A kind of multistage centrifugal pump guide vane and its processing method

A centrifugal pump and guide vane technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of precise control of hydraulic performance, size deviation, and large deviation of hydraulic performance of multi-stage centrifugal pumps, to ensure product quality. performance, the effect of reducing performance deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

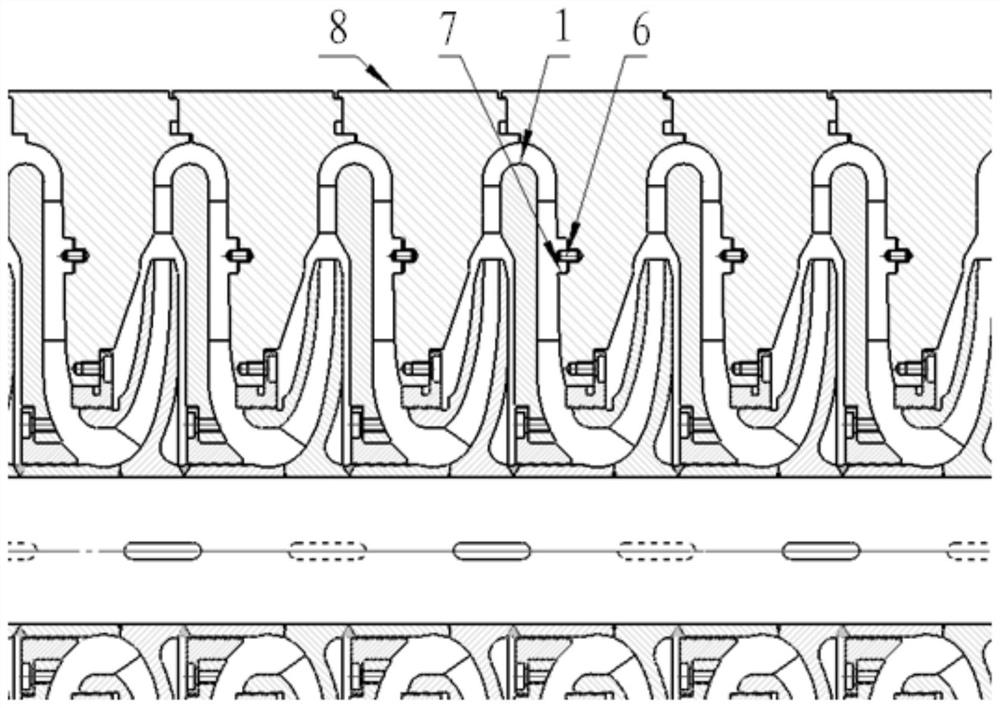

[0022] see figure 1 , a multi-stage centrifugal pump guide vane provided by an embodiment of the present invention, the guide vane is a curved guide vane 1, and the curved guide vane 1 is combined with the middle section 8 to form a fluid passage between the two the runner.

