Preparation method of diamond doped silicon carbide (SiC) ceramics with high heat conductivity

A diamond and high thermal conductivity technology, applied in the field of materials, can solve the problems of silicon or graphite, high experimental conditions, and inability to prepare large-scale Diamond/SiC plates on a large scale, so as to avoid residual silicon, excellent performance, and exclude high temperature and high pressure difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

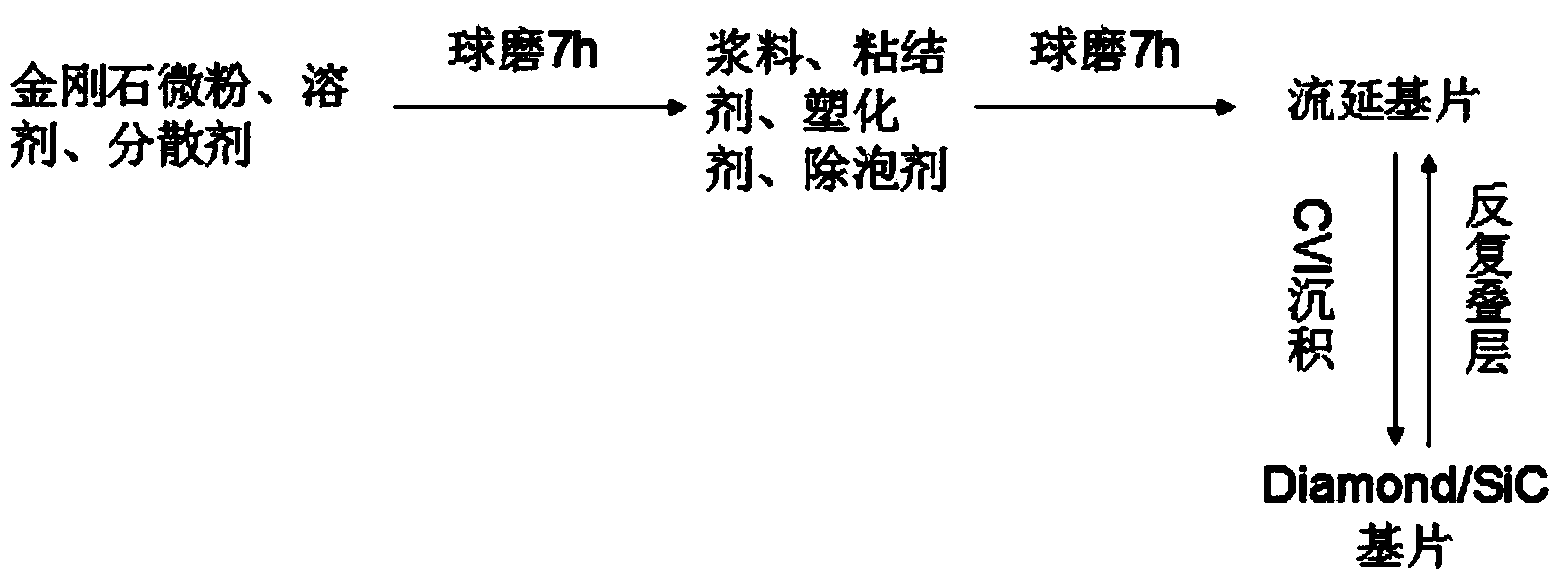

[0024] This embodiment is a preparation method of a Diamond / SiC composite material, and the specific process is:

[0025] Raw material preparation: 30-70wt.% of diamond powder (average particle size 7 microns), 10-30wt.% of solvent toluene and isopropanol, 1-5wt.% of dispersant triethyl phosphate, binder polyvinyl alcohol Butyraldehyde 1-5wt.%, defoamer n-butanol and ethylene glycol each 0.1-2wt.%, plasticizer glycerin and dioctyl phthalate each 0.1-3wt.%;

[0026] Step 1: Preparation of diamond slurry casting substrate: the specific process is:

[0027] a. Mix diamond micropowder, solvent toluene and isopropanol, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 7h, and the ball milling drum speed is 120r / min;

[0028] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerol and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and bin...

Embodiment 2

[0034]Raw material preparation: diamond micropowder (average particle size 20 microns) 30-70wt.%, solvent toluene and isopropanol 10-30wt.%, dispersant triethyl phosphate 1-5wt.%, binder polyvinyl alcohol Butyraldehyde 1-5wt.%, defoamer n-butanol and ethylene glycol each 0.1-2wt.%, plasticizer glycerin and dioctyl phthalate each 0.1-3wt.%;

[0035] Step 1: Preparation of diamond slurry casting substrate: the specific process is:

[0036] a. Mix diamond micropowder, solvent toluene and isopropanol, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 7h, and the ball milling drum speed is 120r / min;

[0037] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerin and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and binder polyvinyl butyral according to the ratio. Then put it into the drum ball mill again, the ball milling time and the ...

Embodiment 3

[0043] Raw material preparation: diamond micropowder (average particle size 30 microns) 30-70wt.%, solvent toluene and isopropanol 10-30wt.%, dispersant triethyl phosphate 1-5wt.%, binder polyvinyl alcohol Butyraldehyde 1-5wt.%, defoamer n-butanol and ethylene glycol each 0.1-2wt.%, plasticizer glycerin and dioctyl phthalate each 0.1-3wt.%;

[0044] Step 1: Preparation of diamond slurry casting substrate: the specific process is:

[0045] a. Mix diamond micropowder, solvent toluene and isopropanol, and dispersant triethyl phosphate in the raw materials of step 1 according to the proportioning ratio and carry out ball milling. The ball milling time is 7h, and the ball milling drum speed is 120r / min;

[0046] b. Take out the aforementioned ball-milled slurry, and then add plasticizer glycerin and dioctyl phthalate, defoamer n-butanol and ethylene glycol, and binder polyvinyl butyral according to the ratio. Then put it into the drum ball mill again, the ball milling time and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com