Titanium-microalloyed economical high-strength weathering steel and production method thereof

A technology of microalloying and production methods, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems that are unfavorable to the development of lightweight and thinning steel structures, reduce low-temperature impact toughness and welding performance, and high production costs. Excellent cold-bending performance, excellent strength and toughness matching, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

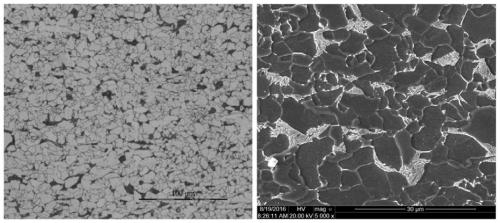

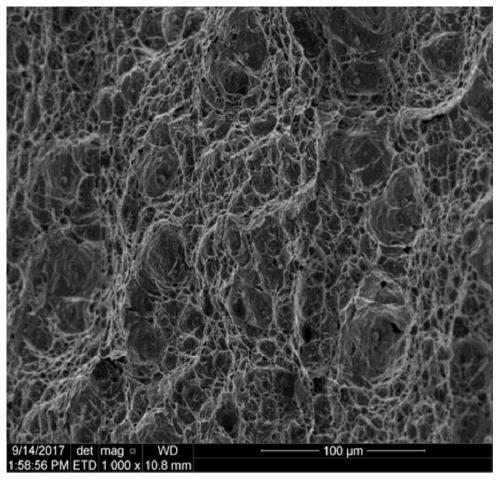

Image

Examples

Embodiment 1- Embodiment 3

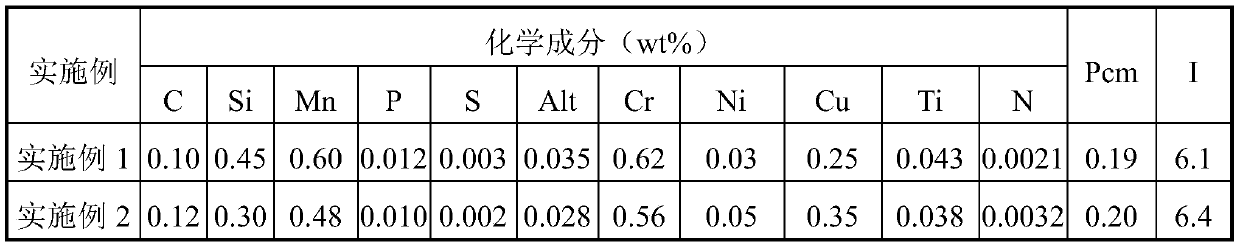

[0049] A titanium microalloyed economical high-strength weathering steel, said titanium microalloyed economical high-strength weathering steel contains the following chemical elements in mass percentage: see Table 1 below, the balance being Fe and unavoidable inclusions.

[0050] Table 1 The chemical composition (wt%) of the weathering steel of Example 1-3 of the present invention

[0051]

[0052]

[0053] The production method of titanium microalloyed economical high-strength weathering steel described in Examples 1-3 is produced by traditional hot continuous rolling process, including the following process flow: hot metal pretreatment deep desulfurization→converter top and bottom combined blowing→external refining→ Continuous casting → slab heating → controlled rolling → controlled cooling → coiling → finishing → delivery.

[0054] 1) The molten iron is pre-treated for deep desulfurization to [S]≤0.0050%. It is refined in an LF furnace. Calcium treatment is performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com