Technology and apparatus for manufacturing shaped conductor

A manufacturing process and wire technology, which is applied in the field of wire and cable manufacturing process and its processing equipment, can solve the problems of low wire take-up efficiency, low wire outlet speed, and insufficient wire corners, and achieves lower production costs, faster wire outlet speed, and higher production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

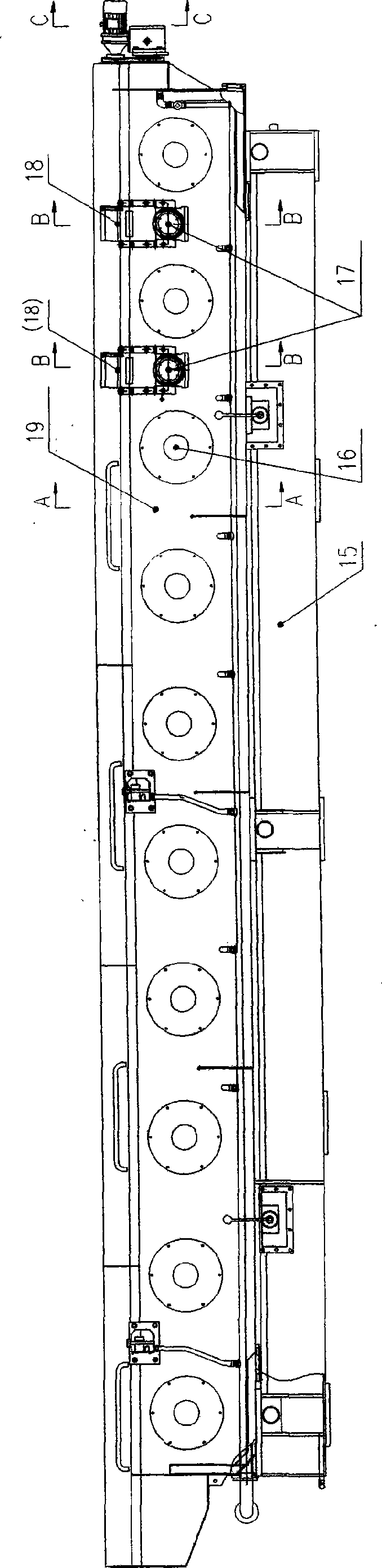

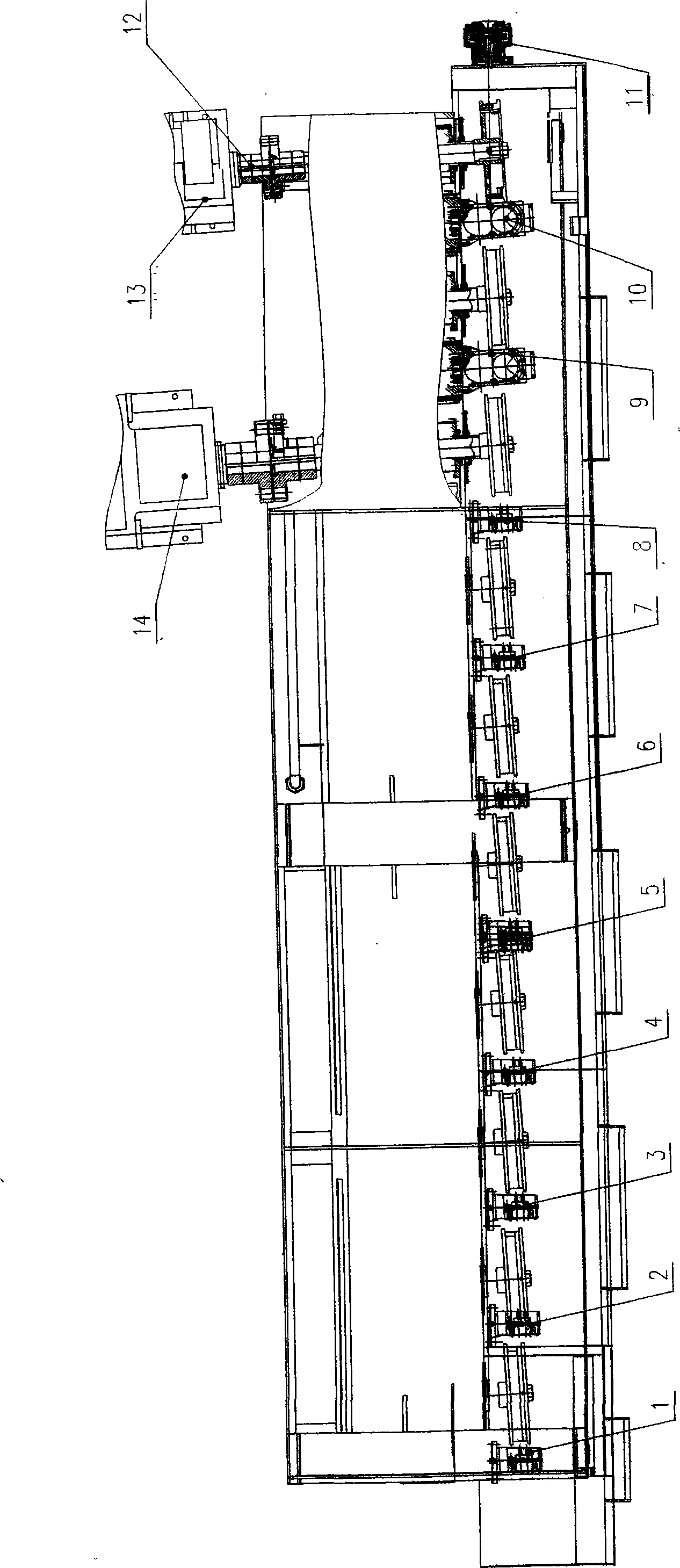

[0060]In order to manufacture wires with special-shaped cross-sections, the applicant has developed a drawing and rolling unit, which is improved on the basis of the drawing unit, and part of the drawing die is replaced by a roll box. The structural design of the roll box meets the requirements for interchangeability with the drawing die. . The roll box is still driven by the gear box of the wire drawing machine, but it is driven by an independent motor. The output shaft of the motor is equipped with a clutch. When it is changed to a drawing die, the clutch is separated. The number and position of roll boxes in the unit depends on the process requirements.

[0061] The roll box is divided into a horizontal rolling box and a vertical rolling box, which one to use depends on the cross-sectional shape of the wire. For example: fan-shaped and prismatic are suitable for horizontal rolling, while S-shaped is suitable for vertical rolling.

[0062] The present invention adopts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com