Patents

Literature

30results about How to "Less machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

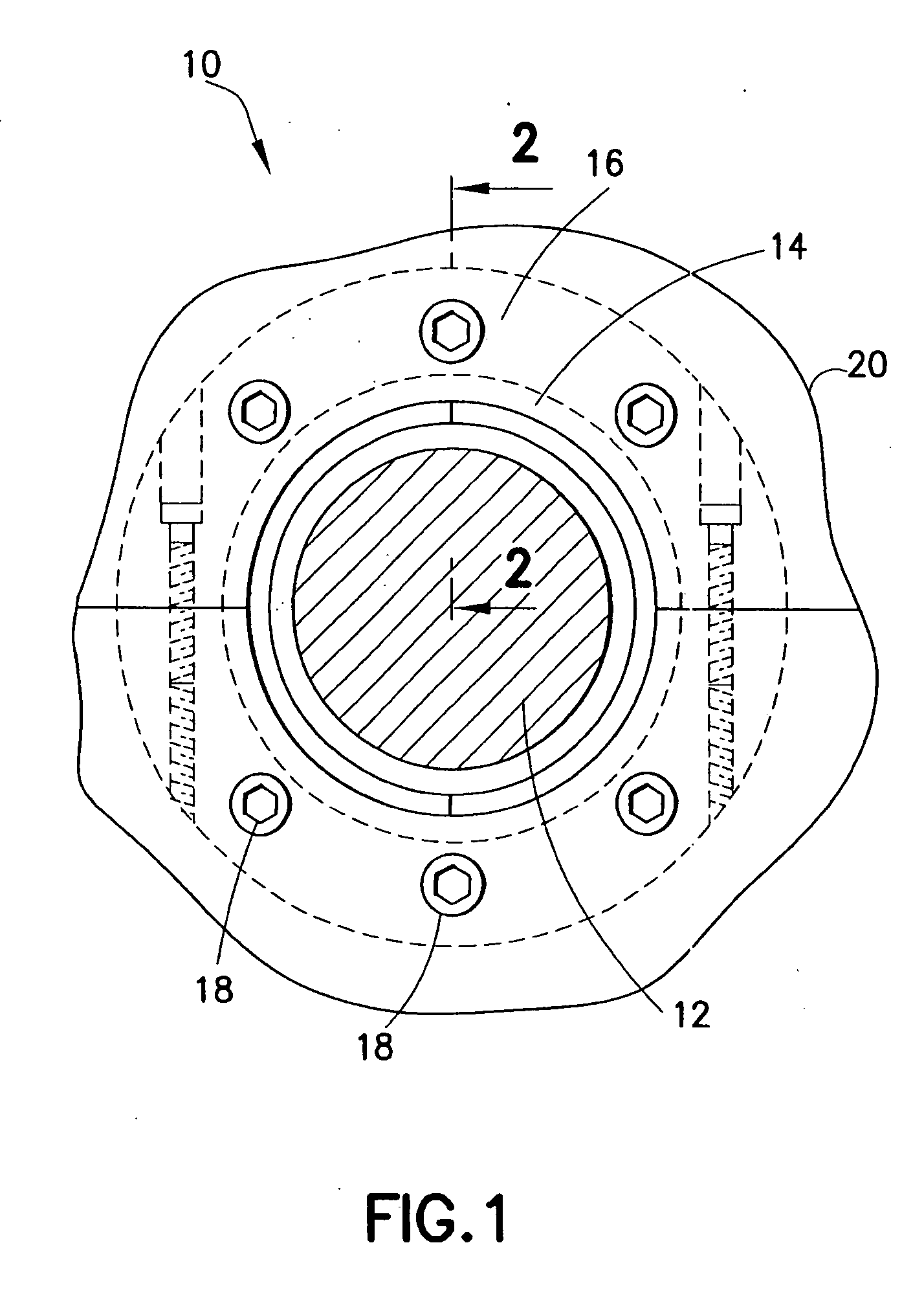

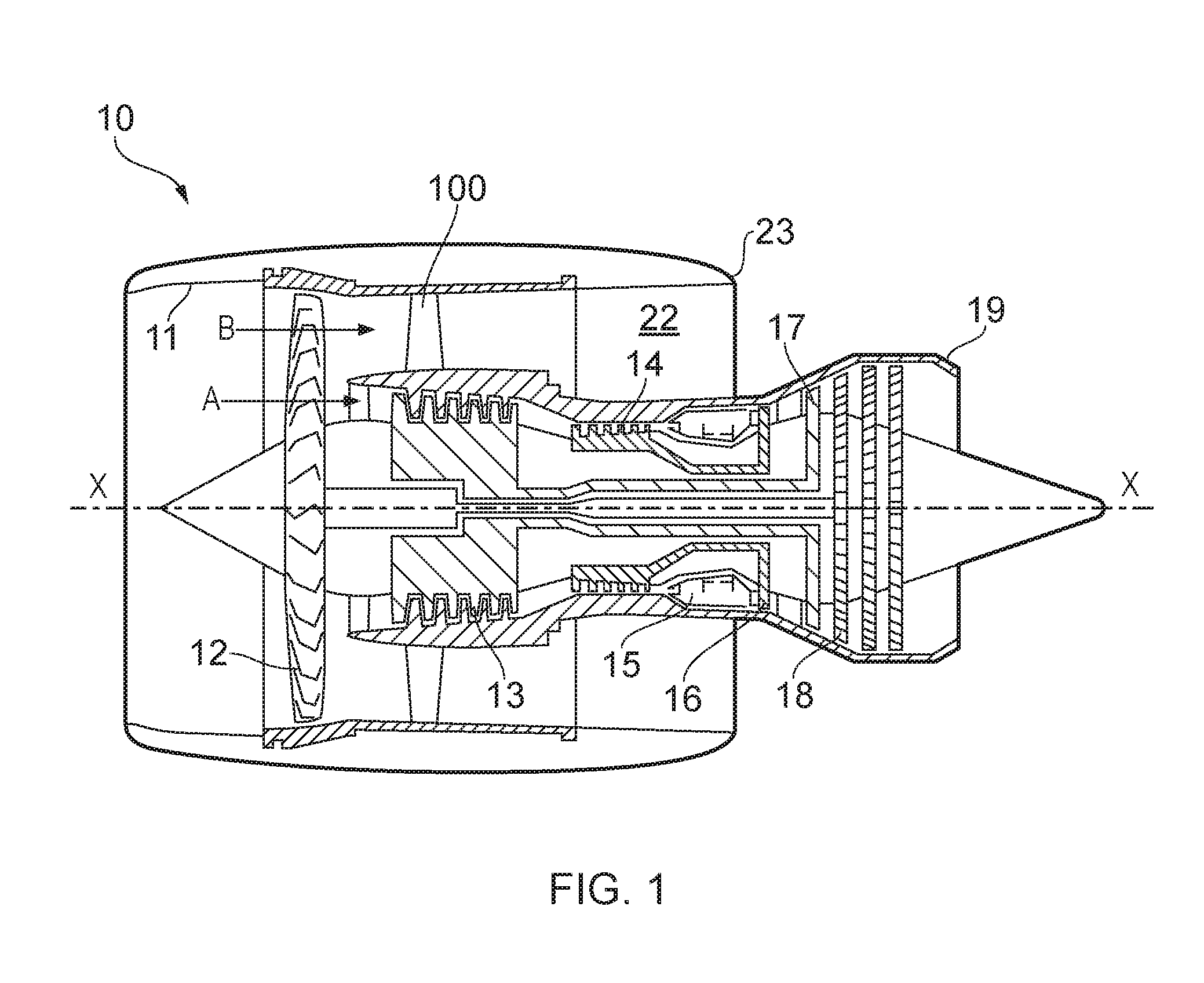

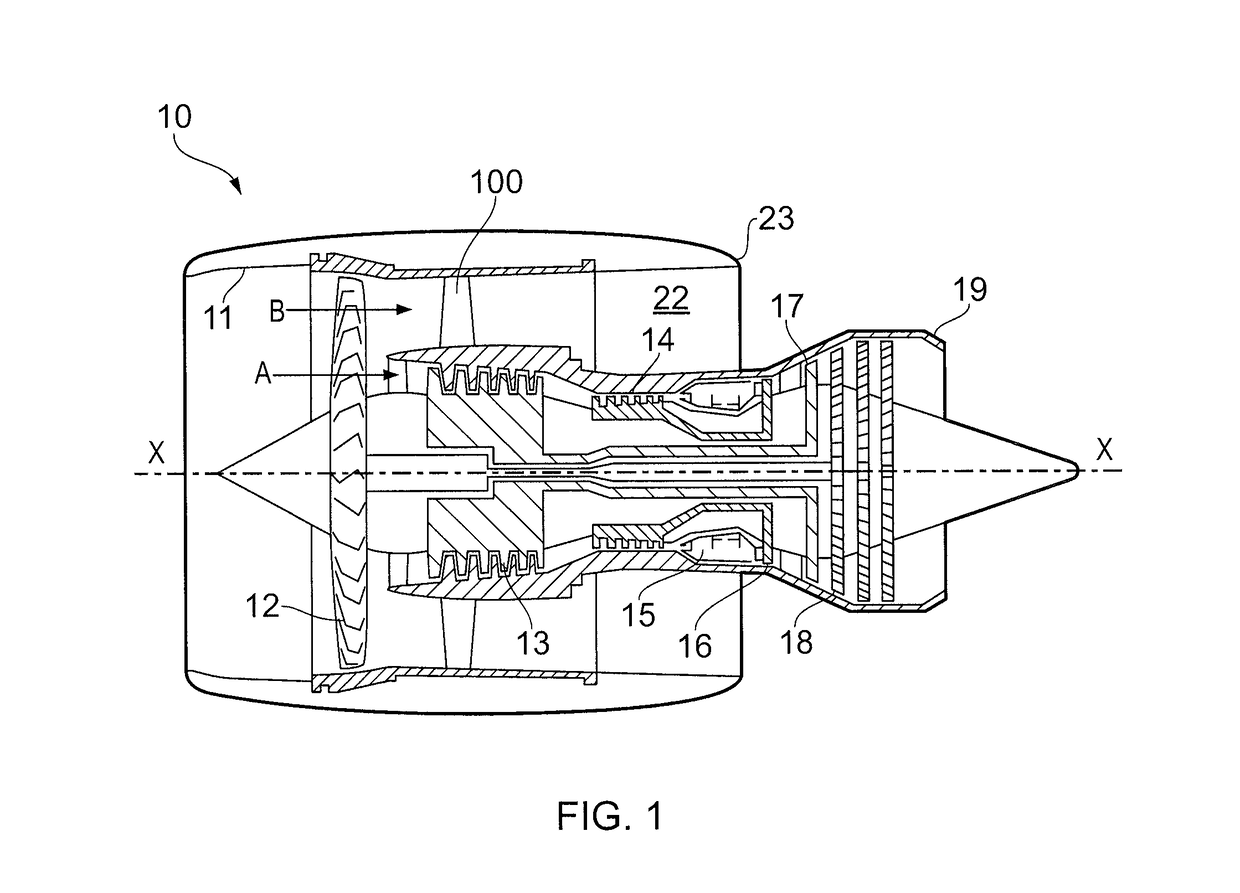

Method of repairing a stationary shroud of a gas turbine engine using plasma transferred arc welding

InactiveUS6914210B2Less process variationFaster and cheapTurbinesMolten spray coatingEngineeringGas turbines

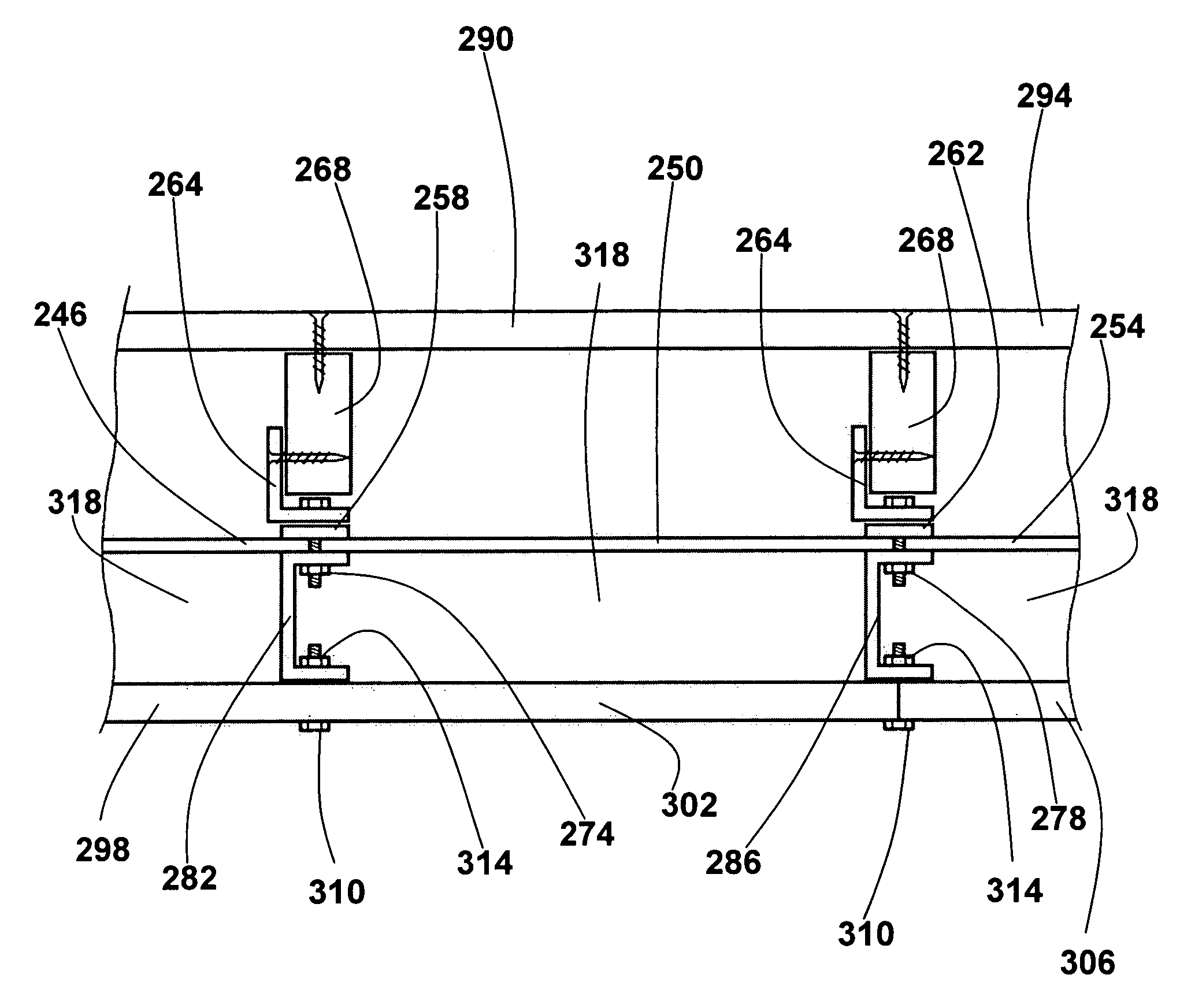

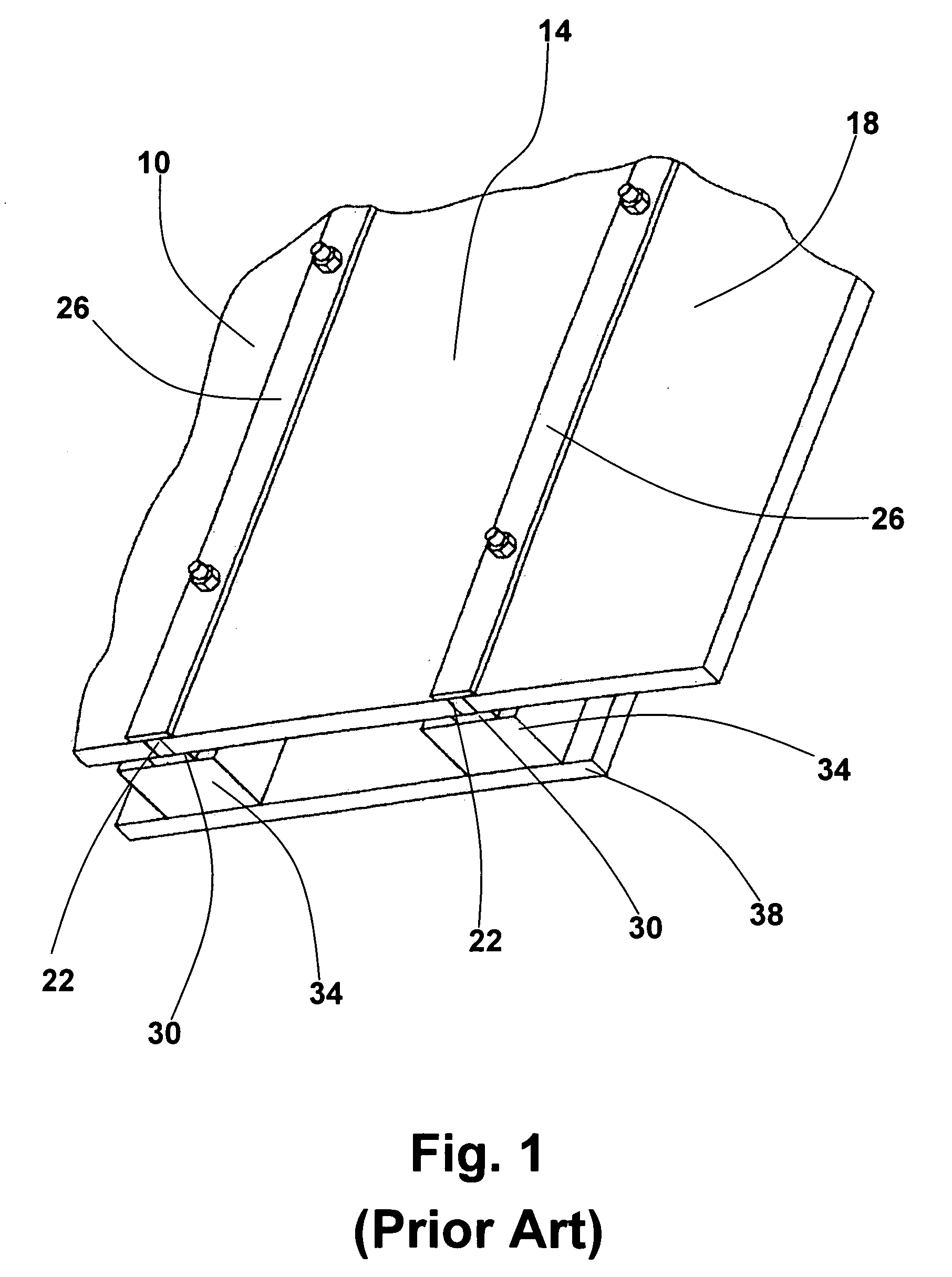

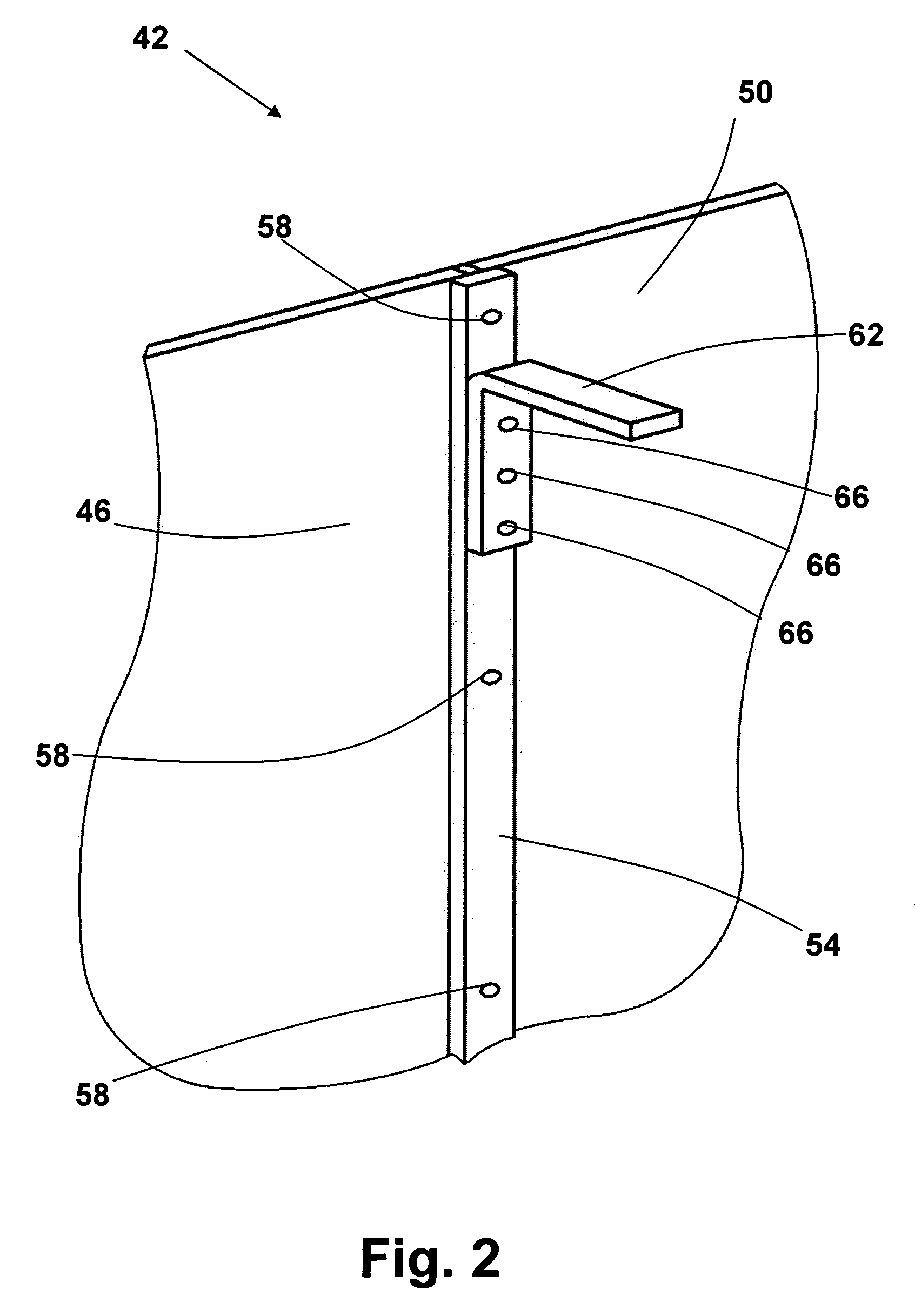

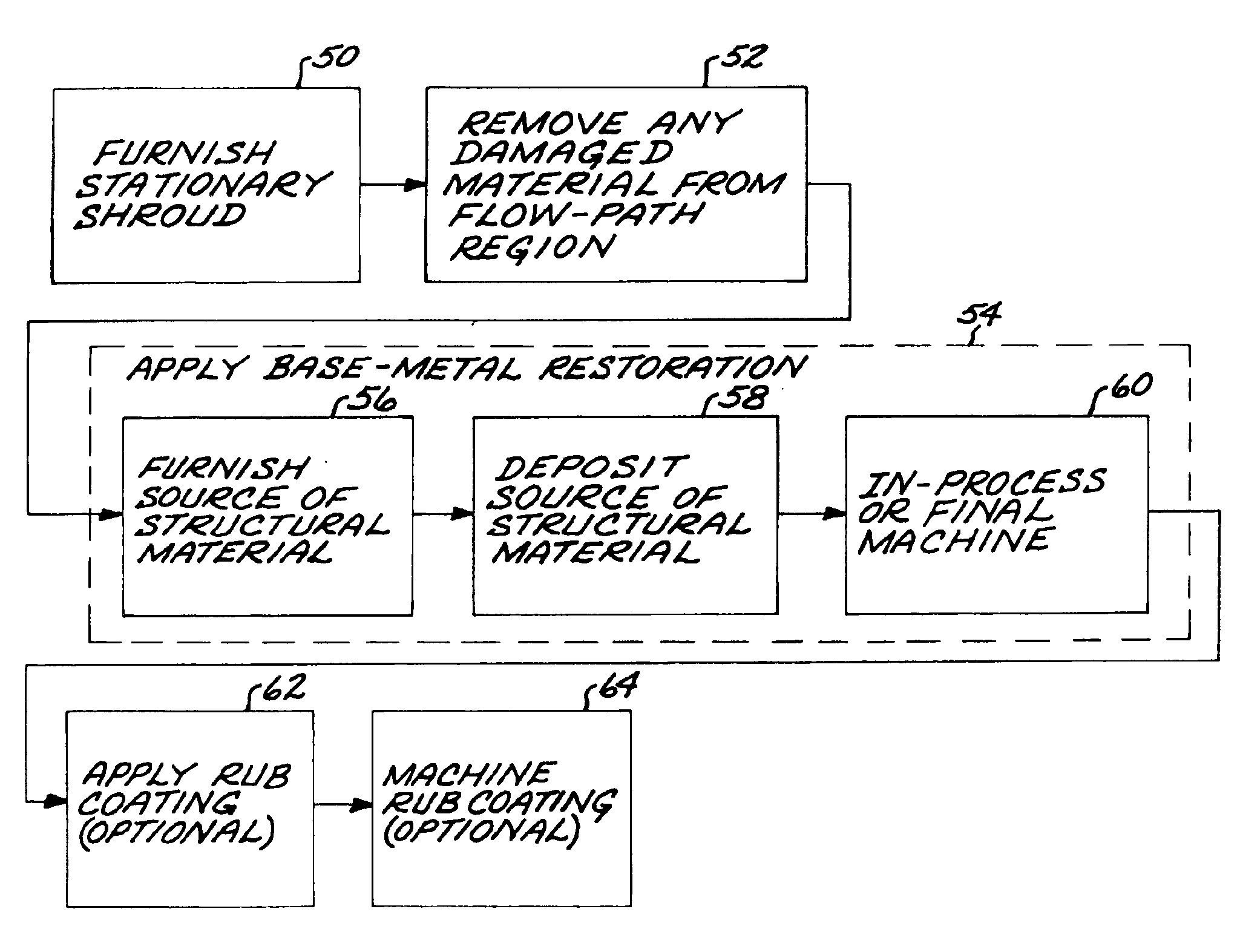

A stationary shroud of a gas turbine engine made of a base metal is repaired by removing any damaged material from a flow-path region of the stationary shroud to leave an initially exposed base-metal flow-path surface; and applying a base-metal restoration overlying the initially exposed flow-path surface. The base-metal restoration is applied by furnishing a source of a structural material that is compatible with the base metal, and depositing the source of the structural material overlying the initially exposed base-metal flow-path surface of the stationary shroud by plasma transferred arc welding to form a repaired base-metal flow-path surface. An environmentally resistant rub coating may be applied overlying the base-metal restoration.

Owner:GENERAL ELECTRIC CO

Method of repairing a stationary shroud of a gas turbine engine using laser cladding

InactiveUS20070205189A1Less process variationFaster and cheap and effectiveTurbinesBlade accessoriesEngineeringTurbine

A stationary shroud of a gas turbine engine made of a base metal is repaired by removing any damaged material from a flow-path region of the stationary shroud to leave an initially exposed base-metal flow-path surface; and applying a base-metal restoration overlying the initially exposed flow-path surface. The base-metal restoration is applied by furnishing a source of a structural material that is compatible with the base metal, in a form such as a powder or a wire, and depositing the source of the structural material overlying the initially exposed base-metal flow-path surface of the stationary shroud by laser cladding to form a repaired base-metal flow-path surface. An environmentally resistant rub coating may be applied overlying the base-metal restoration.

Owner:GENERAL ELECTRIC CO

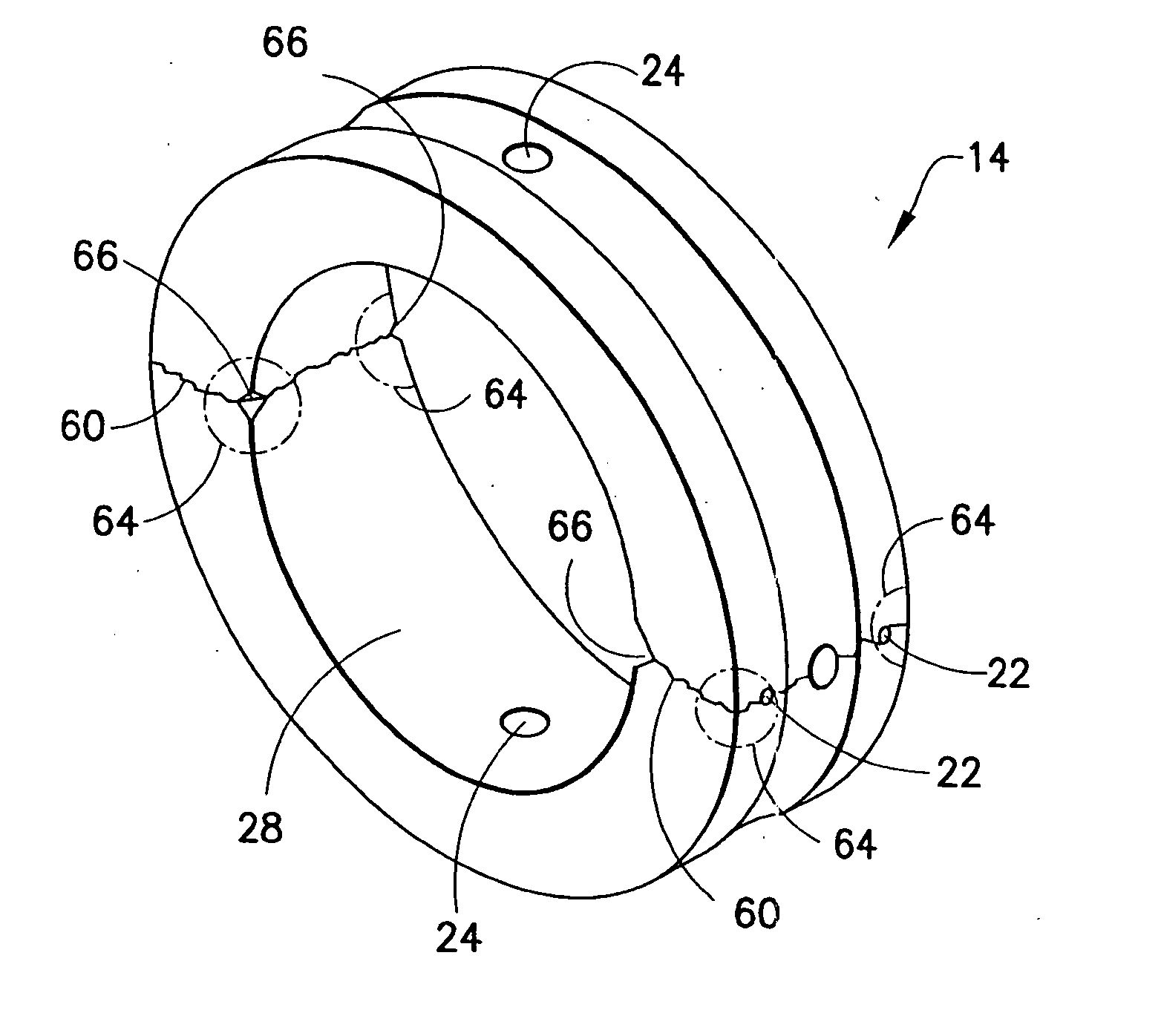

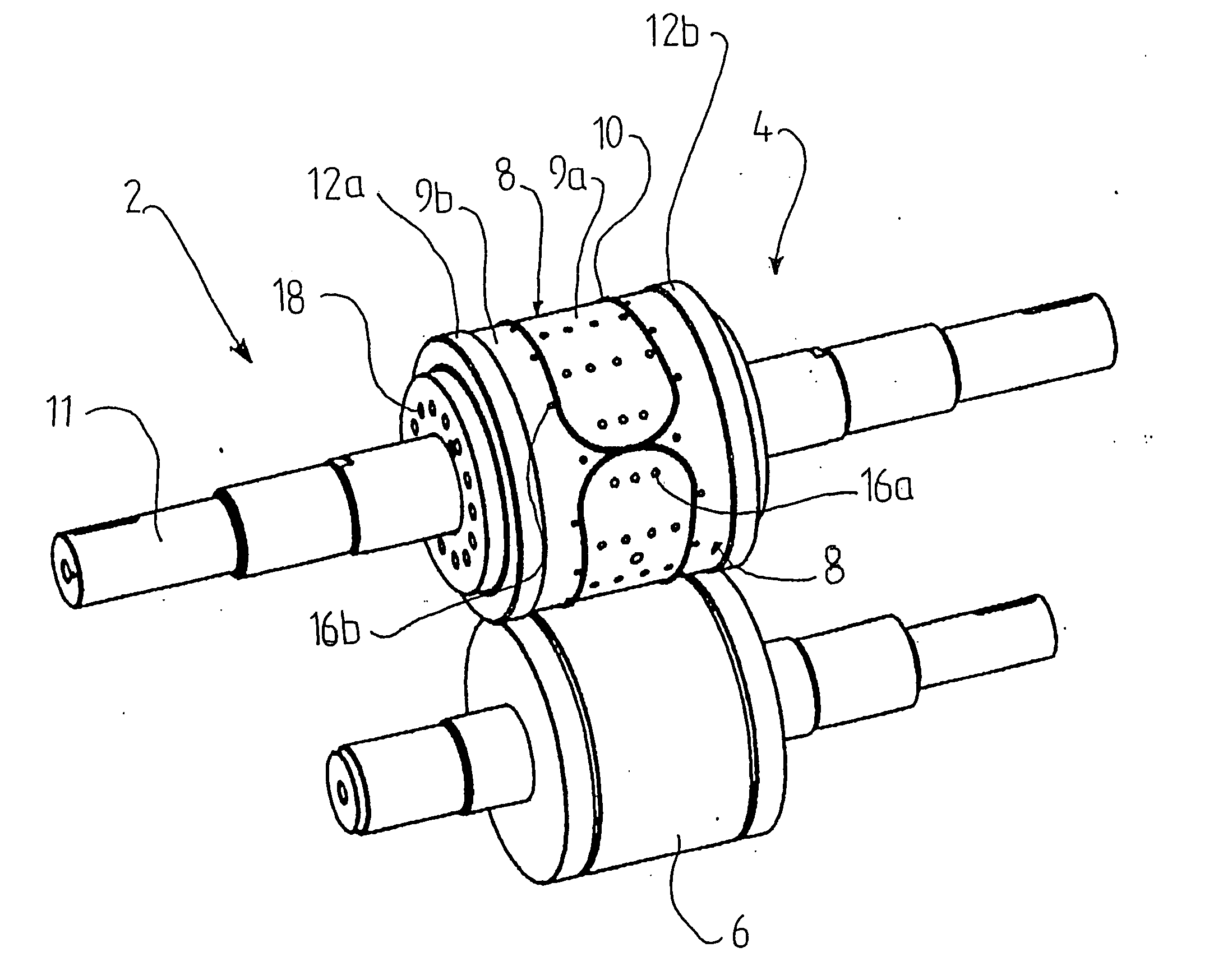

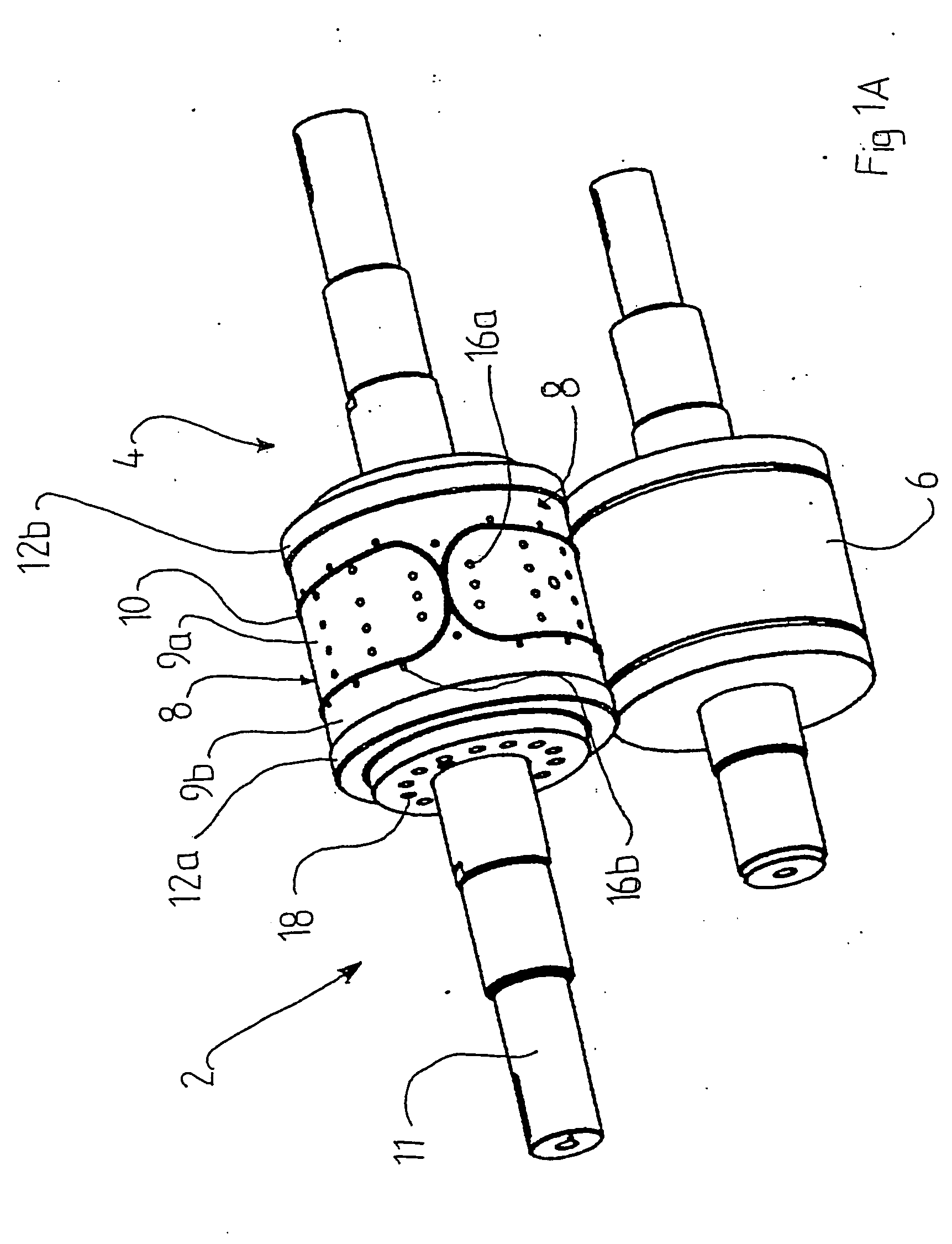

Bearing arrangement for an axle mount of an articulated vehicle

InactiveUS20070269150A1Uniform and efficient distributionLess stressRolling contact bearingsSliding contact bearingsConvex sideEngineering

A bearing arrangement includes a hinge pin and a ring rotatably mounted on an outer surface of the hinge pin. The hinge pin has a spherical convex surface on which a spherical concave surface of the ring can ride. In a bearing having a pin and a ring that is rotatable about an outer surface of the pin, the pin has a spherical convex surface that extends around an outer surface of the pin, and the ring has a corresponding spherical concave surface that extends around an inner surface of the ring. In a method for articulably mounting an axle to a vehicle, a ring having a spherical concave surface is assembled around a hinge pin having a spherical convex surface such that the spherical concave surface and the spherical convex surface engage. A split housing is assembled around the outer surfaces of the ring.

