Heat treatment method of low-expansion high-temperature alloy

A heat treatment method and technology for superalloys, applied in the field of heat treatment of low-expansion superalloys, can solve the problems of high notch sensitivity and insufficient comprehensive properties of alloys, and achieve the effects of improving high-temperature durability, eliminating notch sensitivity, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] GH2909 alloy was tested for composition and met the requirements: C: ≤0.06%, Ni: 35%-40%, Co: 12%-16%, Nb+Ta: 4.3%-5.2%, Ti: 1.3%-1.8%, Si: 0.36% to 0.5%, B: ≤0.012%, Al: ≤0.2%.

[0033] The microstructure of the GH2909 alloy before heat treatment was tested, and the requirements were met: equiaxed grain microstructure, and the grain boundary contained a very small amount of Laves phase.

[0034] The GH2909 alloy is subjected to standard heat treatment. The specific process is: 980°C for 1h, air cooling; 720°C for 8h, 55°C / h furnace cooling to 620°C for 8h, air cooling.

[0035] The GH2909 alloy is subjected to bent crystal heat treatment, the specific process is: 880°C for 40 minutes, air cooling; 980°C for 1 hour, air cooling; 720°C for 8 hours, 55°C / h furnace cooling to 620°C for 8 hours, air cooling.

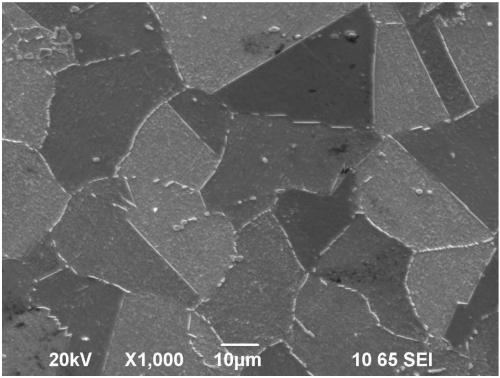

[0036] The alloy microstructure after standard heat treatment was tested, the results are as follows figure 1 shown.

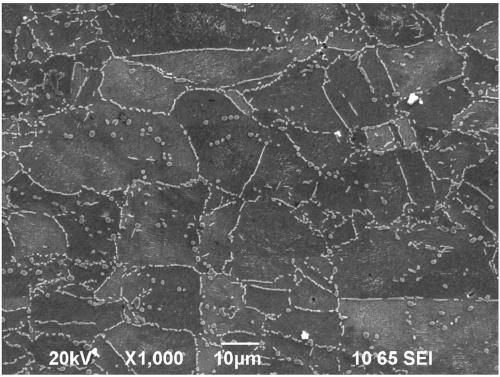

[0037] The microstructure of the alloy after...

Embodiment 2

[0040] The composition of GH2909 alloy is tested and meets the requirements: C: ≤0.06, Ni: 35%-40%, Co: 12%-16%, Nb+Ta: 4.3%-5.2%, Ti: 1.3%-1.8%, Si : 0.36% to 0.5%, B: ≤0.012, Al: ≤0.2.

[0041] The microstructure of the GH2909 alloy before heat treatment was tested, and the requirements were met: equiaxed grain microstructure, no Laves phase precipitation at the grain boundary.

[0042] The GH2909 alloy is subjected to standard heat treatment. The specific process is: 980°C for 1h, air cooling; 745°C for 4h, 55°C / h furnace cooling to 620°C for 4h, air cooling.

[0043] The GH2909 alloy is subjected to bent crystal heat treatment, the specific process is: 880°C for 1min, air cooling; 980°C for 1h, air cooling; 745°C for 4h, 55°C / h furnace cooling to 620°C for 4h, air cooling.

[0044] The detection of alloy microstructures after standard heat treatment and bent-grain heat treatment found that after bent-grain heat treatment, more grain boundary Laves phases can be obtained, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com