Preparation method of hot-working-state cobalt-based alloy rod wire

A cobalt-based alloy and hot-working technology, which is applied to the preparation of hot-worked cobalt-based alloy rods and wires, and the field of hot-worked CoCrMo alloy rods and wires, can solve the problem of not being able to meet the production needs of domestic medical devices, affecting product promotion and application, Affect product quality and other problems, achieve uniform structure and mechanical properties, good strong-plastic matching, and achieve the effect of strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

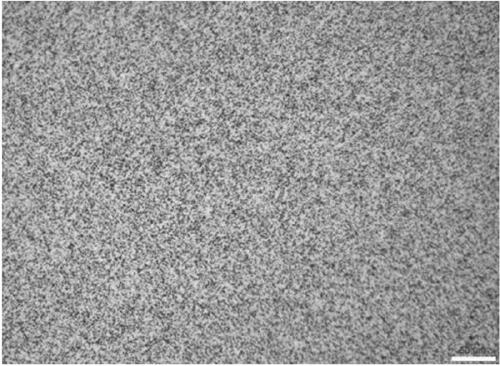

Embodiment 1

[0034] In this embodiment, the chemical composition of the cobalt-based alloy is: Cr 28.0%, Mo 6.0%, Ni 0.6%, C 0.08%, Fe 0.5%, Si 0.3%, Mn 0.4%, N 0.27%, and the rest The amount is Co.

[0035] The preparation method of this cobalt-based alloy rod is as follows:

[0036] Step 1. Using metal Co, metal Cr, metal Mo, metal Ni, metal Fe, metal Mn, elemental Si and elemental C, according to the composition of the cobalt-based alloy, the vacuum induction melting and electroslag remelting process is used to prepare a Φ170mm diameter casting ingot.

[0037] Step 2: Carry out homogenization heat treatment on the cobalt-based alloy ingot: choose the homogenization heat treatment system at 1170° C., keep it warm for 20 hours, and air-cool to room temperature.

[0038] Step 3. Forging the homogenized heat-treated cobalt-based alloy ingot to Φ150mm: use an air hammer or a fast forging machine to forge the billet. The forging temperature is 1200°C, hold for 6 hours, and the final forging...

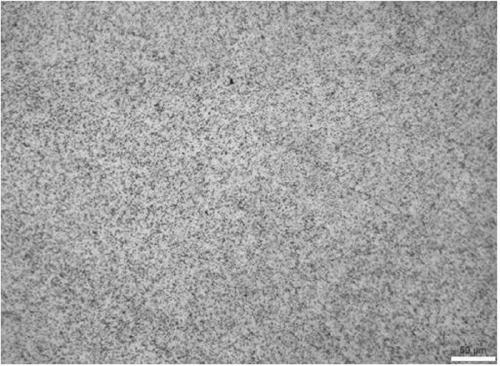

Embodiment 2

[0044] In this embodiment, the chemical composition of the cobalt-based alloy is: Cr 27.0%, Mo 6.5%, Ni 0.5%, C 0.06%, Fe 0.6%, Si 0.7%, Mn 0.6%, N 0.32%, and the rest The amount is Co.

[0045] The preparation method of this cobalt-based alloy rod is as follows:

[0046] Step 1. Using metal Co, metal Cr, metal Mo, metal Ni, metal Fe, metal Mn, elemental Si and elemental C, according to the composition of the cobalt-based alloy, the vacuum induction melting and electroslag remelting process is used to prepare a Φ170mm diameter casting ingot.

[0047] Step 2: Carry out homogenization heat treatment on the cobalt-based alloy ingot: select the homogenization heat treatment system at 1190° C., keep it warm for 10 hours, and air-cool to room temperature.

[0048]Step 3. Forging the homogenized heat-treated cobalt-based alloy ingot to Φ150mm: choose a fast forging machine for billet forging, the forging temperature is 1190°C, hold for 6 hours, and the final forging temperature is ...

Embodiment 3

[0055] In this embodiment, the chemical composition of the cobalt-based alloy is: Cr 29.0%, Mo 5.5%, Ni 0.4%, C 0.04%, Fe 0.3%, Si 0.1%, Mn 0.5%, N 0.16%, and the rest The amount is Co.

[0056] The preparation method of this cobalt-based alloy rod is as follows:

[0057] Step 1. Using metal Co, metal Cr, metal Mo, metal Ni, metal Fe, metal Mn, elemental Si and elemental C, according to the composition of the cobalt-based alloy, the vacuum induction melting and electroslag remelting process is used to prepare a Φ170mm diameter casting ingot.

[0058] Step 2: Perform homogenization heat treatment on the cobalt-based alloy ingot: select the homogenization heat treatment system as 1200° C., keep the temperature for 10 hours, and air-cool to room temperature.

[0059] Step 3: Forging the homogenized heat-treated cobalt-based alloy ingot to Φ150mm: choose a fast forging machine for billet forging, the forging temperature is 1200°C, hold for 6 hours, and the final forging temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com