Owner:ROLLER BEARING OF AMERICA

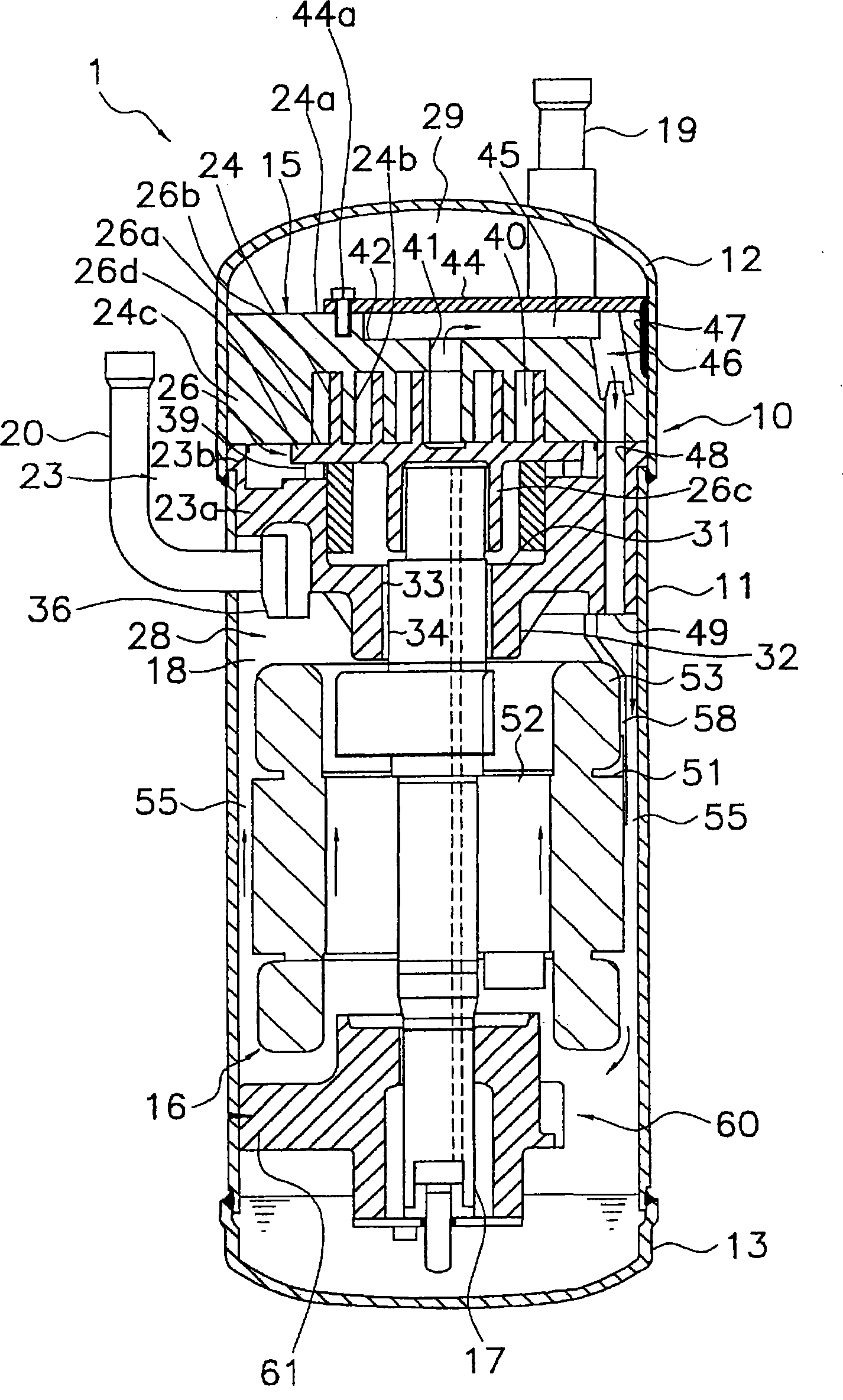

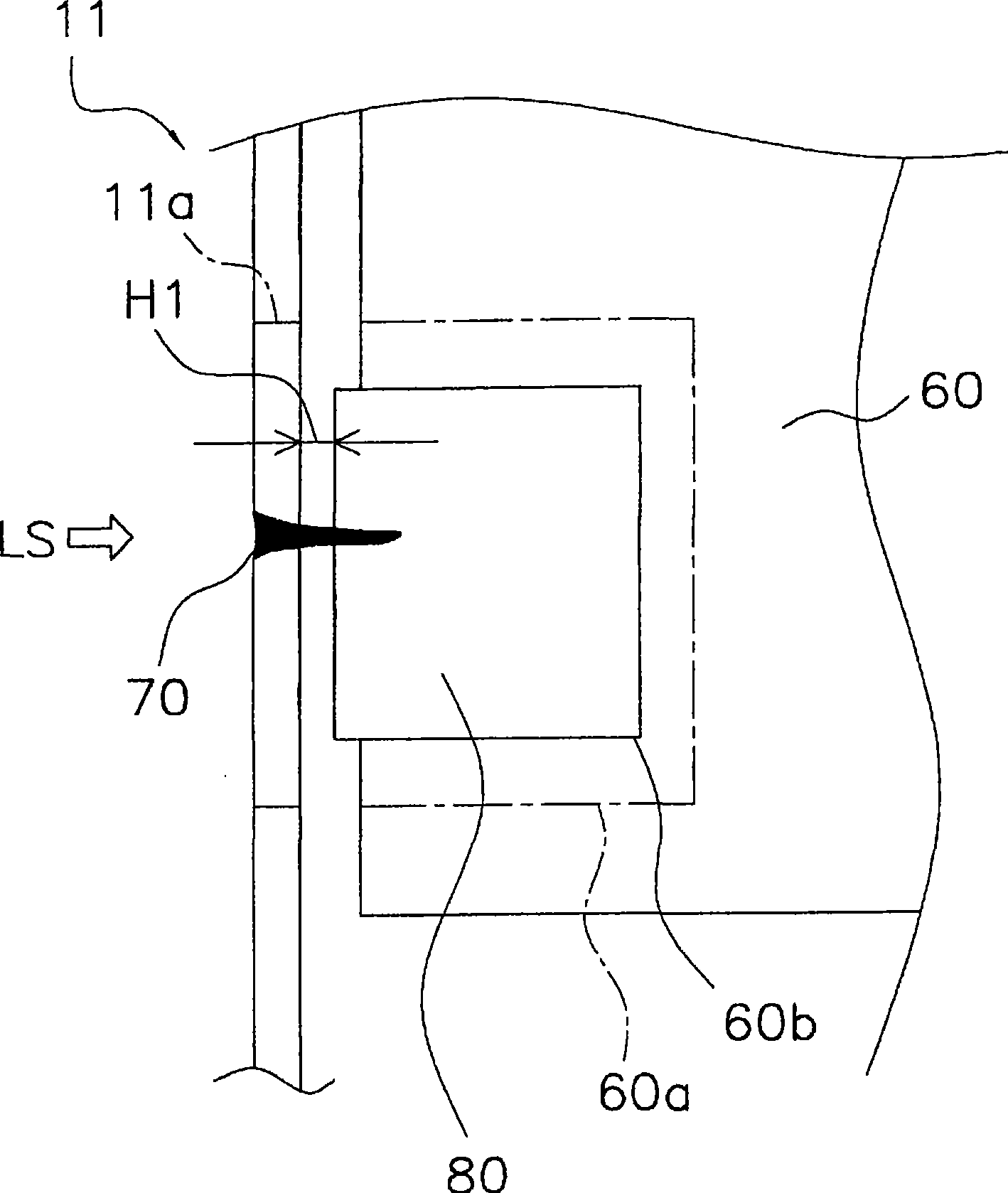

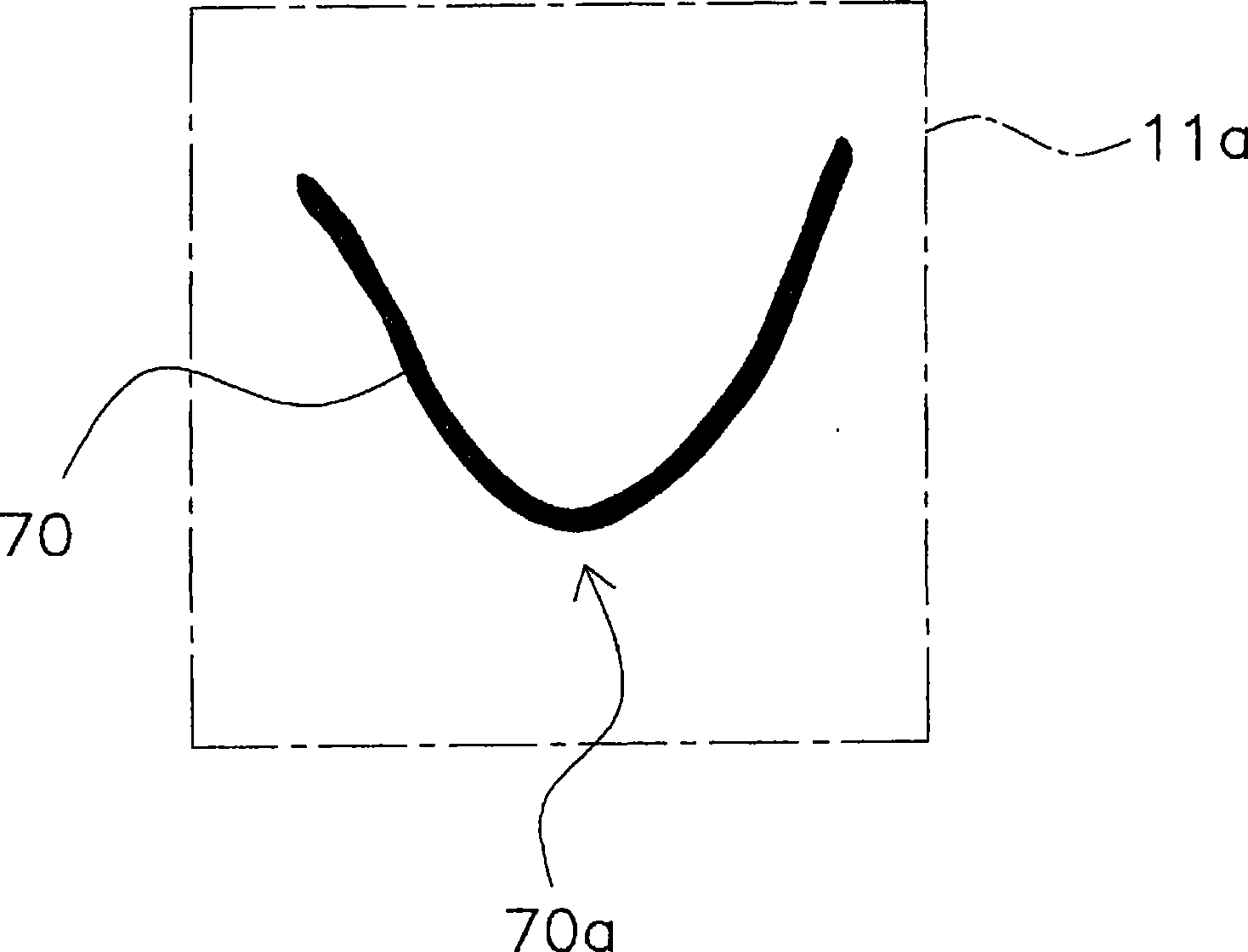

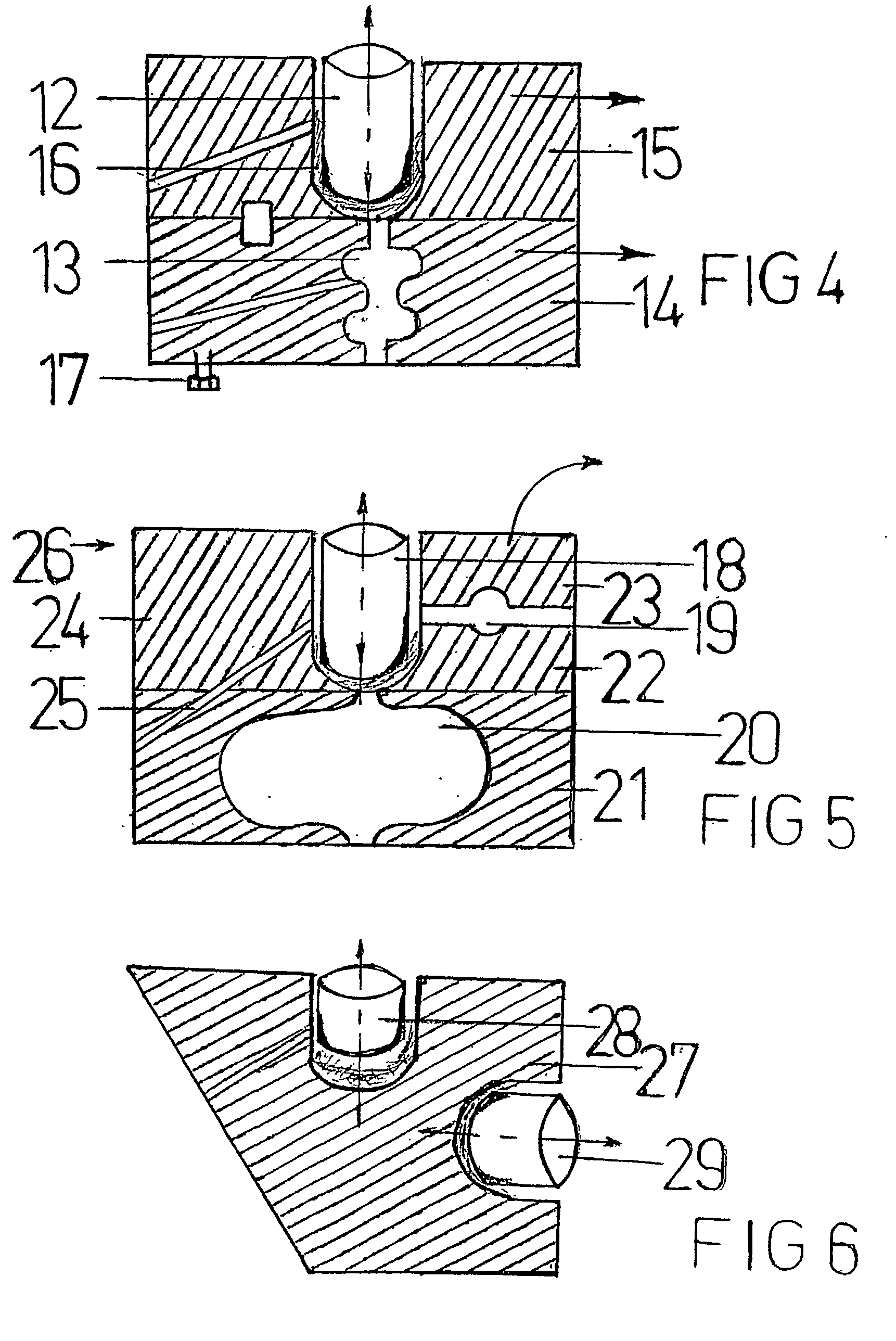

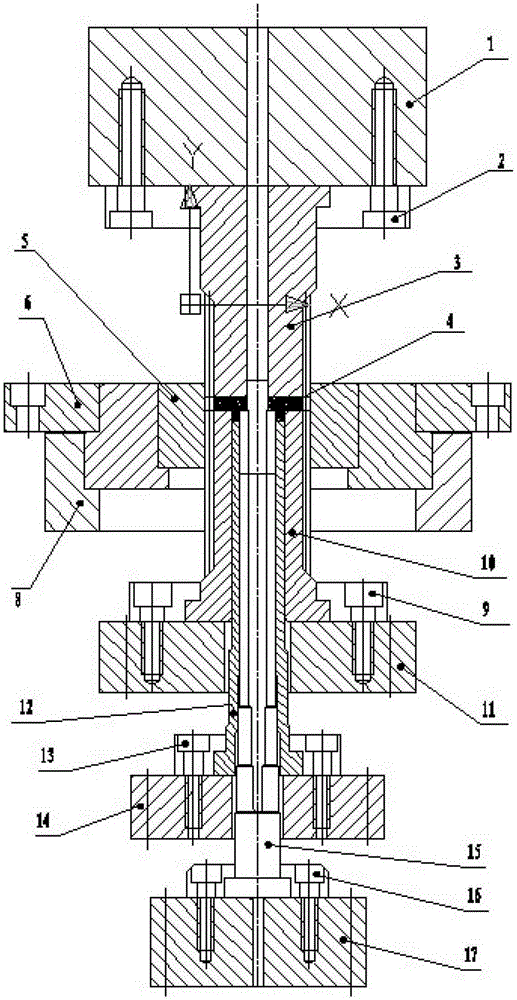

Method for producing compressor, and compressor

InactiveCN101395379ALow costAvoid deformationPositive displacement pump componentsPositive-displacement liquid enginesEngineeringLaser beams

A compressor where welding between a casing and an inner component or welding between a barrel casing and an end casing has sufficient strength and the welding has low strain achieved by suppressing an influence of heat by welding. A method of producing the compressor (1, 101) has a positioning process and a welding process. The compressor has the casing (10, 11, 111) and the inner component (60, 125) received in the casing. The casing has at its inner surface (11s, 111s) a first section (11a, 11w, 111w), and the inner component has a second section (60a, 61, 125b). The second section faces the first section. The first section and the second section are made to face each other in the positioning process. In the laser welding process, a laser beam is applied to at least a portion of the part where the first section and the second section are faced each other to laser-weld the casing and the inner component together.

