Preparation method of mining hard alloy of ultra-thick mixcrystal structure

A technology of cemented carbide and crystal structure, which is applied in the field of preparation of cemented carbide raw material powder, can solve the problems of reducing the thermal fatigue resistance of the alloy, uneven distribution of the bonding phase, and low toughness of the cemented carbide, so as to improve the thermal fatigue. performance, retention of hardness and wear resistance, effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of ultra-coarse mixed crystal structure mining cemented carbide, prepared according to the following steps:

[0024] (1) Dissolve 25.8 g of cobalt oxalate in absolute ethanol, and the mass ratio of cobalt oxalate to absolute ethanol is 1:1.

[0025] (2) Heat the above solution to 60°C while stirring, according to hydrazine: Co 2+ Add hydrazine at a molar ratio of 1:2, then add ammonia to keep the pH value of the solution at 8.5, then add the activator cetyltrimethylammonium bromide, the mass of cetyltrimethylammonium bromide in the solution The percentage is 5%.

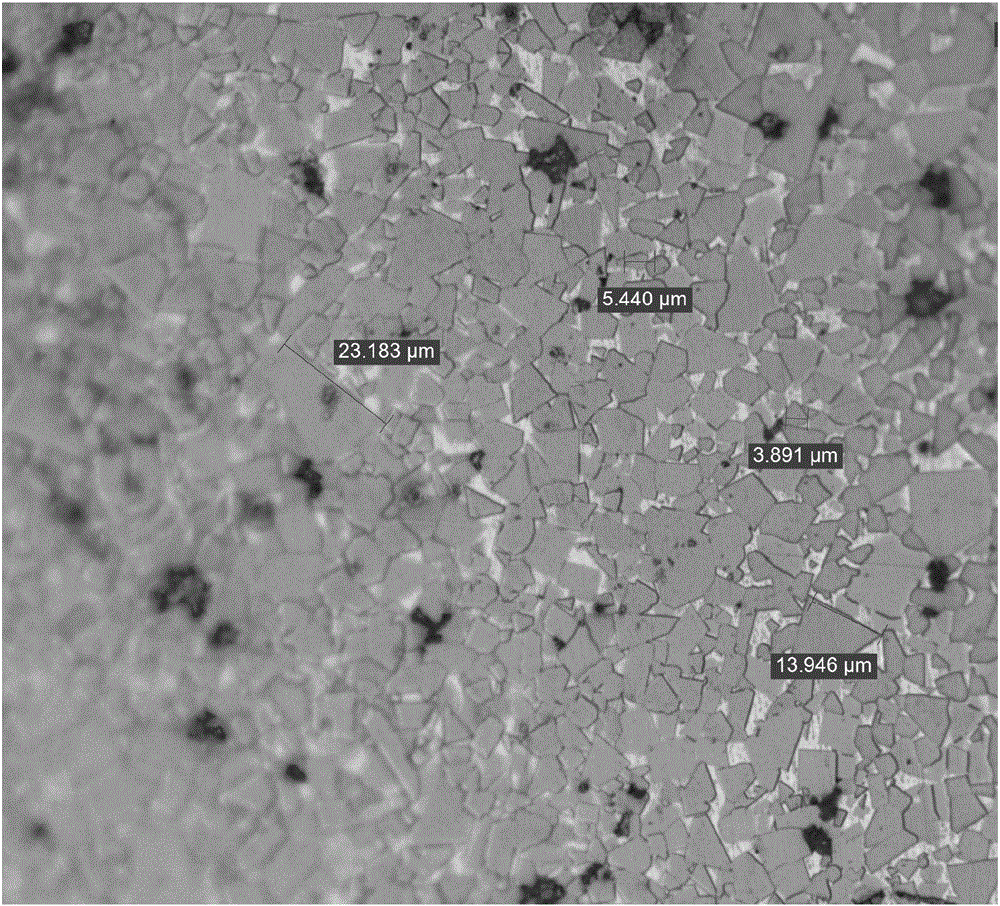

[0026] (3) Add WC to the solution in step 2. The weight ratio of WC to cobalt in step 2 is 85:15. According to the weight percentage, WC is composed of 65% 20-26 μm WC, 35% 3-4 μm WC, and the total carbon is 6.14 .

[0027] (4) The mixed solution obtained in step (3) is ultrasonically oscillated, and the temperature of the mixed solution is kept at 60-70°C, and then the mixed solution i...

Embodiment 2

[0033] A preparation method of ultra-coarse mixed crystal structure mining cemented carbide, prepared according to the following steps:

[0034] (1) Dissolve 32.3 g of cobalt oxalate in absolute ethanol, and the mass ratio of cobalt oxalate to absolute ethanol is 2.5:1.

[0035] (2) Heat the above solution to 40°C while stirring, according to hydrazine: Co 2+ Add hydrazine at a molar ratio of 1: 1.5, then add ammonia to keep the pH value of the solution at 12, then add the activator cetyltrimethylammonium bromide, the mass of cetyltrimethylammonium bromide in the solution The percentage is 8%.

[0036] (3) Add WC to the solution in step 2. The weight ratio of WC to cobalt in step 2 is 90:10. WC consists of 65g of 20-26μmWC and 25g of 3-4μmWC, with a total carbon of 6.14.

[0037] (4) ultrasonically oscillate the mixed solution obtained in step (3), and keep the temperature of the mixed solution at 60-70° C., place the above solution in an inert gas environment for reaction, ...

Embodiment 3

[0043] A preparation method of ultra-coarse mixed crystal structure mining cemented carbide, prepared according to the following steps:

[0044] (1) Dissolve 32.5 g of cobalt oxalate in absolute ethanol, and the mass ratio of cobalt oxalate to absolute ethanol is 5:1.

[0045] (2) Heat the above solution to 50°C while stirring, according to hydrazine: Co 2+ Add hydrazine at a molar ratio of 1: 2.5, then add ammonia to keep the pH value of the solution at 8.5, then add the activator cetyltrimethylammonium bromide, the mass of cetyltrimethylammonium bromide in the solution The percentage is 5%.

[0046] (3) Add WC to the solution in step 2. The weight ratio of WC to cobalt in step 2 is 94:6. According to the weight, WC consists of 60% 20-26μmWC, 40% 3-4μmWC, and the total carbon is 6.17 .

[0047](4) ultrasonically oscillate the mixed solution obtained in step (3), and keep the temperature of the mixed solution at 60-70° C., place the above solution in an inert gas environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com