Heat-resistant stainless steel seamless pipe and preparation method thereof

A heat-resistant stainless steel and seamless tube technology, applied in the field of stainless steel, can solve the problems of poor thermal conductivity, lasting strength and oxidation resistance of the tube screen, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

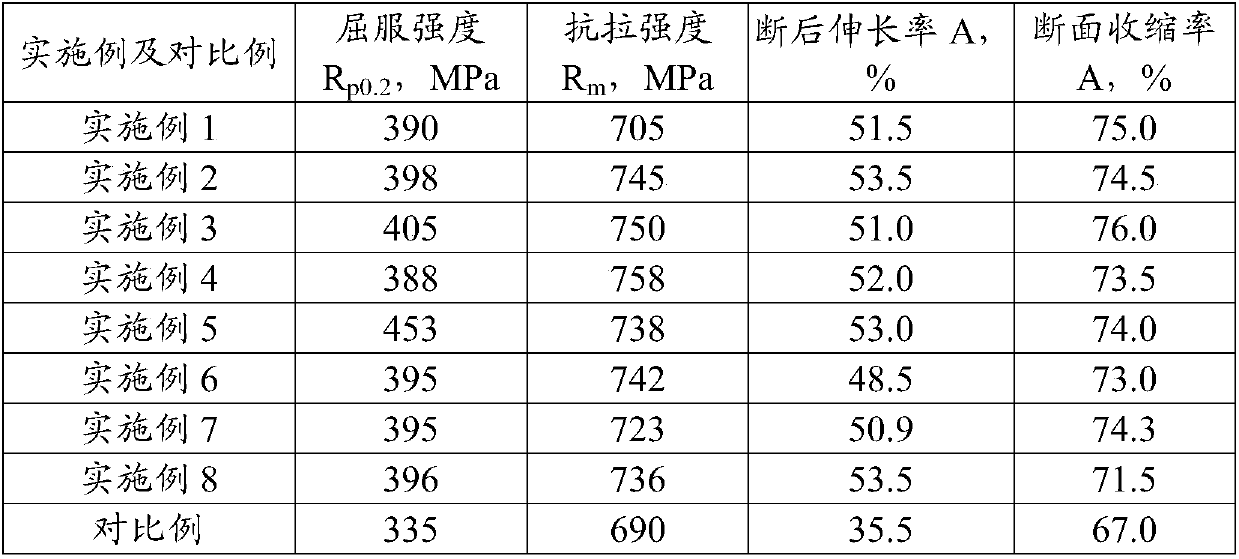

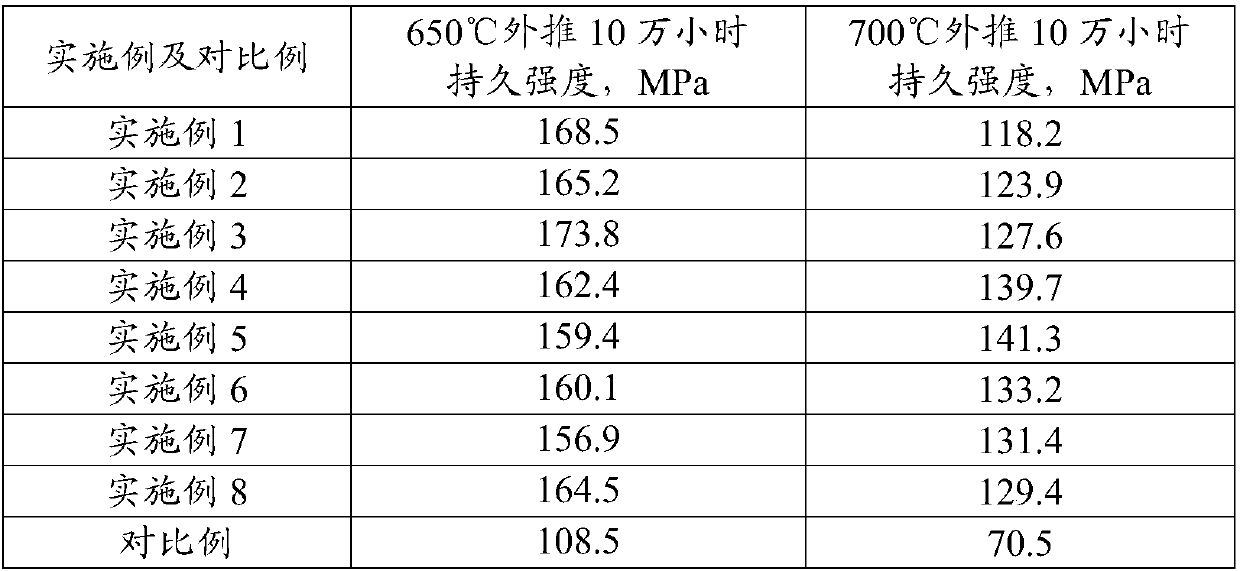

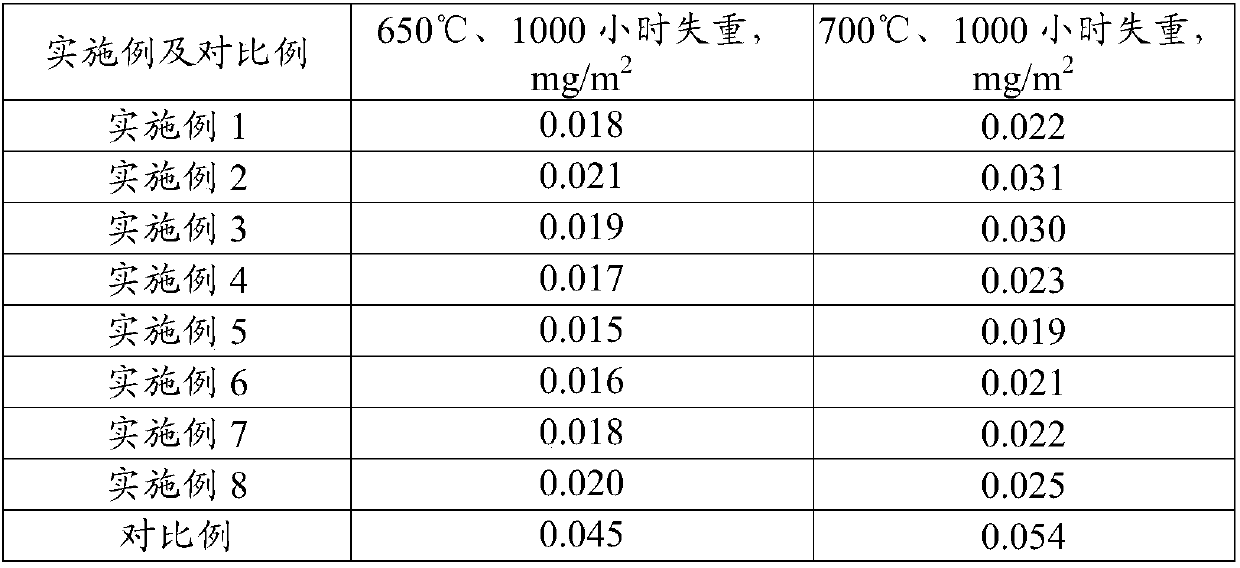

Examples

Embodiment 1-6

[0074] (1) Smelting

[0075] Adopt VIM+ESR technology and electric furnace+AOD+LF technology to smelt the ingot of Φ498 respectively, the ingot composition of each embodiment and comparative example (S31042) is shown in Table 1 (embodiment 1-3 has adopted VIM+ESR smelting technology, Embodiment 4-6 and comparative examples have adopted electric furnace+AOD+LF smelting process).

[0076] Table 1 embodiment 1-6 and comparative example chemical composition (percentage by weight)

[0077] Element

C

Si

mn

P

S

Cr

Ni

Cu

W

Nb

N

Mo

B

Example 1

0.07

0.20

0.15

0.013

0.001

22.35

25.04

3.11

3.62

0.45

0.20

0.10

0.005

Example 2

0.08

0.16

0.20

0.011

0.002

21.17

24.54

2.00

2.00

0.48

0.17

0.05

0.004

Example 3

0.06

0.24

0.21

0.008

0.001

23.87

26.13

2.72

2.54

0.33

0.23

0.15

0.002

Example 4

0.04

0...

Embodiment 7

[0085] The chemical composition of the heat-resistant stainless steel pipe of the present embodiment is identical with embodiment 1, and preparation method is as follows:

[0086] (1) Smelting

[0087] With embodiment 1.

[0088] (2) Thermal processing of tube billets