Owner:DAIKIN IND LTD

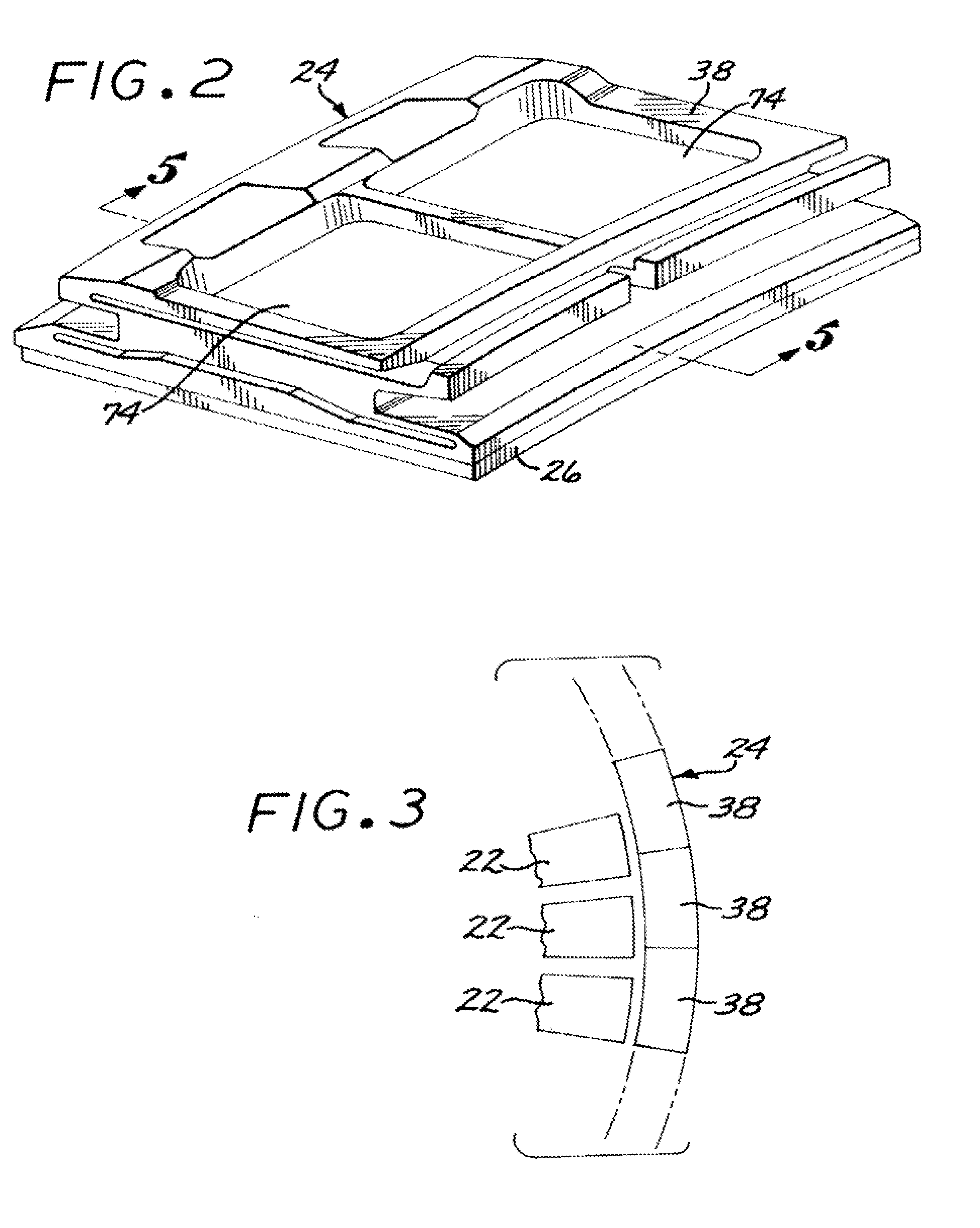

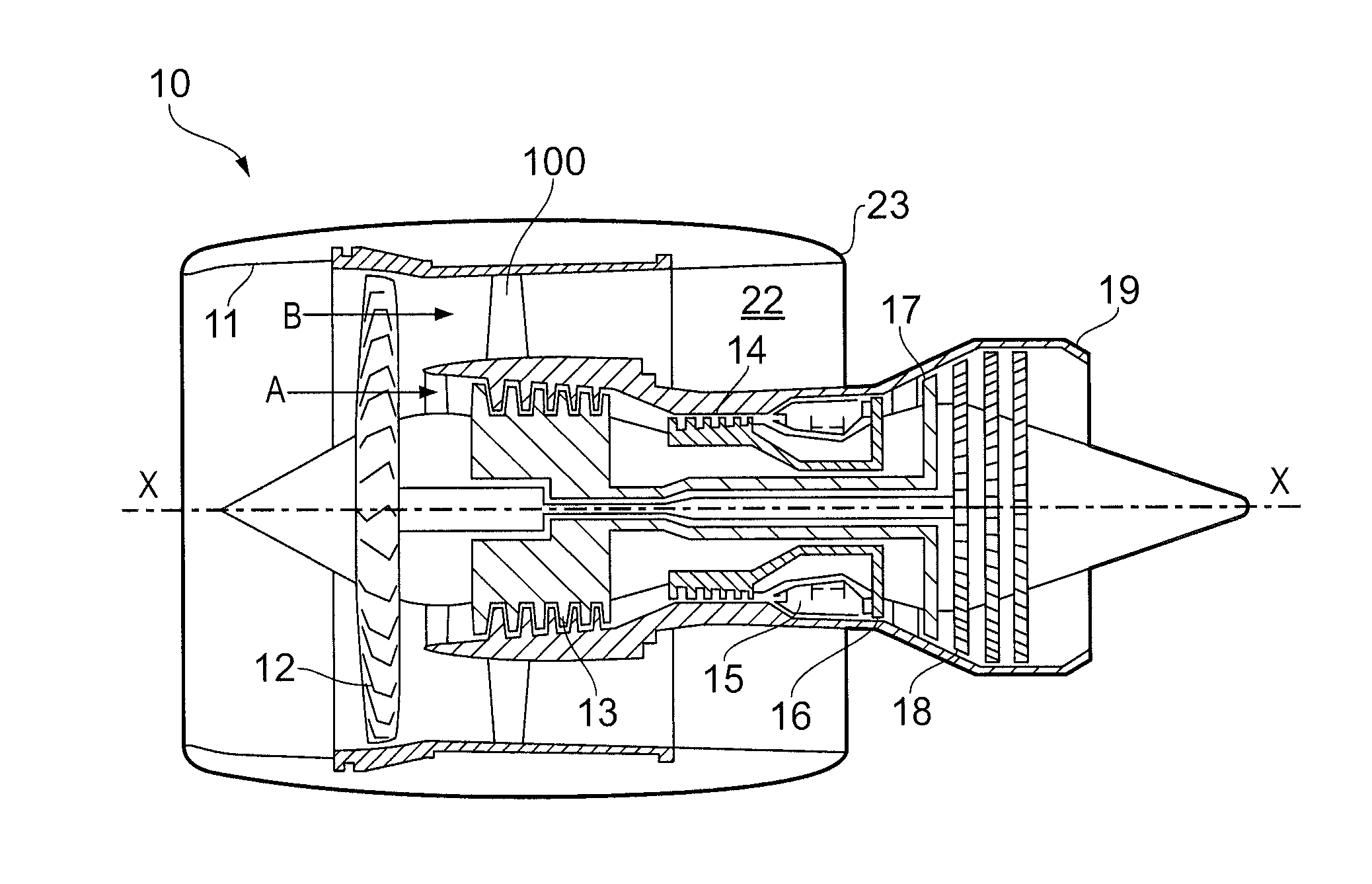

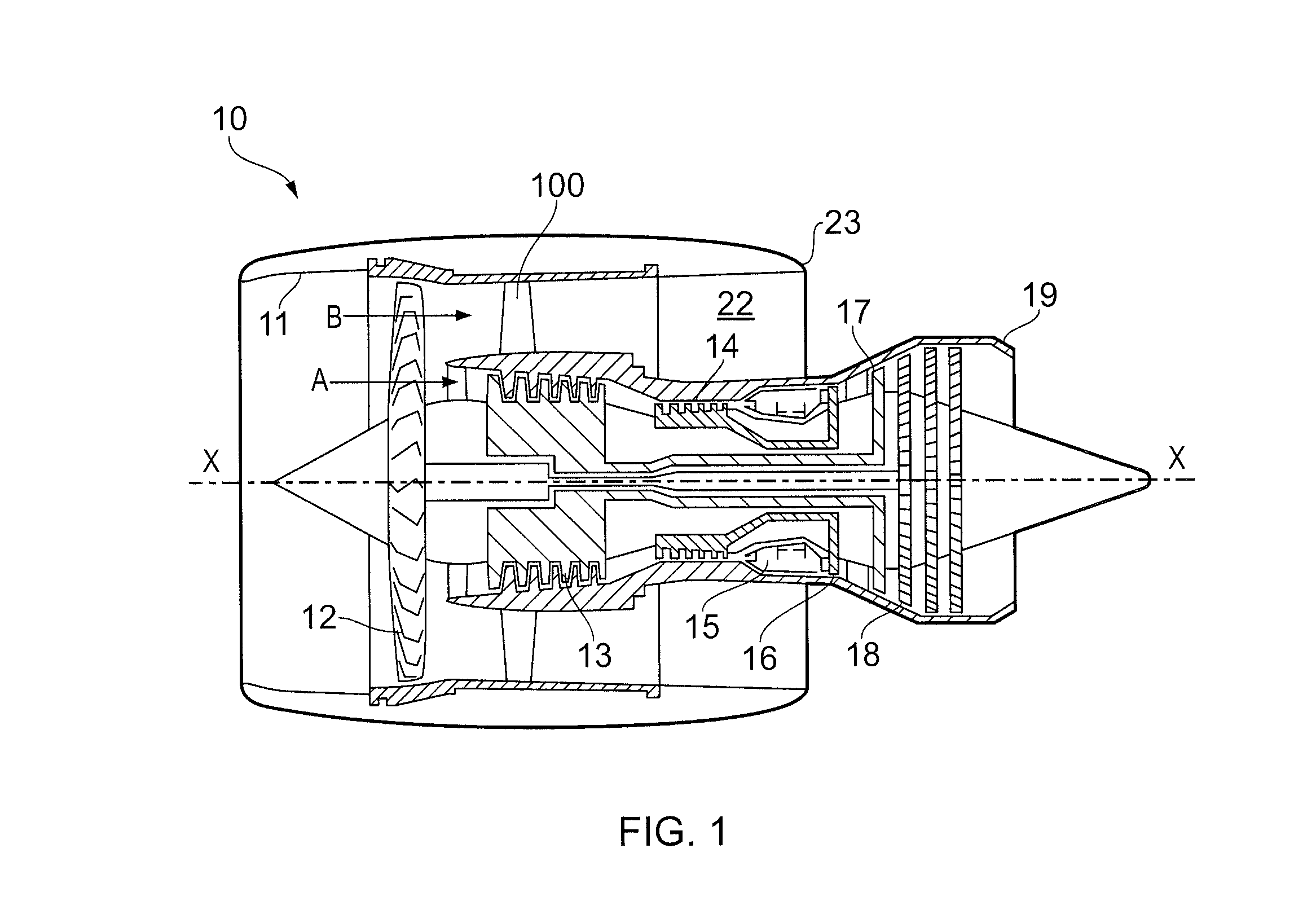

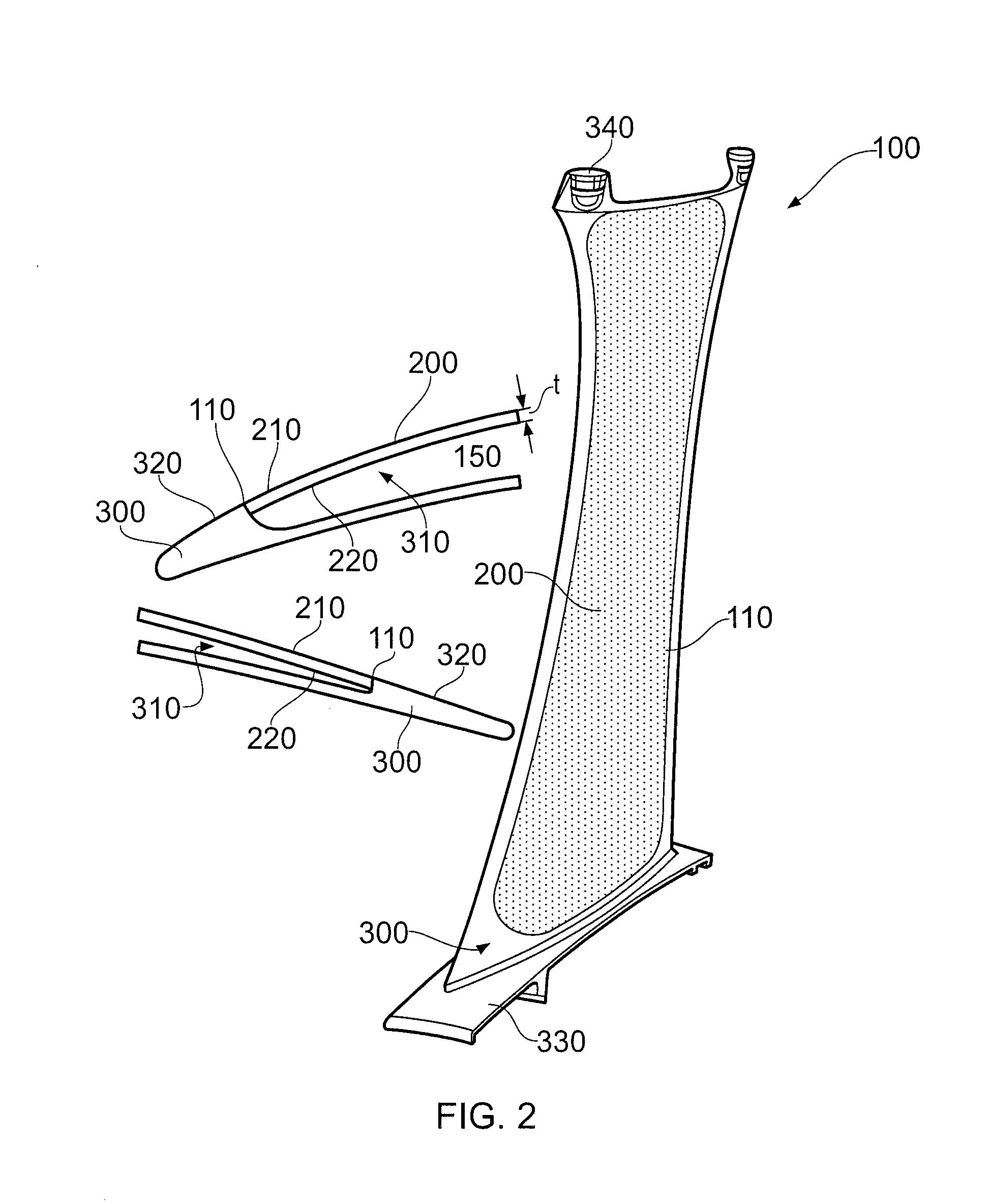

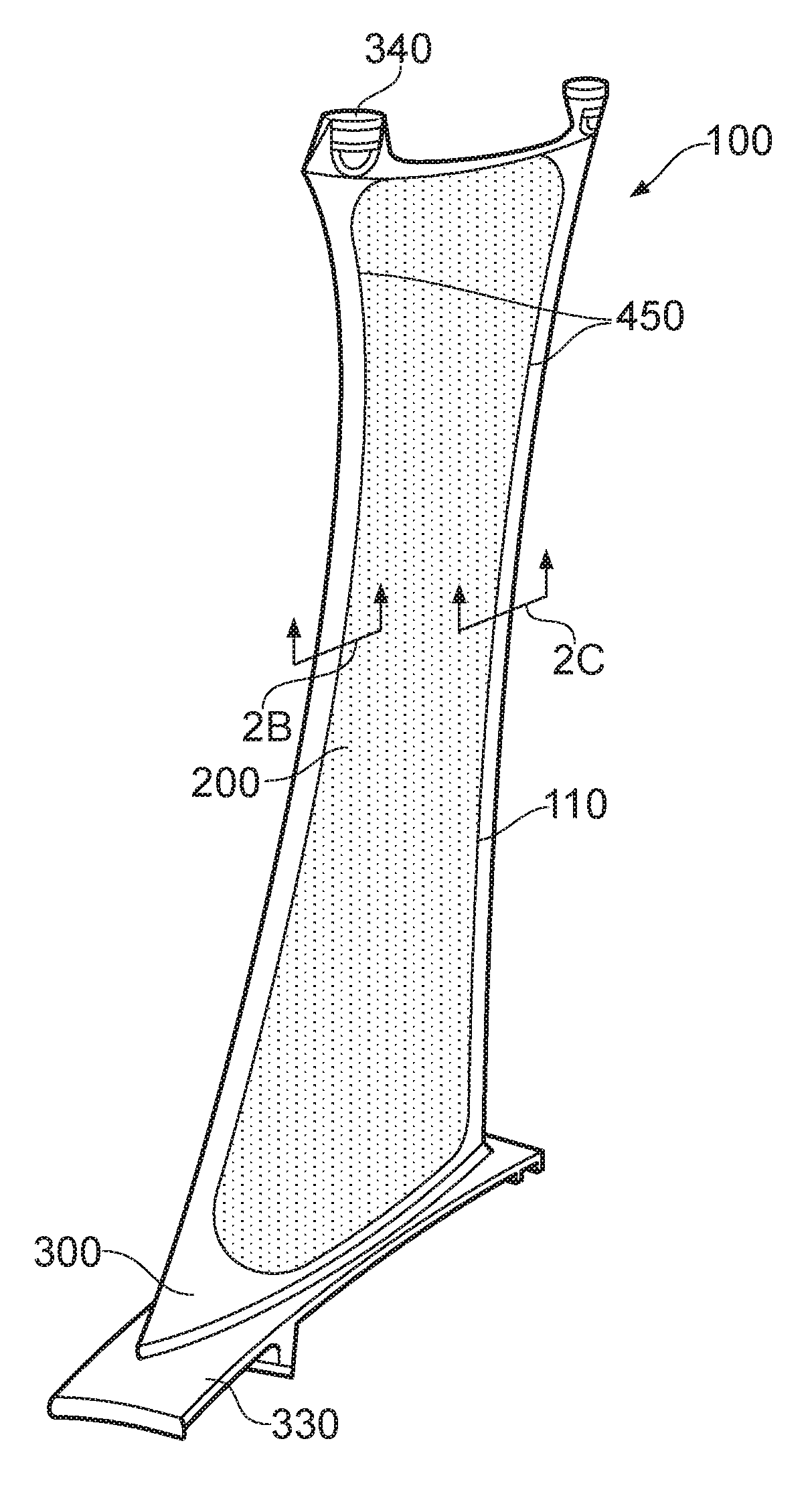

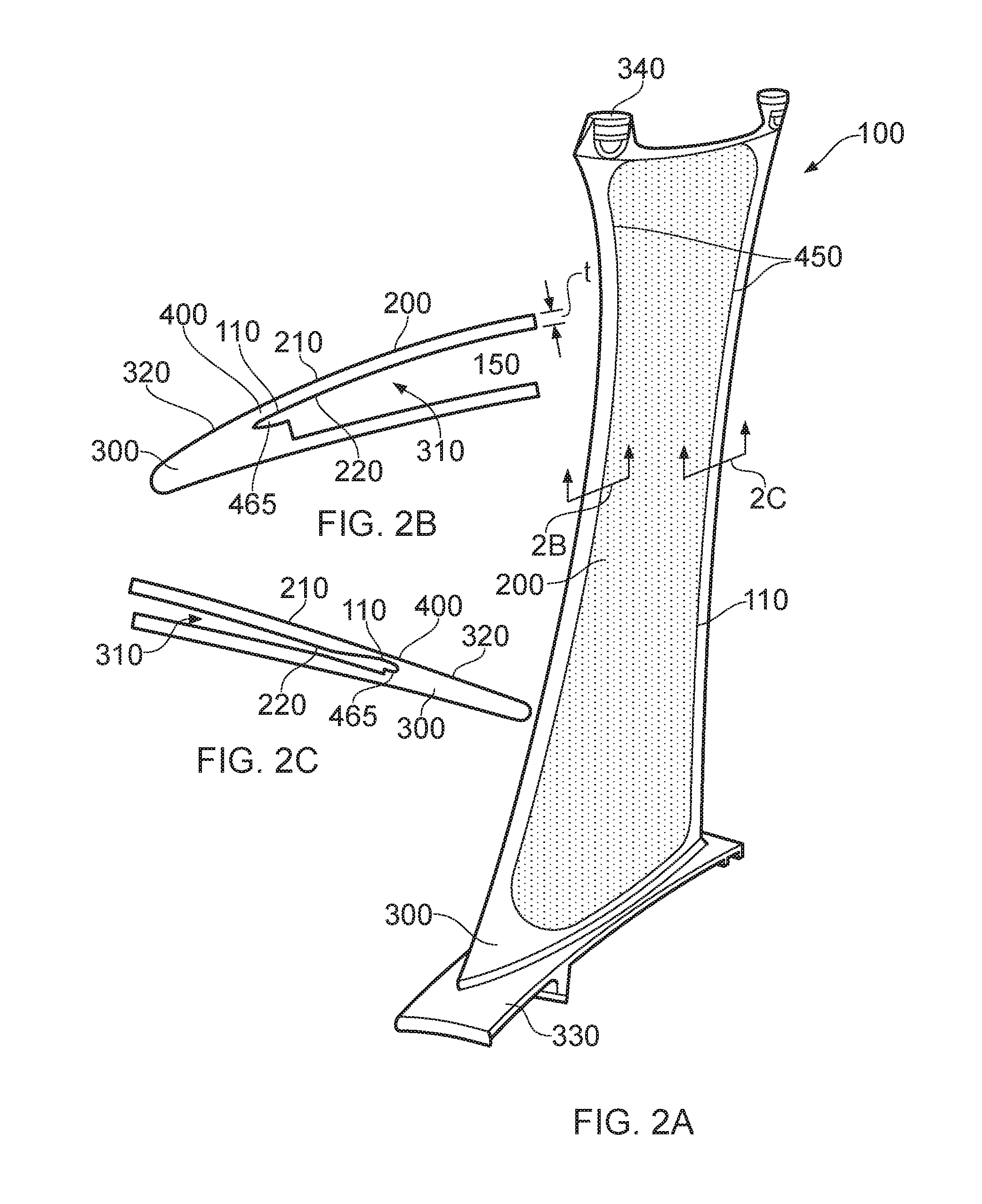

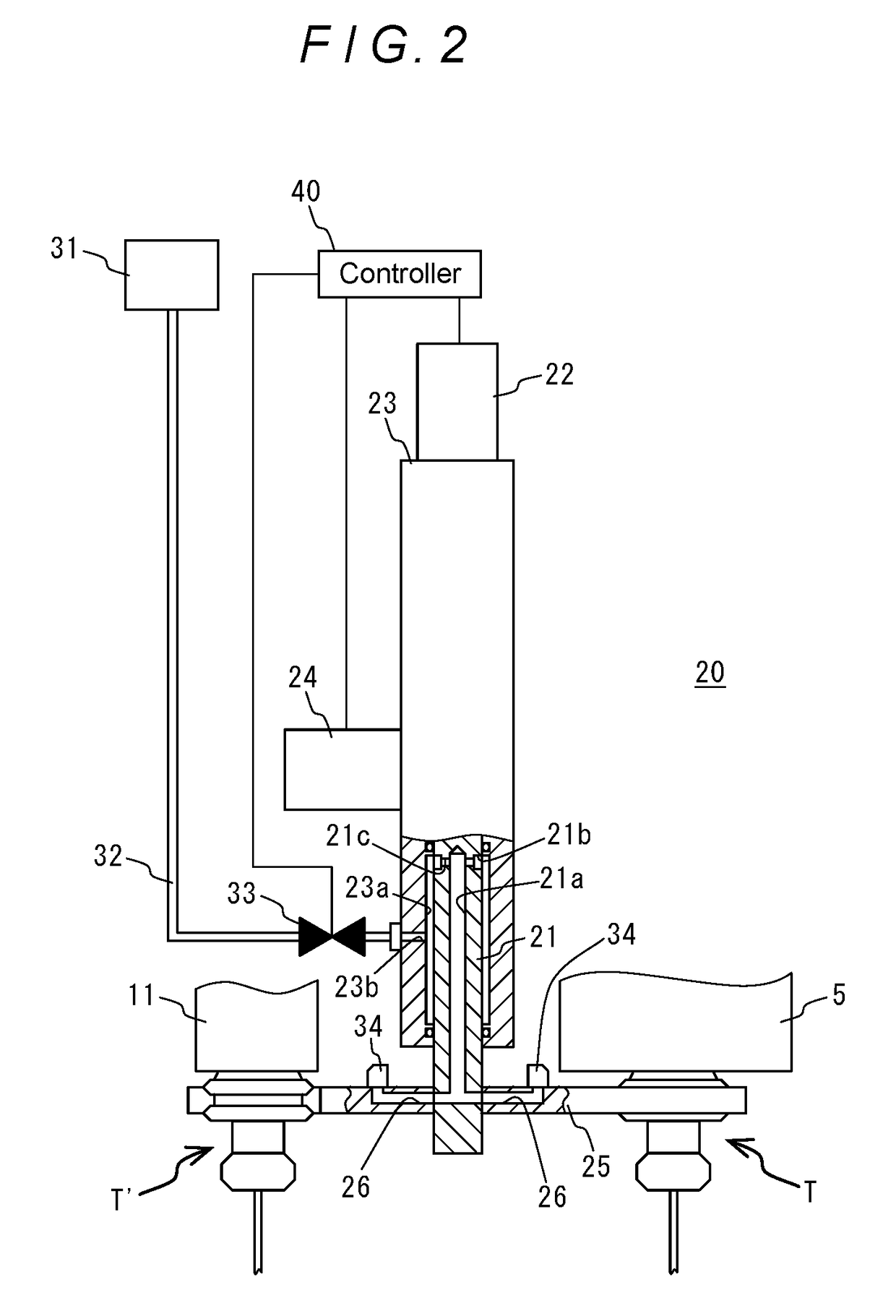

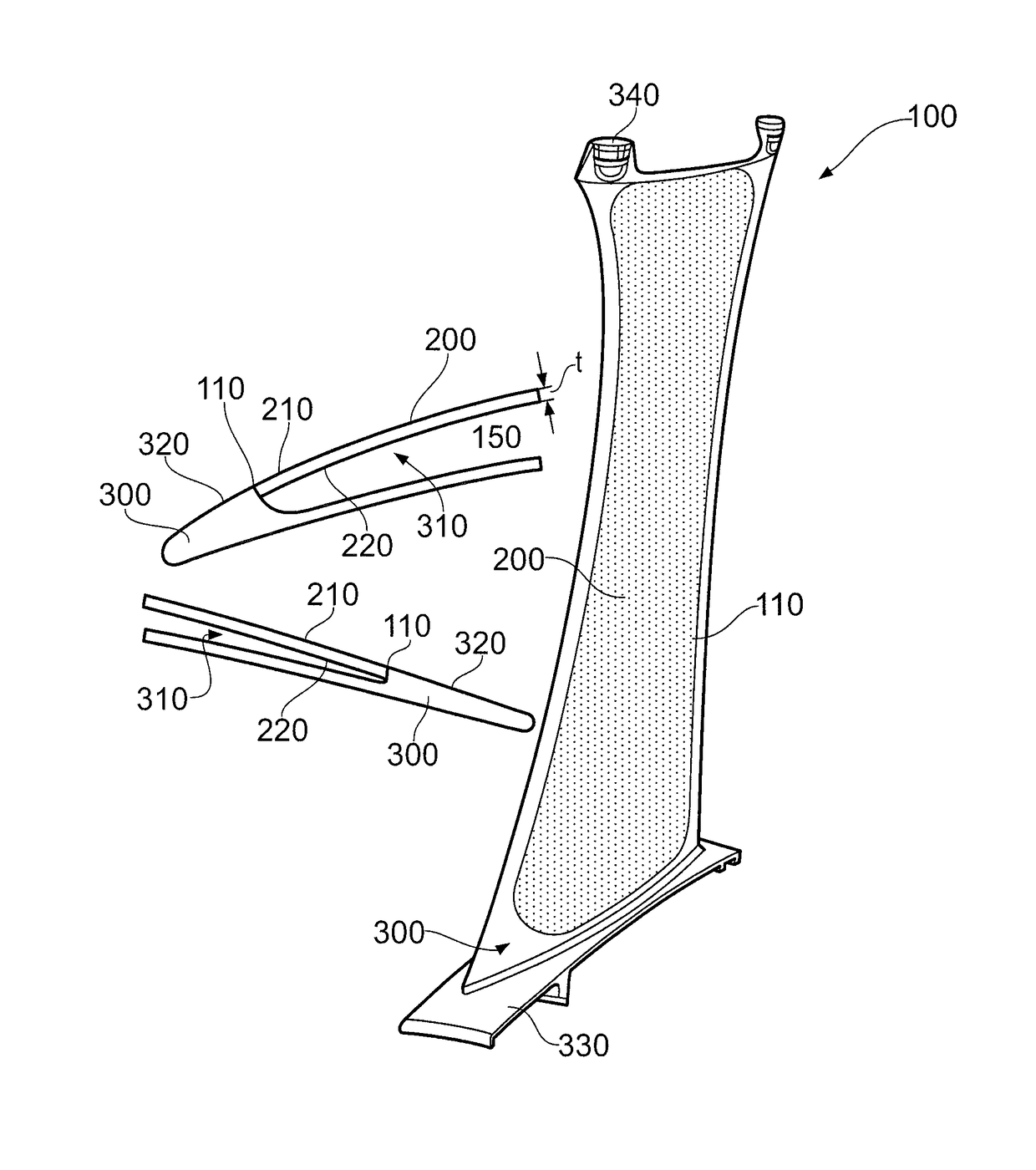

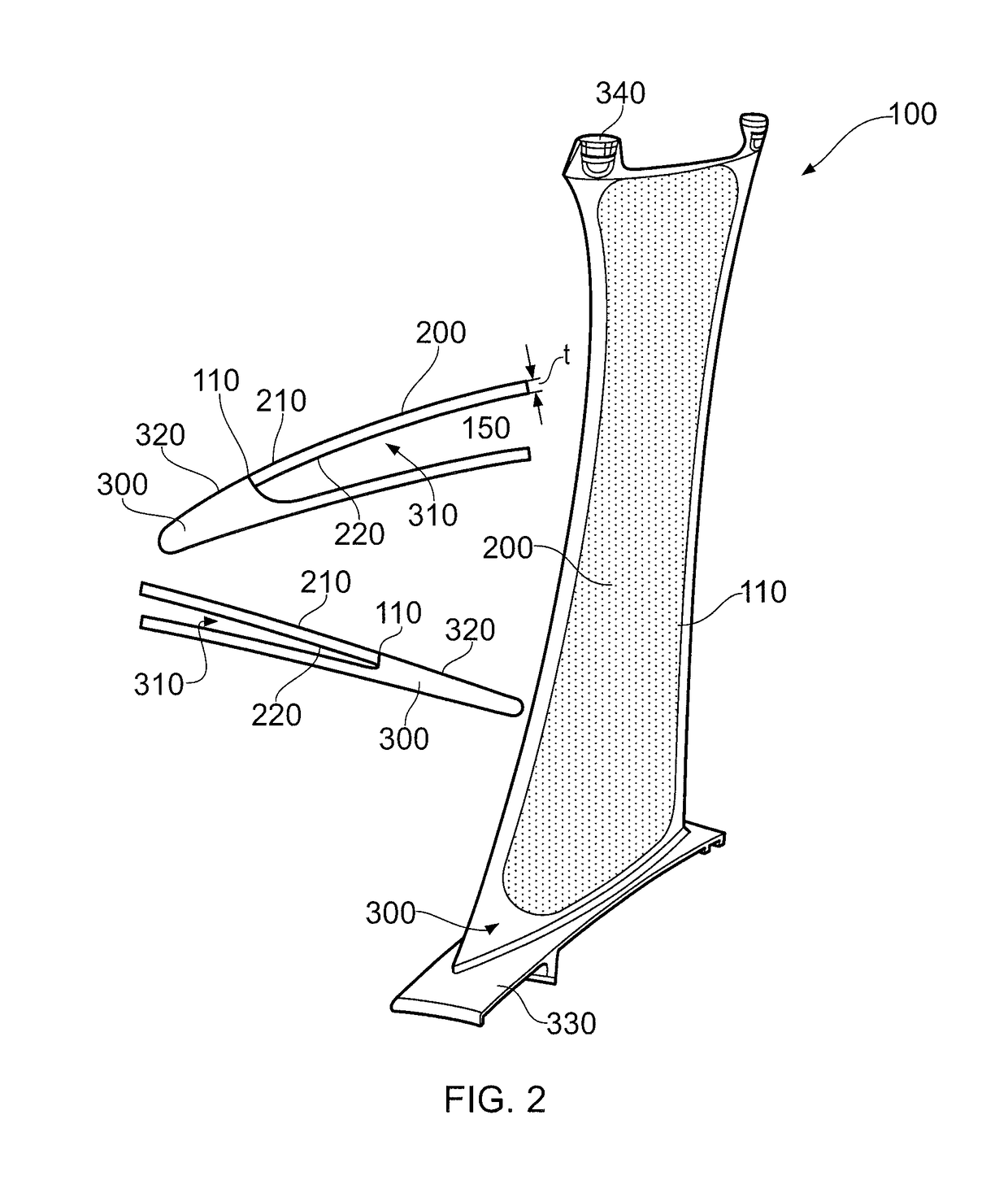

Manufacture of hollow aerofoil

ActiveUS20140271227A1Surface damageEliminate) spatterBlade accessoriesMetal-working apparatusEngineeringGas turbines

A method of manufacturing a hollow aerofoil component for a gas turbine engine includes using a capping panel to cover a pocket in a pocketed aerofoil body. During manufacture, the outer surface of the capping panel is located relative to the pocketed aerofoil body. This ensures that the outer surface of the capping panel is located as accurately as possible. This means that the capping panel can be made to be as thin as possible, which in turn reduces weight and material wastage. Once the capping panel has been located in position, it may be welded to the aerofoil body in order to produce the hollow aerofoil component.

Owner:ROLLS ROYCE PLC

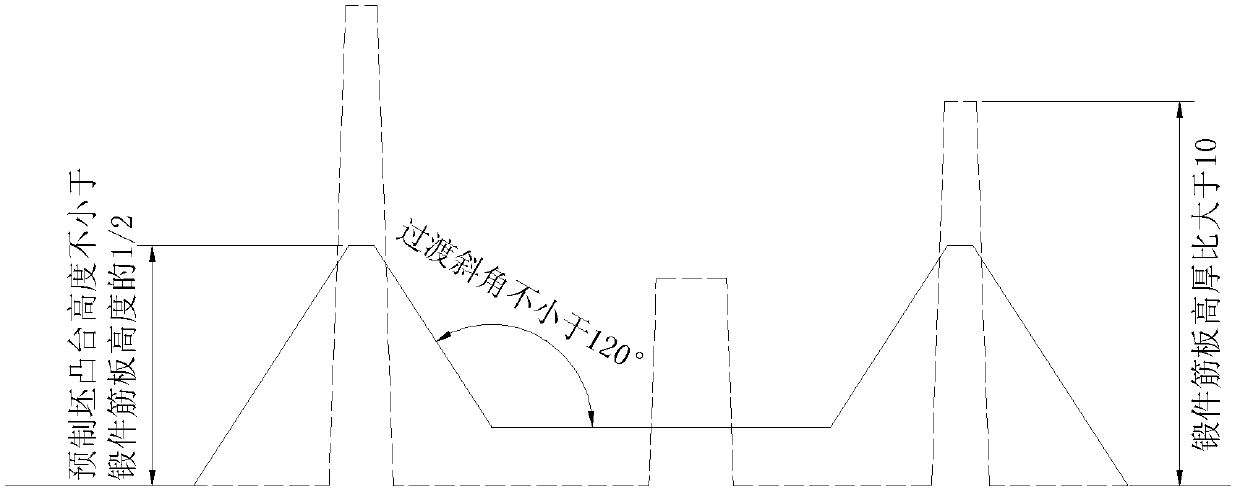

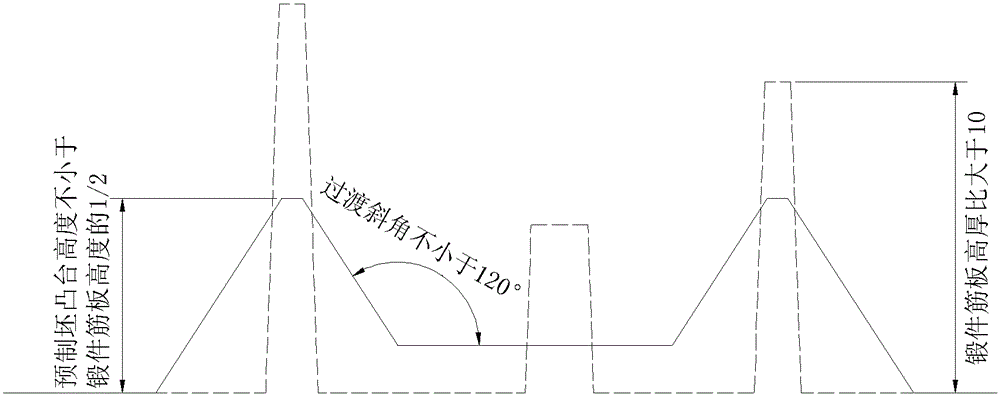

Precision forming method of large high-strength aluminum alloy forged piece

The invention discloses a precision forming method of a large high-strength aluminum alloy forged piece. The precision forming method comprises the steps of designing a forged piece and a mould, designing and manufacturing a prefabricated blank, forming the prefabricated blank into the forged piece in an isothermal forging manner, and the like. With the precision forming method, a large complicated aluminum alloy forged piece with a high-strength plate can be manufactured; compared with a casting piece, the forged piece is more compact in structure and fewer in defects, and the machining treatment required by the forged piece is little; the forged piece belongs to a near net shape forming precision forged piece; the product quality is greatly improved.

Owner:宝武特种冶金有限公司

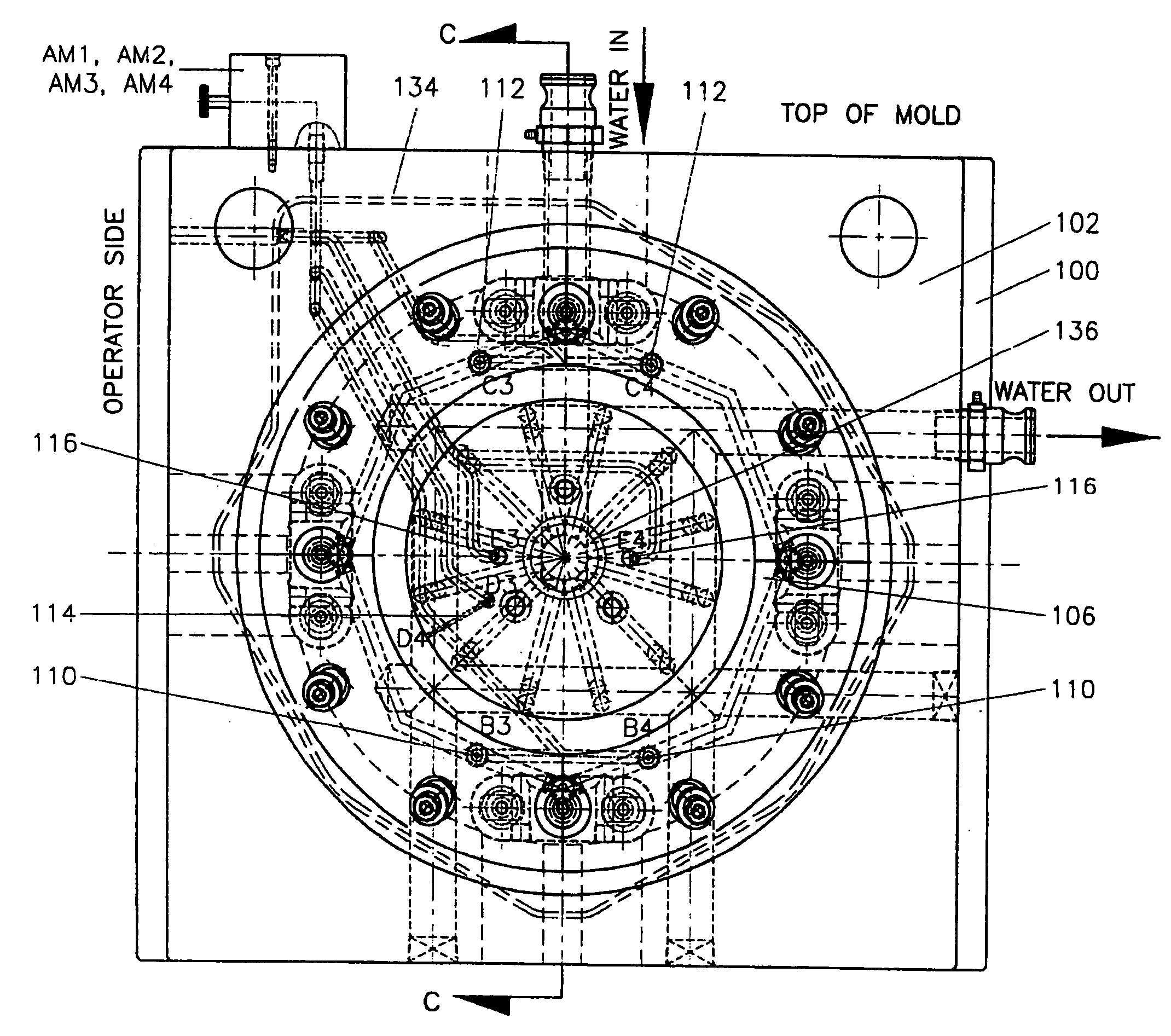

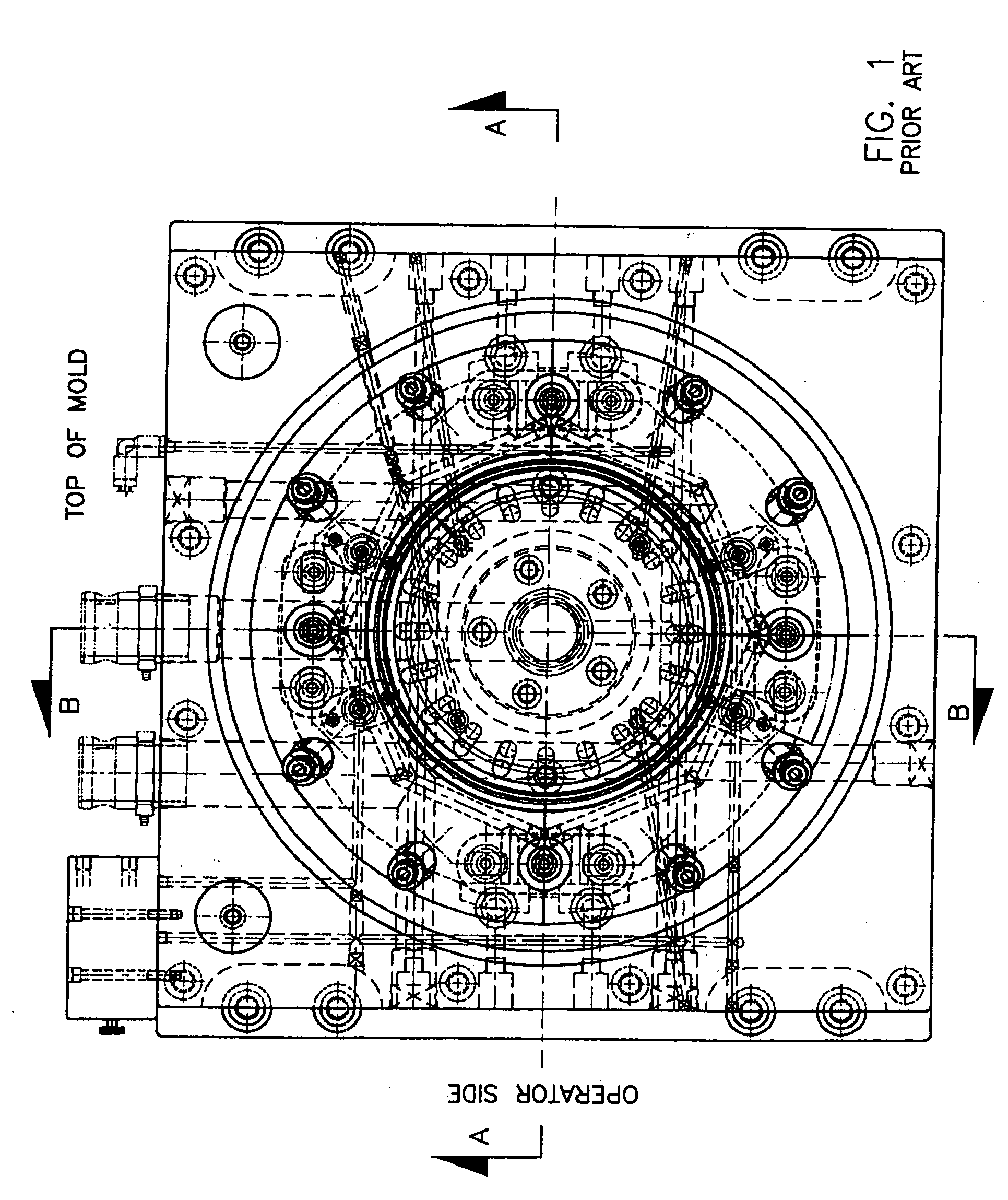

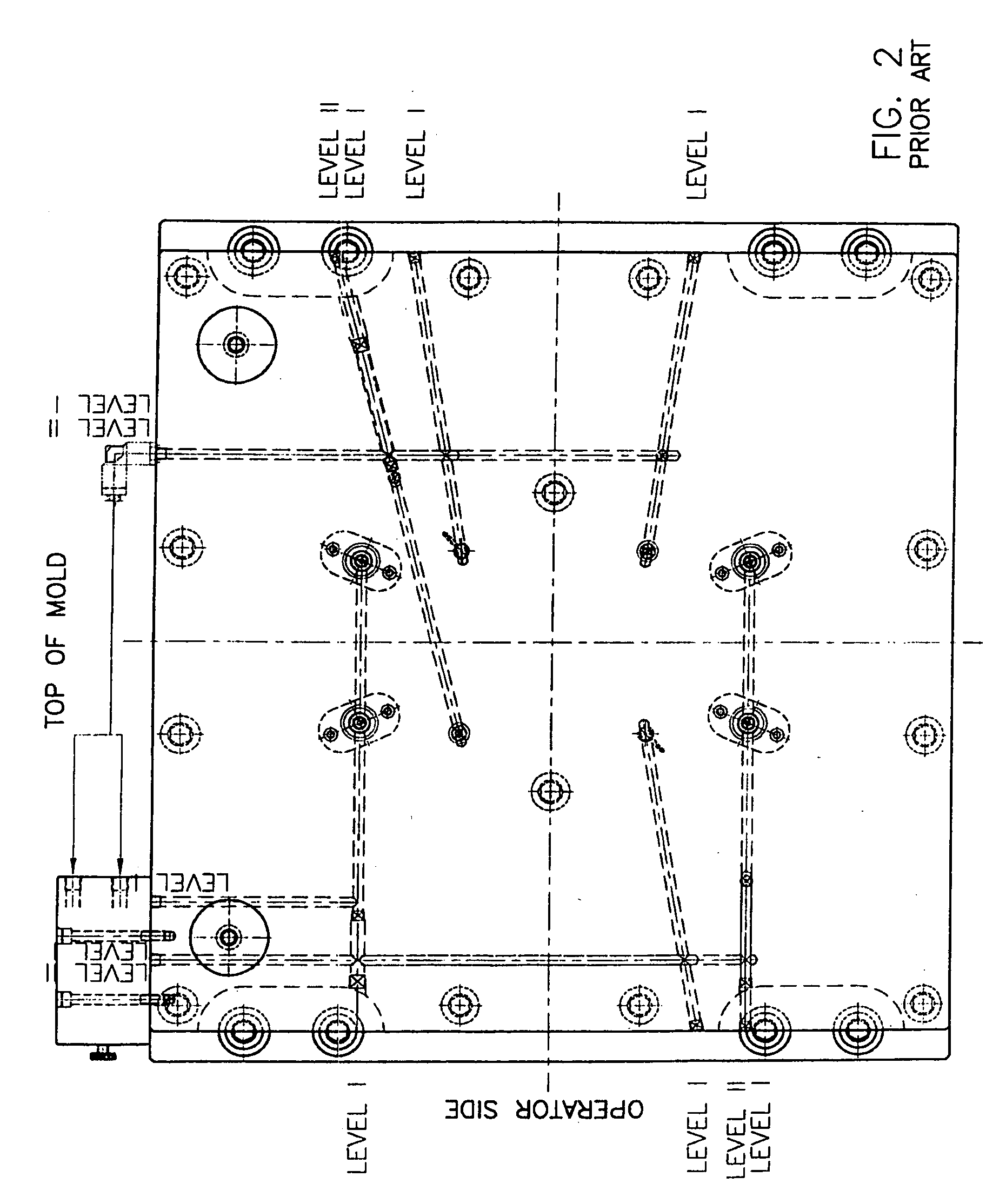

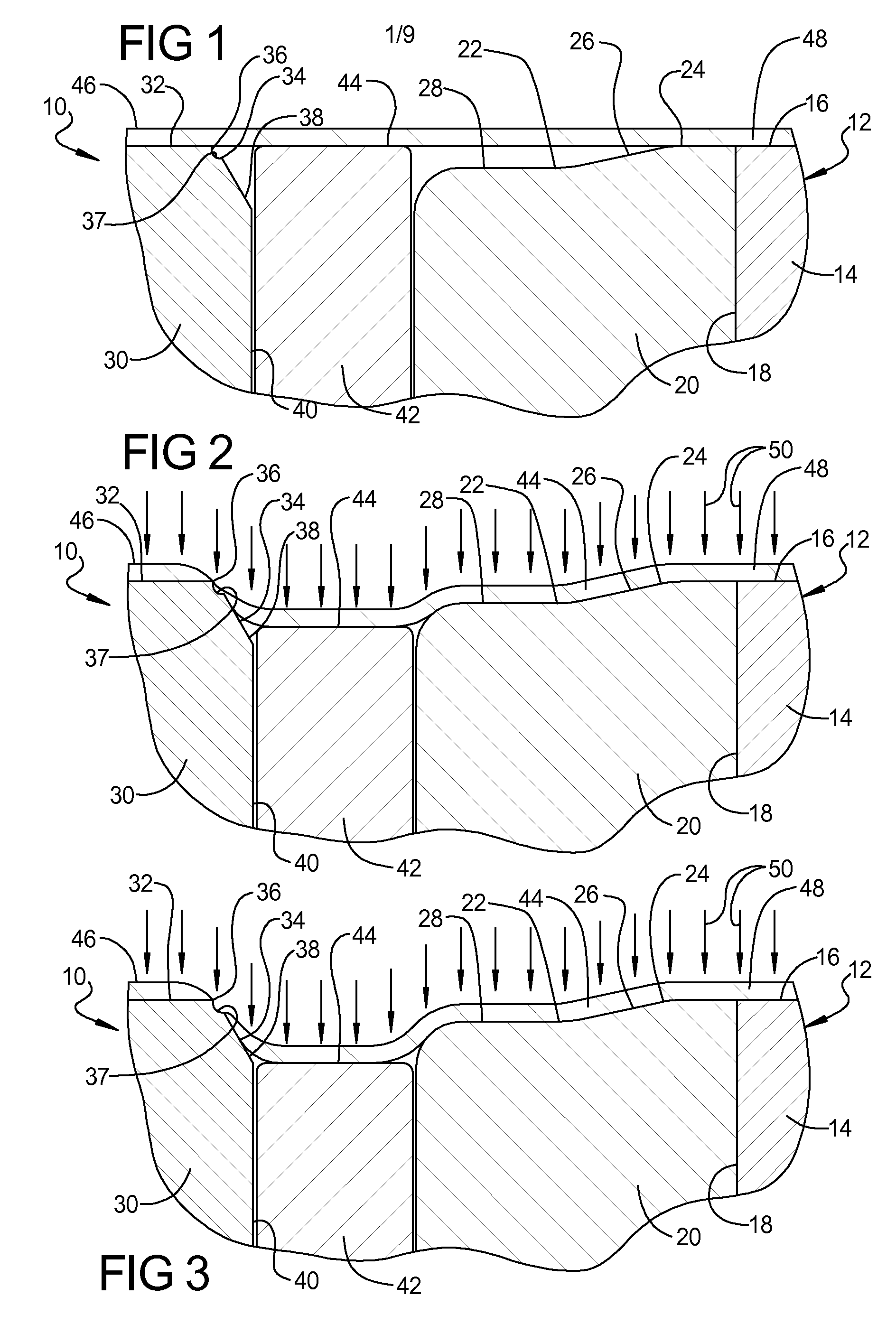

Grooved-surface air conduit for injection molds

An improved mold assembly for producing an article and for use with an air source is disclosed. The mold assembly is of the type including at least two mold portions configurable to form a mold having an interior mold cavity in the shape of said article, one or more of said mold portions each including an interior conduit for delivering air from said air source in use. The improvement comprises, for each of said one or more mold portions, a pair of mold parts each having an abutment surface, one of said abutment surfaces having defined therein a groove. The pair of mold parts is disposed in an operative configuration whereat they define at least in part said each mold portion, whereat the abutment surfaces lie flush against one another and whereat the groove defines at least part of the interior conduit in said each mold portion.