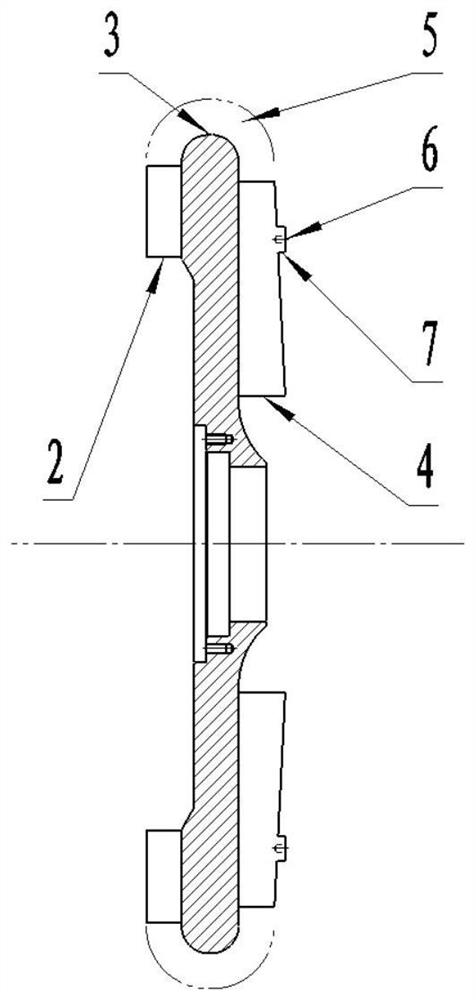

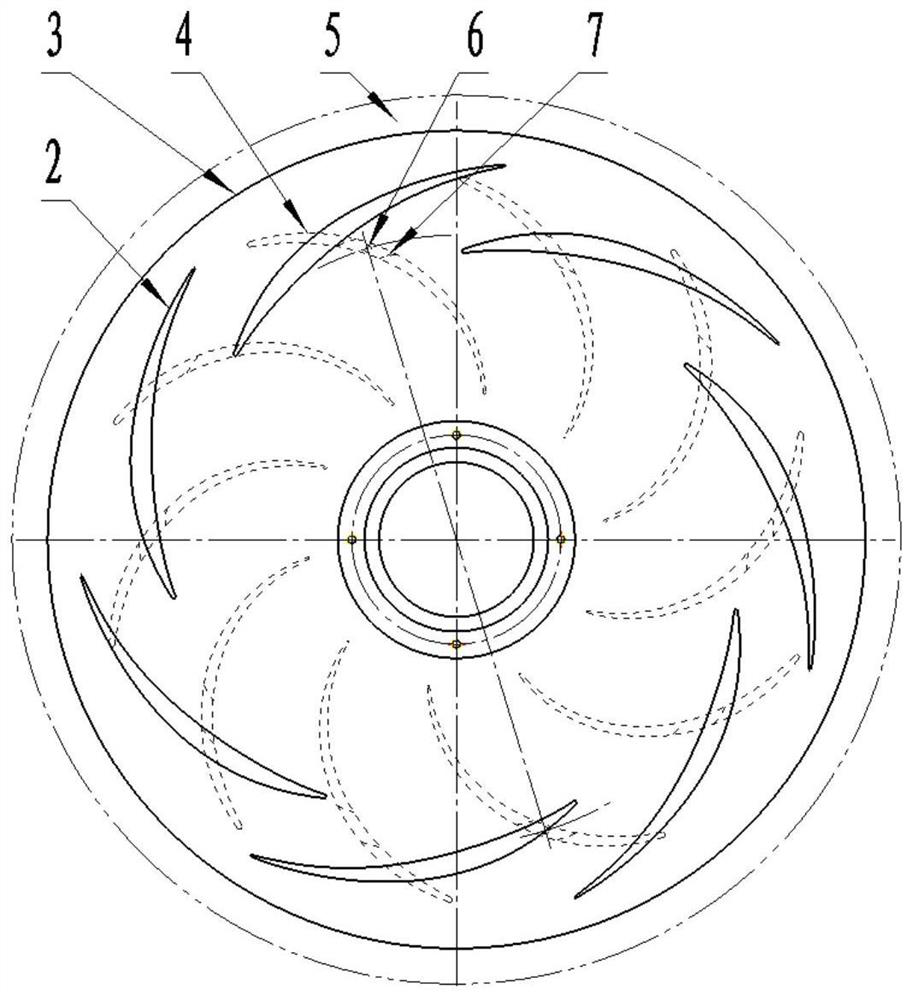

[0023] see figure 2 and image 3 , the curved guide vane 1 includes a forward guide vane 2 , a rear shroud 3 , a reverse guide vane 4 , and a bladeless bend 5 formed by flowing from the forward guide vane 2 to the reverse guide vane 4 . The forward guide vane 2 and the reverse guide vane 4 are respectively arranged on the front and rear of the rear cover 3 to form an integral body with the rear cover 3 . Among them, in order to facilitate the overall milling of the curved guide vane 1, the blades of the forward guide vane 2 and the reverse guide vane 4 both adopt binary blades with a blade inclination angle of 90°, that is, the blades are perpendicular to the rear cover plate 3 . When the fluid flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com