Sintered body for forming rare-earth magnet, and rare-earth sintered magnet

A technology of sintered body and magnet, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of unmanufacturability and the degree of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

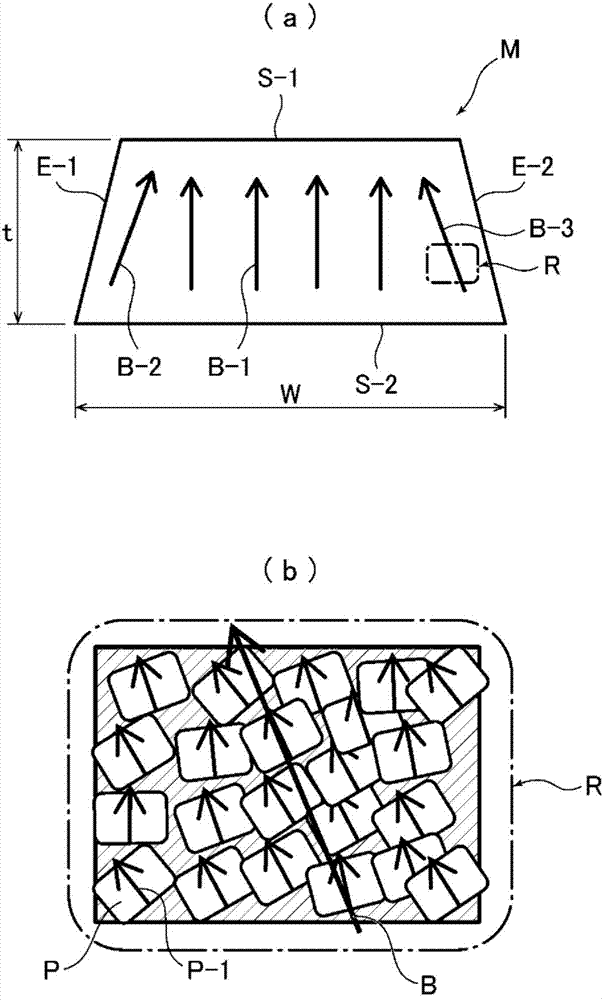

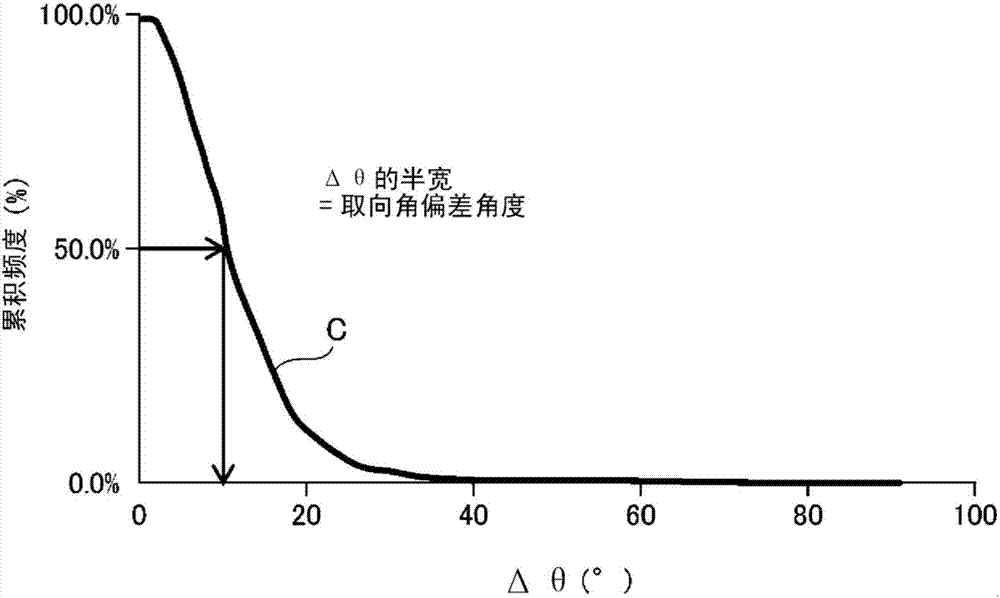

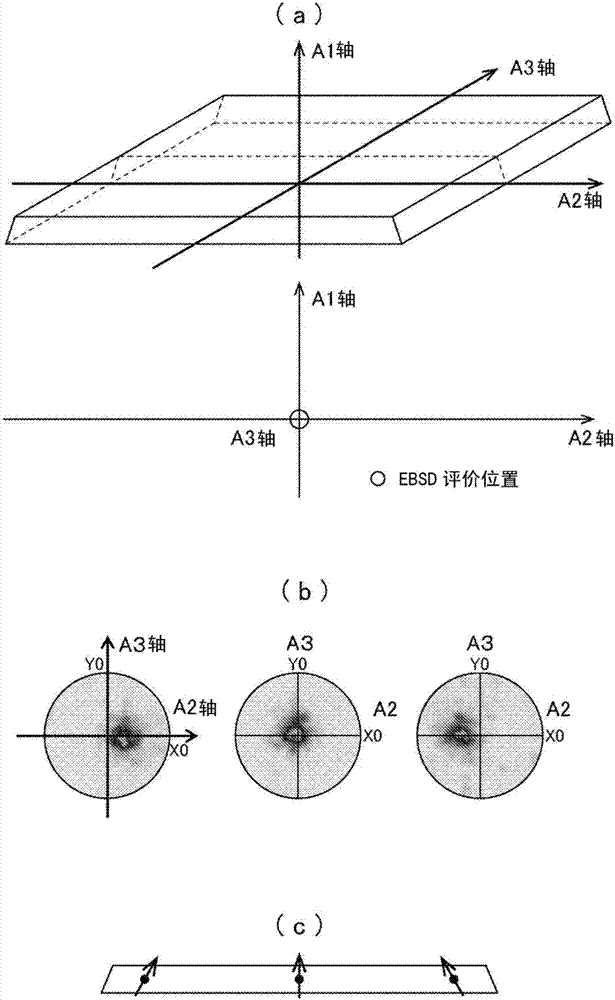

[0068] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0069] exist Figure 4 ~ Figure 7 An example of an electric motor incorporating a sintered body for forming a rare-earth magnet according to another embodiment of the present invention and a permanent magnet formed from the sintered body is shown in . The sintered body 1 for forming a rare-earth magnet contains a Nd—Fe—B-based magnet material as a magnet material. Here, as the Nd-Fe-B-based magnet material, for example, one containing R (R is one or two or more rare earth elements containing Y) in a ratio of 27.0 wt% to 40.0 wt% in weight percentage can be cited. , B is contained in a ratio of 0.6 wt % to 2 wt %, and Fe is contained in a ratio of 60 wt % to 75 wt %. Typically, the Nd-Fe-B magnet material contains Nd at a ratio of 27 wt % to 40 wt %, B at a ratio of 0.8 wt % to 2 wt %, and Fe as electrolytic iron at a ratio of 60 wt % to 75 wt %. For the purpose of im...

