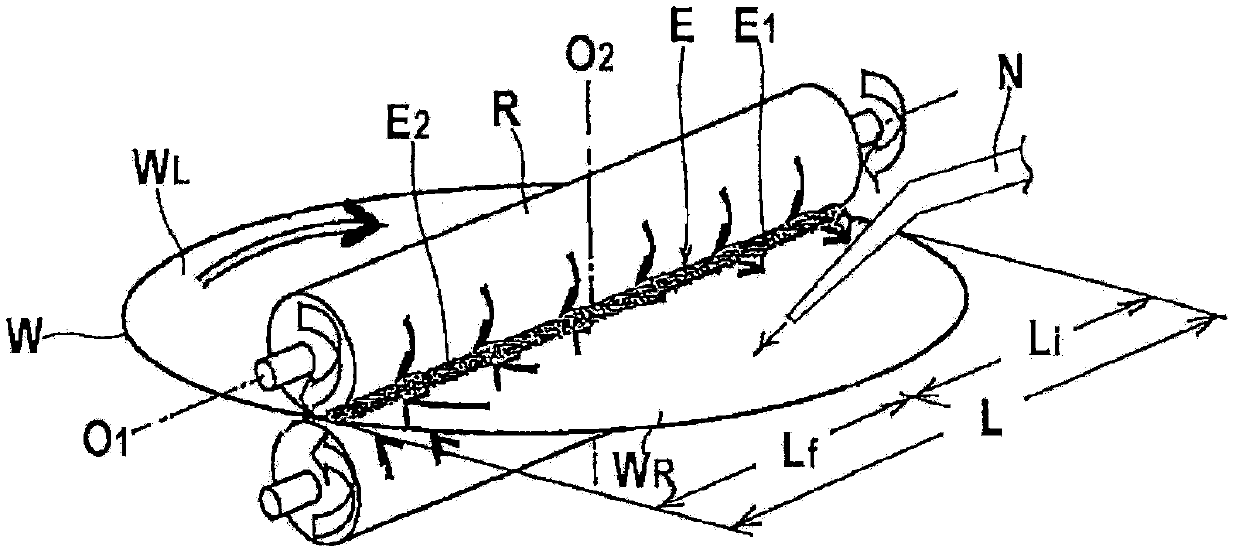

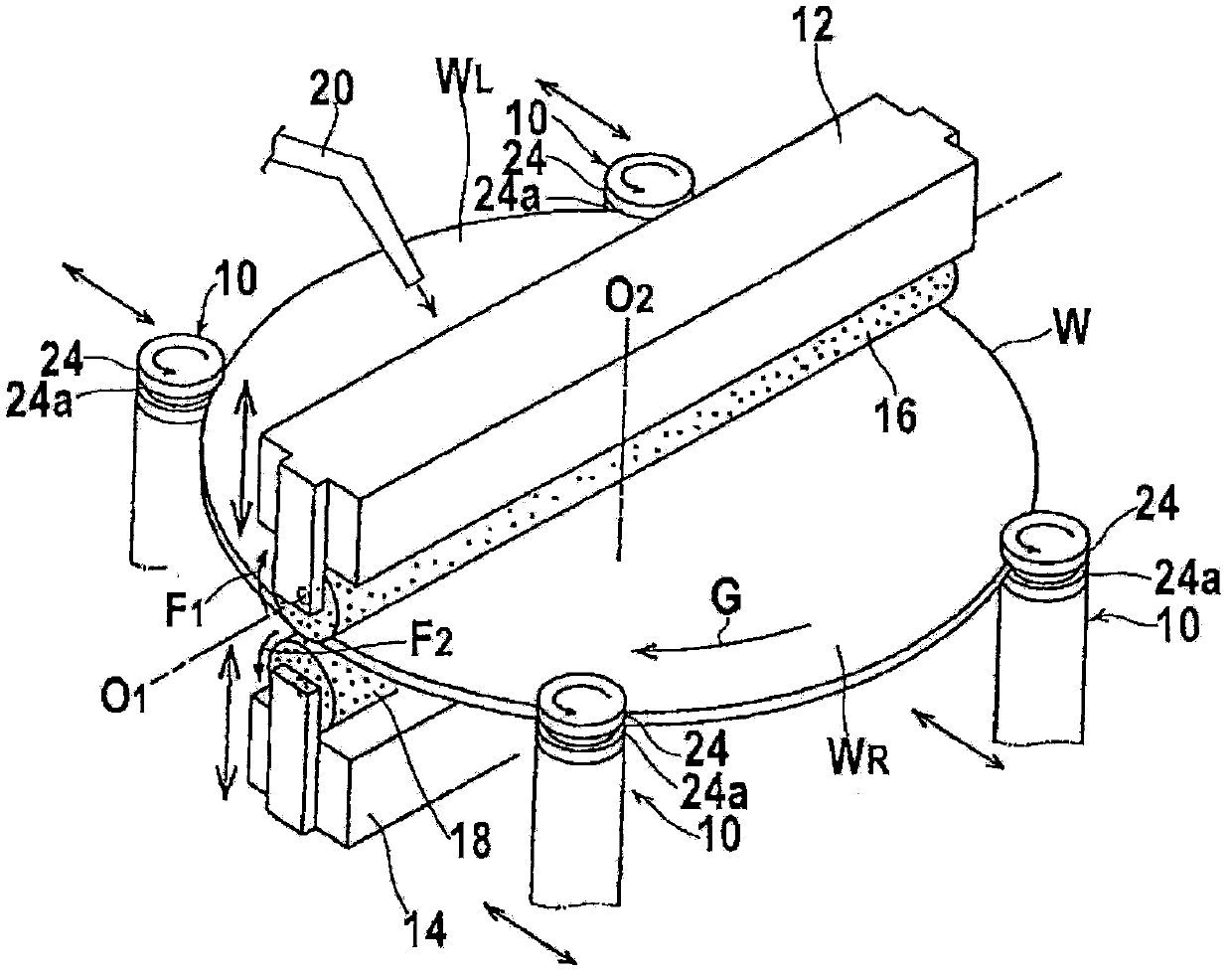

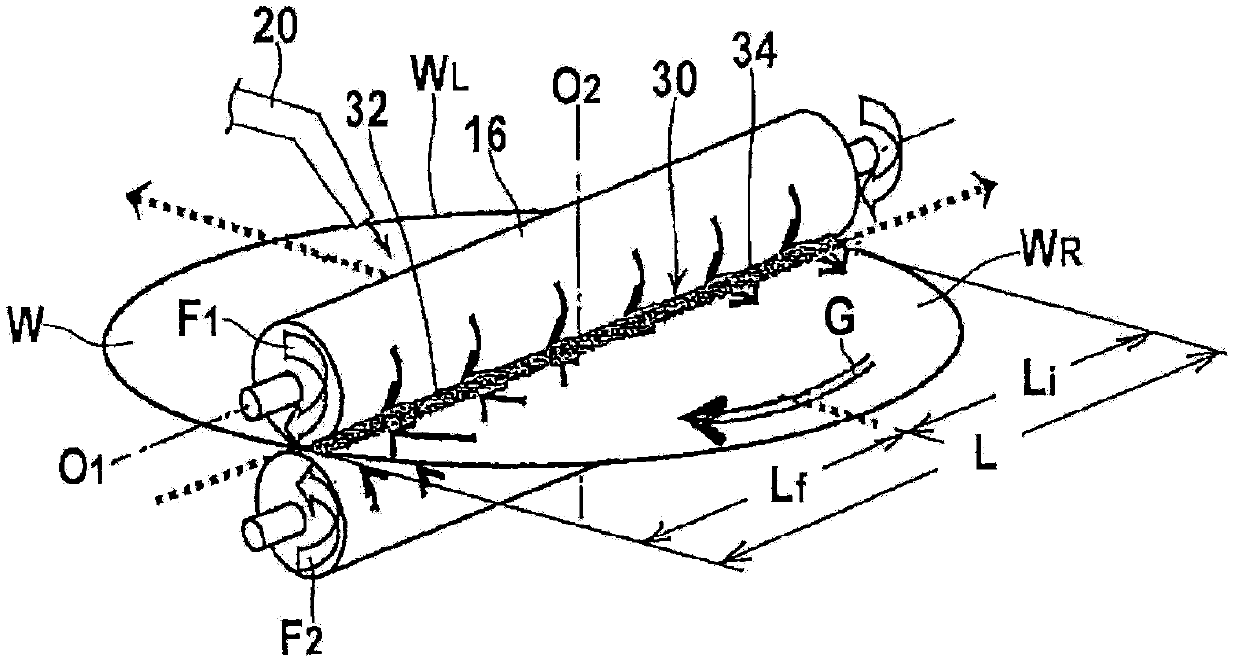

[0080] Example 1 shows that one side faces the area W on the left side of the substrate L (refer to figure 2 ) Measurement results of the number of defects of 42 nm or more remaining on the substrate surface when the first flow rate of the cleaning solution is supplied, the substrate surface is cleaned under the first cleaning condition and the second cleaning condition, and then dried. In Example 2, one side faces the left area W of the substrate L (refer to figure 2 ) Measurement results of the number of defects of 42 nm or more remaining on the substrate surface when the substrate surface is cleaned by the first cleaning condition and the second cleaning condition while the second flow rate of the cleaning liquid is supplied to the first flow rate and then dried. In Comparative Example 1, one side faces the right region W of the substrate. R (refer to figure 2 ) Measurement results of the number of defects of 42 nm or more remaining on the substrate surface when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com