Processing method for Ti2AlNb alloy wide thin plate

A processing method and alloy technology, applied in metal rolling, temperature control, etc., can solve the problems of poor processing plasticity, thin plate difficulty, difficulty, etc., achieve good matching of strength and plasticity, complete technical scheme, and reduce edge cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

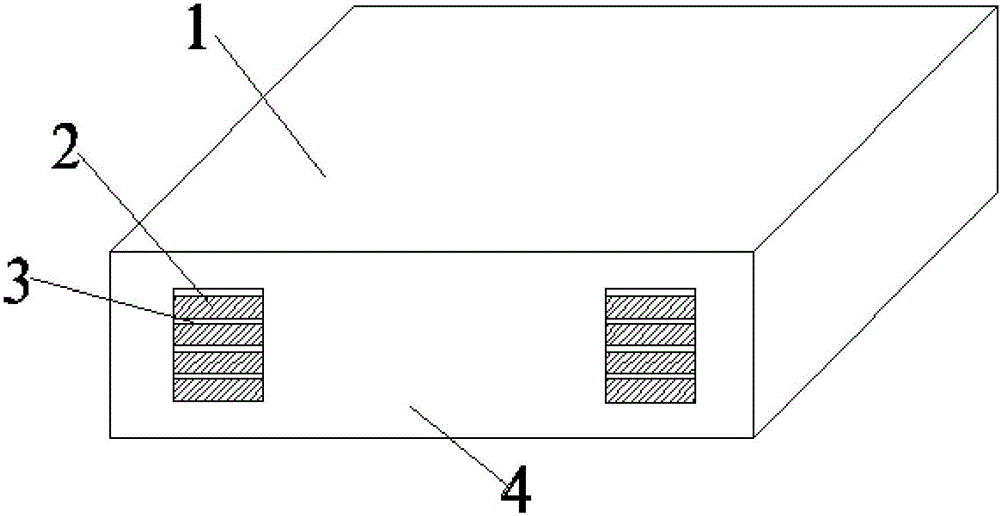

[0032] This embodiment processes Ti 2 The method for AlNb alloy wide sheet comprises the following steps:

[0033] Step 1. Ti 2 The AlNb alloy slab is placed at a temperature of (T β -30) ° C heating furnace for 30min, then sent to the hot rolling mill for 5 passes of the first rolling, the first rolling is unidirectional rolling, the rolling rate of the first rolling is 1.0m / s, the deformation of each pass is 15.00%, 13.97%, 12.82%, 11.76%, 11.11%, and the total deformation is 50%. In the first rolling process, an infrared thermometer is used to measure Ti 2 The surface temperature of the AlNb alloy slab is monitored, when the temperature is lower than (T β -150)℃, the Ti 2 The AlNb alloy slab is placed in the heating furnace for reheating to ensure that the Ti in the first rolling process 2 The temperature of the AlNb alloy slab is at (T β -150)℃~(T β -90) ℃; Obtaining the first semi-finished slab whose size is 8mm (thick) × 800mm (wide) × 2000mm (long);

[0034] Ste...

Embodiment 2

[0040] This embodiment processes Ti 2 The method for AlNb alloy wide sheet comprises the following steps:

[0041] Step 1. Ti 2 The AlNb alloy slab is placed at a temperature of (T β -90) ℃ heating furnace insulation 15min, then sent to the hot rolling mill for 5 passes of the first rolling, the first rolling is unidirectional rolling, the rolling rate of the first rolling is 2.0m / s, the deformation of each pass is 15.00%, 14.12%, 13.70%, 12.70%, 9.09%, and the total deformation is 50%. In the first rolling process, an infrared thermometer is used to measure Ti 2 The surface temperature of the AlNb alloy slab is monitored, when the temperature is lower than (T β -150)℃, the Ti 2 The AlNb alloy slab is placed in the heating furnace for reheating to ensure that the Ti in the first rolling process 2 The temperature of the AlNb alloy slab is at (T β -150)℃~(T β -90) ℃; Obtaining the first semi-finished slab whose size is 5mm (thick) × 1200mm (wide) × 2400mm (long);

[0042...

Embodiment 3

[0047] This embodiment processes Ti 2 The method for AlNb alloy wide sheet comprises the following steps:

[0048] Step 1. Ti 2 The AlNb alloy slab is placed at a temperature of (T β -60) ° C heating furnace for 22.5min, then sent to the hot rolling mill for 5 passes of the first rolling, the first rolling is unidirectional rolling, the rolling of the first rolling The speed is 1.5m / s, the deformation of each pass is 12.31%, 11.40%, 10.89%, 8.78%, 5.00%, and the total deformation is 40%. In the first rolling process, an infrared thermometer is used to measure Ti 2 The surface temperature of the AlNb alloy slab is monitored, when the temperature is lower than (T β -150)℃, the Ti 2 The AlNb alloy slab is placed in the heating furnace for reheating to ensure that the Ti in the first rolling process 2 The temperature of the AlNb alloy slab is at (T β -150)℃~(T β -90) ℃; Obtaining the first semi-finished slab whose size is 7.8mm (thick) × 1500mm (wide) × 2500mm (long);

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com