Owner:TOP GRADE MOLDS

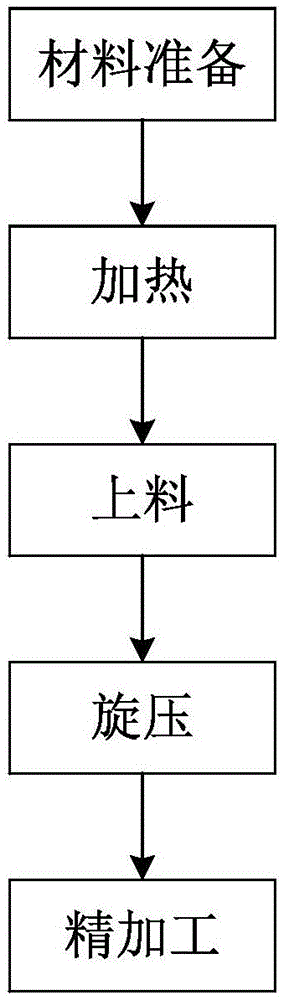

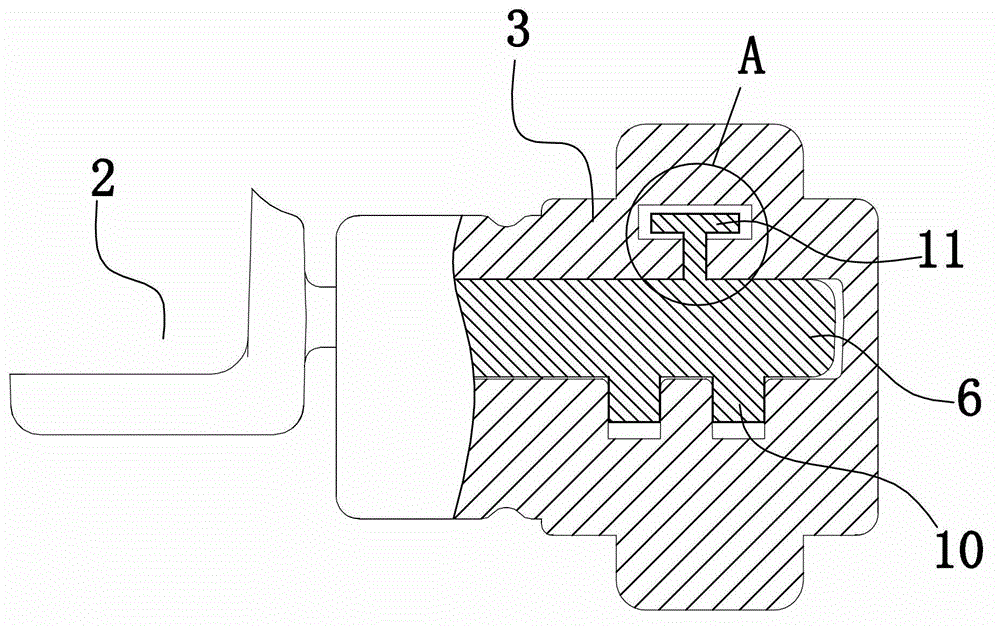

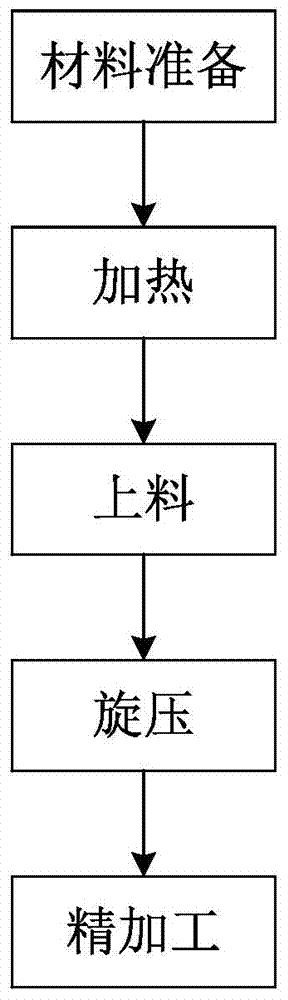

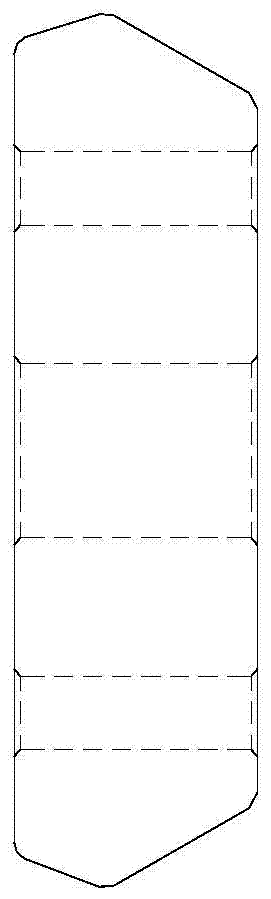

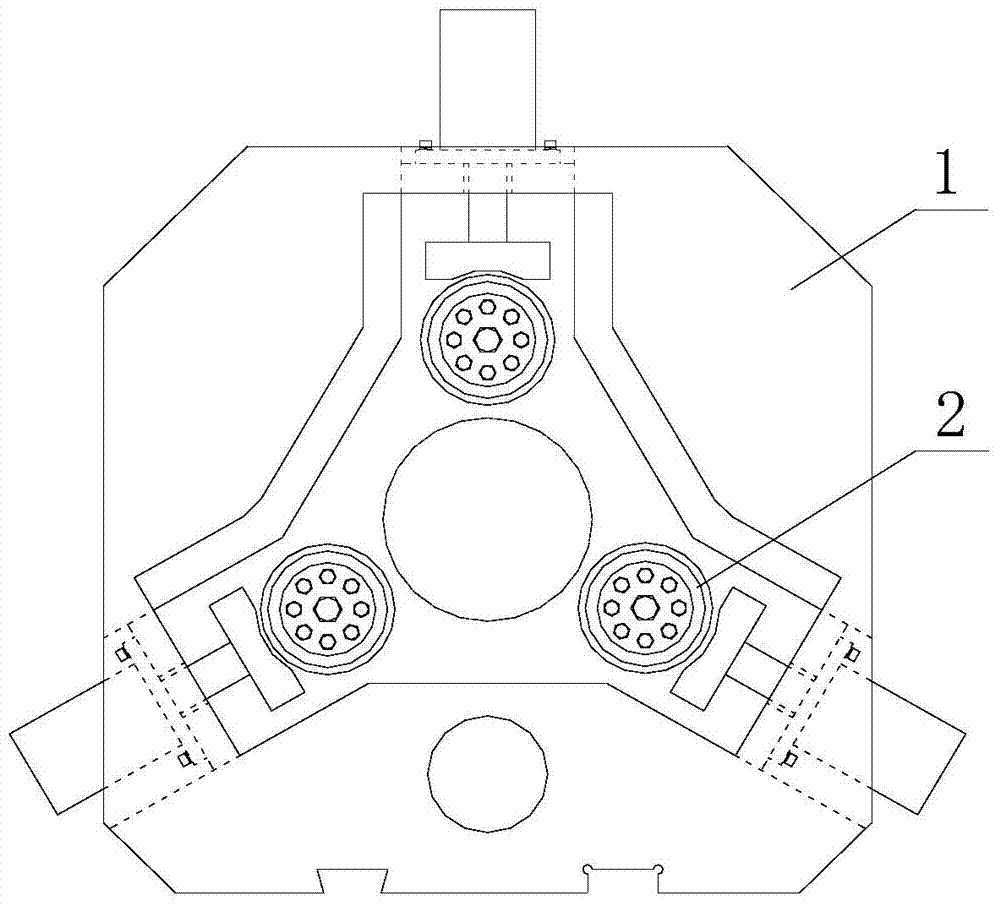

Brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank

ActiveCN105081041AReduce processing workloadHigh forming precisionVehicle componentsMaterials preparationBrute force

The invention relates to a brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank and belongs to the technical field of plastic forming of long-shaft parts. According to the brute-force hot-spinning accurate plastic forming method, the problems that hollow train shaft moulds are difficult to manufacture and complex in manufacturing process are solved. The brute-force hot-spinning accurate plastic forming method comprises the steps of material preparing, heating, feeding, spinning and refining. By means of a brute-force hot-spinning technique, the rotating speed of work pieces, the feeding speed of a rotary wheel and the axial moving speed of a rotary wheel frame are controlled by a numerical controlling technique. Thus, high-accuracy hollow train shaft workblank can be obtained in a spinning manner, and quick accurate plastic forming of the hollow train shaft workblank can be achieved. The brute-force hot-spinning accurate plastic forming method is simple in manufacturing procedure, good in metal fiber flow direction, small in machining allowance, high in material utilizing rate, mouldless in forging, low in manufacturing cost and suitable for large batch production of various specifications of hollow train shafts.

