Color-stabilizing protective glaze, ceramic tile and preparation method of ceramic tile

A technology for color protection and ceramic tiles, applied in the field of ceramic tiles, can solve the problems that the true color of decorative ink cannot be stabilized, the influence of pattern color is large, etc., and achieves the effect of being conducive to repeated production and online, shortening the firing time, and small effect deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

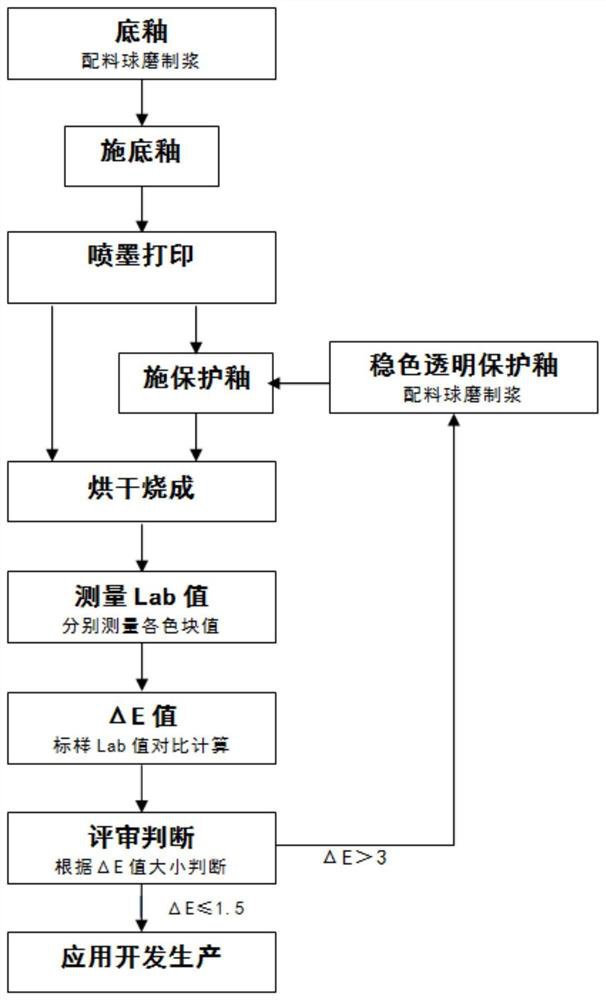

Method used

Image

Examples

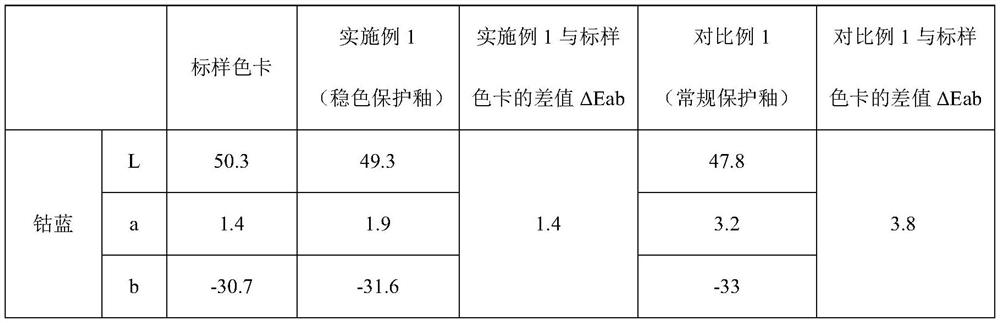

Embodiment 1

[0076] Preparation of ceramic tiles:

[0077] 1. Using the method of spraying glaze, the primer glaze slurry is applied to the green ceramic tile to obtain the primer glaze layer. Glazing process parameters: the specific gravity of the bottom glaze slurry is 1.75g / mL, the flow rate is 18s, and the glazing amount is 520g / m2 2 .

[0078] Wherein, by weight, the chemical composition of the bottom glaze includes:

[0079] SiO 2 49.91 parts, Al 2 O 3 19.67 parts, Fe 2 O 3 0.19 copies, K 2 O 1.16 parts, Na 2 3.52 parts of O, 7.55 parts of CaO, 2.36 parts of MgO, ZrO 2 12.39 parts, BaO 3.25 parts.

[0080] The bottom glaze slurry is prepared by the following steps:

[0081] After mixing the bottom glaze of the above chemical composition, 0.15 part of sodium carboxymethyl cellulose, 0.25 part of sodium tripolyphosphate and a certain amount of water, after ball milling for 12 hours, then using a 120-mesh sieve to filter and remove iron to obtain a bottom Glaze slurry, t...

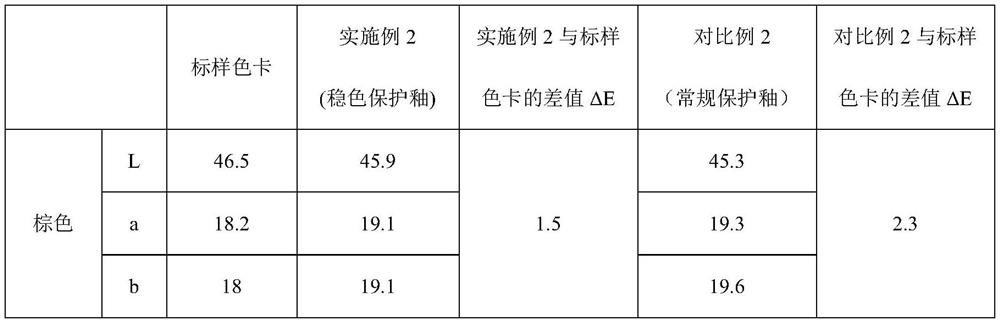

Embodiment 2

[0090] The only difference from Example 1 is that when the decorative pattern is printed by inkjet, the ink is brown ink with a gray value of 100%.

Embodiment 3

[0092] The only difference from Example 1 is that when the decorative pattern is printed by inkjet, the ink is an orange ink with a gray value of 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com