Al-Co-Cr-Ni quaternary high-entropy alloy system and preparation method thereof

An al-co-cr-ni, high-entropy alloy technology, applied in the field of Al-Co-Cr-Ni quaternary high-entropy alloy system and its preparation, can solve the problems of poor plasticity matching of high-entropy alloys, and achieve strong Good plasticity matching, excellent mechanical properties, and the effect of enriching the high-entropy alloy system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

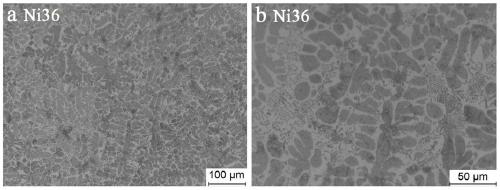

[0029] An Al-Co-Cr-Ni quaternary high-entropy alloy system, the chemical composition of the high-entropy alloy system is designed according to the atomic ratio: Al a co b Cr c Ni d ; Wherein, a=20, b=24, c=20, d=36, that is, the high-entropy alloy system is expressed as Al 20 co 24 Cr 20 Ni 36 , abbreviated as Ni36.

[0030] In this embodiment, the preparation method of the Al-Co-Cr-Ni quaternary high-entropy alloy system has the following steps:

[0031] 1) Use No. 60 SiC sandpaper to remove impurities and oxides on the surface of the metal elements Al, Co, Cr, and Ni, then use acetone to ultrasonically vibrate and clean twice, dry, and set aside;

[0032] Specifically, acetone is used as a cleaning solution to carry out ultrasonic vibration cleaning to achieve the purpose of cleaning surface impurities; the power density of the ultrasonic vibration cleaning is 0.8W / cm 2 , the frequency is 33Hz, and the purity of the metal elements Al, Co, Cr and Ni is higher than 99....

Embodiment 2

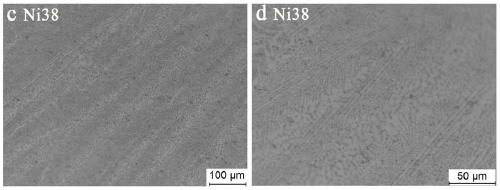

[0038] An Al-Co-Cr-Ni quaternary high-entropy alloy system, the chemical composition of the high-entropy alloy system is designed according to the atomic ratio: Al a cob Cr c Ni d ; Wherein, a=18, b=24, c=20, d=38, that is, the high-entropy alloy system is expressed as Al 18 co 24 Cr 20 Ni 38 , abbreviated as Ni38.

[0039] In this embodiment, the preparation method of the Al-Co-Cr-Ni quaternary high-entropy alloy system has the following steps:

[0040] 1) Use a grinder to remove impurities and oxides on the surface of the metal elements Al, Co, Cr and Ni, then use acetone to ultrasonically vibrate and clean twice, dry, and set aside;

[0041] Specifically, acetone is used as a cleaning solution to carry out ultrasonic vibration cleaning to achieve the purpose of cleaning surface impurities; it can be understood that the parameters of the ultrasonic vibration cleaning are limited and selected according to requirements, and there is no limitation here, as long as the sur...

Embodiment 3

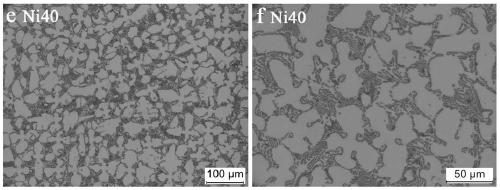

[0046] An Al-Co-Cr-Ni quaternary high-entropy alloy system, the chemical composition of the high-entropy alloy system is designed according to the atomic ratio: Al a co b Cr c Ni d ; Wherein, a=16, b=24, c=20, d=40, that is, the high-entropy alloy system is expressed as Al 16 co 24 Cr 20 Ni 40 , abbreviated as Ni40.

[0047] In this embodiment, the preparation method of the Al-Co-Cr-Ni quaternary high-entropy alloy system has the following steps:

[0048] 1) Use No. 60 SiC sandpaper or a grinder to remove impurities and oxides on the surface of the metal elements Al, Co, Cr and Ni, then use acetone to ultrasonically vibrate and clean twice, dry, and set aside; specifically, by using acetone Ultrasonic vibration cleaning is performed as a cleaning solution to achieve the purpose of cleaning surface impurities; the power density of the ultrasonic vibration cleaning is 0.8W / cm 2 , the frequency is 33Hz, and the purity of the metal elements Al, Co, Cr and Ni is higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com