Owner:QINGDAO ZHONGTIANPENG FORGING MFG CO LTD

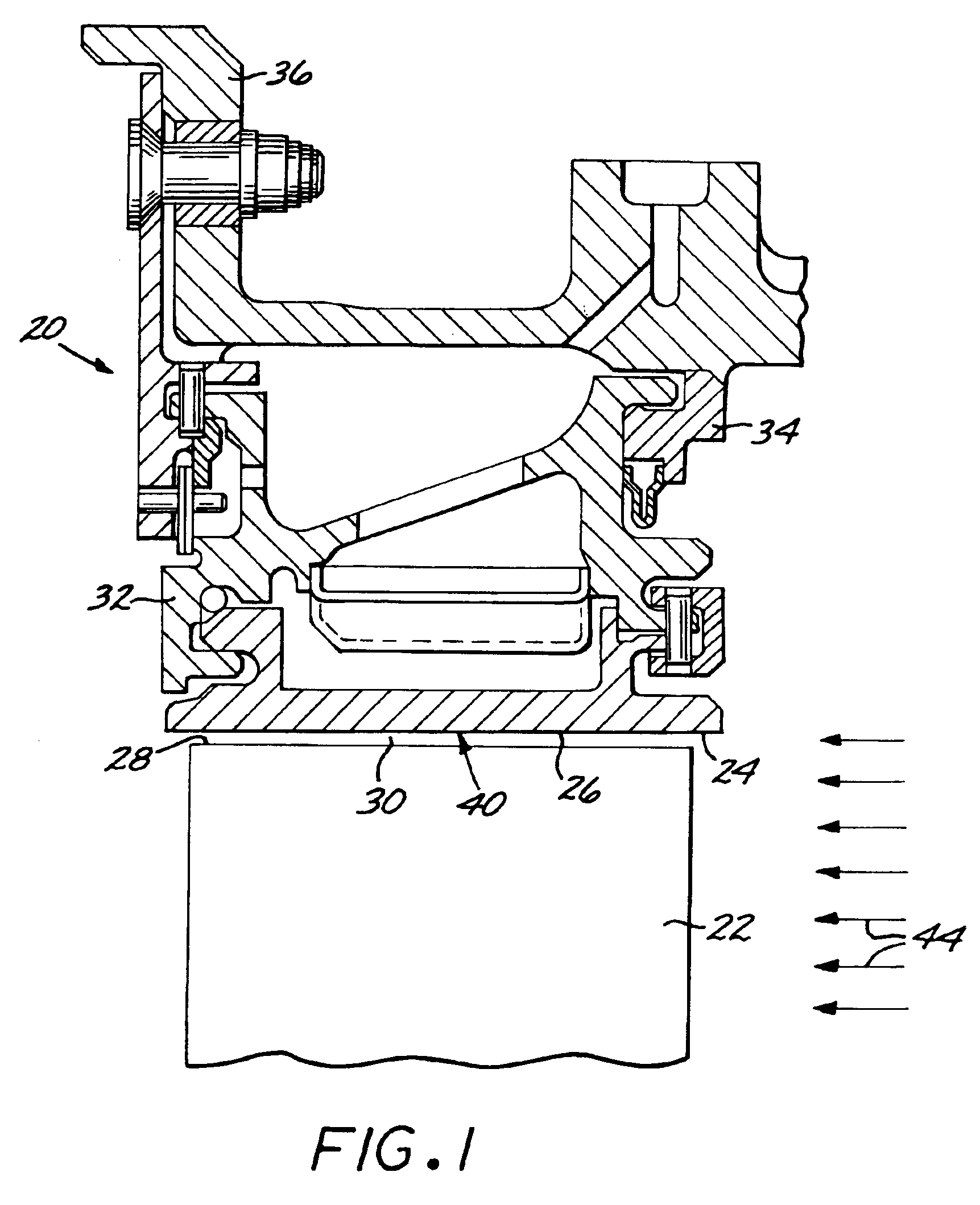

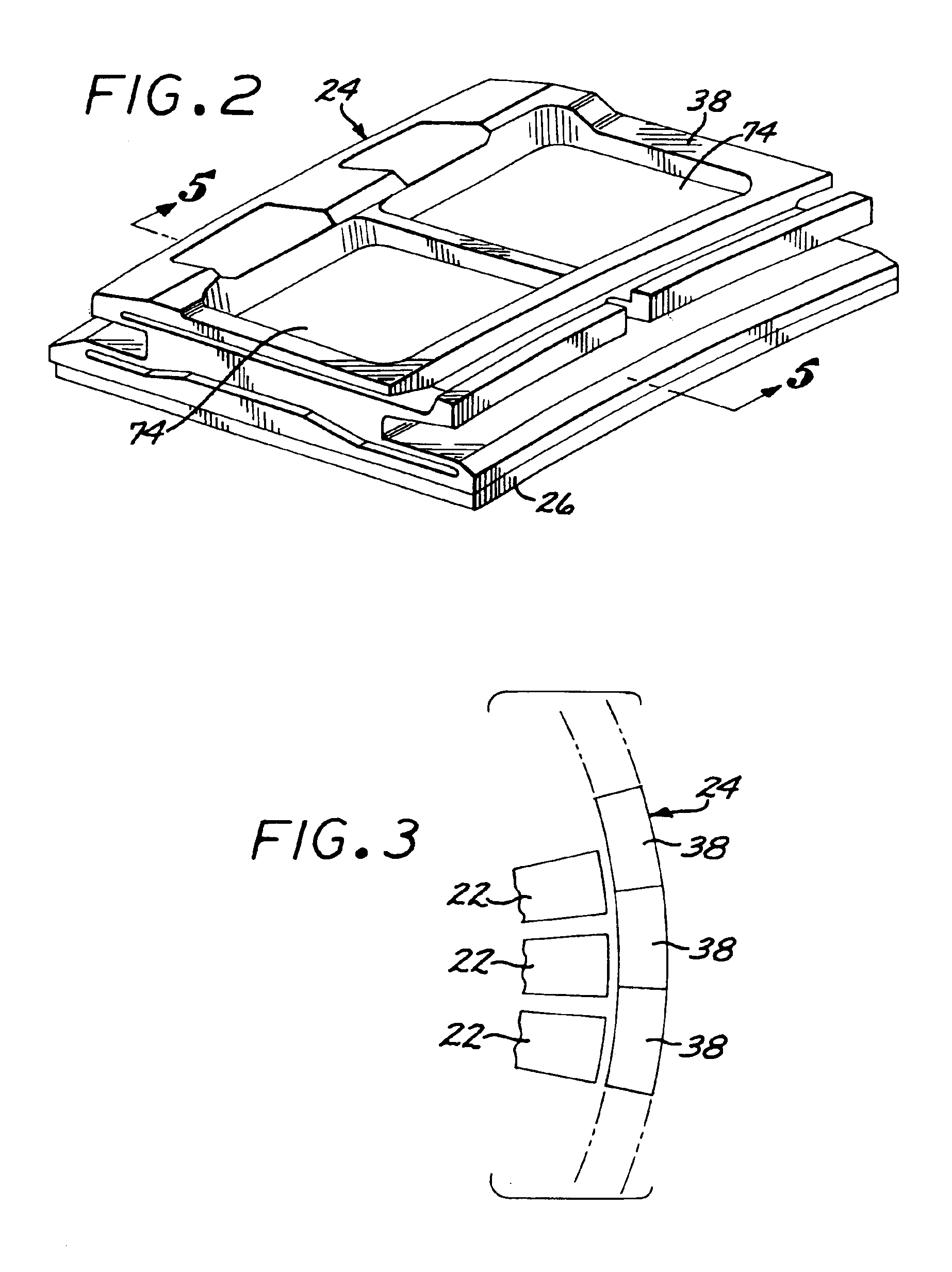

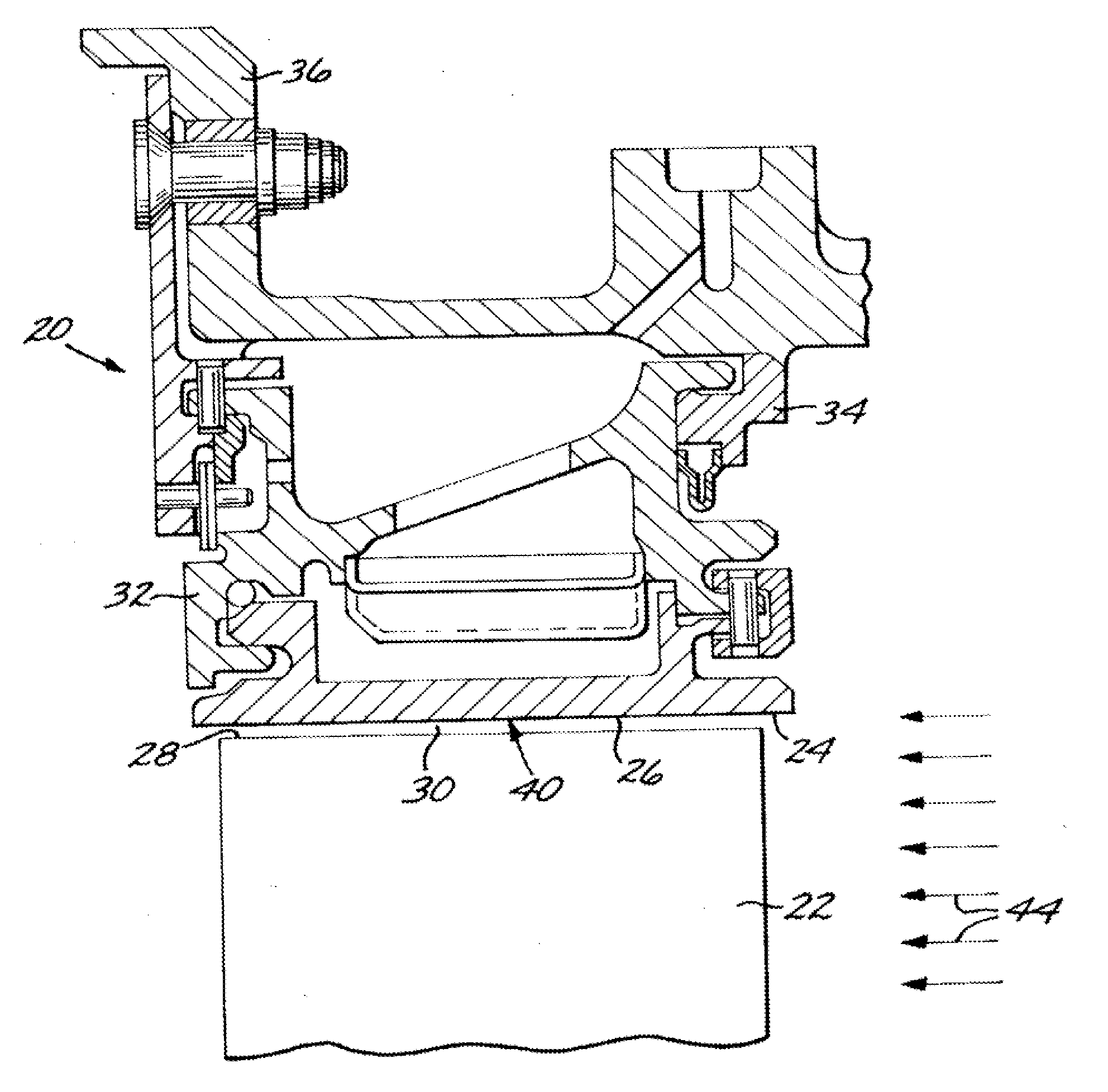

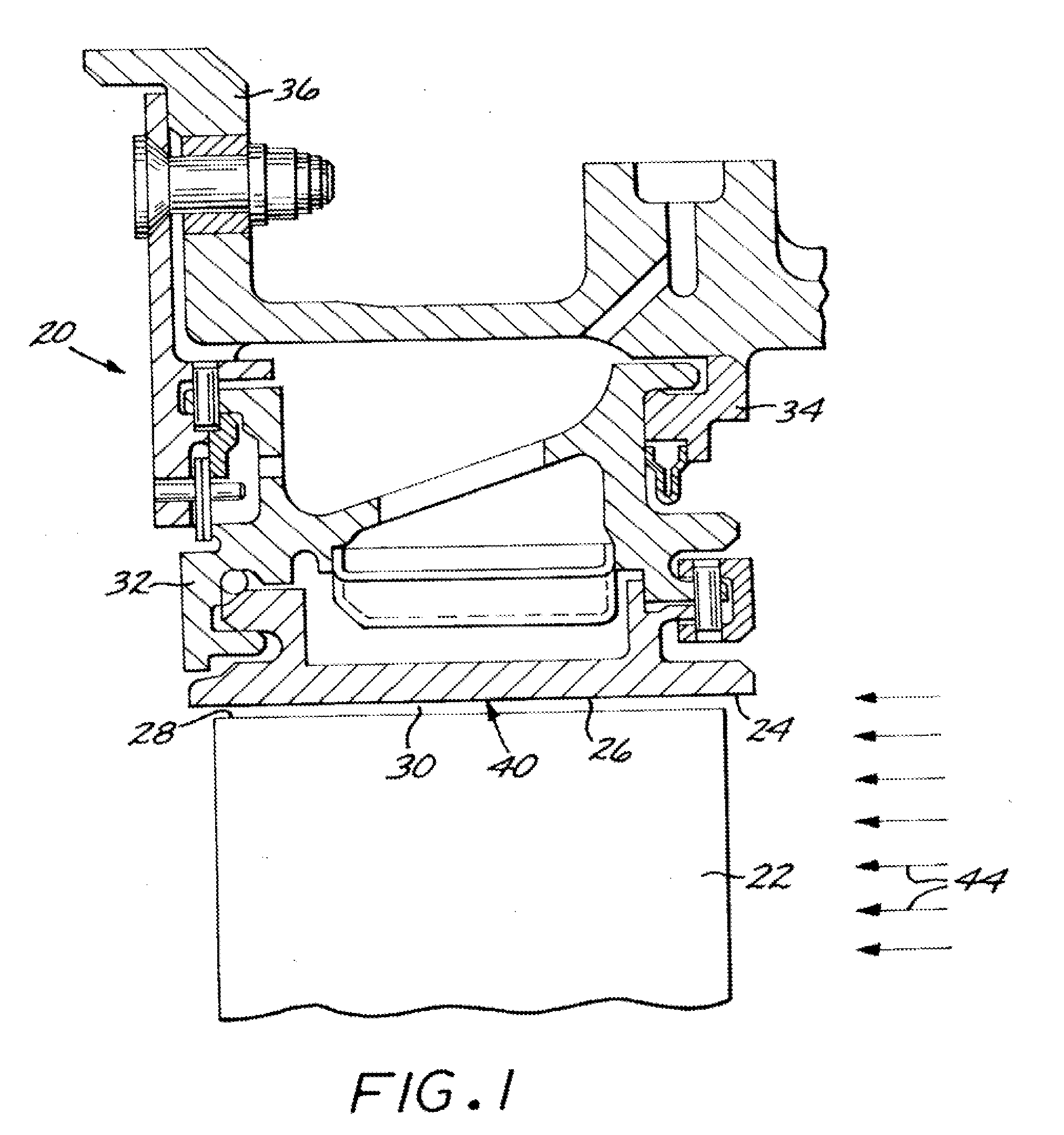

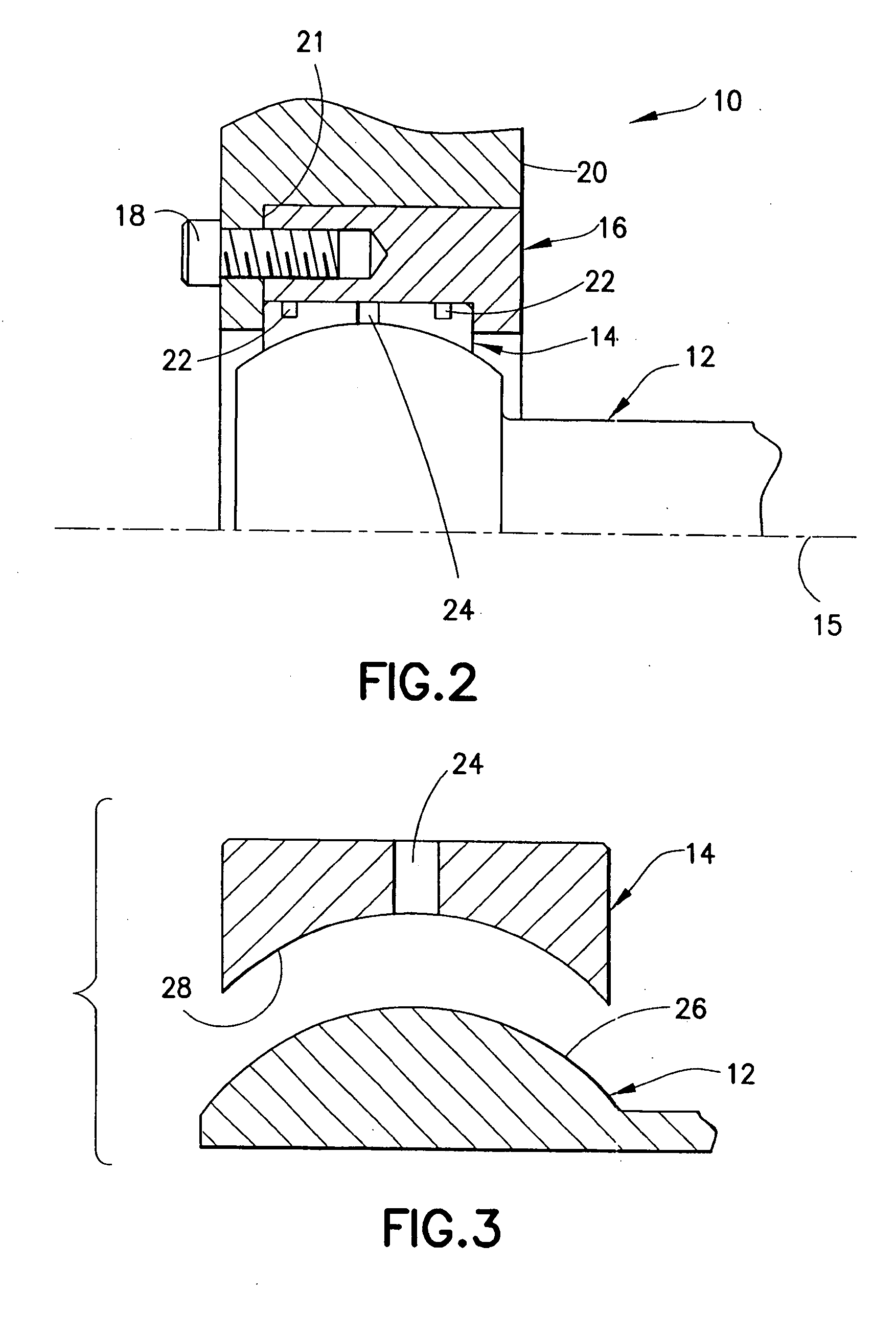

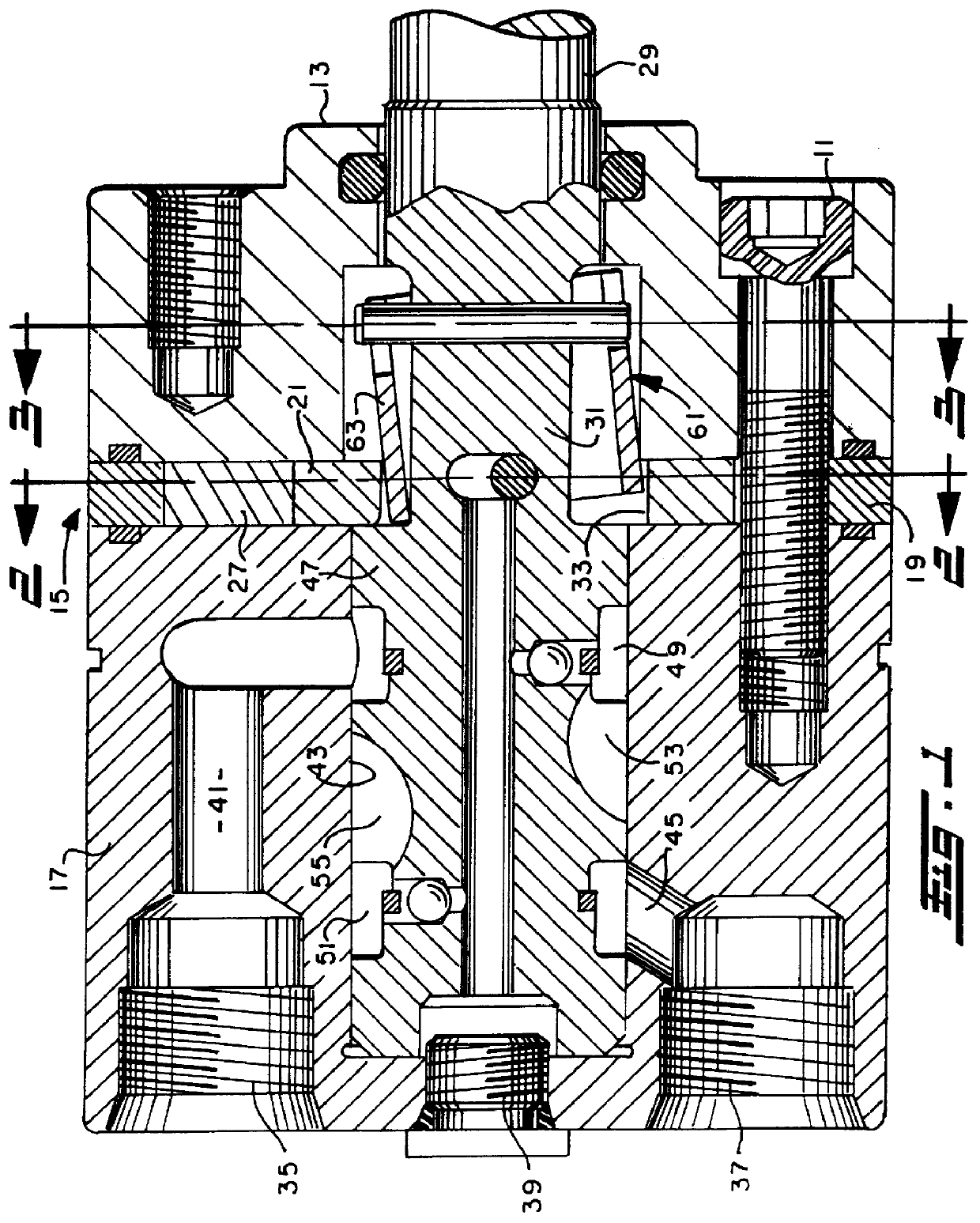

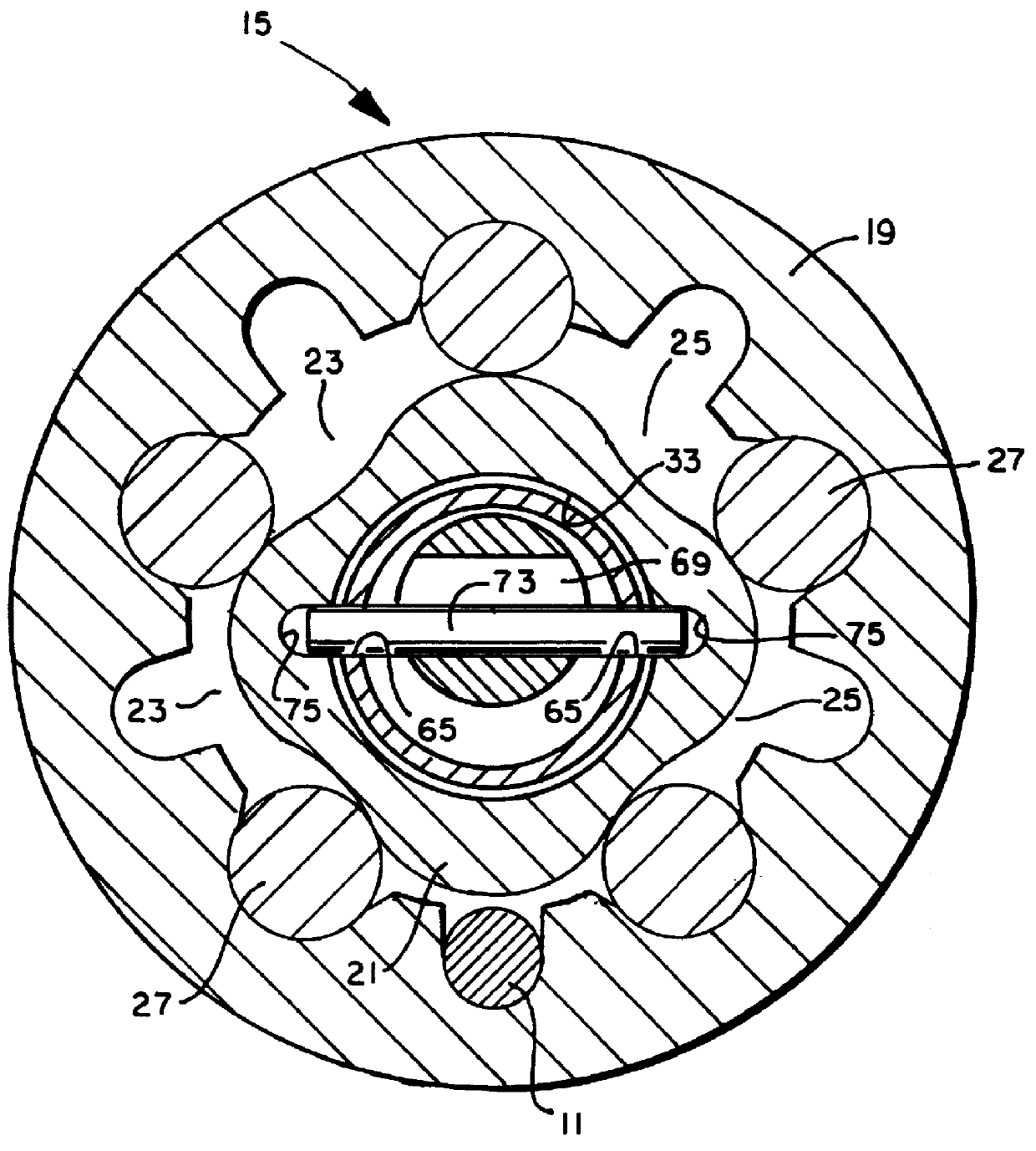

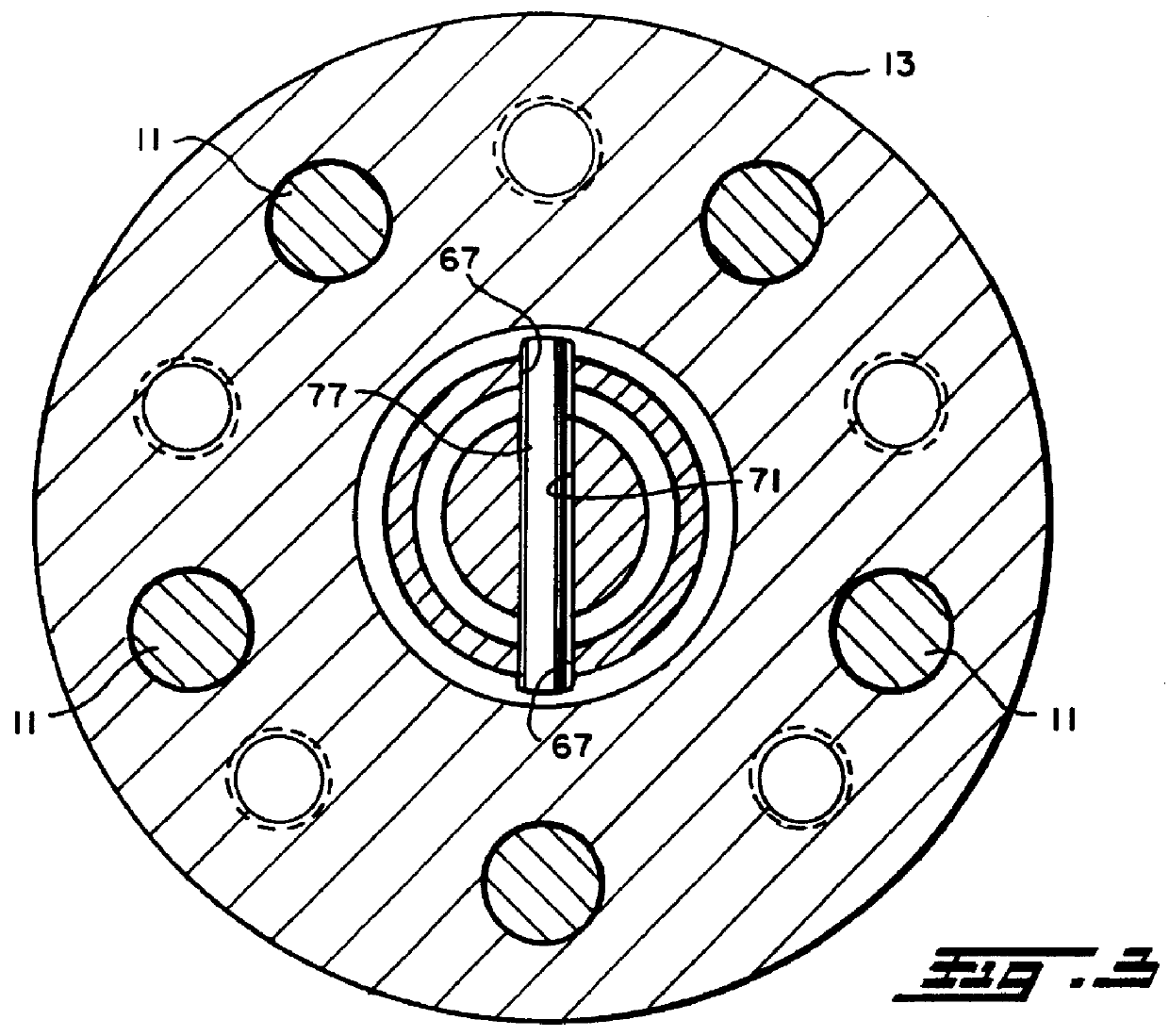

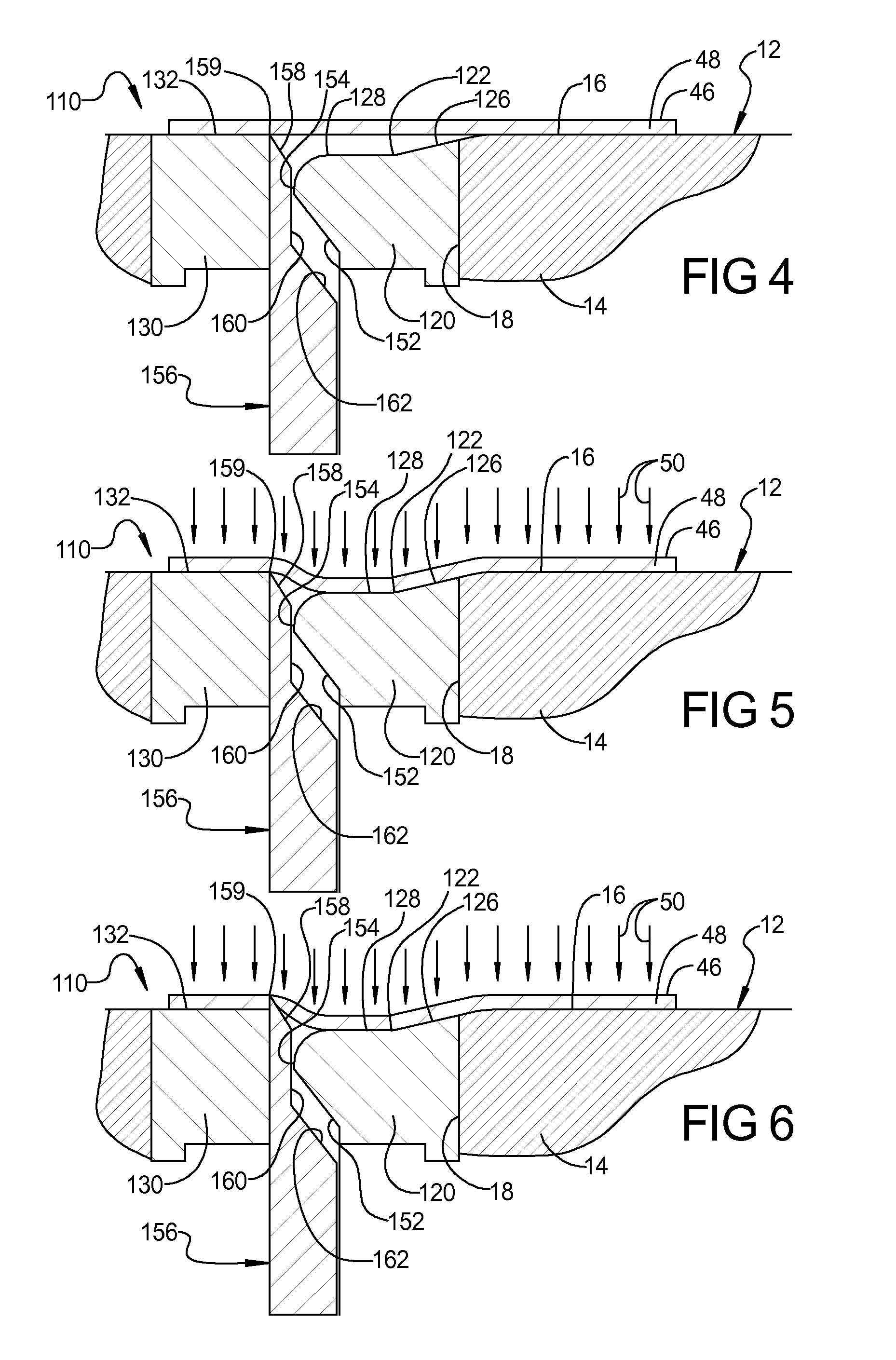

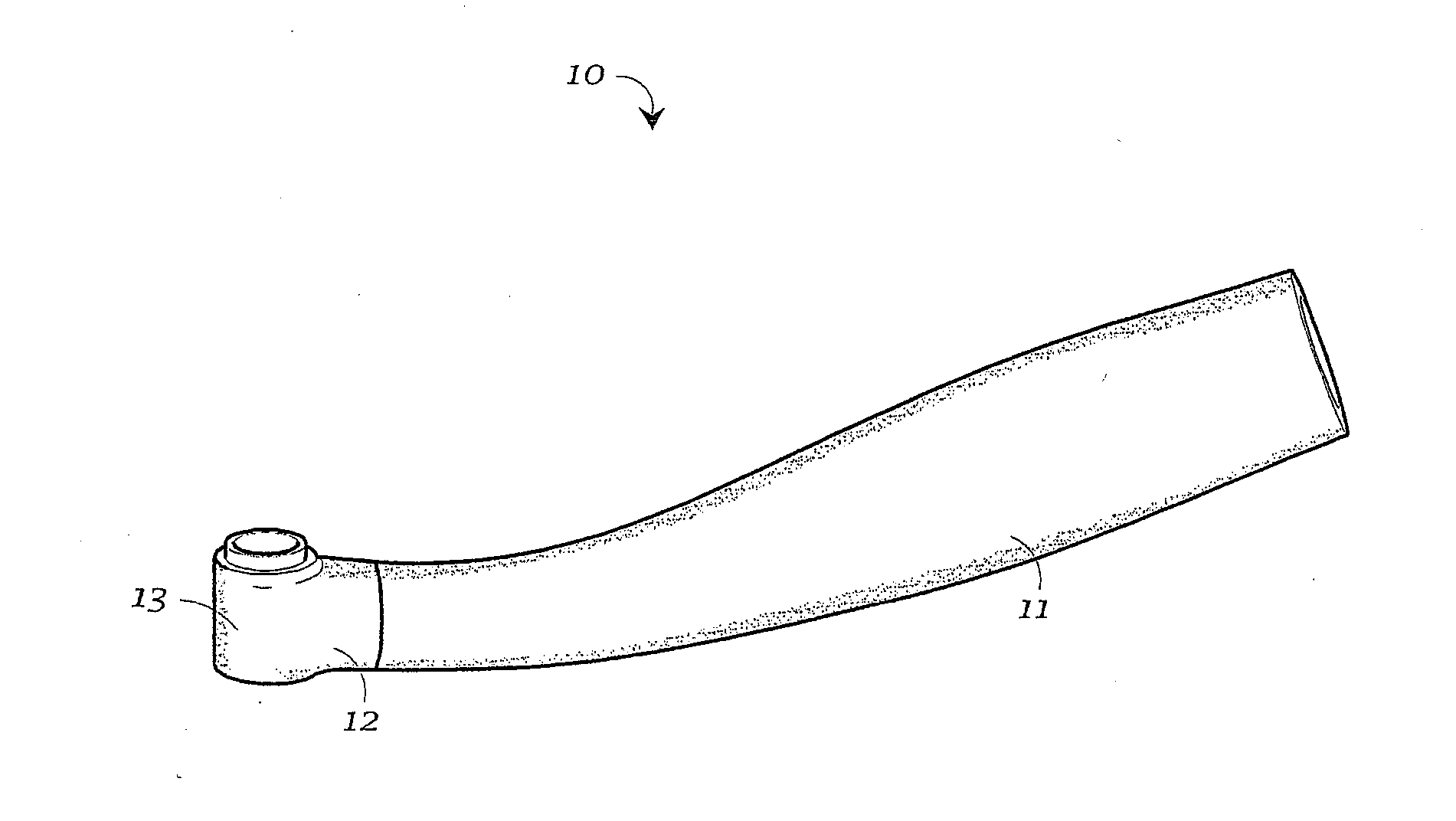

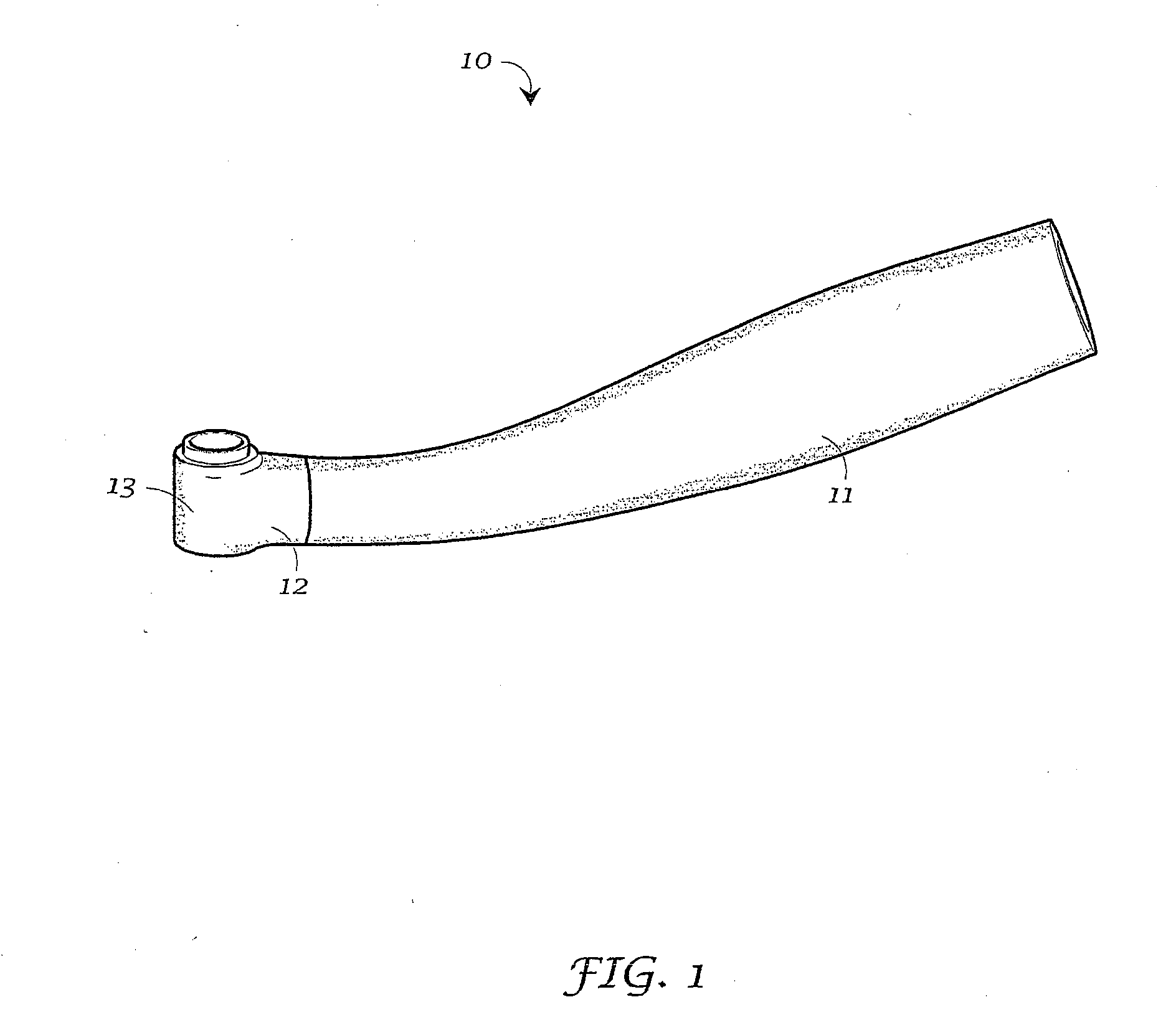

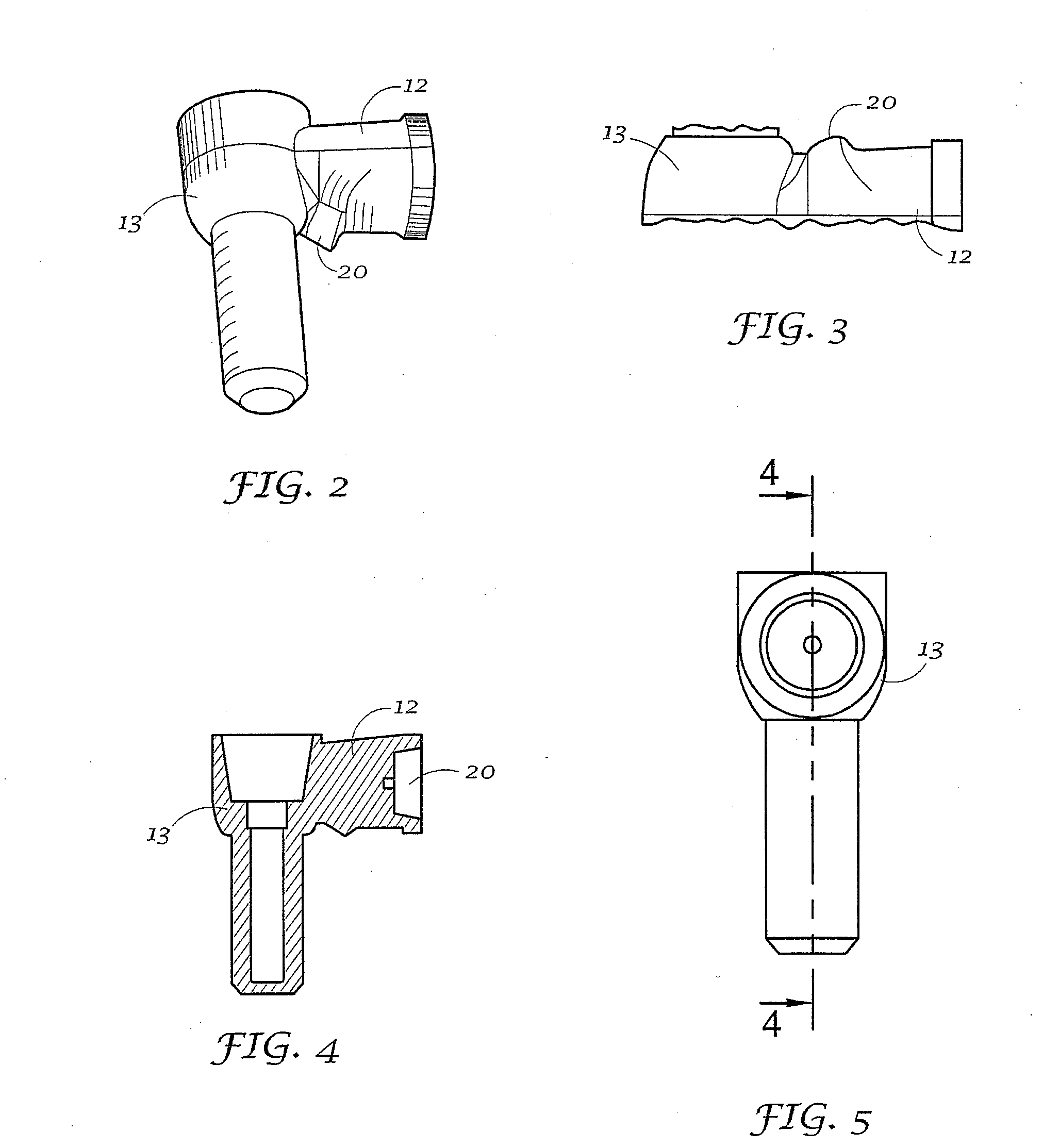

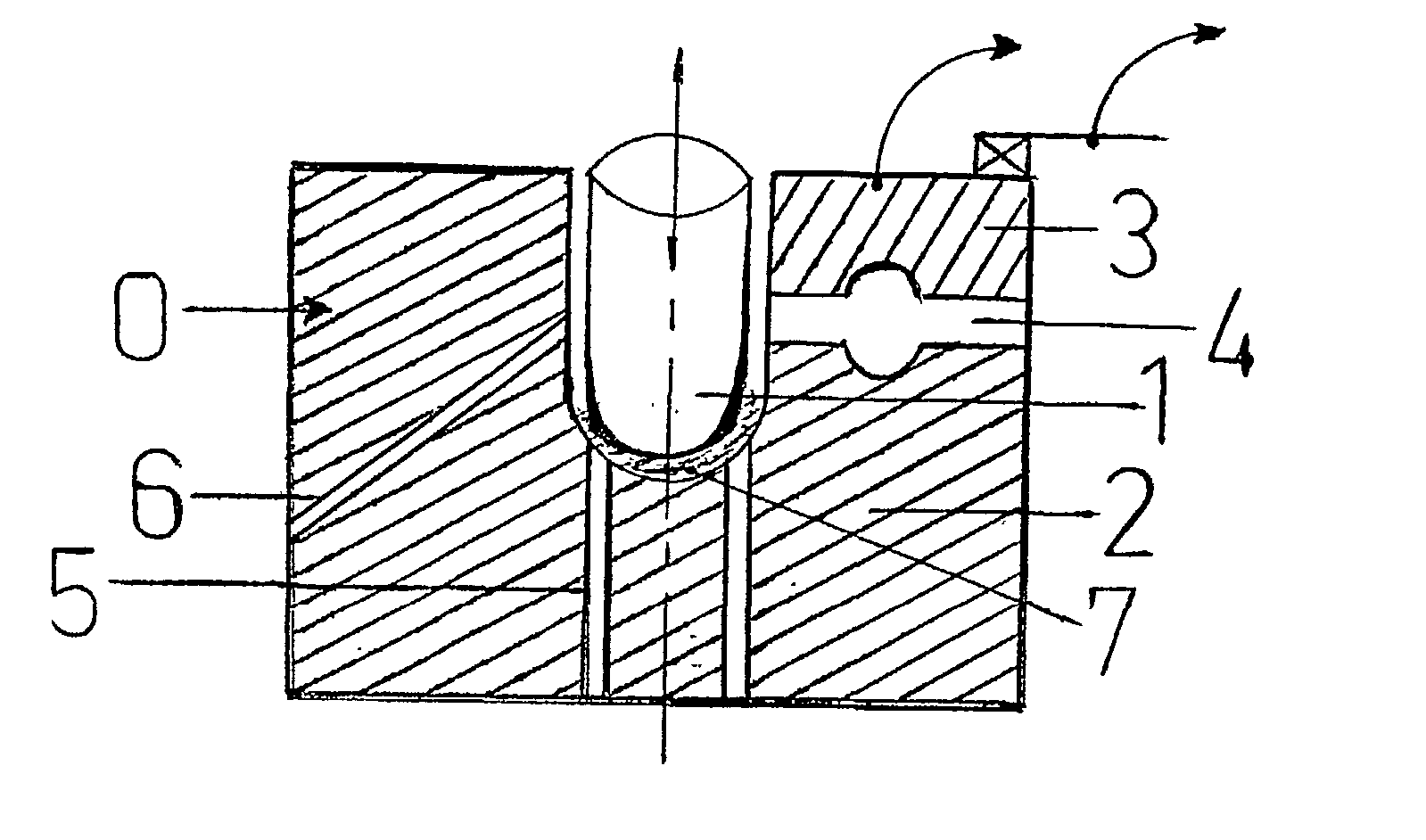

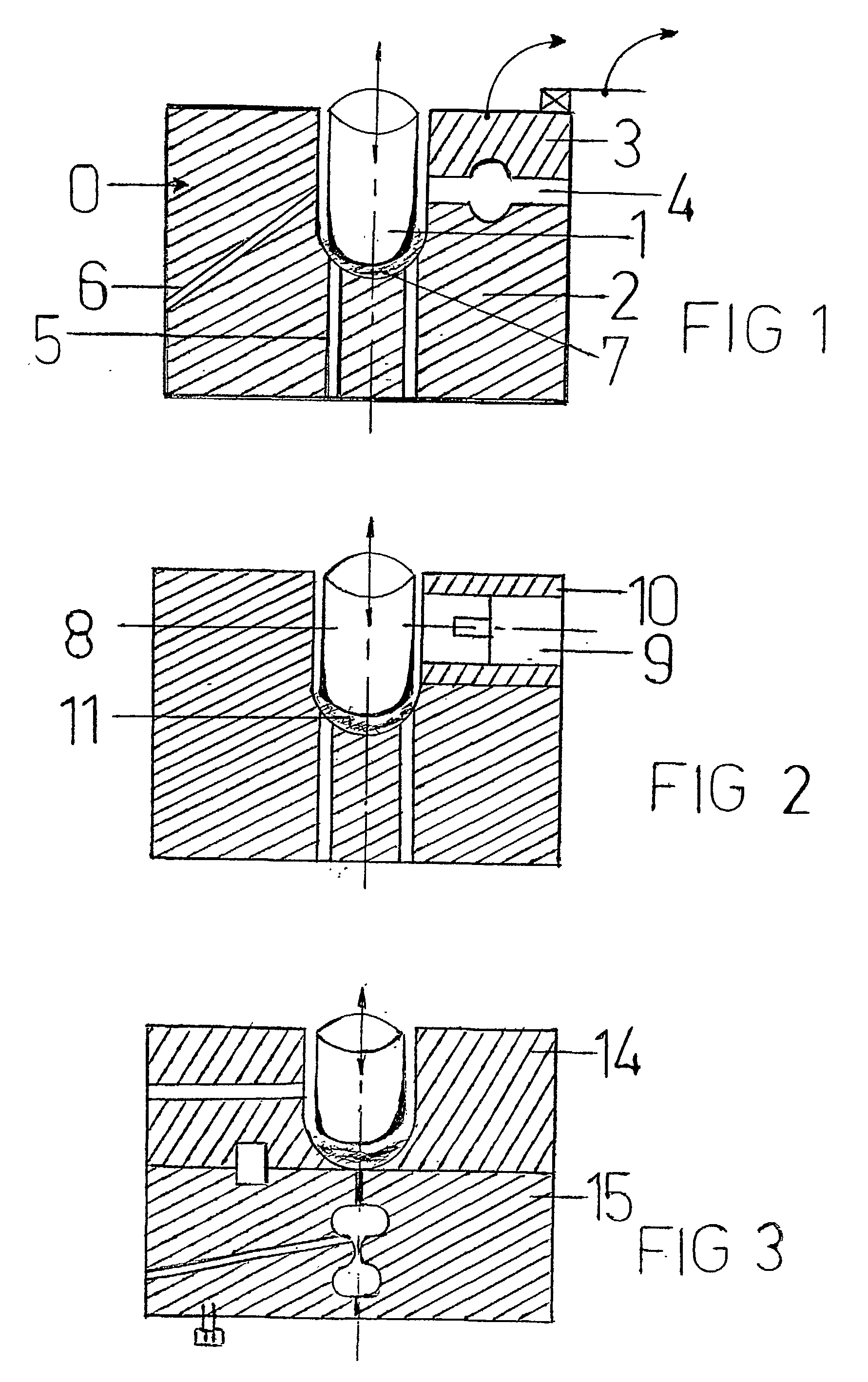

Coupling for use with a gerotor device

InactiveUS6019584ALess machiningLess expensiveEngine of arcuate-engagement typeOscillating piston enginesEngineeringFluid pressure

A coupling arrangement (63;107;229) for use in a fluid pressure device including a gerotor gear set (15;83;205). The gerotor gear set includes an orbiting and rotating star (21;95;209). In a motor embodiment (FIGS. 1-4 and FIG. 6), the coupling (63;229) transmits the orbital and rotational movement of the star (21;209) to an output shaft (29;203). In a steering unit embodiment (FIG. 5) the orbital and rotational movement of the star (95) is transmitted as rotational follow-up movement to a sleeve valve (101). In either case, the invention eliminates the need for the conventional solid dogbone arrangement, thus making the device much less expensive and more compact, and giving the designer greater flexibility with regard to various options, such as the provision of thru-shaft capability for a motor.

