Particulate fillers

A granular filler and granular technology, which is applied in the direction of fibrous filler, thin material treatment, inorganic pigment treatment, etc., can solve the problems of pressure rise, etc., and achieve the effect of improving processability and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

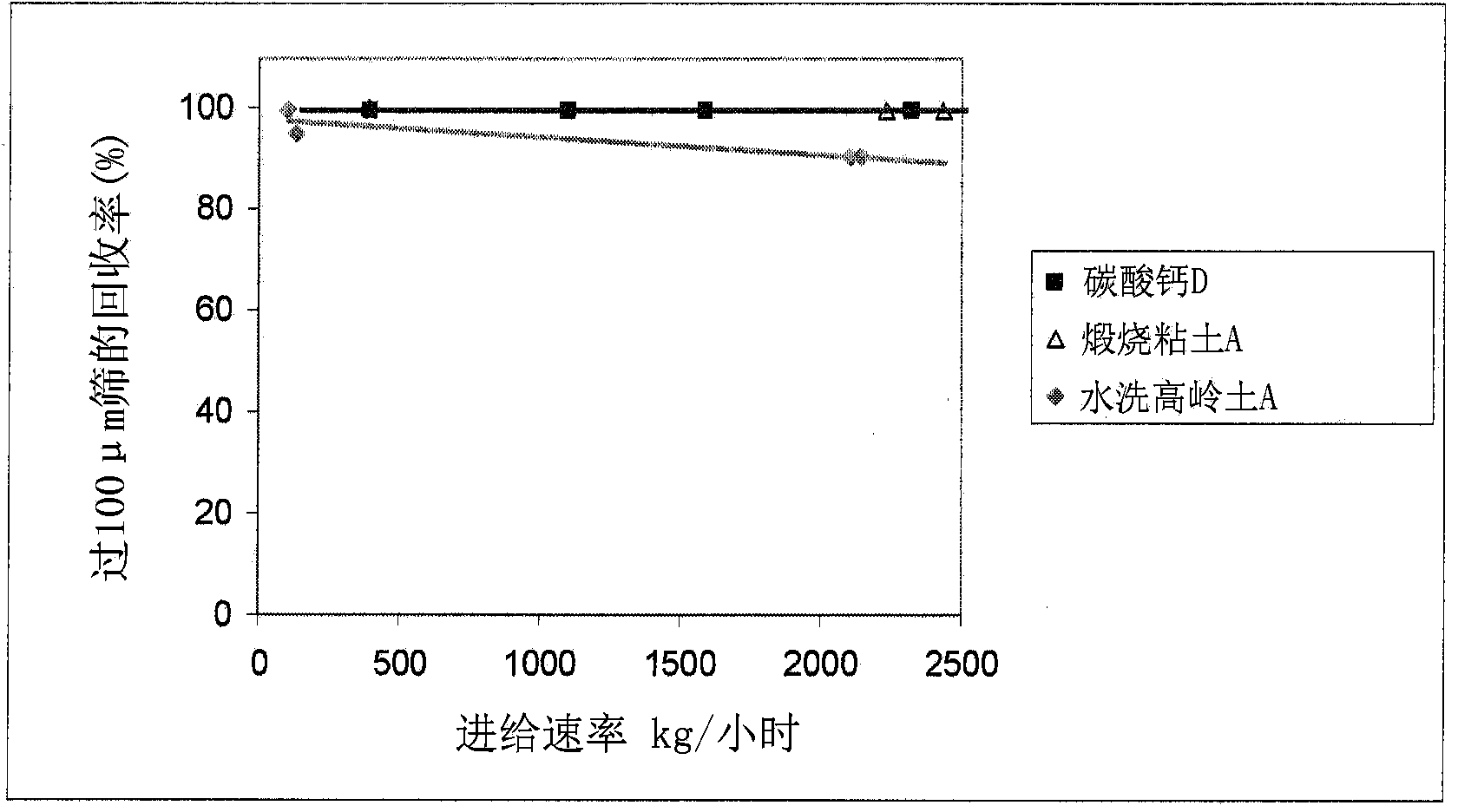

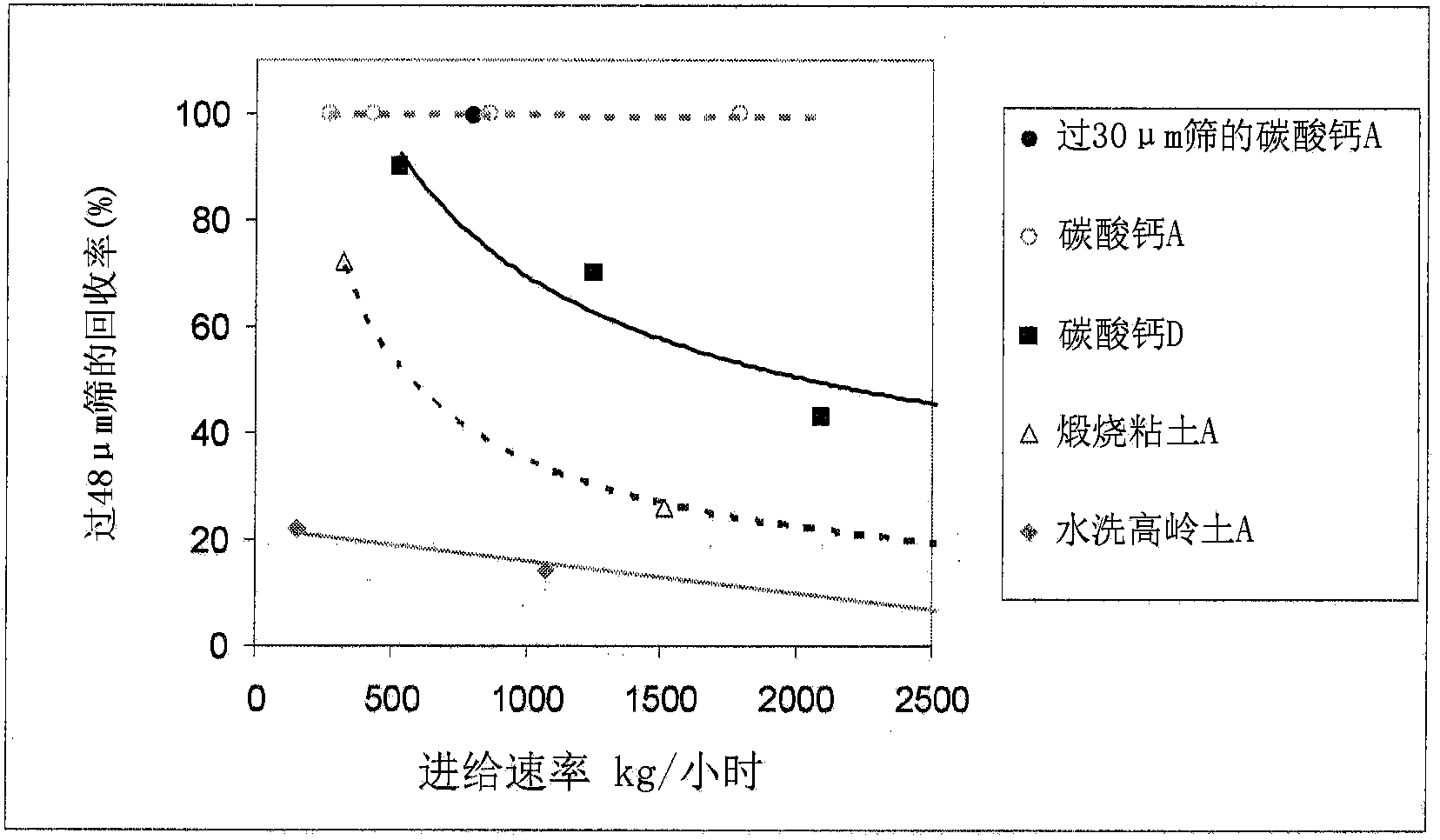

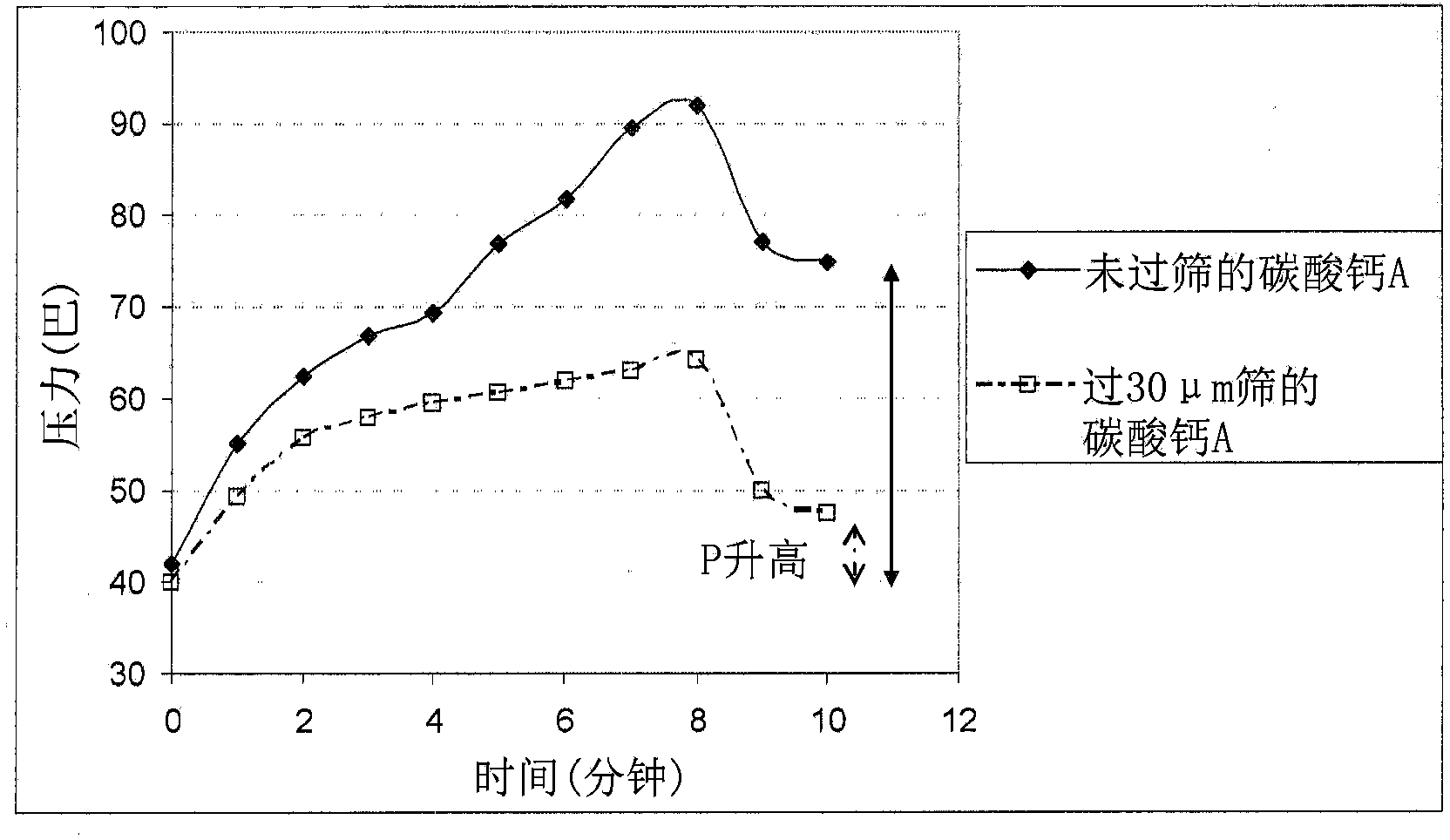

[0032] granular filler

[0033] Suitable fillers include particulate inorganic fillers. For example, mineral fillers such as alkaline earth metal carbonates (e.g., dolomite, ie CaMg(CO 3 ) 2 , or calcium carbonate), metal sulfates (for example, barite or gypsum), metal silicates, metal oxides (for example, titanium oxide, iron oxide, chromium oxide, antimony trioxide or silicon dioxide), Metal hydroxides (eg, alumina trihydrate), kaolin, calcined kaolin, wollastonite, alumina, talc, or mica, including combinations thereof. Any of the above materials may be coated (or uncoated) or treated (or untreated). In particular, the filler may comprise, consist of, or consist essentially of coated calcium carbonate, treated calcined kaolin, or treated talc. Other suitable fillers may include those with low water absorption. The filler can be a single filler or can be a blend of fillers. For example, the filler can be a blend of two or more fillers listed herein.

[0034] The aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com