Water absorbent sheet

A water-absorbing sheet and water-absorbing technology, applied in the field of water-absorbing sheet, can solve the problems of leakage, the absorption performance may not show sufficient effect, etc., and achieve the effect of realizing leakage, avoiding the phenomenon of gel blocking, and realizing the phenomenon of gel blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

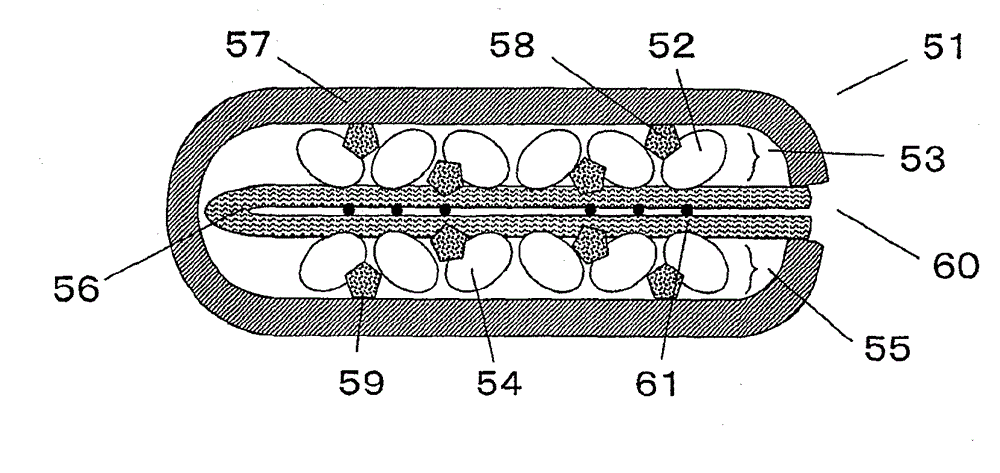

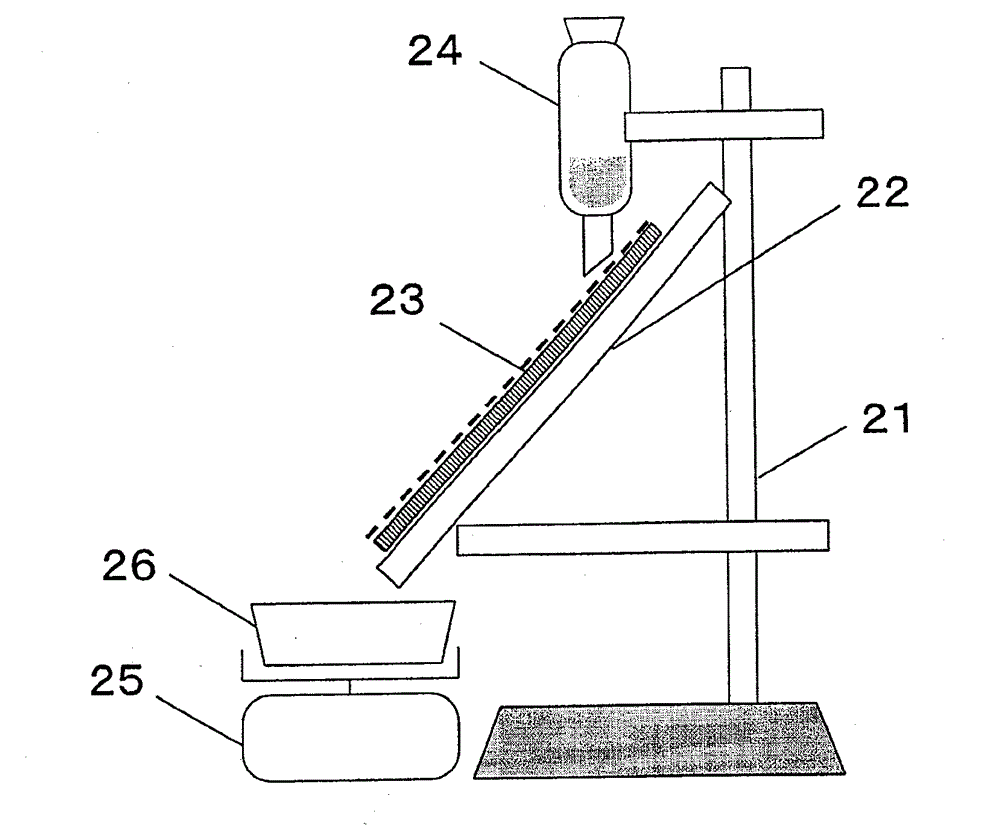

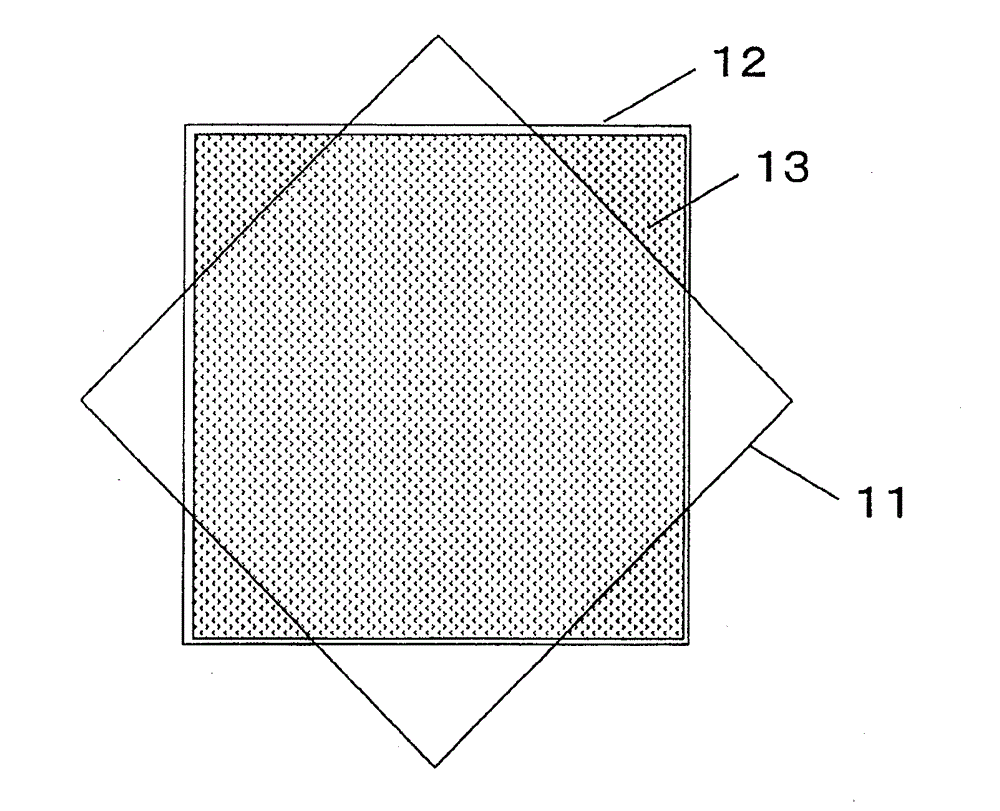

[0135] Add 55 parts by mass of ethylene-vinyl acetate copolymer (melting point 95° C., median particle size: 200 μm ), and 270 parts by mass of sodium polyacrylate cross-linked product A (manufactured by Sumitomo Seika Co., Ltd., Accurate SA55SX-11, median particle size: 360 μm, physiological saline water absorption speed: 42 seconds, physiological Salt water retention capacity: 35 g / g, abbreviated as "resin A" in the table) the mixture obtained by uniform mixing. On the other hand, lay a 30 cm wide nonwoven fabric A (rayon spunlace nonwoven fabric with a weight per unit area of 45 g / m2) on the conveyor belt at the lower part of the spreader. 2 , thickness: 400 μm, rayon content 100%), except image 3 All areas other than area A (width: 10 cm, interval between area A and B: 2 cm) are covered with paper. Then, the spreading roller and the lower conveyor belt are operated, so that the weight per unit area is 325 g / m 2 The above-mentioned mixture was uniformly laminated only...

Embodiment 2