Owner:EATON CORP

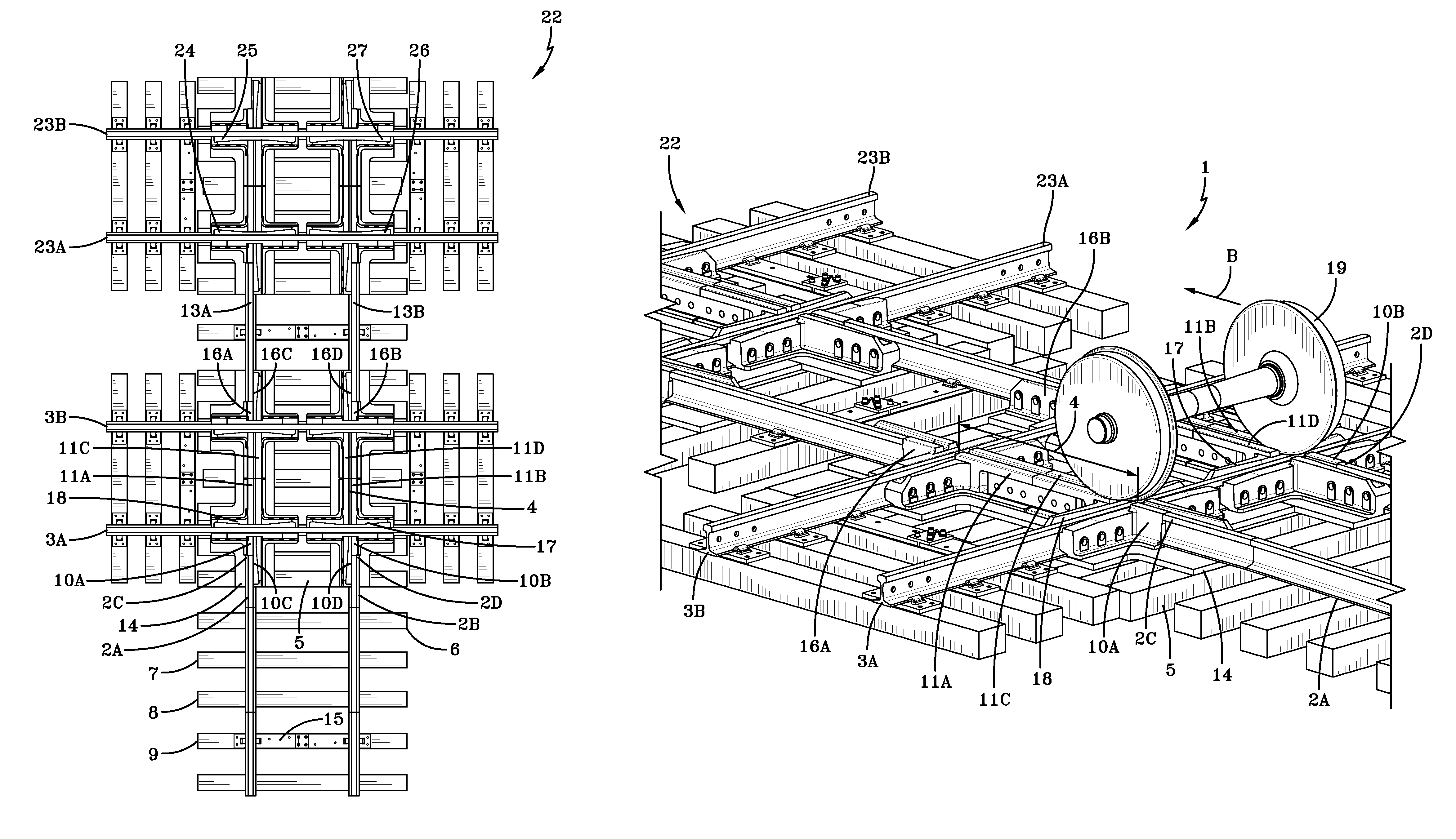

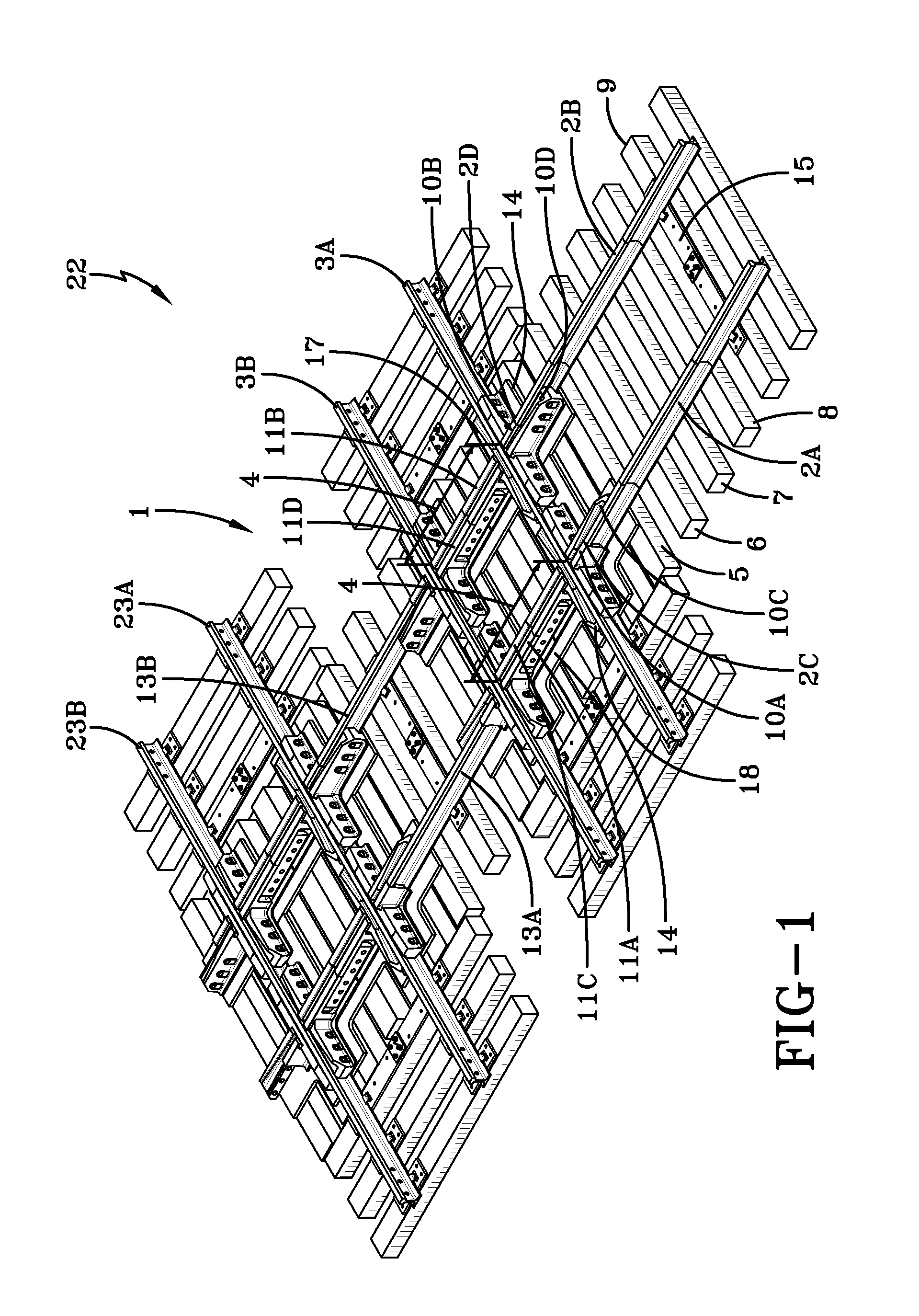

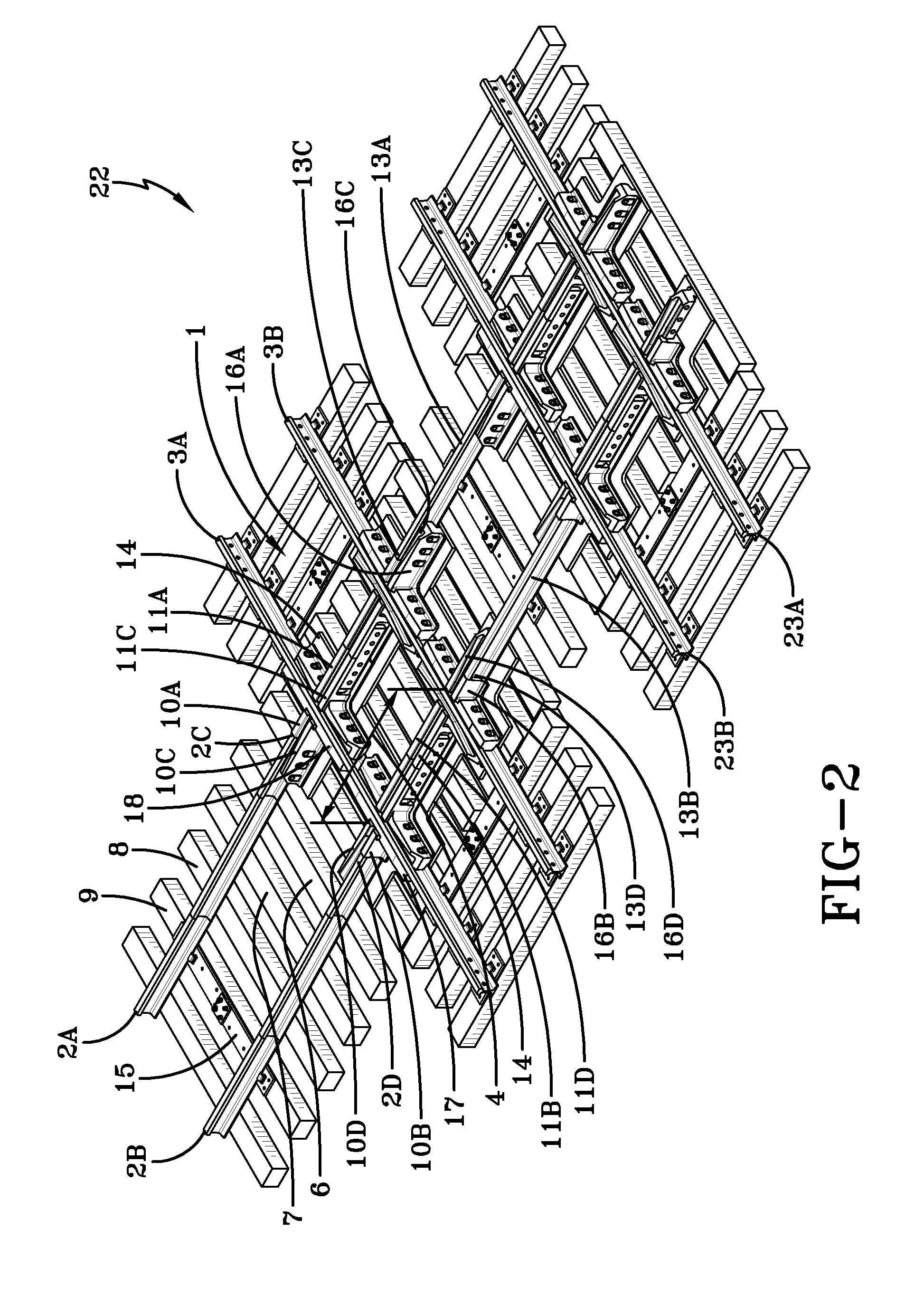

Elevated frog and rail crossing track assembly

ActiveUS8556217B1Small and easy to machineLess complex shapingRail switchesEngineeringBearing surface

A crossing panel includes a pair of intersecting rails, a pair of crossing line rails, a plurality of railroad ties supporting the crossing line rails such that the crossing line rails are angled upwardly from a base elevation toward the respective main line rail and terminating such that a tread bearing surface of each crossing line rail at its terminal end is at a height above the crown of the intersecting line rail, an external frog casting being aligned with and secured to the terminal ends of the crossing line rails and having an external frog tread bearing surface substantially above the crown of an intersecting line rail, and transitional guide castings disposed between the intersecting rails and respectively aligned with the crossing line rails. The transitional guide castings are substantially horizontal, and each has a crown maintained at a height sufficient to maintain a railcar wheel of a train wheel set above the intersecting line rails.

Owner:CLEVELAND TRACK MATERIAL

Manufacture of a hollow aerofoil

InactiveUS20160265365A1Reduce material wasteImprove propertiesPump componentsBlade accessoriesDistortionGas turbines

A method of manufacturing a hollow aerofoil component for a gas turbine engine comprises using a capping panel to cover a pocket in a pocketed aerofoil body. The pocketed aerofoil body has a ledge of substantially constant thickness that extends around its perimeter, and to which the capping panel is joined (e.g. welded) during manufacture. This ensures that the geometry of the join is consistent around the perimeter, meaning that the resulting join has improved properties, for example in terms of residual stress and / or distortion.

Owner:ROLLS ROYCE PLC

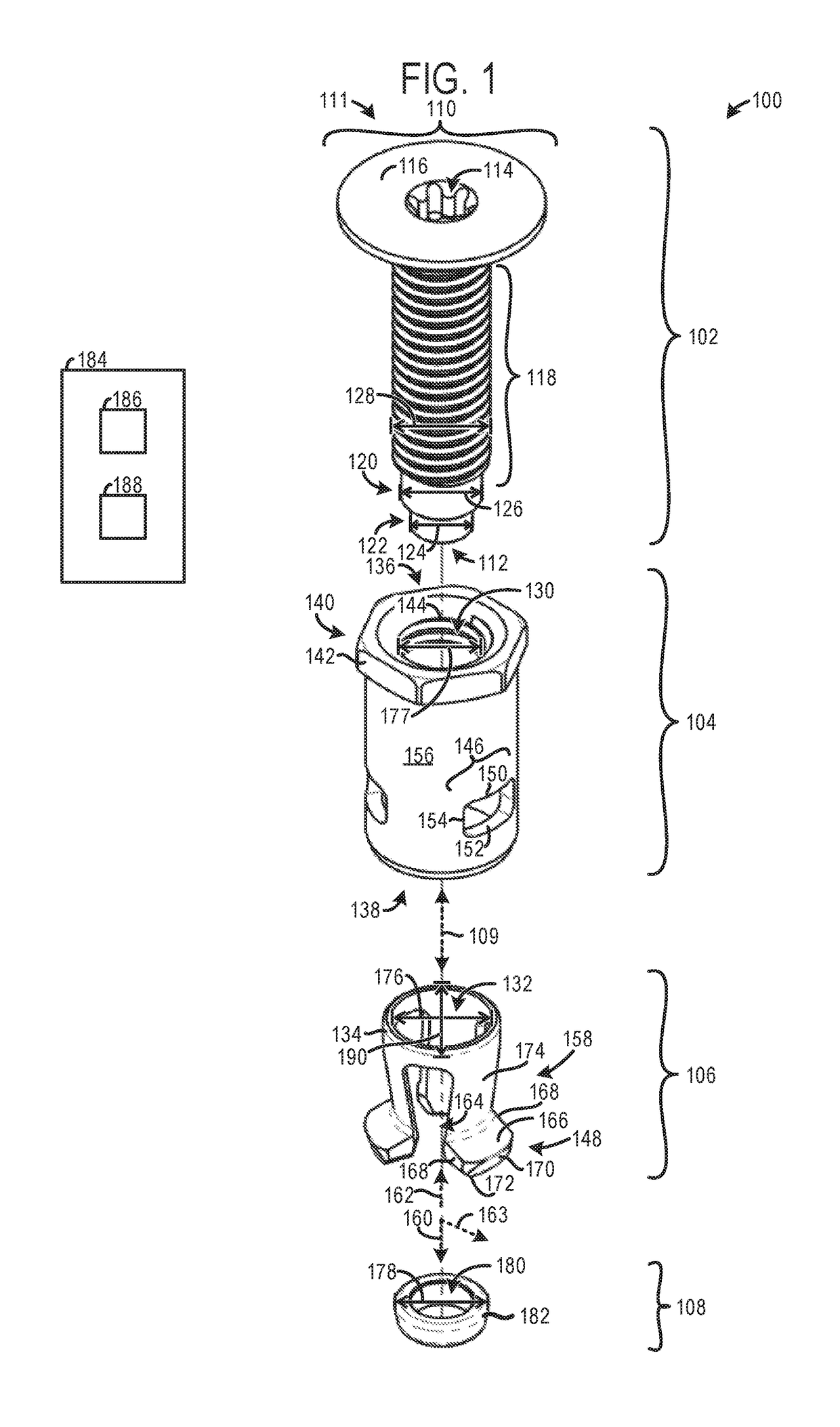

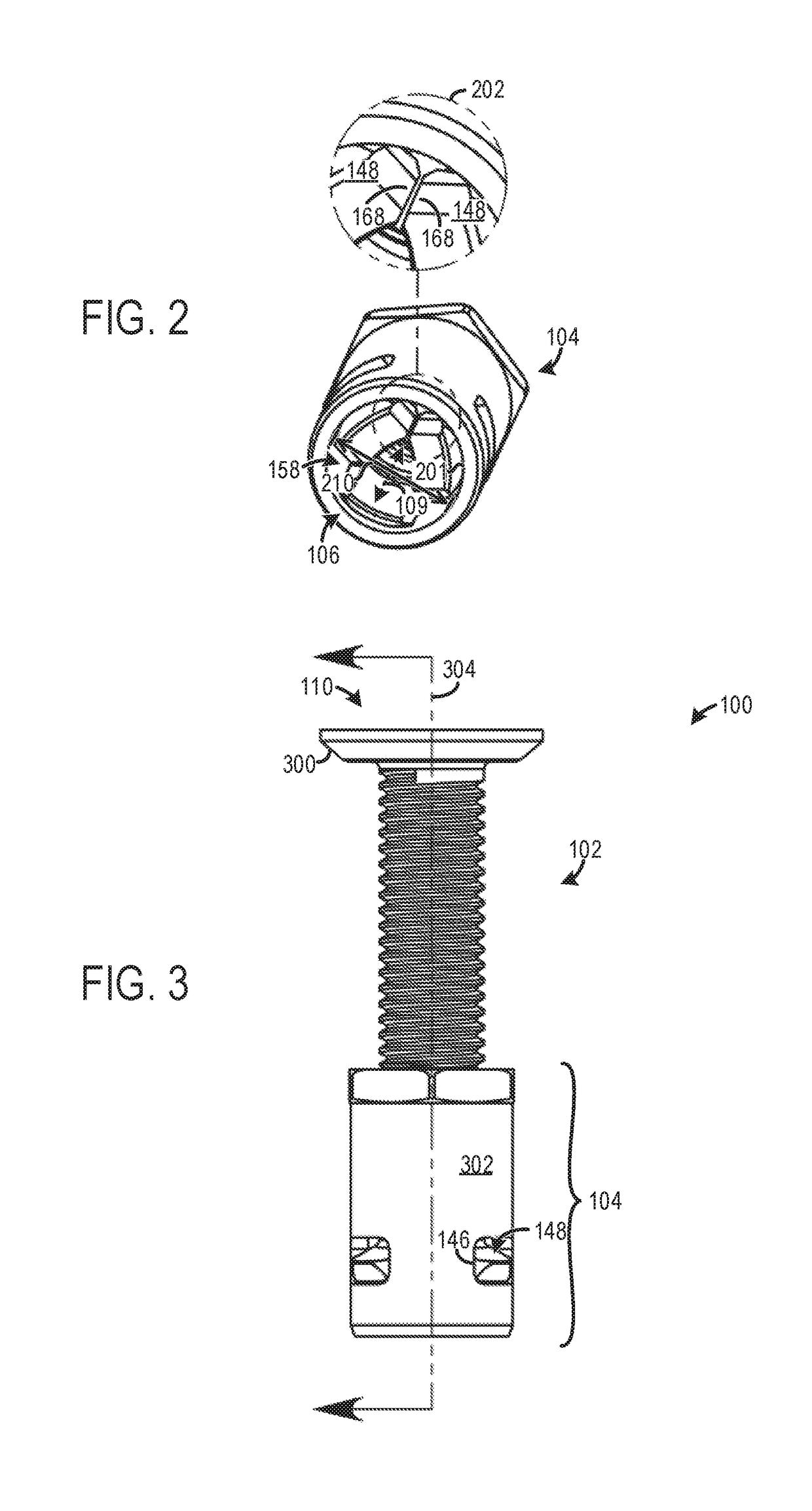

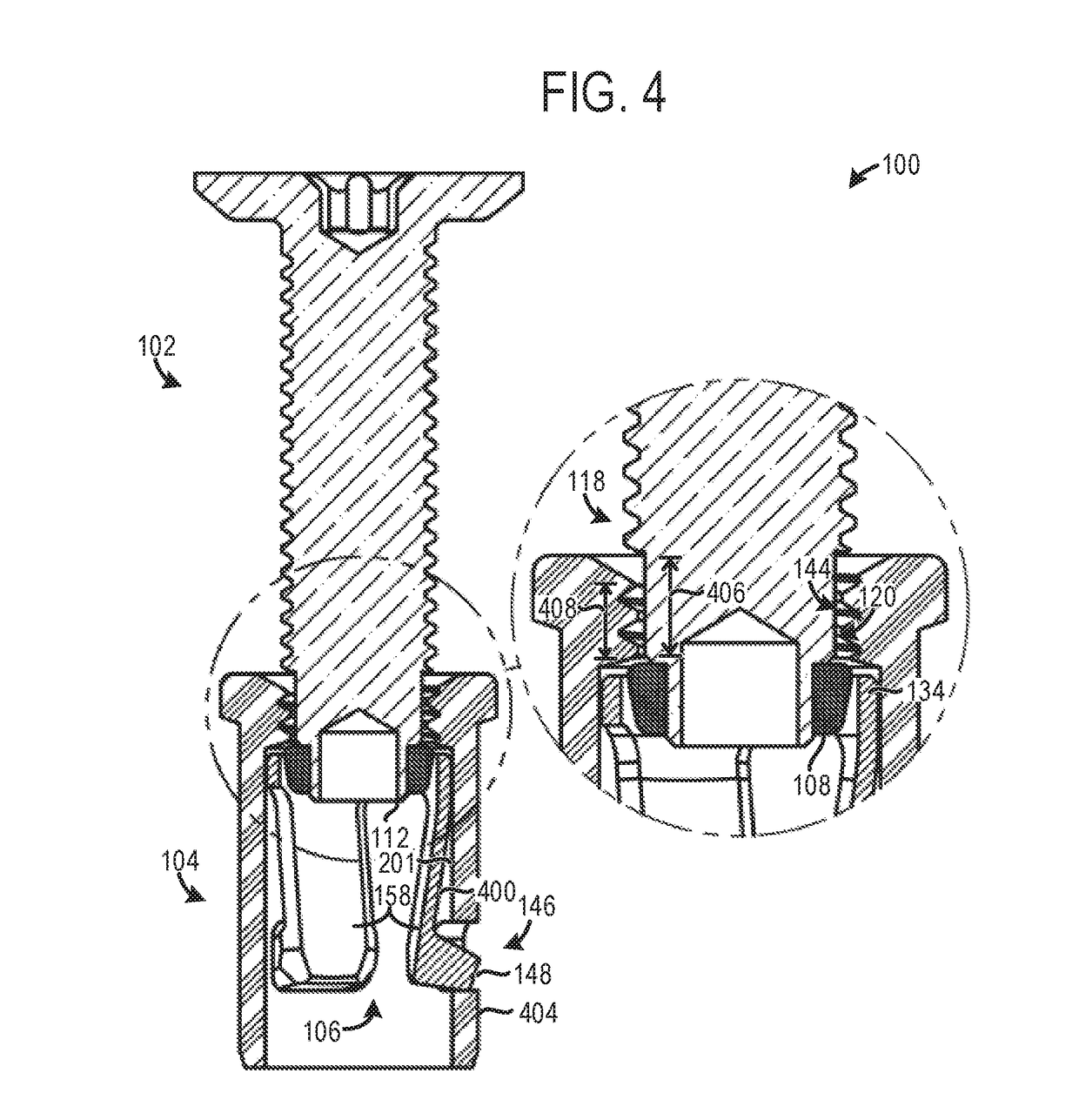

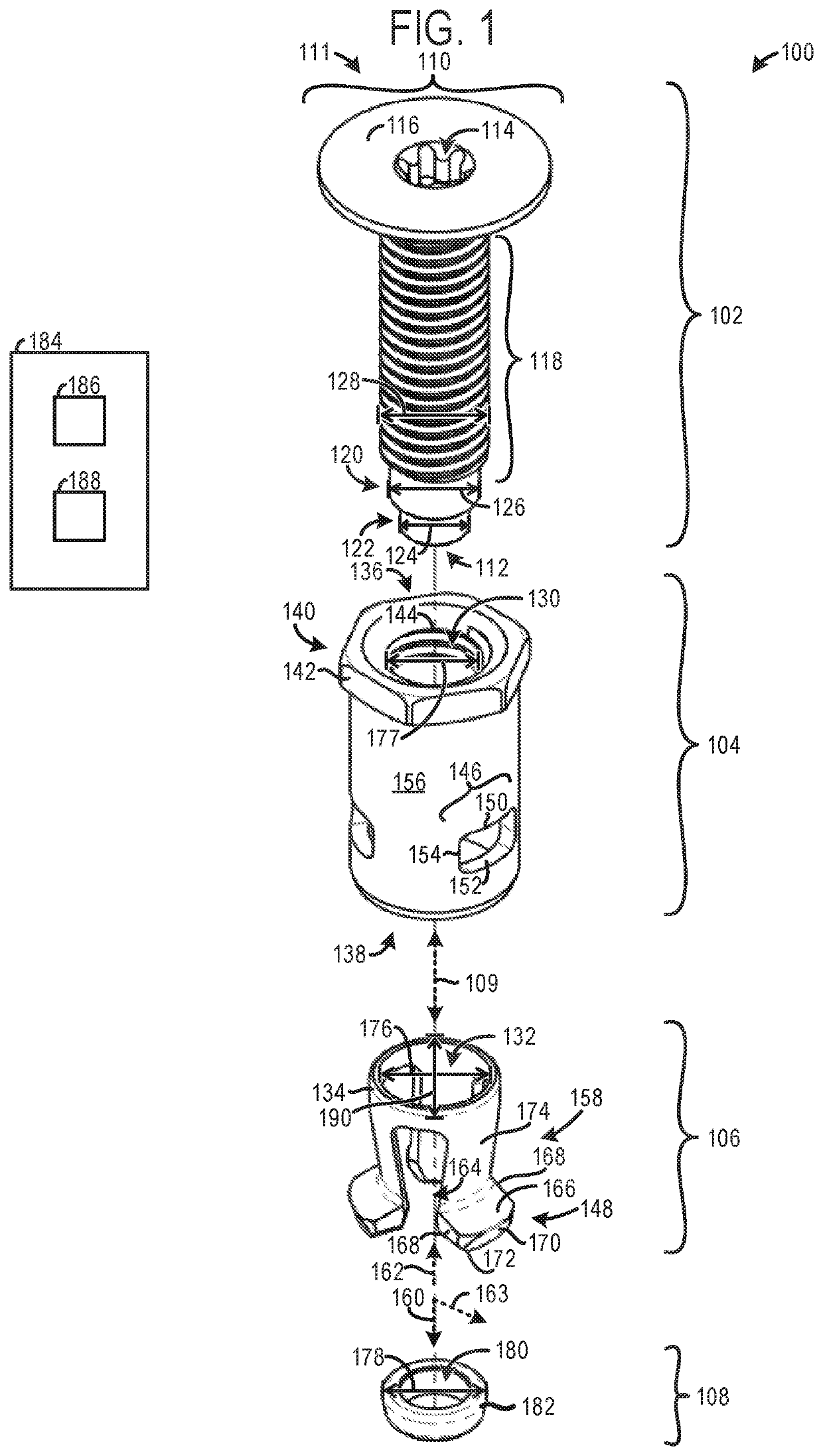

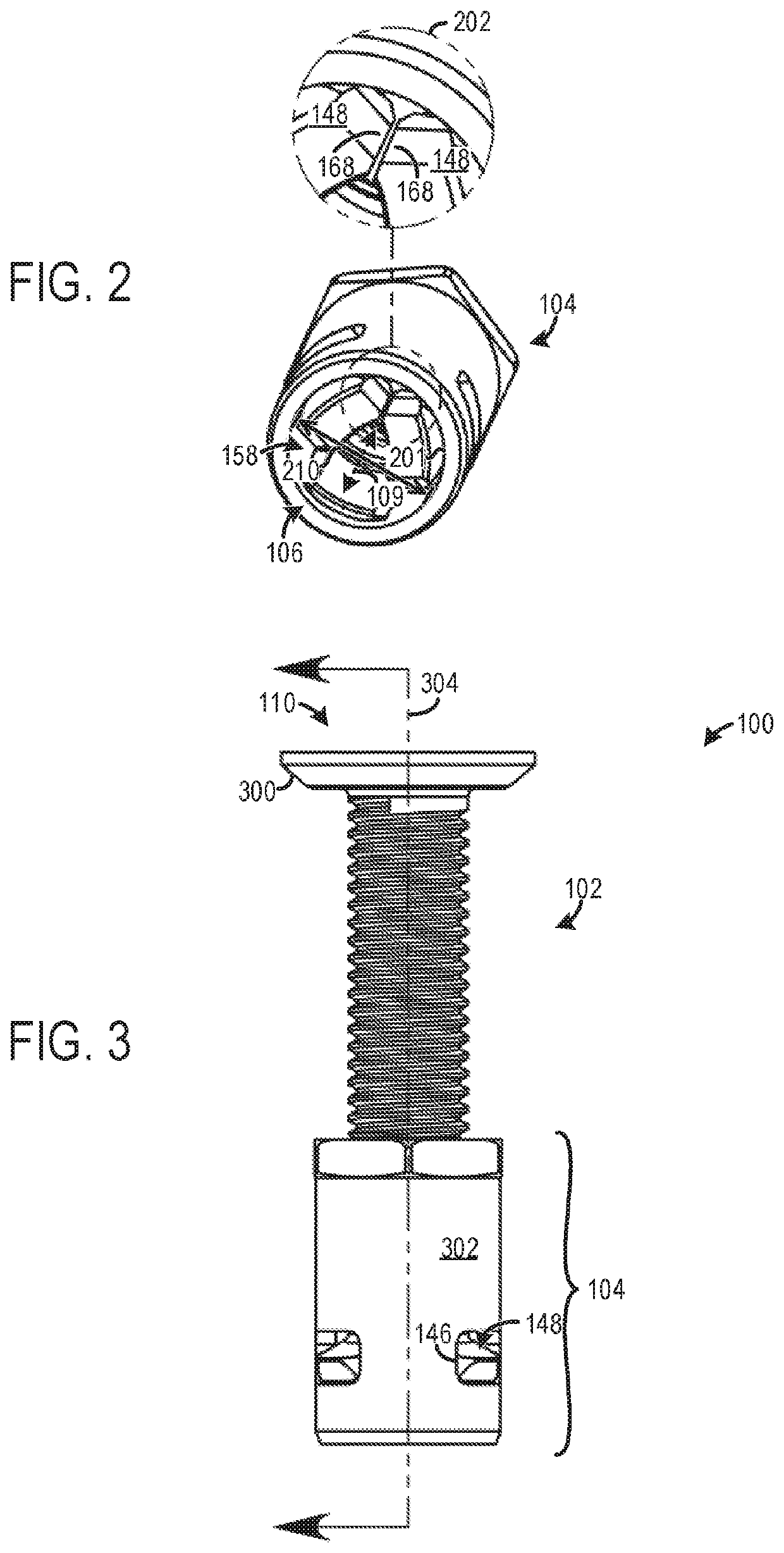

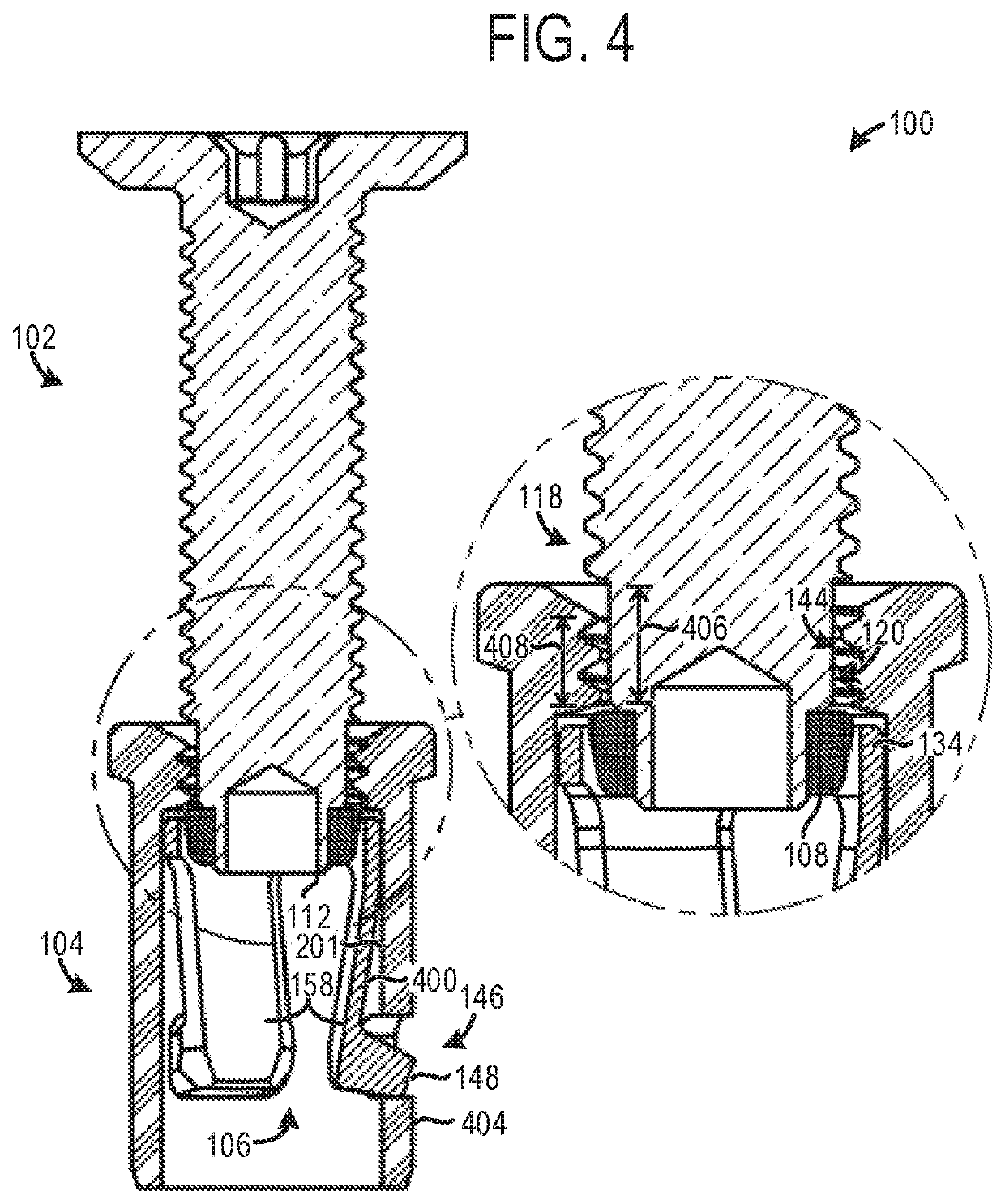

Fastener system

ActiveUS20190078600A1Achieve modularityIncreased manufacturing adaptabilityScrewsSheet joiningFastenerCollet

A fastener system shifting shear stresses away from a collet body and provides clamping action to targeted structures. The fastener system includes feet in the collet body that mate with openings in a sleeve at least partially surrounding the collet body. The sleeve or the collet body includes interior threads that engage with a stud that is configured to extend through the collet body and bend the feet such that they project outward from the sleeve openings in an engaged configuration.