Embodiment 1

[0130] Made in the following order Figure 4 A rare earth sintered magnet of the shape shown.

[0131]

[0132] At room temperature, hydrogen is stored in the alloy obtained by the strip casting method (containing Nd: 25.25wt%, Pr: 6.75wt%, B: 1.01wt%, Ga: 0.13wt%, Nb: 0.2wt%, Co : 2.0wt%, Cu: 0.13wt%, Al: 0.1wt%, the remainder being Fe, and other unavoidable impurities) was kept at 0.85MPa for 1 day. Thereafter, hydrogen fragmentation was carried out by maintaining at 0.2 MPa for 1 day while cooling with liquefied Ar.

[0133]

[0134] After mixing 1 part by weight of methyl hexanoate with 100 parts by weight of the coarsely pulverized alloy powder, it was pulverized by a helium jet mill pulverizer (device name: PJM-80HE, manufactured by NPK). For the collection of pulverized alloy particles, the cyclone method is used to separate and recover the ultrafine powder. The supply rate during pulverization is set to 1kg / h, the introduction pressure of He gas is set to 0.6MPa...

Embodiment 2

[0149] Except changing the conditions described in Tables 2 and 3, the same operation as in Example 1 was carried out to obtain a sintered body for forming a rare earth magnet. In Example 1 and Example 2, the thickness of the trapezoidal magnet is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com