[0089] The ingot is opened by free forging, the heating temperature is 1180°C, the heating time is 1min / mm×the width of the ingot, and it is kept at 1000°C for 1 hour. The starting forging temperature is 1100°C, the final forging temperature is 950°C, the total forging ratio is 3, the deformation pass is 6, the deformation amount of the initial pass is 26%, the deformation amount of the middle pass is 41%, the deformation amount of the final pass is 9%, and the rest pass The secondary deformation is 20%.

[0090] (3) Steel pipe thermal processing

[0091] The tube blank is processed into capillary tube by hot extrusion method, the diameter of the through hole in the machining center is 20mm, and a 33.5° bel...

Embodiment 8

[0095] The chemical composition of the heat-resistant stainless steel pipe of the present embodiment is identical with embodiment 1, and preparation method is as follows:

[0096] (1) Smelting

[0097] With embodiment 1.

[0098] (2) Thermal processing of tube billets

[0099] The ingot is opened by rolling, the heating temperature is 1270°C, the heating time is 4min / mm×the width of the ingot, and it is kept at 1000°C for 3 hours. The starting rolling temperature is 1200°C, the final rolling temperature is 1500°C, the total forging ratio is 9, the deformation pass is 3, the deformation amount of the initial pass is 60%, the deformation amount of the middle pass is 50%, the deformation amount of the final pass is 3%, and the remaining pass The secondary deformation is 40%.

[0100] (3) Steel pipe thermal processing

[0101] The tube blank is processed into capillary tube by hot extrusion method, the diameter of the through hole in the machining center is 30mm, and a 33.5° b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com