Owner:CENTRIX

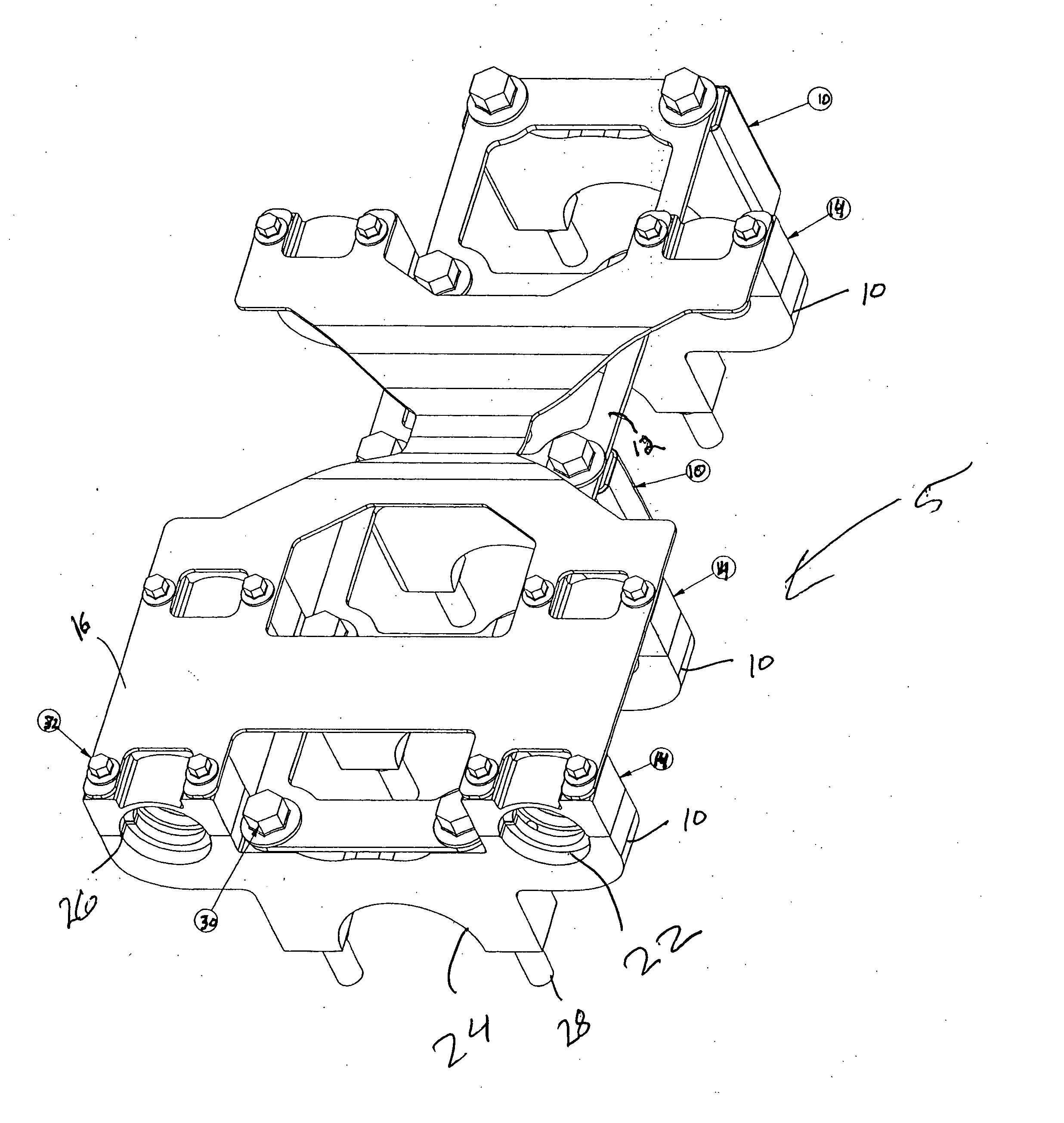

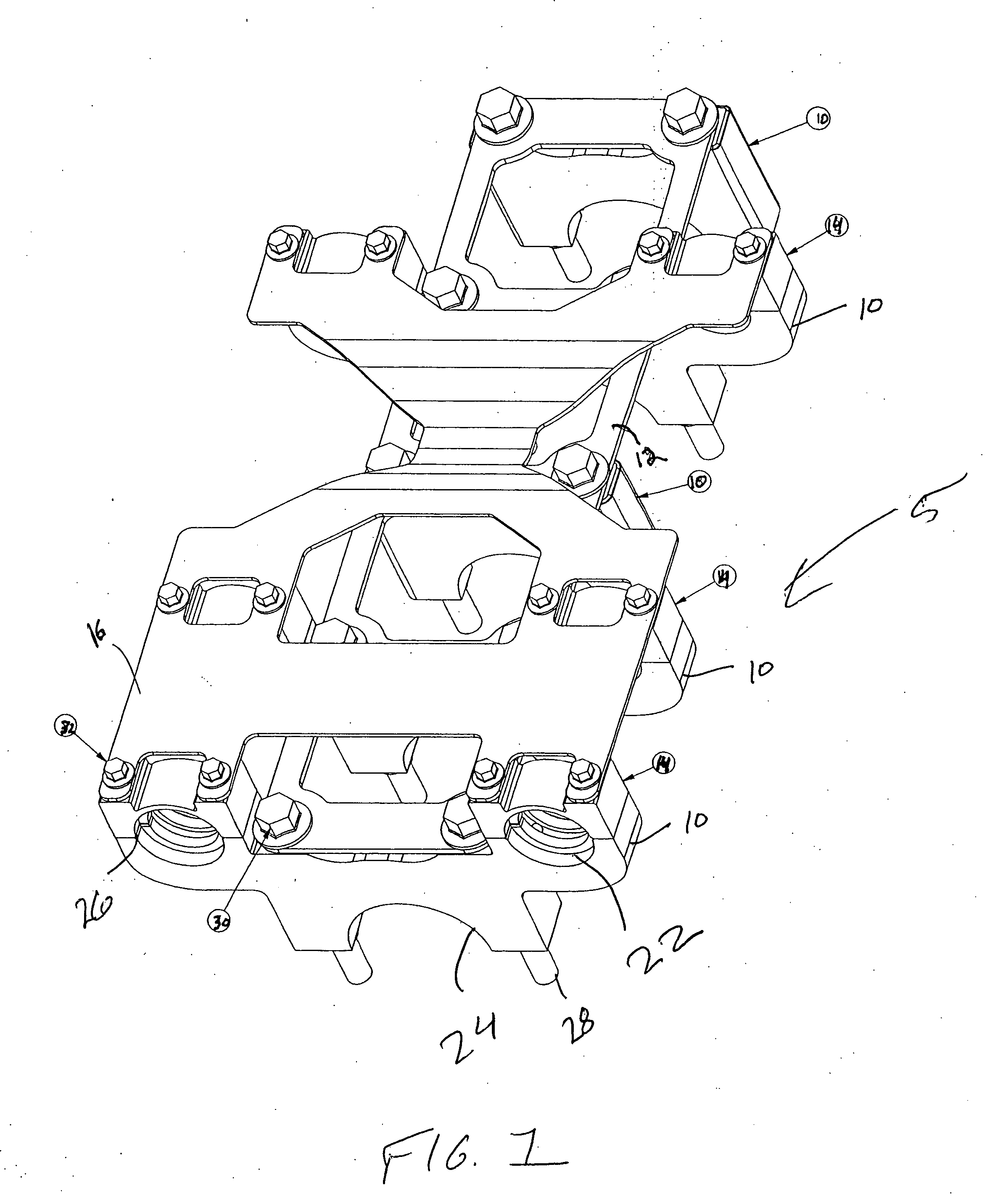

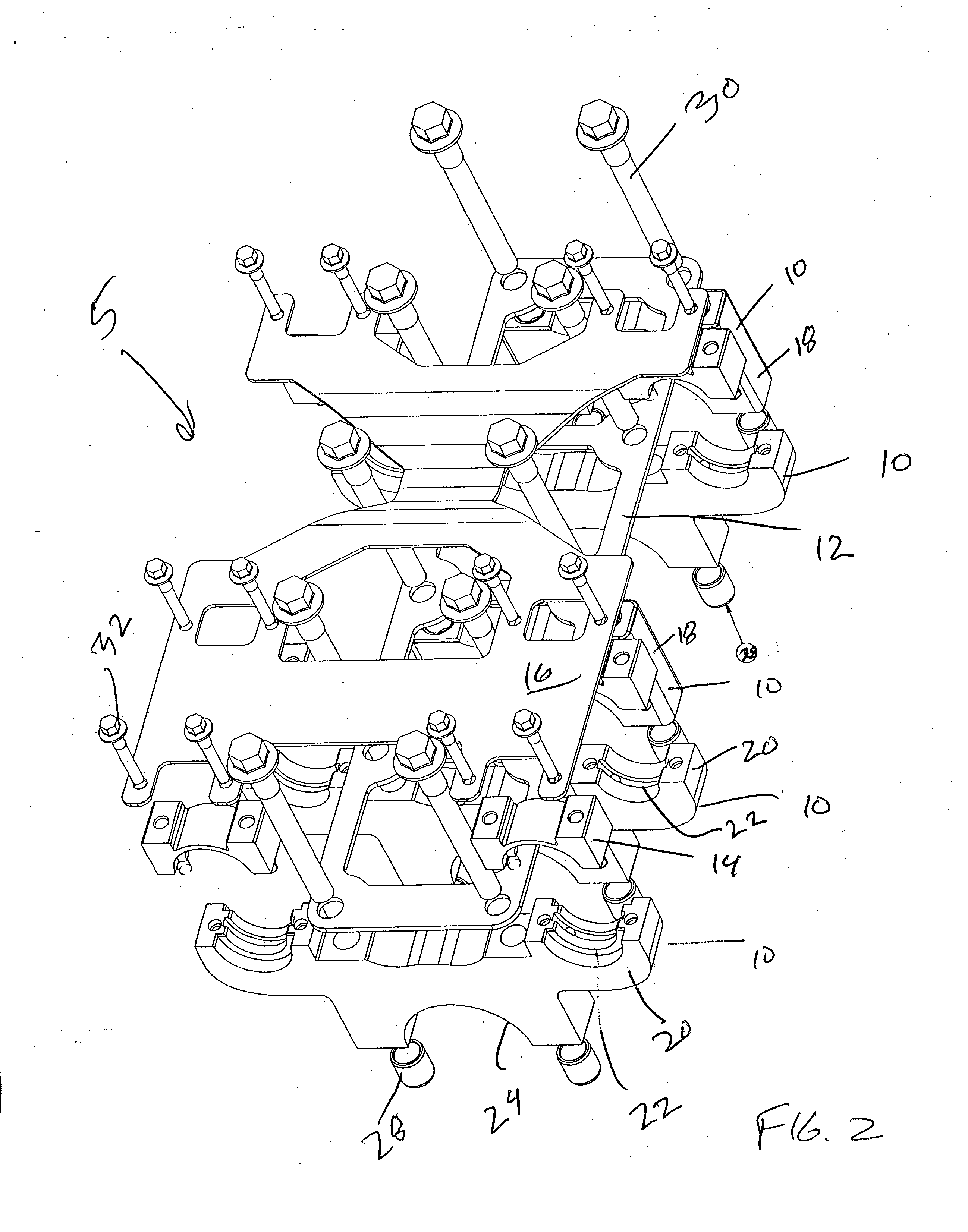

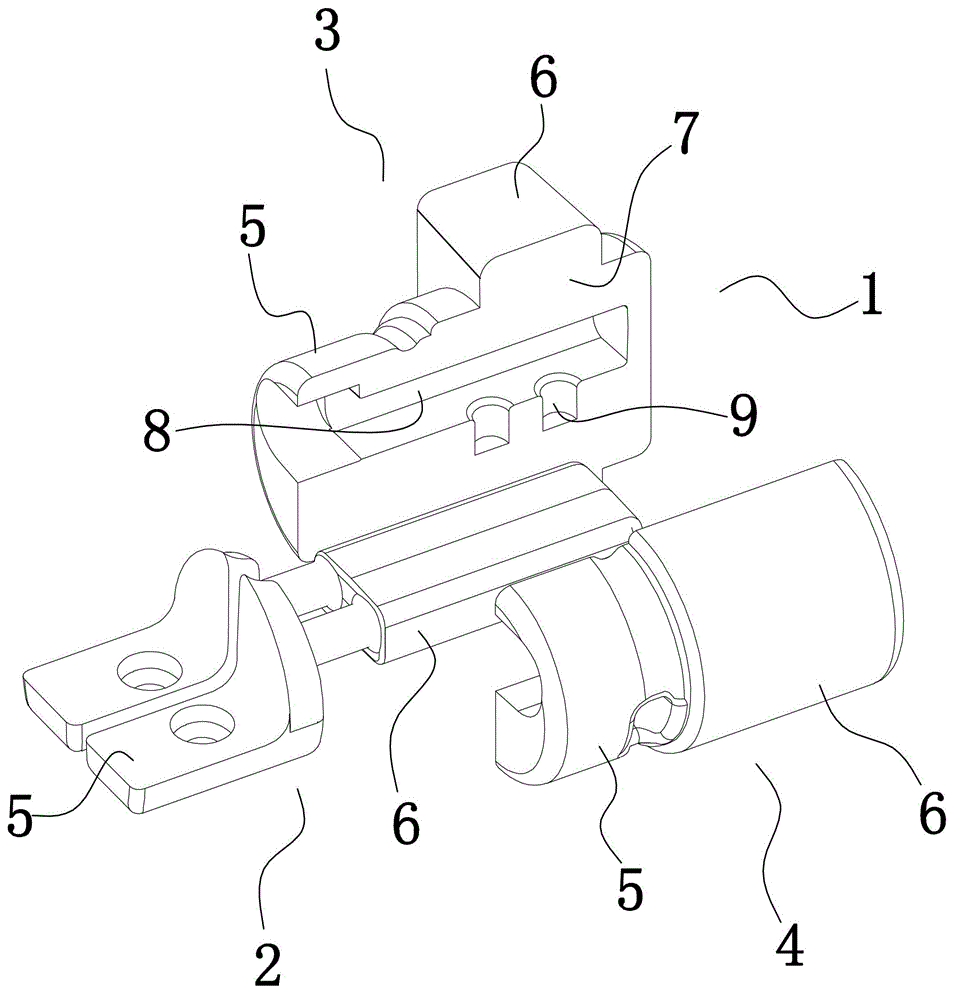

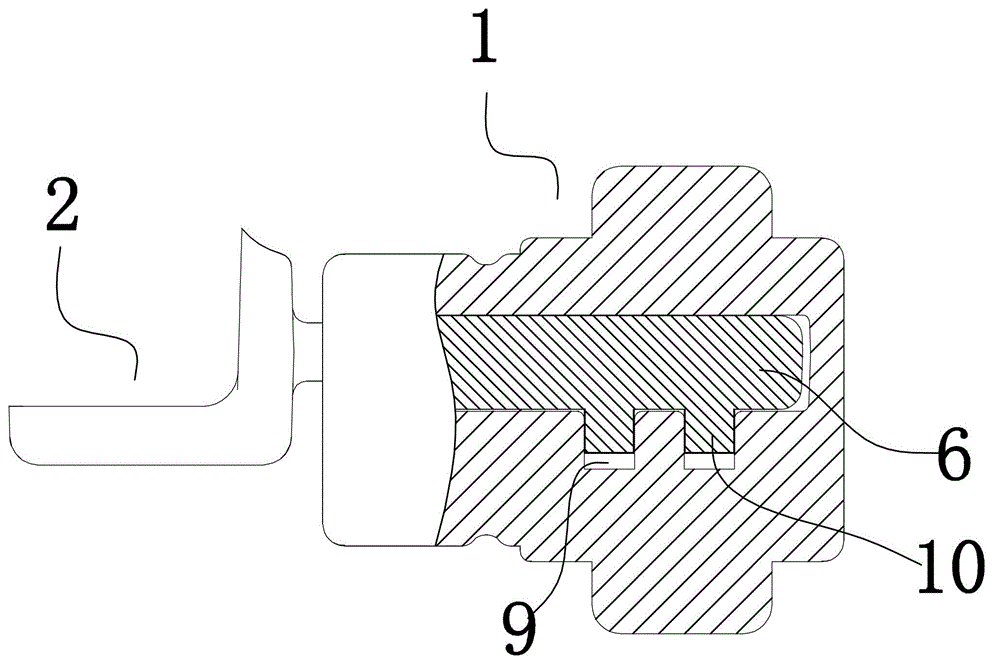

Bearing cap assembly

InactiveUS20070065059A1Reduce and eliminate imbalance forceLess machiningCasingsCrankshaft bearingsCrankshaftBalance shaft

A bearing cap assembly 5 generally comprising at least one bearing cap 10 having a mini-cap bearing cap 20 and a mini-cap 14. The bearing cap 10 having a shaft bore for receiving a balance shaft and a crankshaft bore for receiving a crankshaft upon connection of the bearing cap assembly 5 to an engine. The bearing cap 10 has a fault line extending between the mini-cap bearing cap 20 and the mini-cap 14 whereby split fracturing the bearing cap 10 along the fault line separates the mini-cap bearing cap 20 from the mini-cap 14. The balance shaft is secured between the mini-cap bearing cap 20 and the mini-cap 14.

Owner:METALDYNE LLC

Fastener system

A fastener system shifting shear stresses away from a collet body and provides clamping action to targeted structures. The fastener system includes feet in the collet body that mate with openings in a sleeve at least partially surrounding the collet body. The sleeve or the collet body includes interior threads that engage with a stud that is configured to extend through the collet body and bend the feet such that they project outward from the sleeve openings in an engaged configuration.