[0141] Add 55 parts by mass of copolyester (melting point 80° C., median particle size: 150 μm) and 270 parts by mass of The resulting mixture was uniformly mixed with the cross-linked sodium polyacrylate A as a water-absorbent resin. On the other hand, lay a 30 cm wide nonwoven fabric C (rayon-PET spunlace nonwoven fabric with a weight per unit area of 50 g / m2) on the conveyor belt at the lower part of the spreader. 2 , thickness: 500 μm, rayon content 70%, PET content 30%), except Figure 4 All areas other than area C (width: 10 cm, interval between area C and D: 2 cm) were covered with paper. Then the spreader roller and the lower conveyor belt are run, so that the weight per unit area is 325 g / m 2 The above-mentioned mixture was uniformly laminated only at the region C of the above-mentioned nonwoven fabric.

[0142] The laminate was once again carefully laid down on the roller spreader belt, taking care not to shift the mixture, and then placed on Figure 4 Cover wi...

Embodiment 3

[0147] A nonwoven fabric C with a width of 30 cm was spread on a hot-melt coater (manufactured by Harries Co., Ltd.: Marshall 150) with the heating temperature set at 150°C, and then styrene-butadiene was coated on the nonwoven fabric. - Styrenic block copolymer (SBS, softening point 85° C.) as binder. The coating method is right Figure 4 The area C shown is based on a weight per unit area of 20 g / m 2 , a line width of 100 μm, and a weight per unit area of 5 g / m for area D 2 , Line width 60 μm for coating.

[0148] The cross-linked sodium polyacrylate A as a water-absorbent resin was charged into a feed port of a roll spreader (manufactured by Hashima Co., Ltd., Synter Ace M / C). On the other hand, the above-mentioned nonwoven fabric coated with adhesive is spread on the conveyor belt at the lower part of the spreader, except Figure 4 Areas other than C are covered with paper. Then, the spreader roller and the lower conveyor belt are operated, so that the weight per ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com