Hot rolled Q&P steel with 700MPa grade yield strength and ultralow yield ratio and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of wear-resistant steel, can solve the problems of difficult realization of ferrite, design of alloy composition without micro-Ti treatment, low strength, etc., and achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

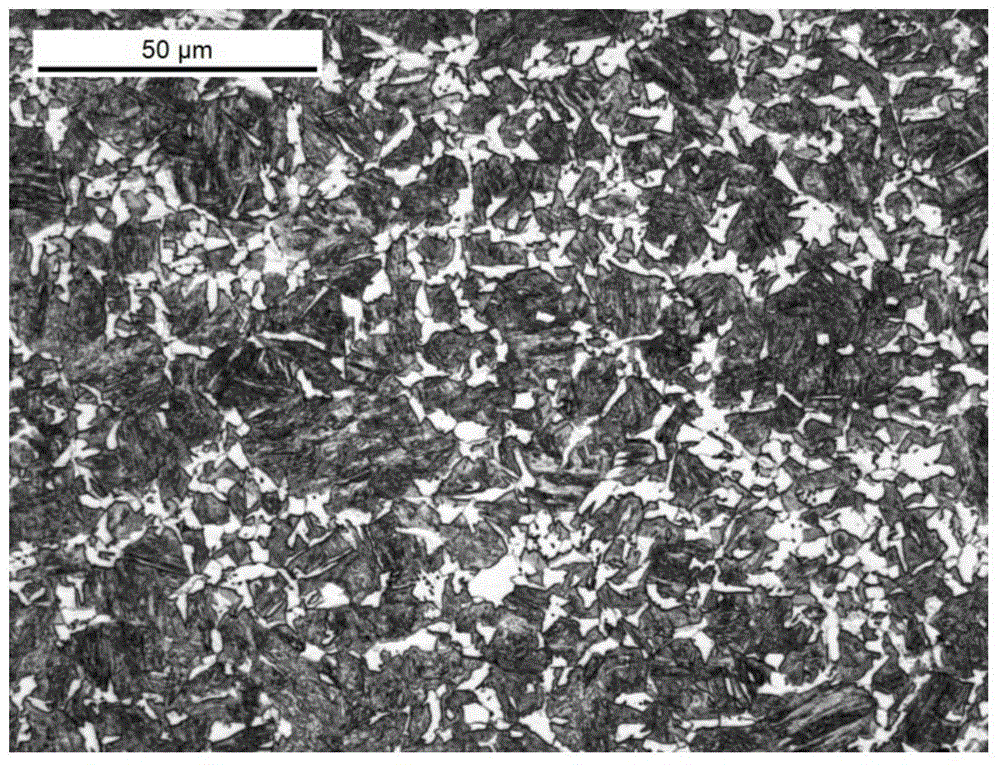

[0048] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

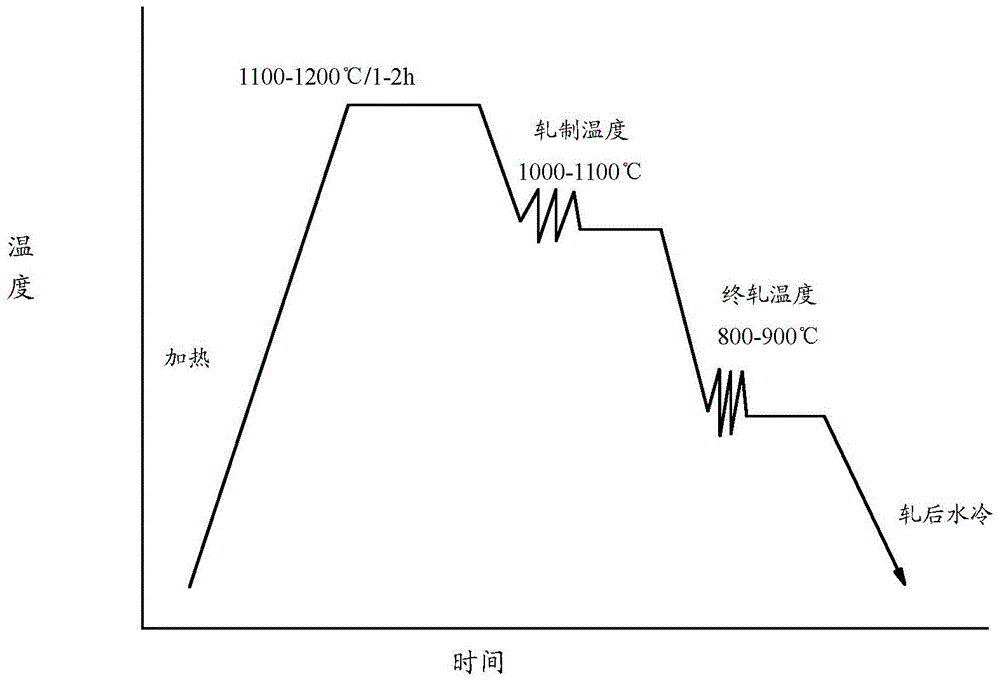

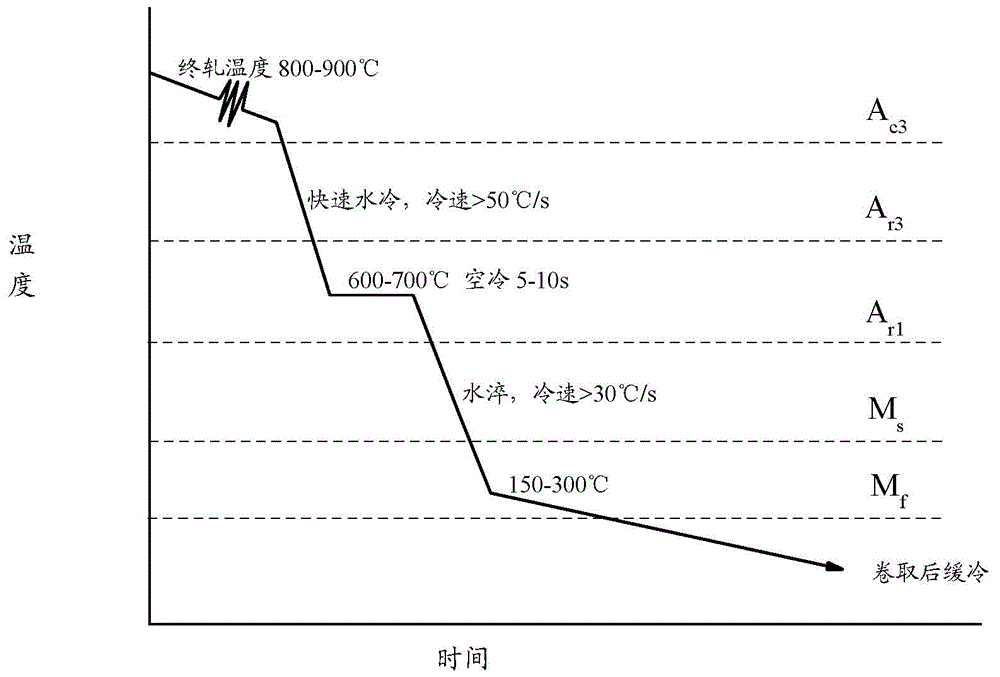

[0049] see figure 1 , figure 2 , the manufacture method of the ultra-low yield strength ratio hot-rolled Q&P steel of yield strength 700MPa grade of the present invention, comprises the steps:

[0050] 1) Smelting and casting

[0051] Converter or electric furnace smelting, vacuum furnace secondary refining, casting into slabs or ingots according to the following composition;

[0052] 2) Reheating of billet or ingot, heating temperature: 1100-1200°C, holding time: 1-2 hours;

[0053] 3) hot rolling

[0054] Rolling start temperature: 1000-1100°C, multi-pass high pressure above 950°C and cumulative deformation ≥ 50%, then the intermediate billet is heated to 900-950°C, and then rolled for the last 3-5 passes and Cumulative deformation ≥ 70%;

[0055] 4) Sectional cooling

[0056] Rapidly water-cool at a cooling rate of >50°C / s to 600-700°C above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com