Preparation method for manufacturing low-cost ultrafine grain transformation-induced plastic steel seamless tube online

A technology of phase change induced plasticity and ultra-fine grain, which is applied in the field of steel pipe preparation, can solve the problems of no further detailed analysis of the mechanical properties of grain ultra-fine, difficult process control, complex process, etc., to achieve low cost, Process stability and the effect of increasing the grain boundary area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The chemical composition of the steel used in this embodiment is C: 0.101%, Si: 1.80%, Mn: 1.09%, P: 0.002%, S: 0.005%, and the balance is Fe. Its A is measured from the thermal expansion curve c1 and A c3 721 and 849°C, respectively. said A c1 is the starting temperature of ferrite to austenite transformation during annealing heating process, A c3 It is the end temperature of ferrite to austenite transformation during the annealing heating process. Due to the different composition of steel (such as changes in carbon content, silicon content, etc.) and changes in process parameters (such as heating rate), A c1 ﹑A c3 will change accordingly. The steel that the present invention adopts records its A by thermal expansion curve c1 and A c3 .

[0048] The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube blank. The tube blank is heated to 1100°C and kept for 2 hours before piercing, and then ...

Embodiment 2

[0058] The chemical composition of the steel used in this embodiment is C: 0.16%, Si: 1.35%, Mn: 1.51%, P: 0.005%, S: 0.007%, and the balance is Fe. Its A is measured from the thermal expansion curve c1 and A c3 735 and 870°C, respectively.

[0059] The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube blank. The tube blank is heated to 1100°C and kept for 2 hours before piercing, and then cooled to room temperature. The tube blank is cold-drawn for 4 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 2.1 mm and an outer diameter of 53 mm.

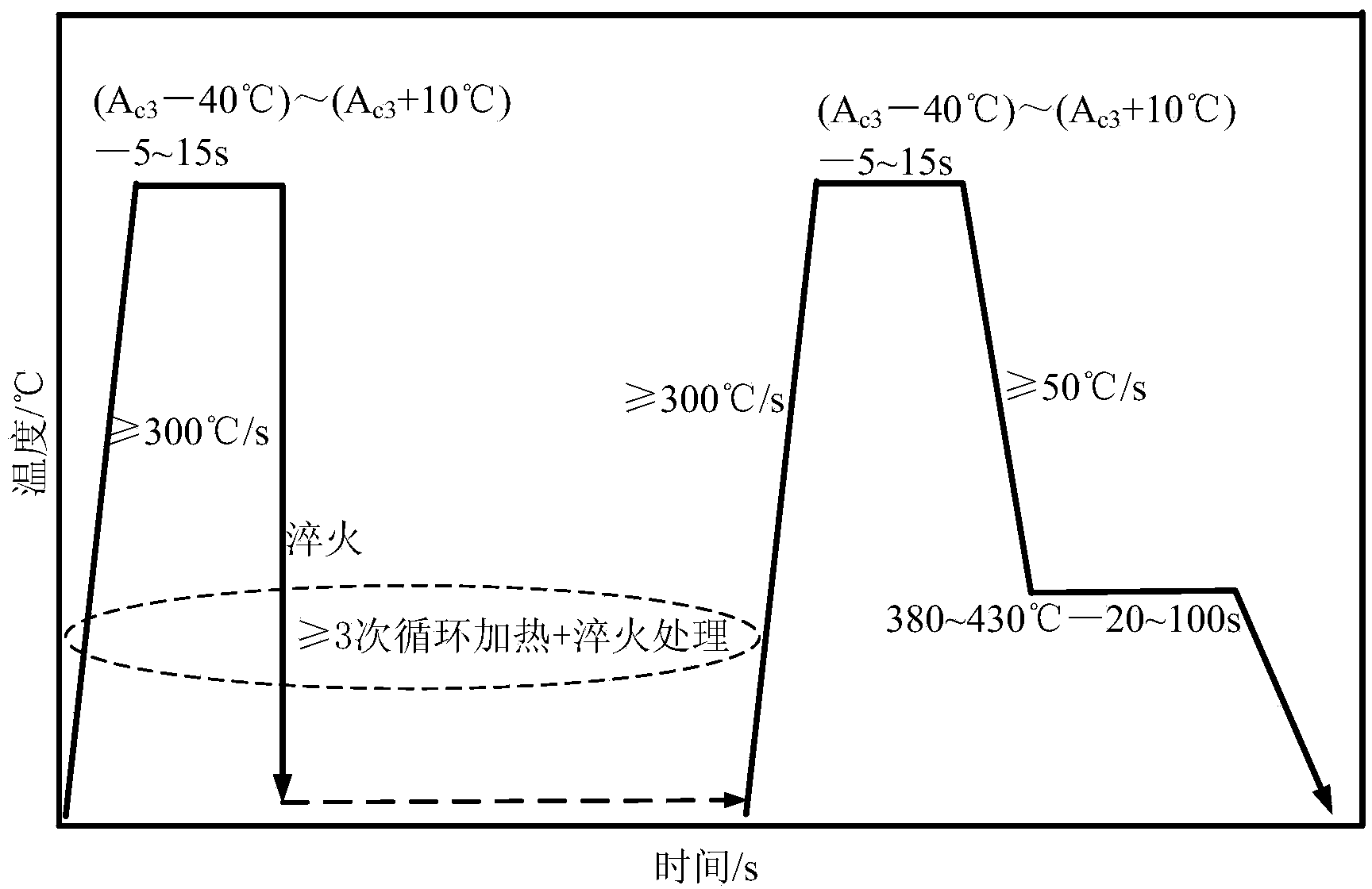

[0060] The seamless cold-drawn steel pipe is subjected to 4 cycles of heating + quenching treatment with a medium-frequency heating induction coil. The specific annealing process parameters are shown in Table 2. The heating rate is about 400 °C / s, and the annealing temperature (A c3 -40℃)~(A c3 +10℃), the annealing time is 5~15s. Cool th...

Embodiment 3

[0067] The chemical composition of the steel used in this embodiment is C: 0.184%, Si: 1.00%, Mn: 1.87%, P: 0.006%, S: 0.003%, and the balance is Fe. Its A is measured from the thermal expansion curve c1 and A c3 730 and 850°C, respectively.

[0068] The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube billet. The tube billet is heated to 1200°C and kept for 2 hours before piercing, and then cooled to room temperature. The tube blank is cold-drawn for 4 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 1.20 mm and an outer diameter of 43 mm.

[0069] The seamless cold-drawn steel pipe is subjected to 4 cycles of heating + quenching treatment with an intermediate frequency heating induction coil. The specific annealing process parameters are shown in Table 3, in which the heating rate is about 300°C / s, and the annealing temperature (A c3 -40℃)~(A c3 +10℃), the annealing time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com