High-performance weather-proof building structural steel and manufacturing method thereof

A technology for building structural steel and a manufacturing method, which is applied in the field of unpainted large-scale bridge structure manufacturing materials and high-rise building structures, and can solve the problems of poor toughness and weldability of base metal steel plates, poor impact toughness, and reduced strength of microstructure steel plates. , to achieve the effect of low yield ratio, excellent strength and toughness, excellent weldability and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The manufacturing process is as follows:

[0067] TDS molten iron deep desulfurization → converter smelting → LF → RH (feeding Si-Ca wire) → continuous casting (using light reduction process) → slab off-line finishing → slab cutting to length → heating → TMCP → slow cooling of steel plate →AUT / MUT (automatic / manual flaw detection)→Steel edge trimming, head and tail trimming→sampling and performance testing→cutting to length steel plates→surface quality and appearance dimensions, marking and testing→delivery.

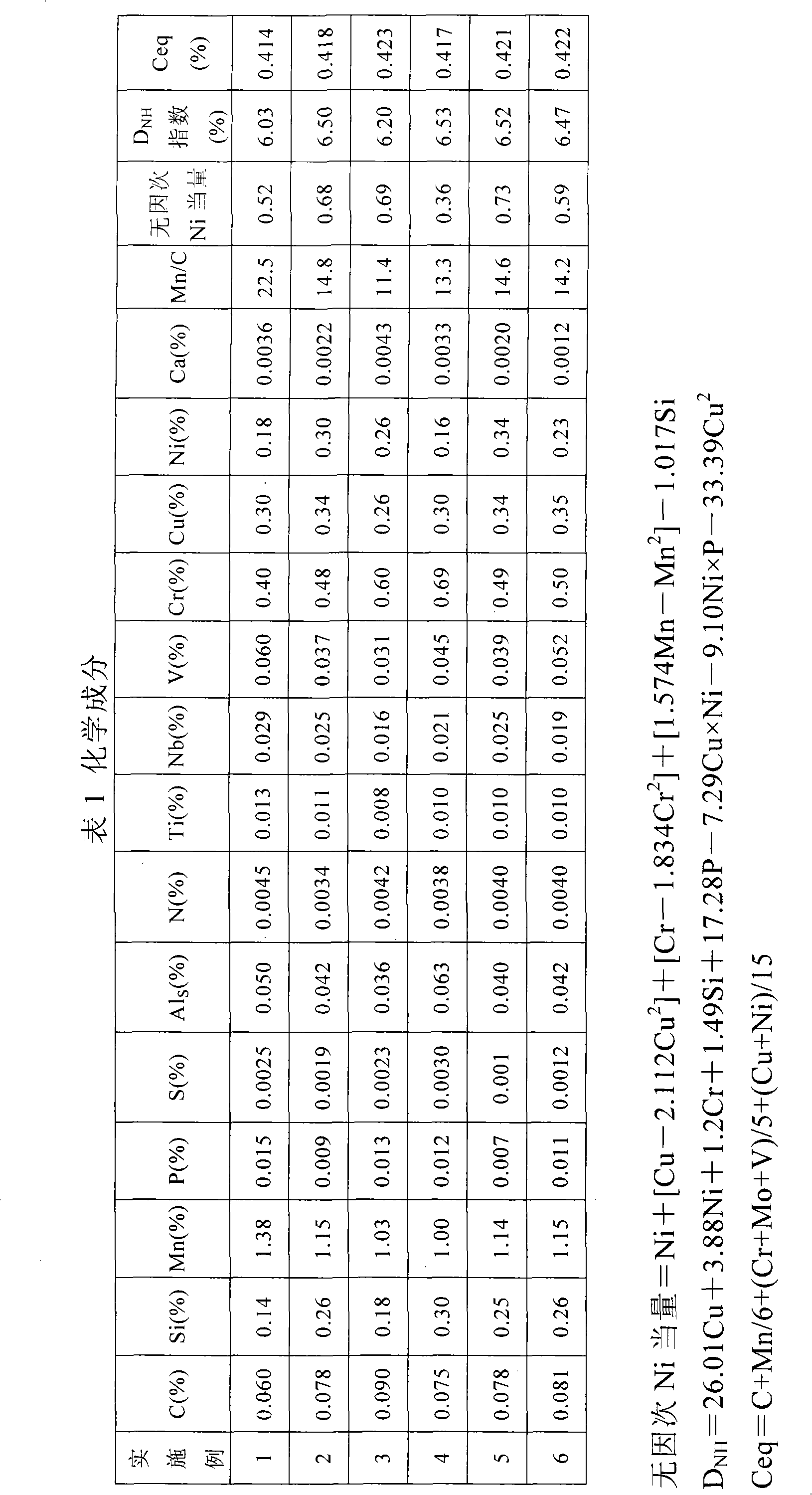

