Processing method of styrene butadiene rubber

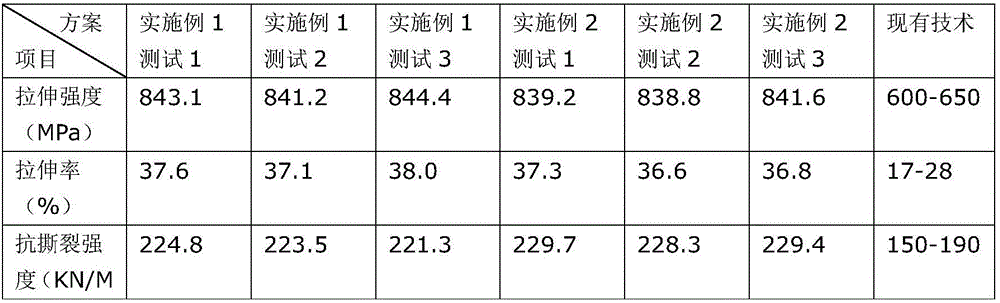

A processing method and technology of styrene-butadiene rubber, applied in the field of rubber processing, can solve the problems of large roughness of styrene-butadiene rubber, the strength and elongation rate cannot meet the demand, and the production process is complicated, and achieves high tear resistance and compression deformation. The effect of large and optimized internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The first processing method for p-styrene-butadiene rubber includes the following processing steps:

[0017] (1) Putting rubber into a pulverizer for pulverization and screening to form particles with a particle diameter of 12-13mm;

[0018] (2) Set the body temperature of the extruder to 62-63°C, the temperature of the machine head to 80°C, and the temperature of the extrusion port to 103°C, add the rubber particles into the extruder, and The heating and melting of the machine head forms a glue solution;

[0019] (3) heating for 5min, adding particle diameter in the extruder is the carbon black of 35mμ;

[0020] (4) After stirring the glue and carbon black for 2-3min, add zinc oxide with a particle size of 123-125mμ, and add calcium carbonate with a particle size of 35-38mμ after mixing;

[0021] (5) Apply paraffin oil at the outlet of the extruder, extrude the glue solution, and form the required styrene-butadiene rubber through cooling and molding.

Embodiment 2

[0023] The second processing method for p-styrene-butadiene rubber includes the following processing steps:

[0024] (1) put rubber into pulverizer and carry out pulverization and screening, form particle diameter and be the particle of 8mm;

[0025] (2) Set the body temperature of the extruder to 53-54°C, the temperature of the machine head to 74°C, and the temperature of the extrusion port to 100°C, add the rubber particles into the extruder, and The heating and melting of the machine head forms a glue solution;

[0026] (3) heating for 7min, adding particle diameter in the extruder is carbon black of 30-32mμ;

[0027] (4) After stirring the glue solution and carbon black for 2 minutes, add zinc oxide with a particle size of 121mμ, and add calcium carbonate with a particle size of 43-45mμ after mixing;

[0028] (5) Apply paraffin oil at the outlet of the extruder, extrude the glue, and form the required styrene-butadiene rubber through cooling and molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com