Heat treatment method for 10Cr11Co3W3NiMoVNbNB blade steel bar

A heat treatment method and technology of a heat treatment furnace, applied in the field of heat treatment, can solve the problems of difficult control of process parameters and high cost, and achieve the effect of simple steps, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A heat treatment method for improving the high-temperature durability performance of 10Cr11Co3W3NiMoVNbNB blade steel, comprising the following steps:

[0022] (1) Annealing treatment: put the 10Cr11Co3W3NiMoVNbNB blade steel bar with a diameter of Ф150 mm after forging directly into a furnace at 750 ° C for 13 hours;

[0023] (2) Austenitizing treatment: the above-mentioned annealed steel is heated below 500°C at a heating rate of 110°C / h to 1090°C for 4.5 hours;

[0024] (3) oil quenching;

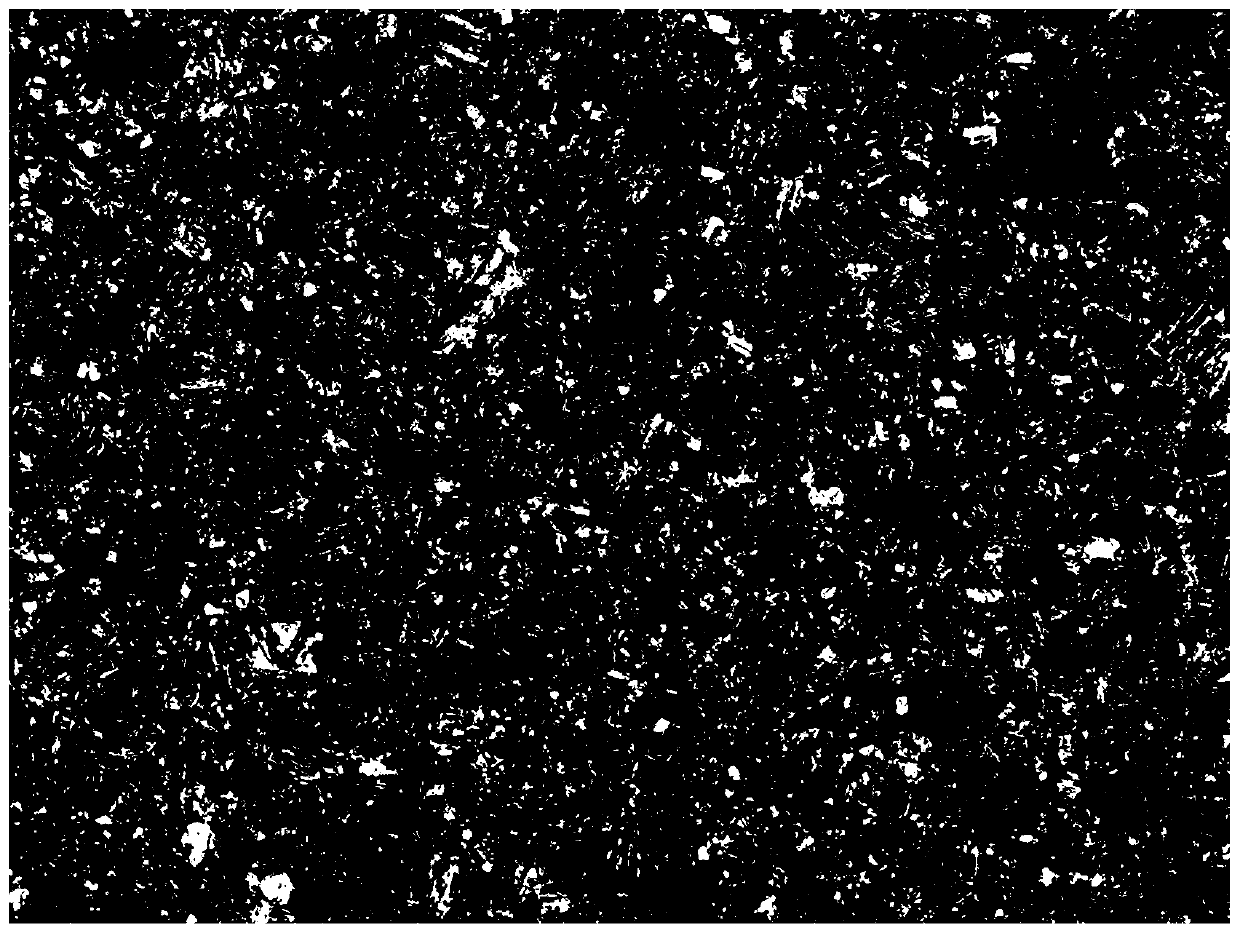

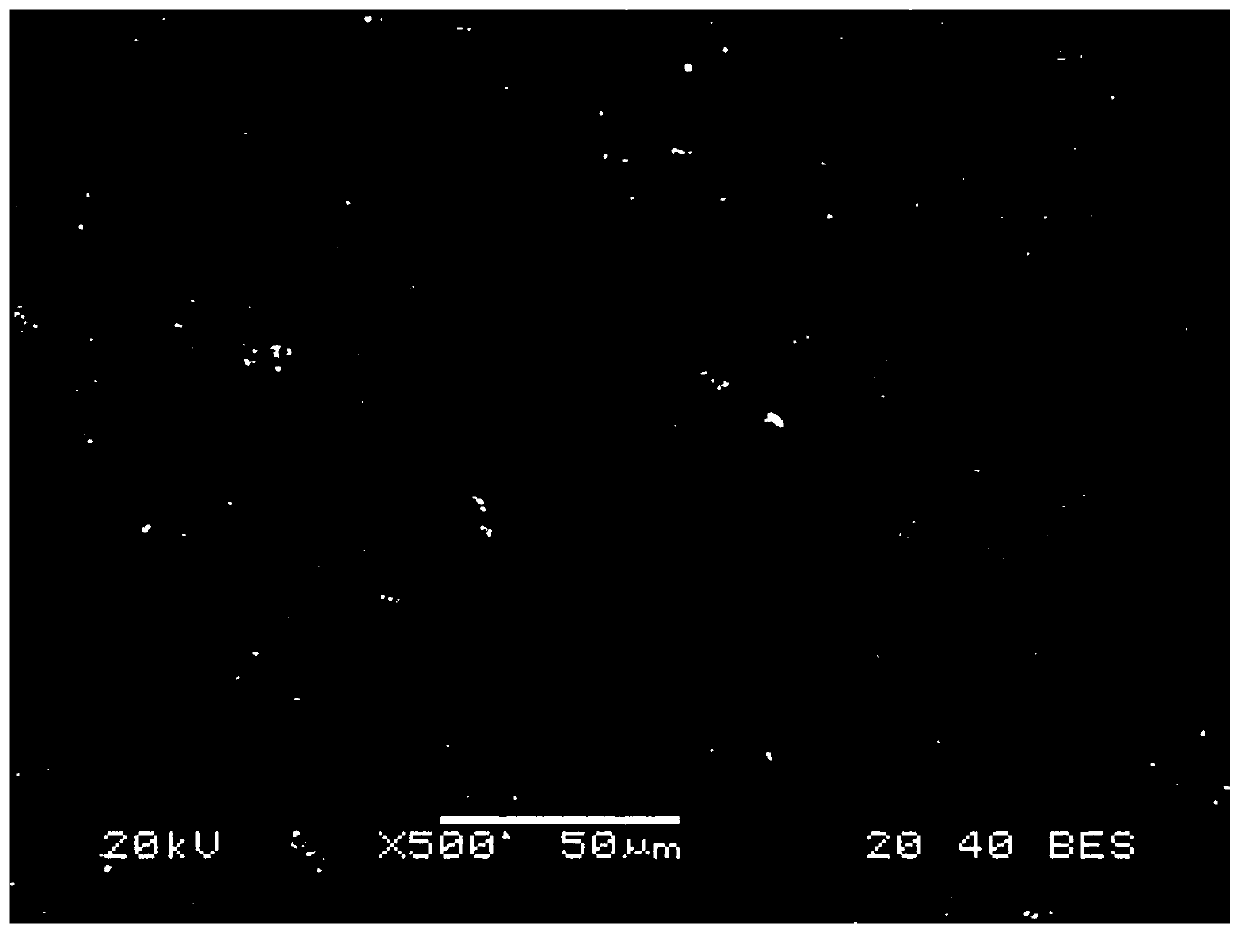

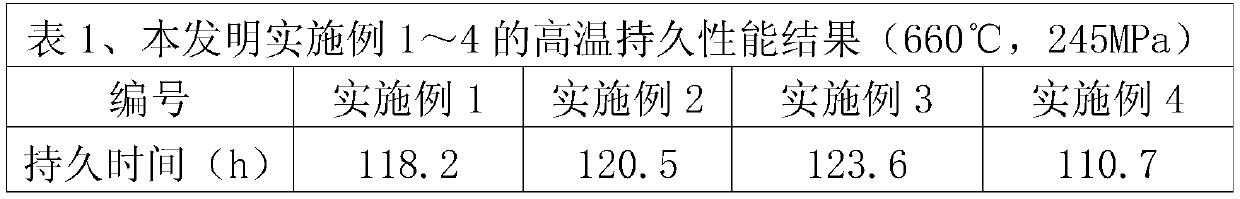

[0025] (4) Tempering treatment: Put the above oil-quenched blade steel directly into a furnace at 750°C to keep it warm for 7.5 hours, and then take it out of the furnace and air cool it to room temperature to obtain product A. figure 1 , the grain size is 5.5, and the morphology of the precipitated phase is as follows figure 2 As shown, the precipitated phases did not aggregate.

Embodiment 2

[0027] A heat treatment method for improving the high-temperature durability performance of 10Cr11Co3W3NiMoVNbNB blade steel, comprising the following steps:

[0028] (1) Annealing treatment: put the 10Cr11Co3W3NiMoVNbNB blade steel bar of Ф120mm after forging directly into the furnace at 740°C for 10 hours;

[0029] (2) Austenitizing treatment: the steel is heated below 500°C at a heating rate of 110°C / h to 1100°C for 3.6 hours;

[0030] (3) oil quenching;

[0031] (4) Tempering treatment: put the above oil-quenched blade steel directly into a furnace at 740°C for 6.0 hours, and then take it out of the furnace and air cool it to room temperature to obtain product B, with a grain size of 6.0 and no precipitates. Aggregation occurs.

Embodiment 3

[0033] A heat treatment method for improving the high-temperature durability performance of 10Cr11Co3W3NiMoVNbNB blade steel, comprising the following steps:

[0034] (1) Annealing treatment: put the 10Cr11Co3W3NiMoVNbNB blade steel bar of Ф110mm after forging directly into the furnace at 730 ° C for 10 hours;

[0035] (2) Austenitizing treatment: the steel is heated below 500°C at a heating rate of 110°C / h to 1100°C for 3.3 hours;

[0036] (3) oil quenching;

[0037] (4) Tempering treatment: put the above oil-quenched blade steel directly into a furnace at 730°C for 6.0 hours to keep it warm, and then take it out of the furnace and air cool it to room temperature to obtain product C with a grain size of 6.0 and no precipitates. Aggregation occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com