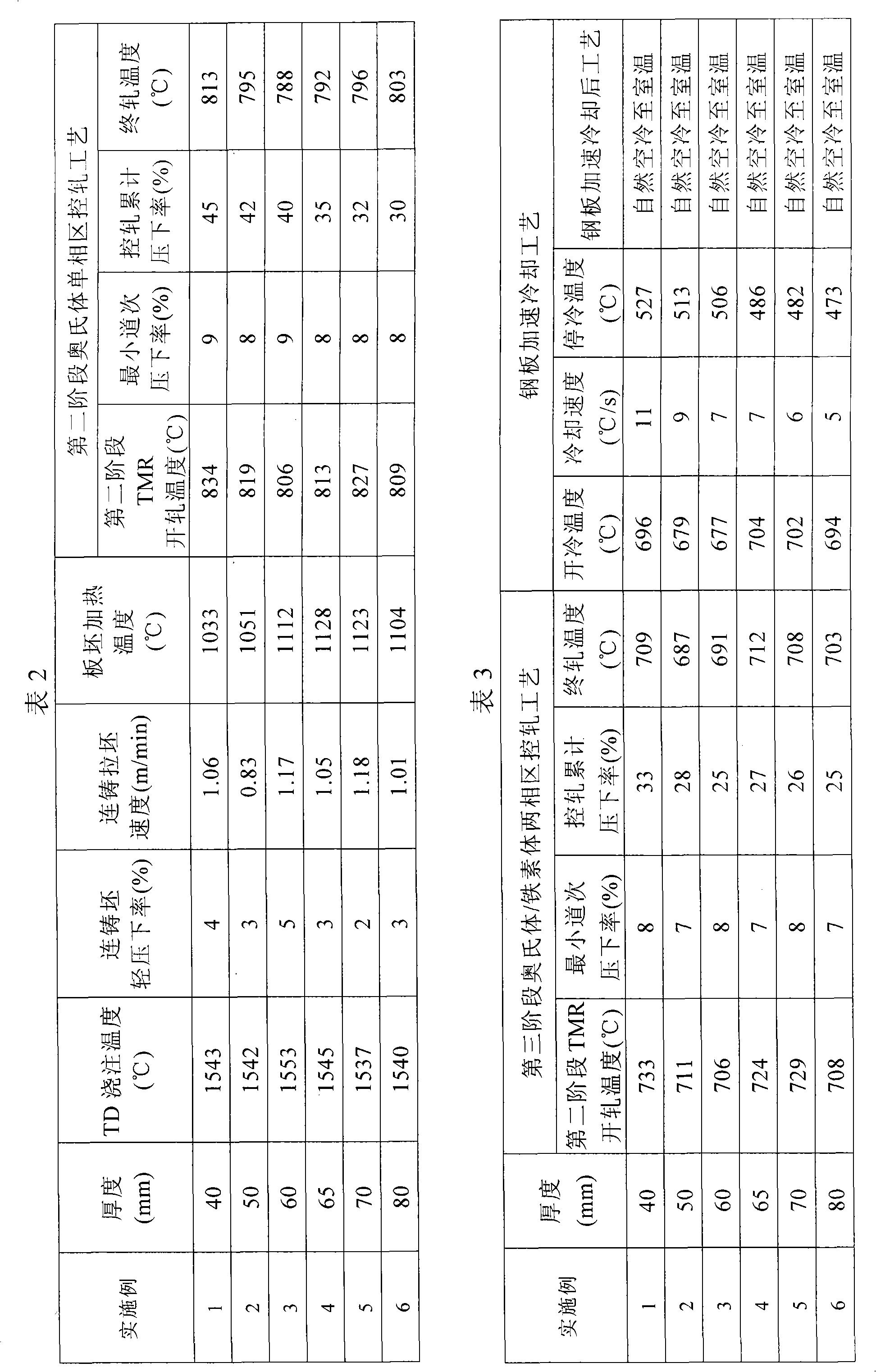

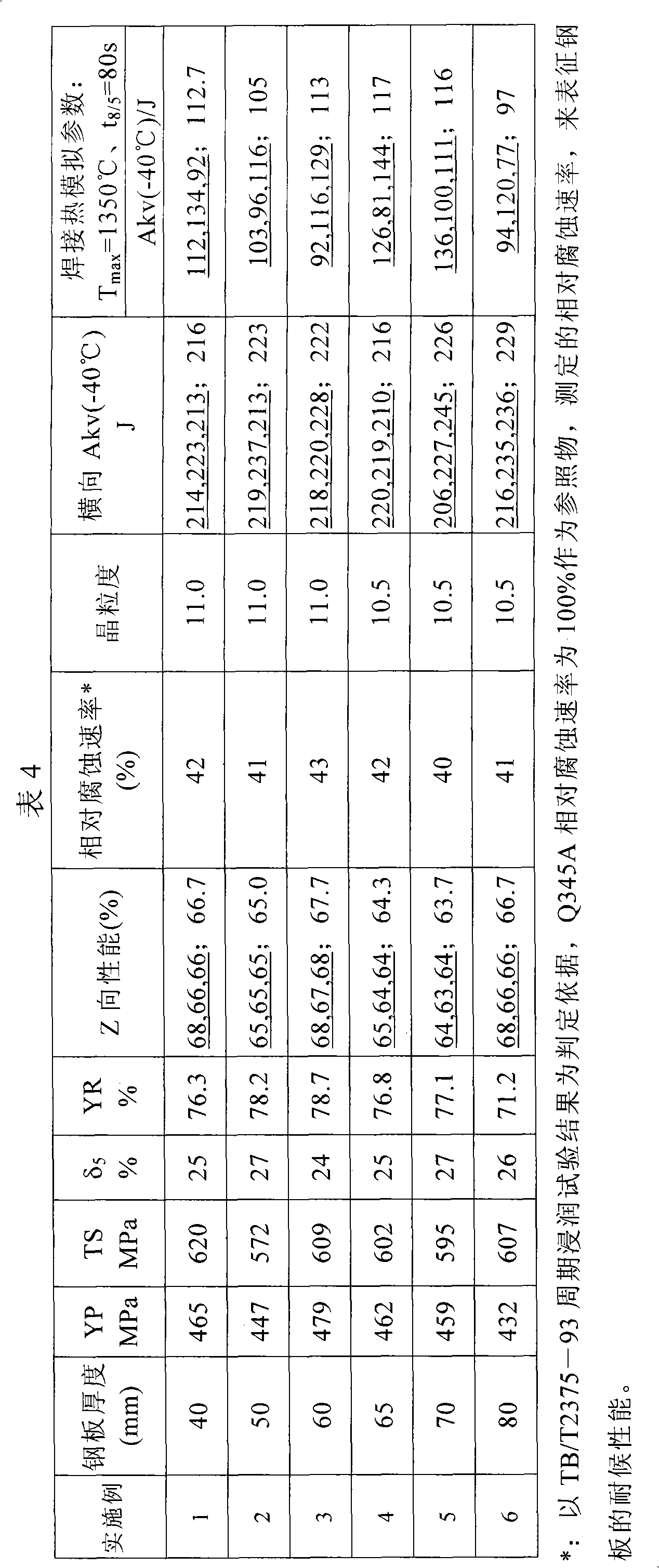

[0068] Examples See Table 1 for the chemical composition, Table 2 and Table 3 for the manufacturing process, and Table 4 for the performance of the steel plate.

[0069]

[0070]

[0071]

[0072] According to the technical characteristics of the steel plate of the present invention, the steel plate of the present invention combines the reasonable combination design of alloy elements with the special TMCP process, and the steel plate can obtain excellent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com