Electric fault detection system for vehicle

A technology for fault detection and power consumption faults, applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve problems such as lack of equipment, hidden dangers of equipment failures that cannot be found in time for regular maintenance, and data that needs to be stored and processed, so as to improve comprehensiveness, The effect of preventing electrical fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

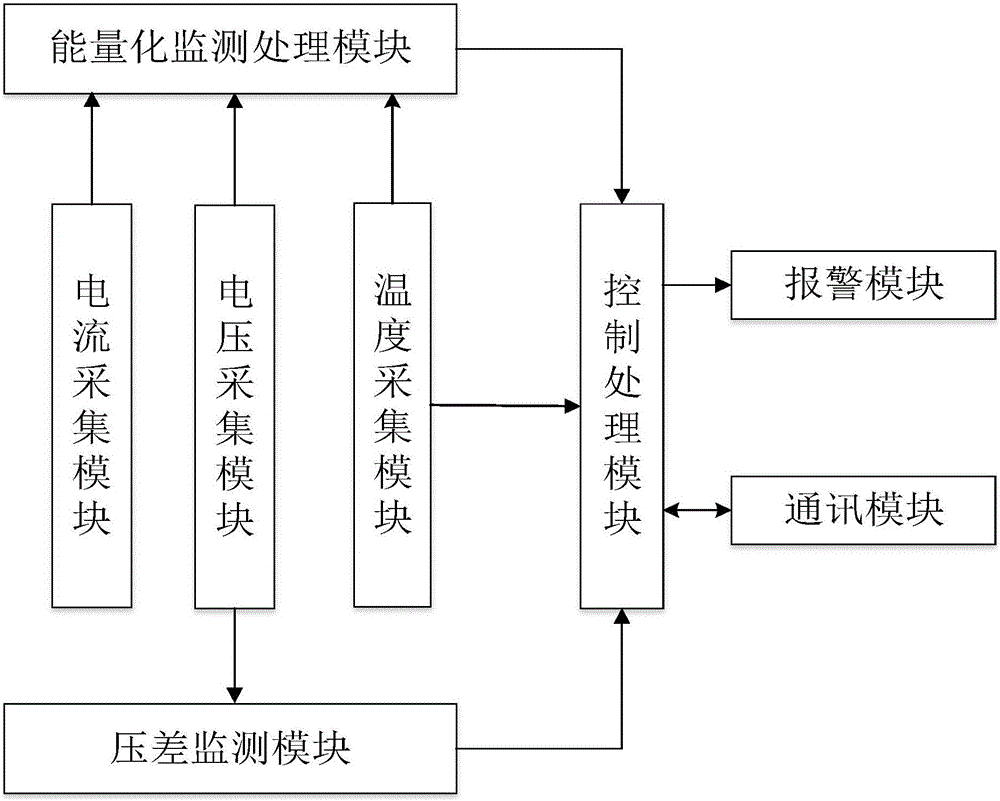

[0023] refer to figure 1 , a vehicle electrical fault detection system proposed in this embodiment is used to detect the power-on working status of the internal power supply module and each power consumption module of the vehicle. The automotive electrical fault detection system includes: a voltage acquisition module, a current acquisition module, a temperature acquisition module, an energy monitoring and processing module, a differential pressure monitoring module, a control processing module, a communication module and an alarm module.

[0024] The voltage acquisition module is connected with the power supply module and each power consumption module, and is used to detect the output voltage of the power supply module and the working voltage of each power consumption module respectively.

[0025] The current collecting module is connected with the power module and each power consumption module, and is used for collecting the output current and residual current of the power mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com