Metal aluminum pore filling method

A technology of metal aluminum and process conditions, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of cracks and cavities in the film, low step coverage, and large heat dissipation of wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

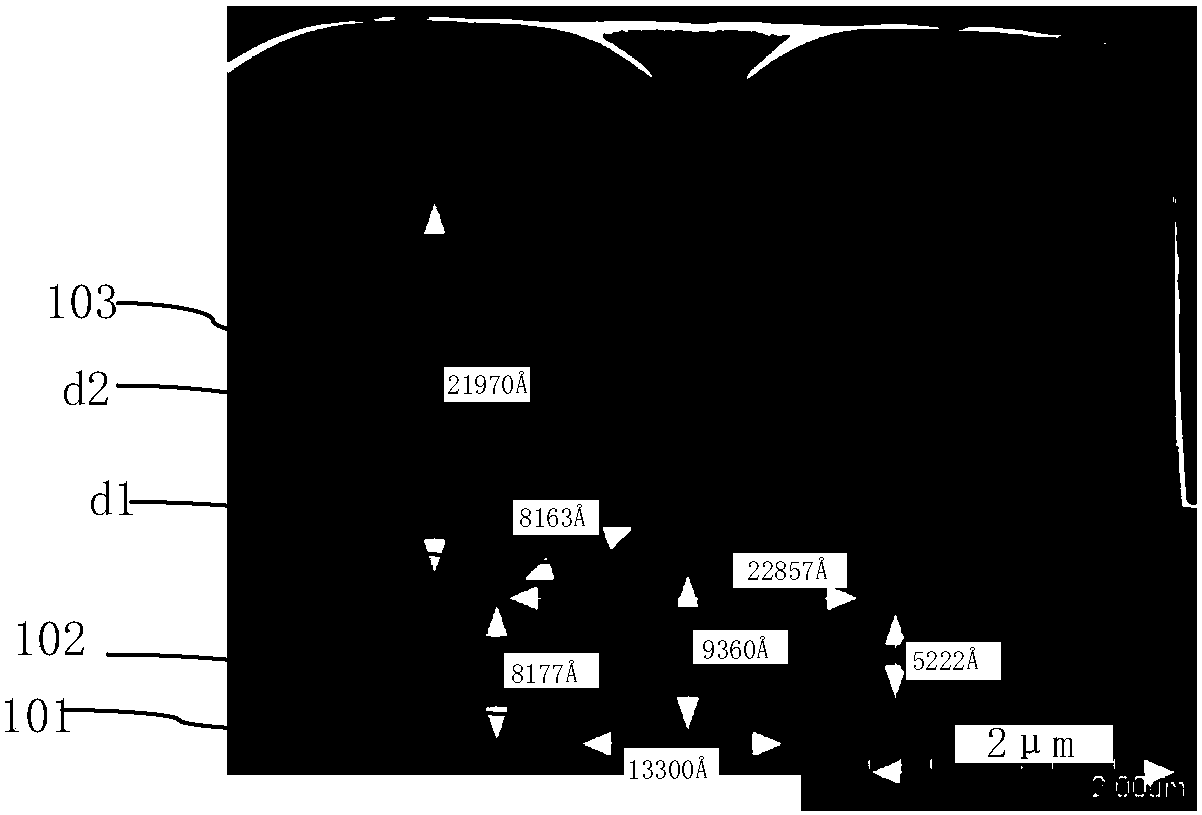

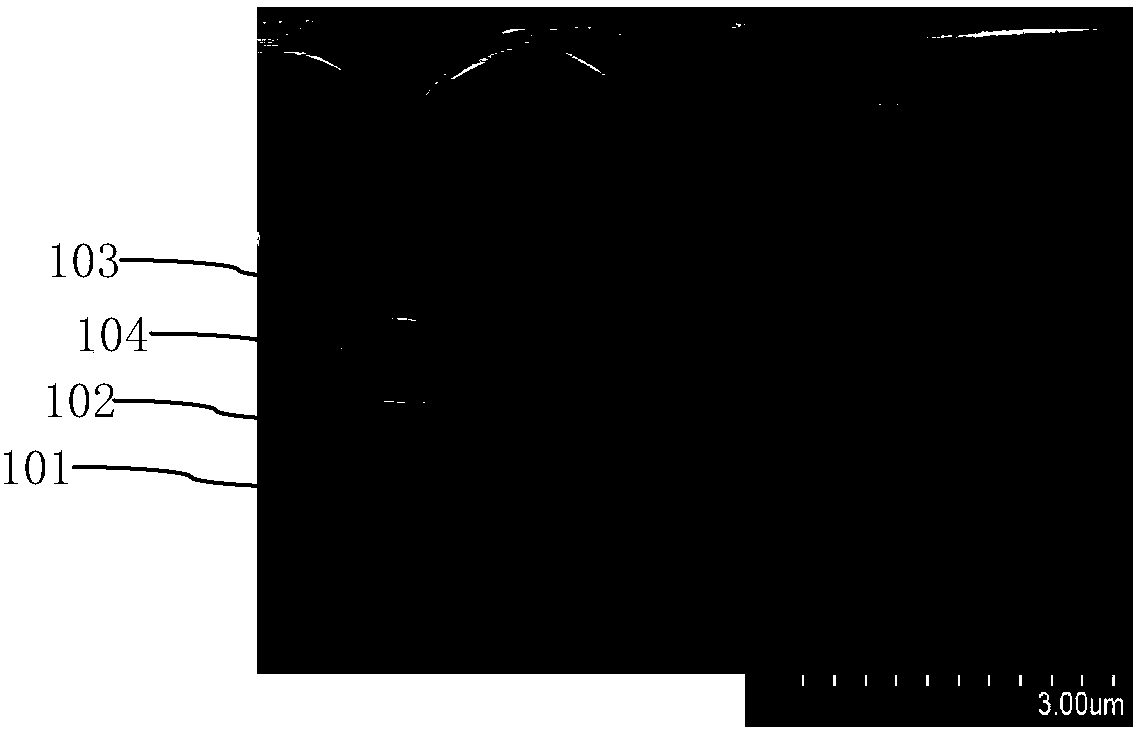

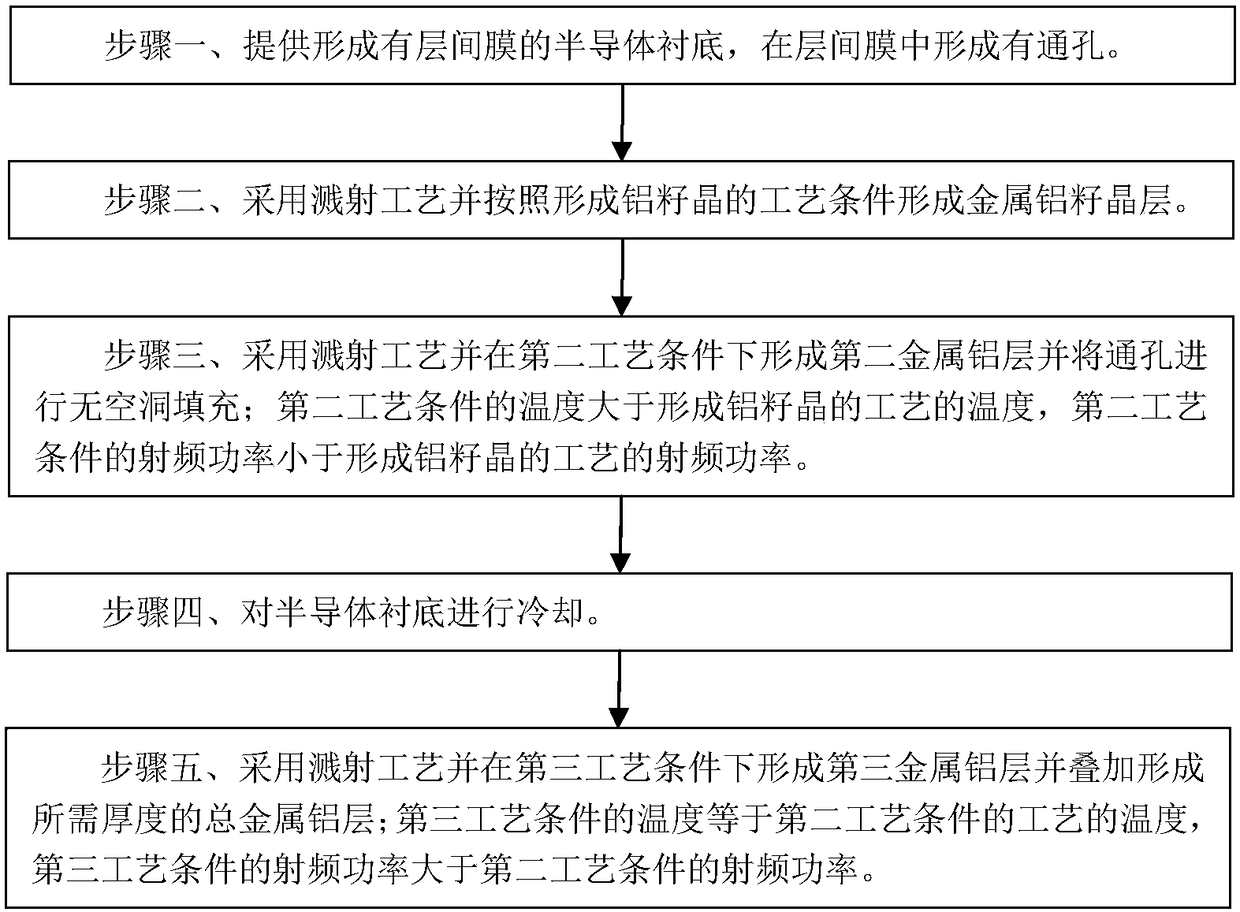

[0037] Such as image 3 Shown is the flow chart of the method for filling holes with metal aluminum in the embodiment of the present invention; as Figure 4 Shown is a photo of the appearance of the through hole 22 formed by the method of filling holes with metal aluminum according to the embodiment of the present invention. The method of filling holes with metal aluminum according to the embodiment of the present invention includes the following steps:

[0038] Step 1: providing a semiconductor substrate, an interlayer film 1 is formed on the semiconductor substrate, and a through hole 2 passing through the interlayer film 1 is formed in the interlayer film 1 .

[0039] In an embodiment of the present invention, the semiconductor substrate is a silicon substrate.

[0040] Preferably, the material of the interlayer film 1 is an oxide film.

[0041] The cross-sectional structure of the through hole 2 is divided into upper and lower parts, the side of the lower part is a verti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com