Owner:CENTRIX

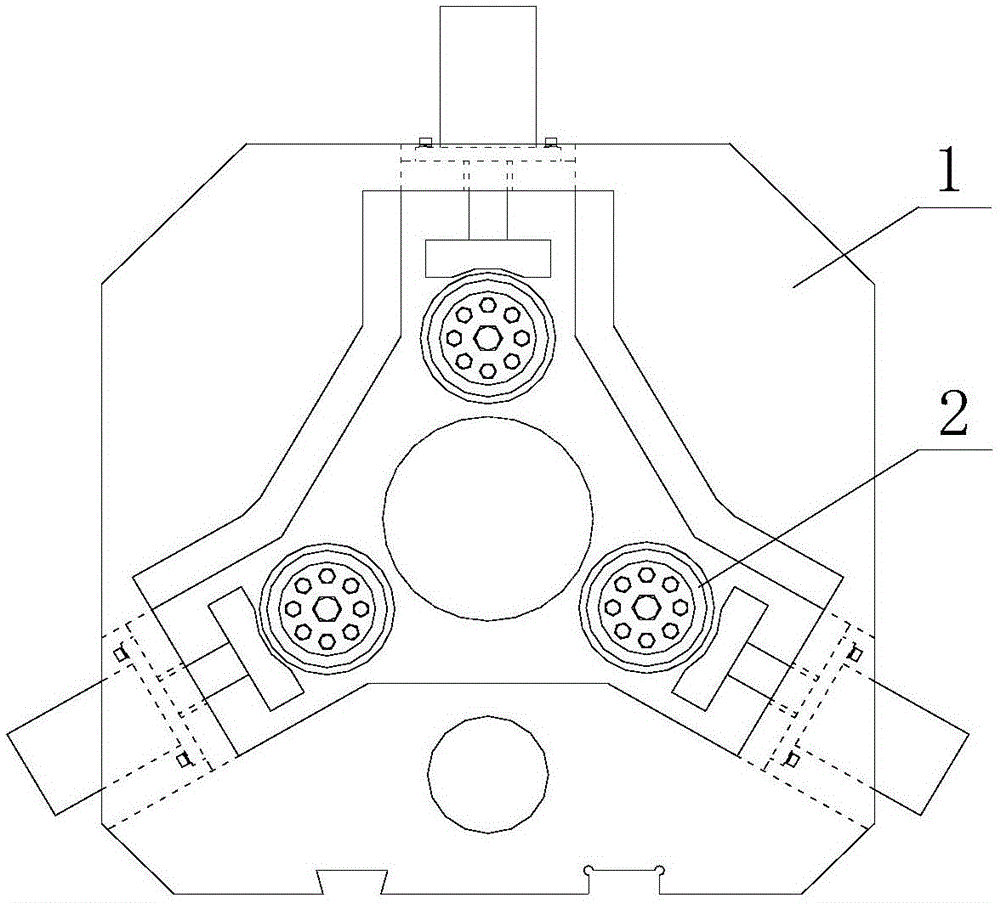

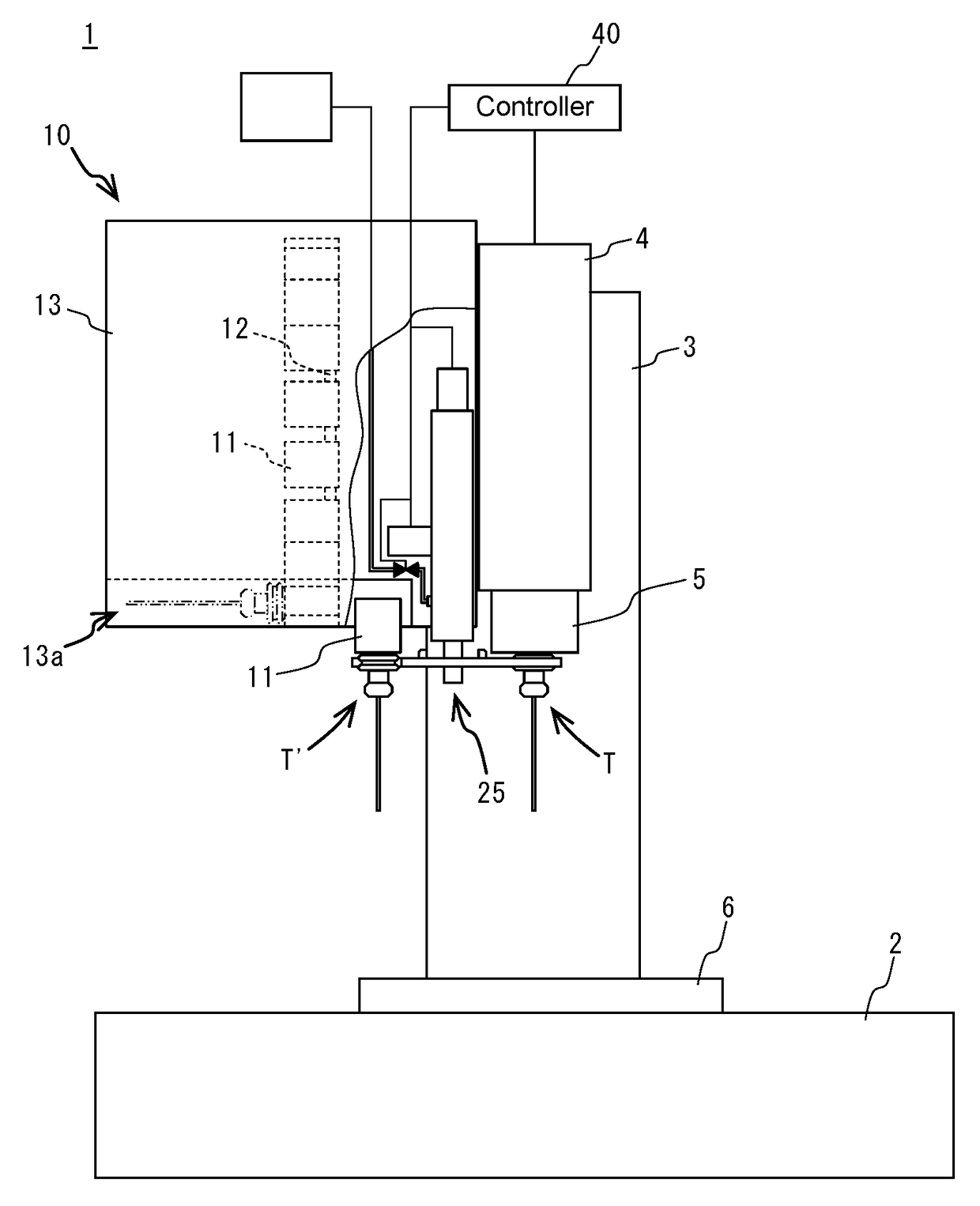

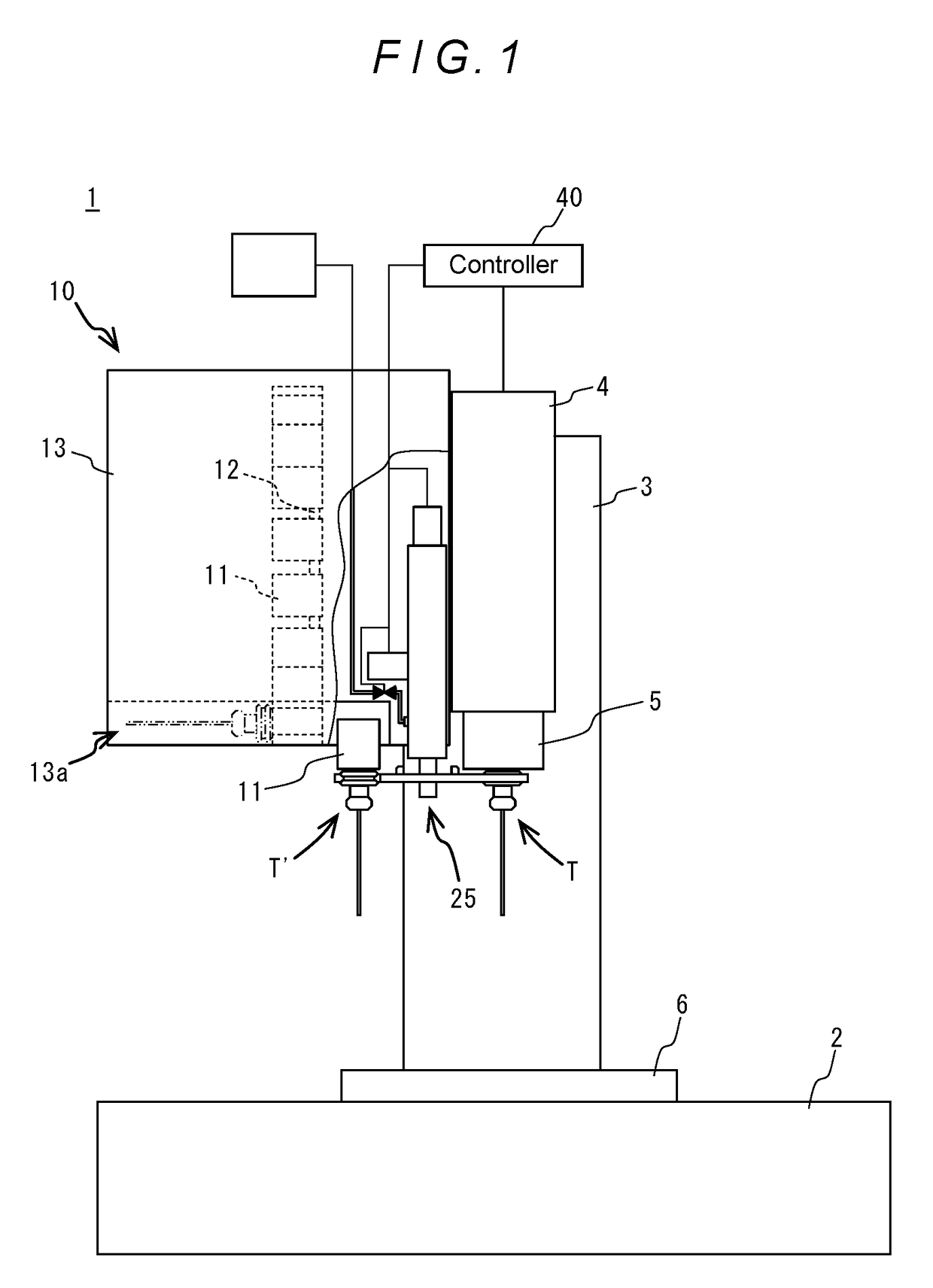

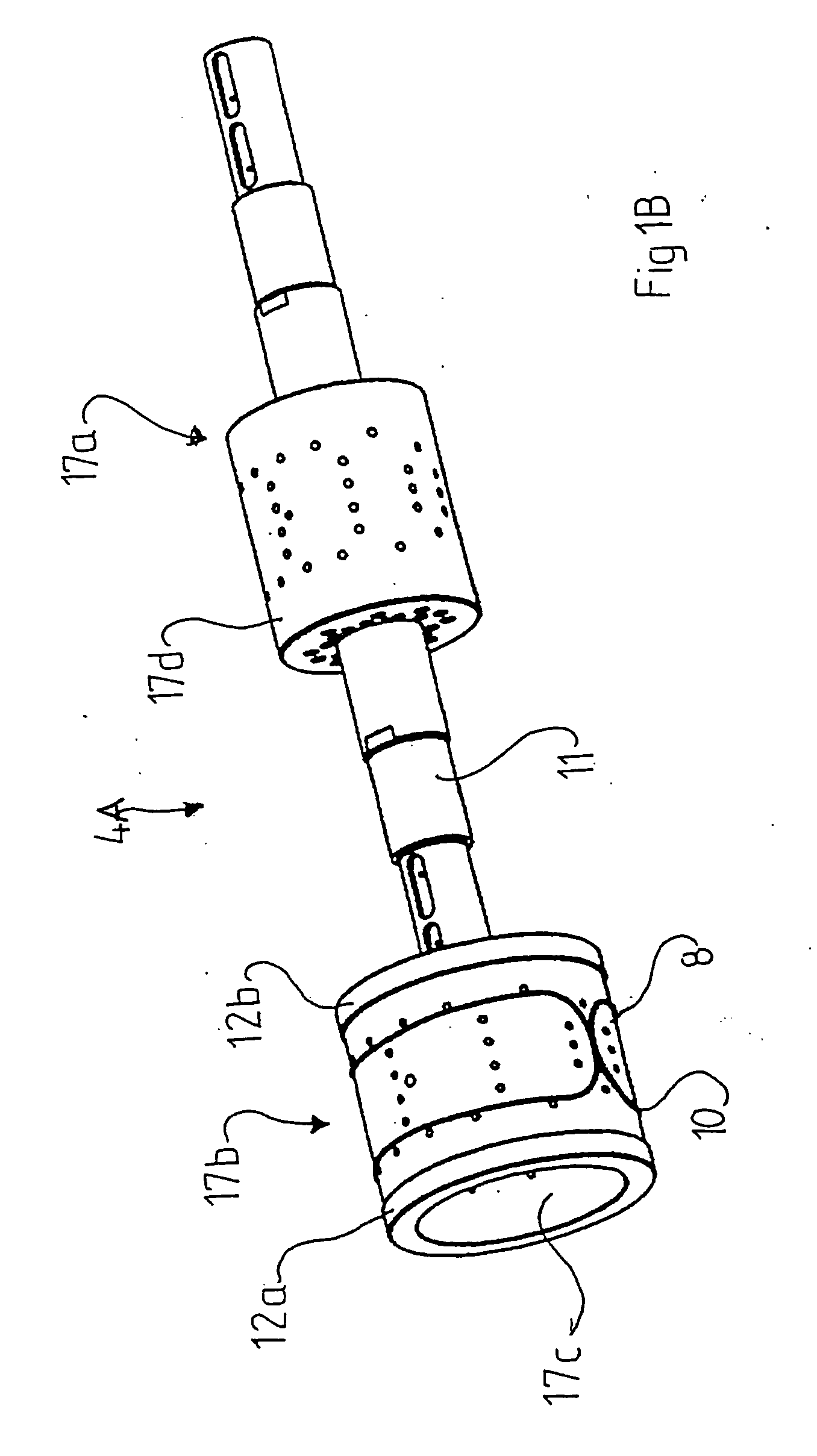

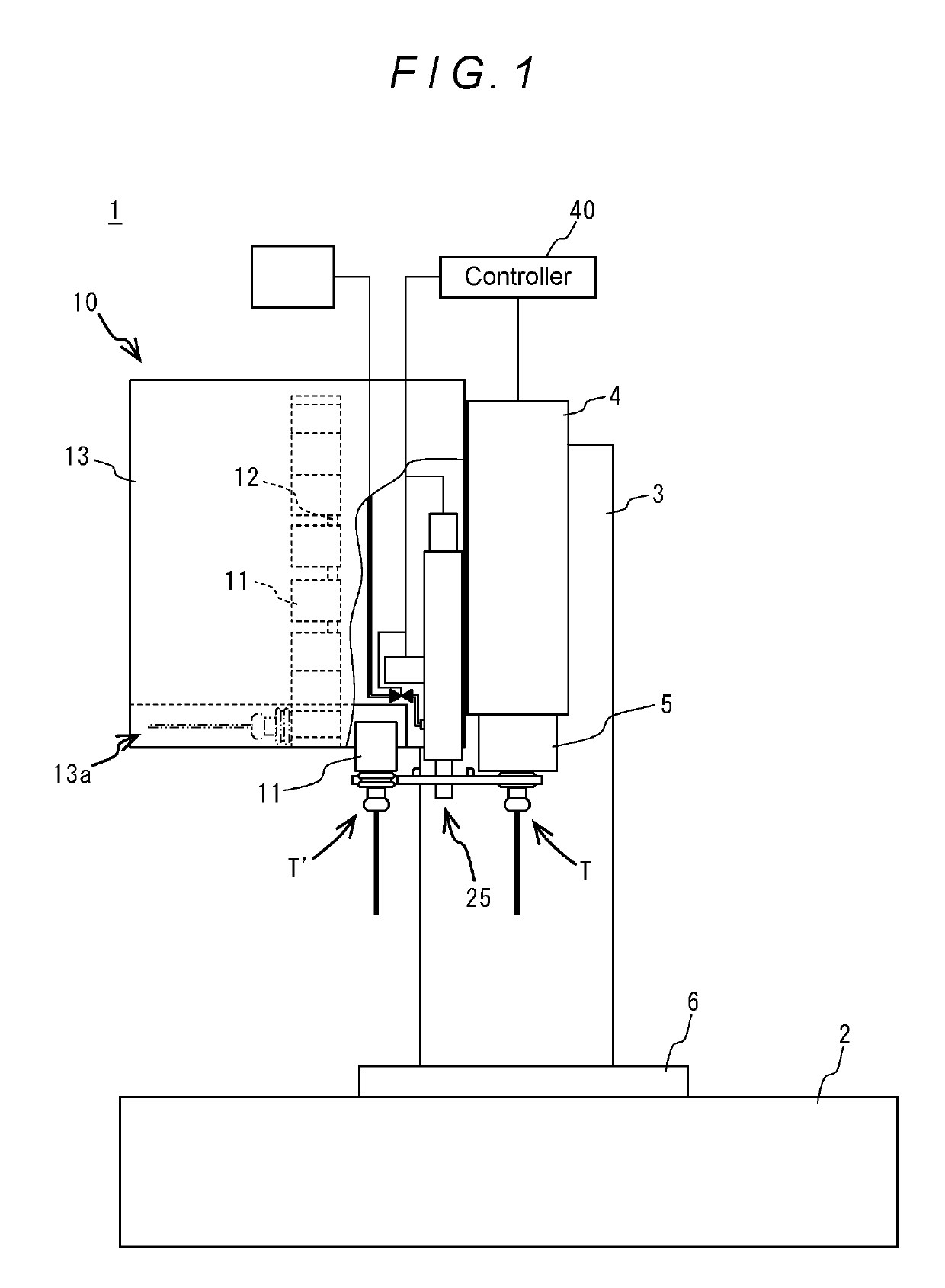

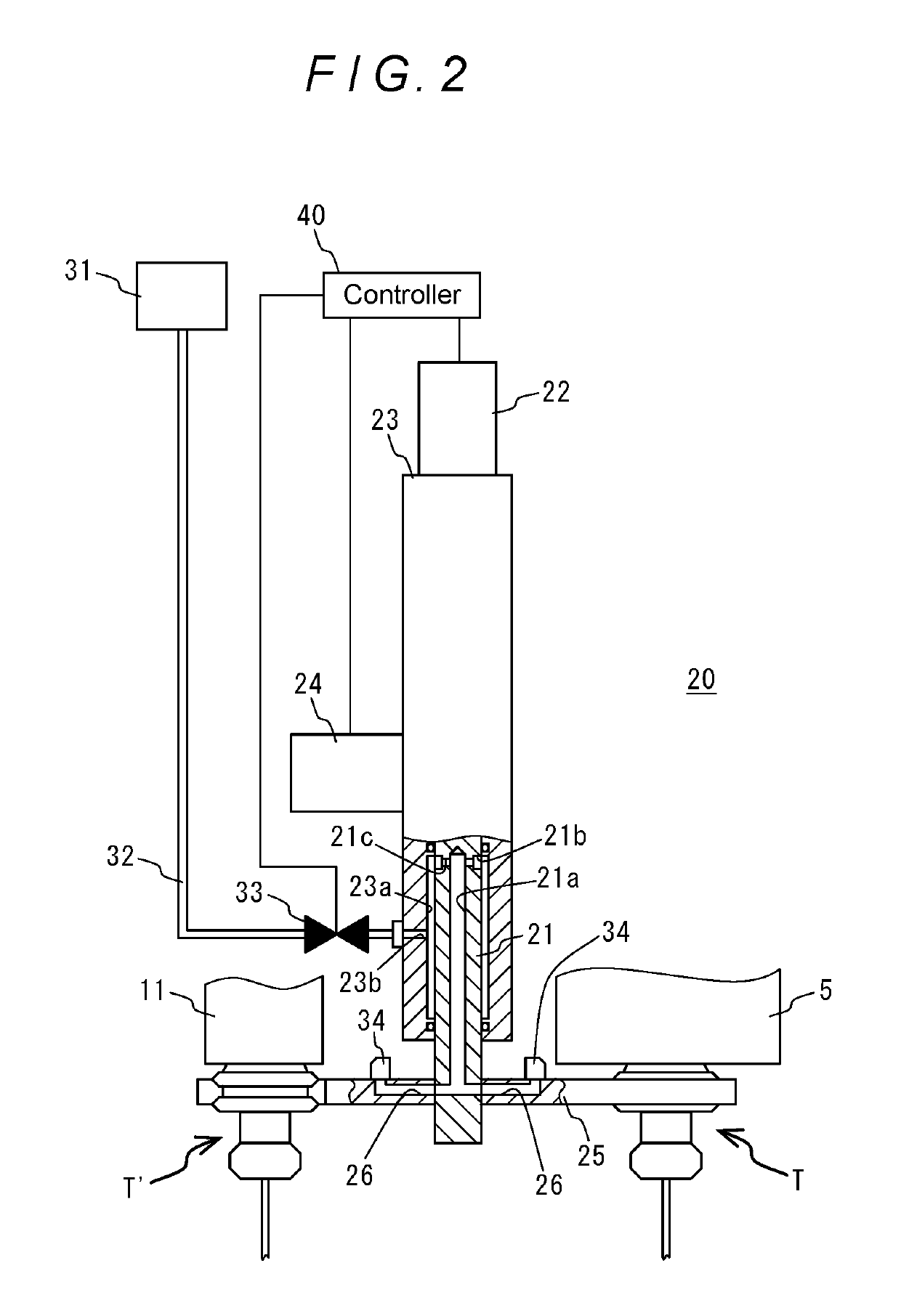

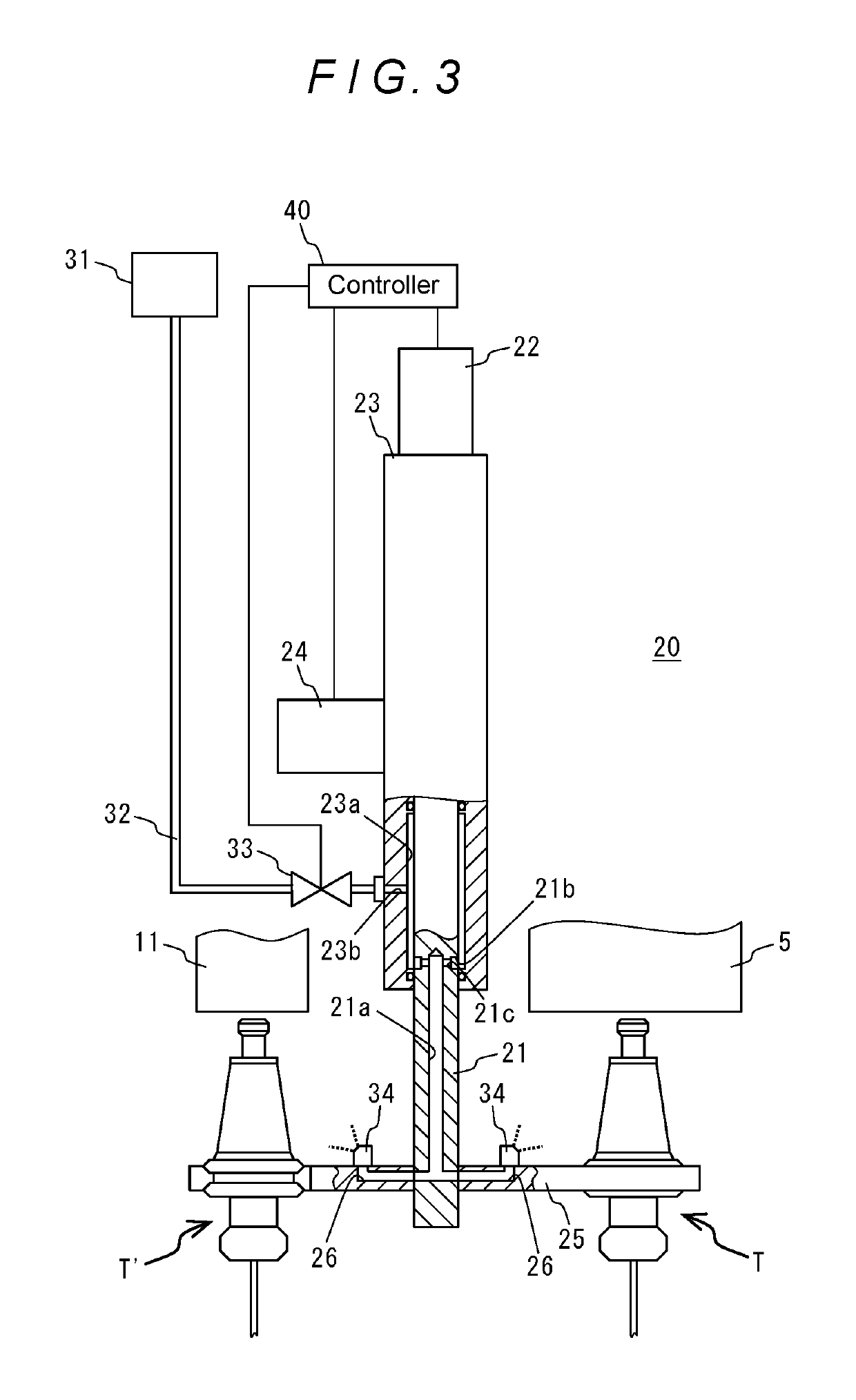

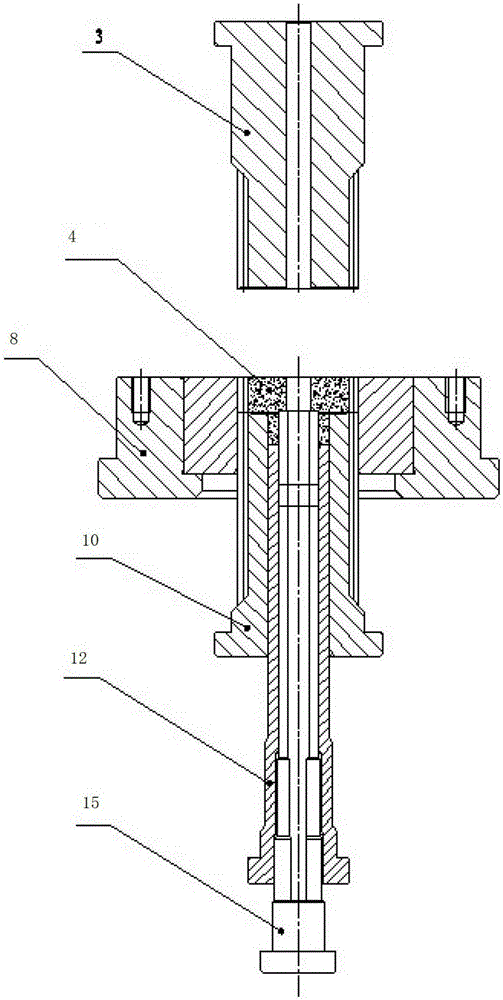

Tool changing method and tool changer

ActiveUS20170190008A1Influence machining timeLess machiningTool adjusterPositioning apparatusEngineeringDrive motor

A tool changer is composed of a support shaft, a forward / backward movement drive motor moving the support shaft upward and downward, a rotation drive motor rotating the support shaft about an axis, a tool change arm having tool grippers formed at both ends thereof, and an air blow mechanism discharging compressed air to a tool and a next tool gripped by the tool grippers. In tool change using this tool changer, in a positioning operation, the tool change arm is rotated by degrees and compressed air is discharged toward the tool and the next tool by the air blow mechanism.

Owner:DMG MORI CO LTD

Apparatus and method for hydroshearing and hydrotrimming for hydroforming die

ActiveUS7360384B1Extension of timeConserving fluid forming pressureKnife bladesBiomedical engineering

An apparatus and method for hydroshearing and hydrotrimming for a hydroforming die includes a cutting insert fixed relative to the hydroforming die. The apparatus and method also includes a disposable insert fixed relative to the hydroforming die. The apparatus and method further includes a plunger movable relative to the hydroforming die to allow fluid within a tubular member to force a wall portion of the tubular member outward against the plunger and be sheared in the hydroforming die to trim the tubular member.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rotary cutter drum and a rotary cutter unit with such a rotary cutter drum

InactiveUS20060070505A1Less machiningEasy and fast mannerShearing machinesMetal working apparatusEngineeringMechanical engineering

A rotary cutter drum includes a cutter portion formed of a multiphase material and includes first and second substantially cylindrical, radially outwardly exposed surfaces, and a knife member formed of one piece with the exposed surfaces and arranged to axially separate the first and second surfaces from one another. The knife member protrudes by a distance in the range of 1 to 5 mm radially outwardly beyond a smallest diameter portion of the first and second exposed surfaces. The knife member includes two sides terminating at respective ones of the first and second exposed surfaces.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Dental handpiece

InactiveUS20120156642A1Efficiently and economically producedLess machiningDental toolsBoring toolsEngineeringMetal injection molding

Owner:PAPANEK TOM +2

Dynamic mold and process

InactiveUS20030018407A1Quality improvementLabor savingSnap fastenersClothes buttonsBlow moldingHydroforming

The dynamic mold concept has a manufacture, a process, and an apparatus. The process is that two or more steps (initial processes) be done simultaneously. A blow molding and an injection molding machine can work within the same mold and do their process together at the same time. The dynamic mold allows the mold to be split up into several parts or it has several dies within the structure. It allows the dies to move to allow the part to exit from the mold and move in accordance to do several steps one after the other also. For manufacturing sake for example shear, thermodynamics, temperature demands for quality of product, and for reduced mold design cost, allow two or more processes be done very close together. The dynamic mold is for metal applications as well incorporating a hydroforming, punch and forging etc. application. The process is open to all known manufacturing processes in metal and in plastic and in ceramics and glass and in pelet form as well, and most particles for feed limited that the product or process does not have unsafe processes and products. The manufactures are new products applicable to today's products reducing labor and tooling and hence cost. It will help recycling and aid in the enviroment for example, more hot and cold beverage drinking plastic containers will reduce the cost of plastics considerable and reducing the cost of recycling to fewer products to recycle.

Owner:VARMA DEVANAND

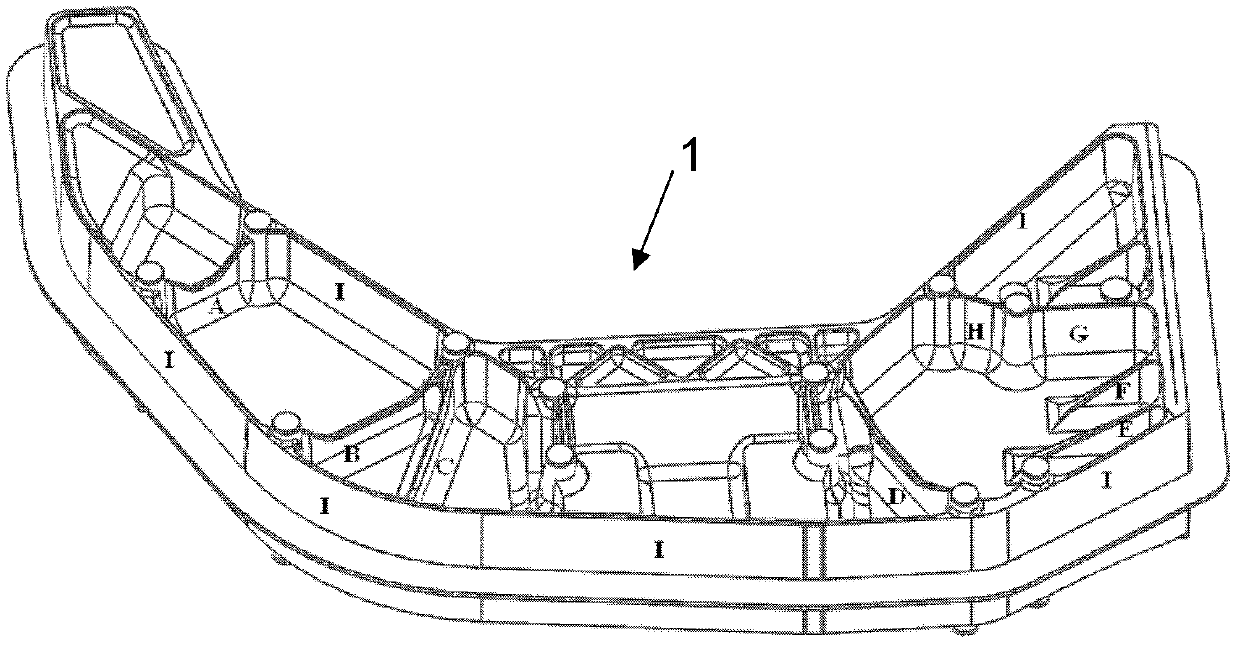

Compression molding process machining method for large composite reinforced thin-wall support structure

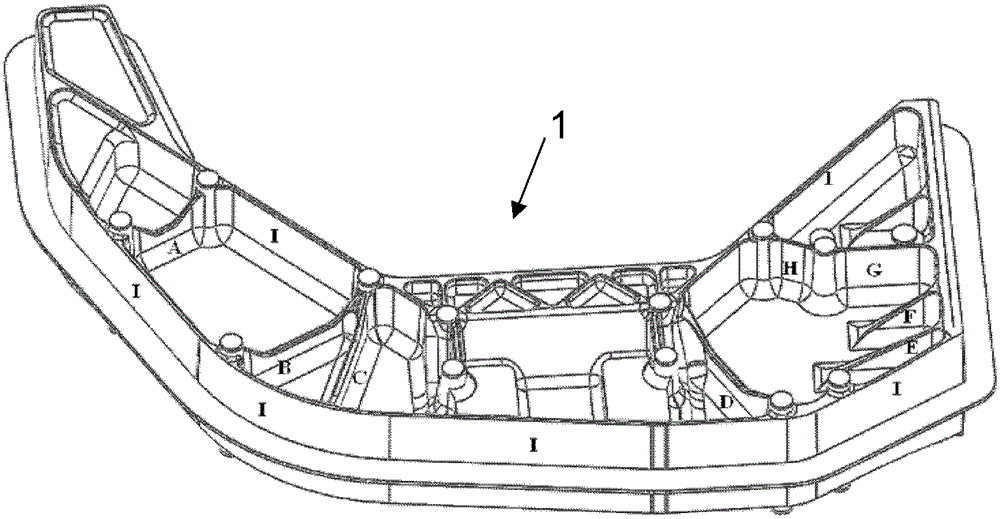

The invention provides a compression molding process machining method for a large composite reinforced thin-wall support structure. The method comprises the following steps that a mold is installed onan oil press; the mold is preheated, and is opened to fill a material after reaching preset temperature; after material filling is completed, the an upper mold assembly and a lower mold assembly aresemi-closed, and heating is continued until the material is in a molten state; after heat preservation is conducted for a certain period of time and the material is completely molten, the upper mold assembly and the lower mold assembly are assembled, and heating is stopped; and a product is extracted after pressure is maintained for a period of time. According to the method, the adopted mold is simple in structure, the production cost is low, and the period is short. The method is suitable for producing various large reinforced thin-wall high-strength fiber composites in complex shapes, the produced product can replace metal parts applied to some occasions, the weight is greatly reduced, and the production cost is lowered.

Owner:大连宇晨高新材料科技有限公司

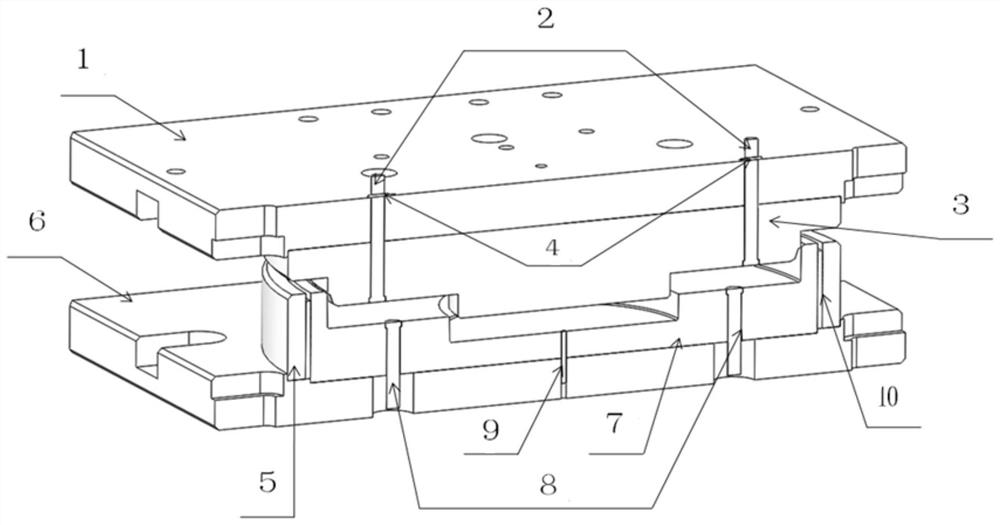

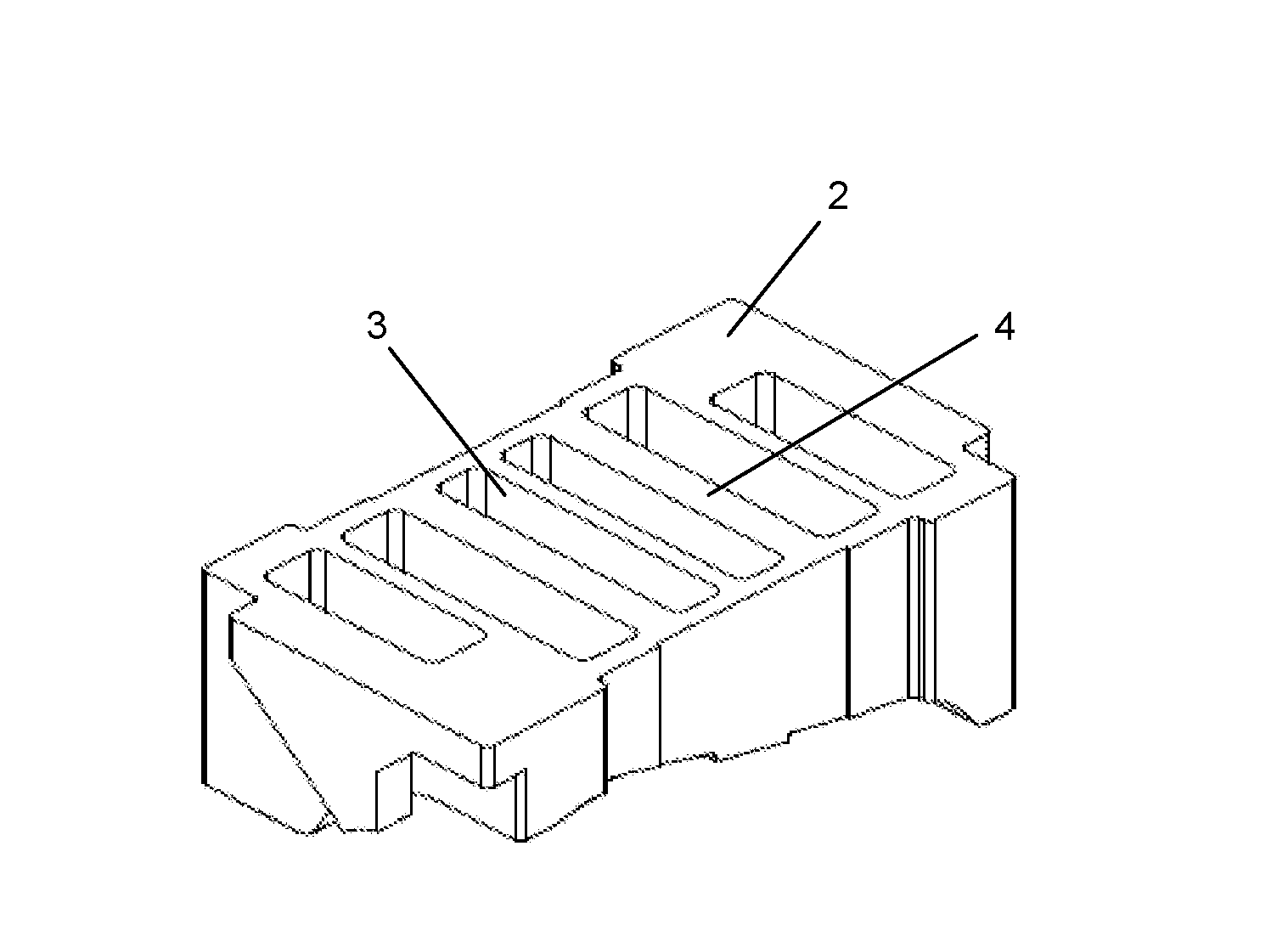

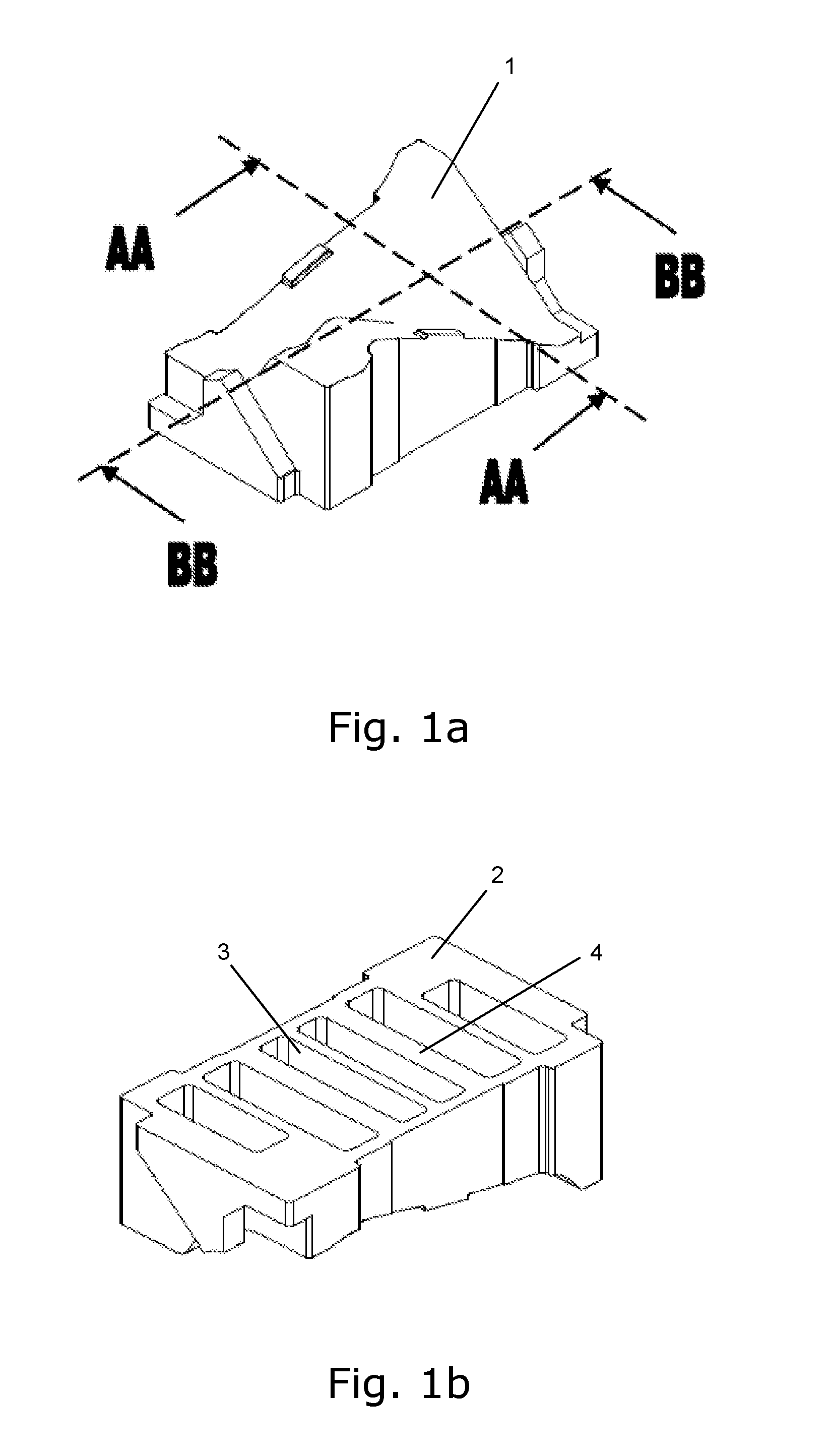

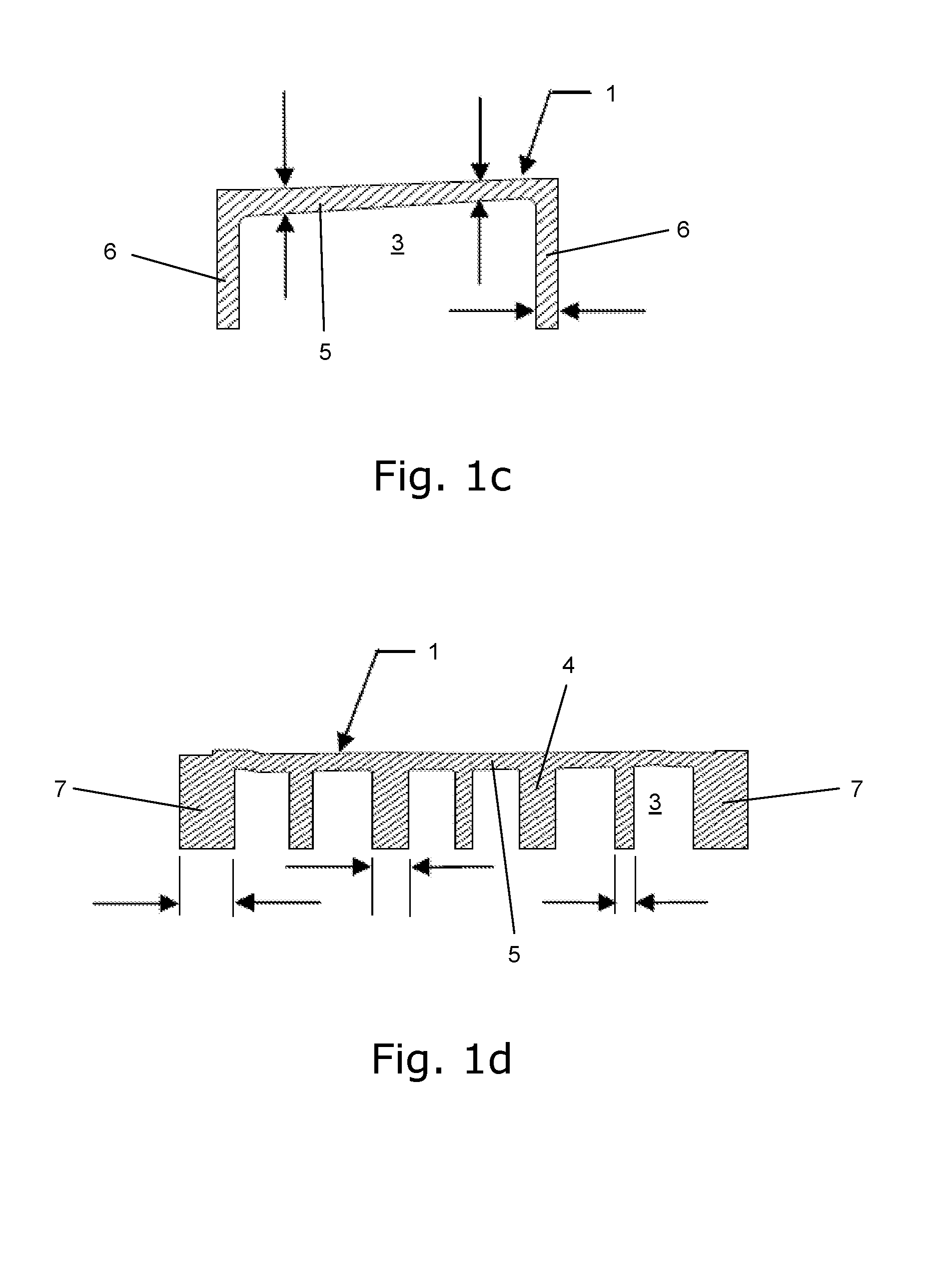

Casting die

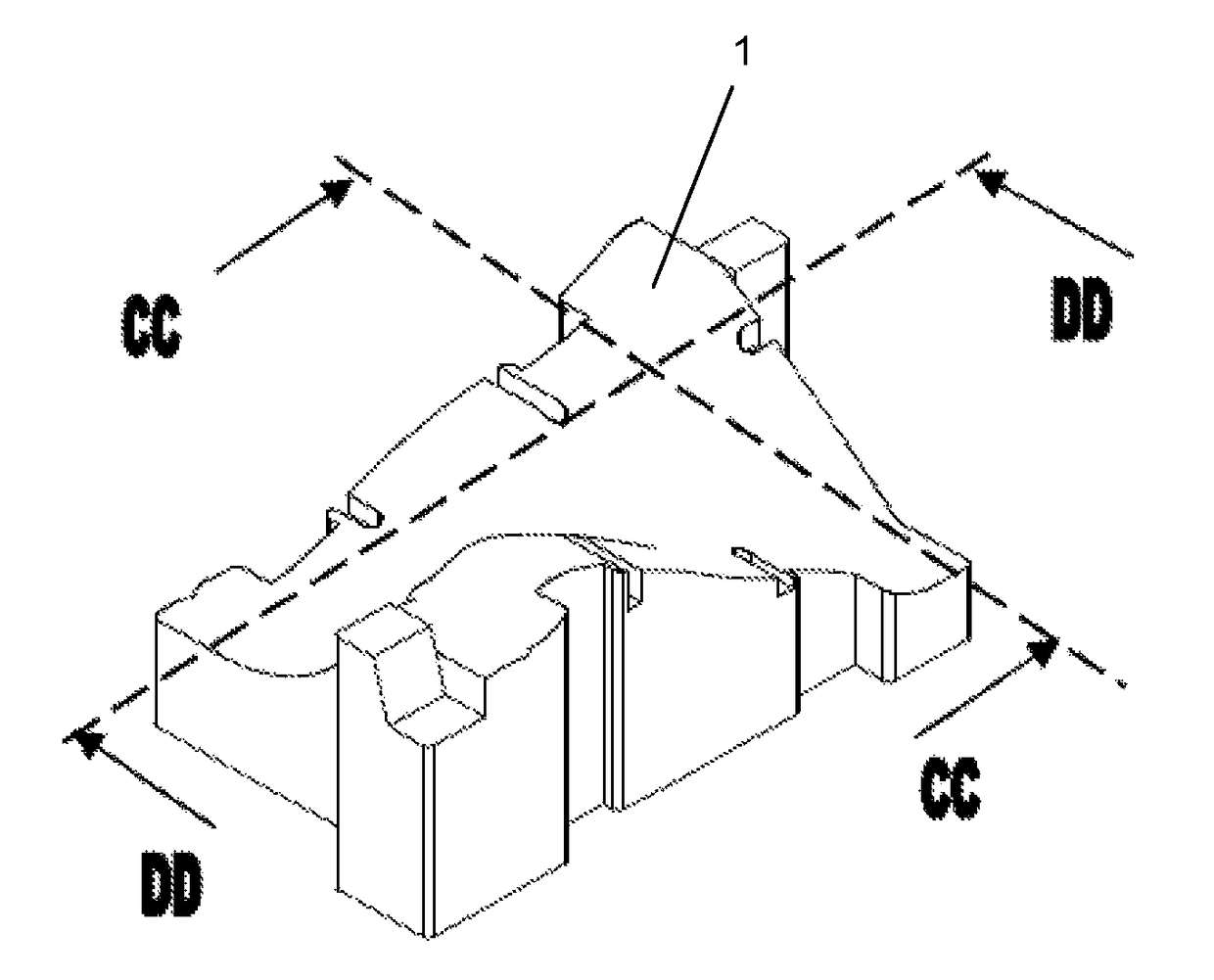

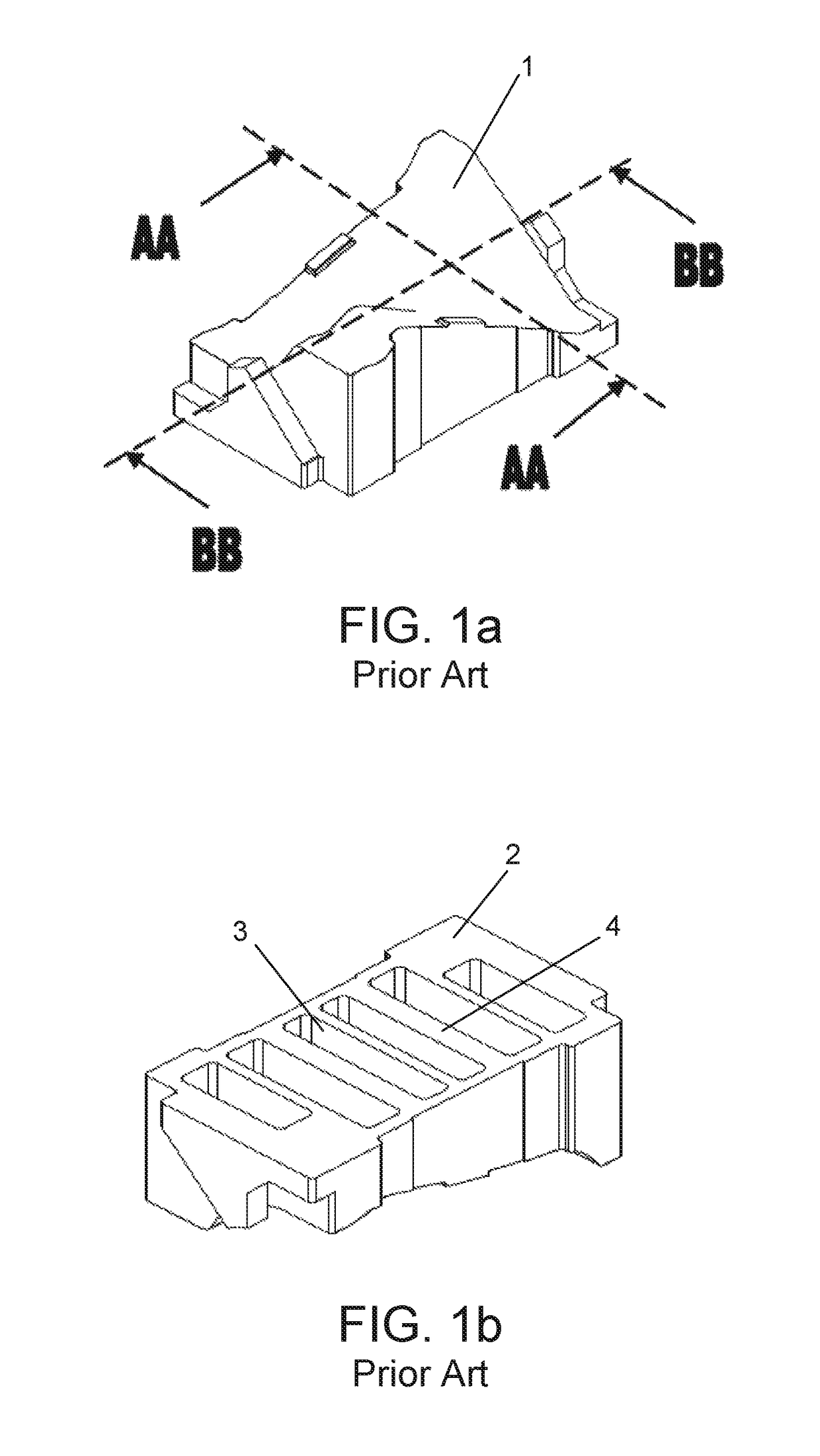

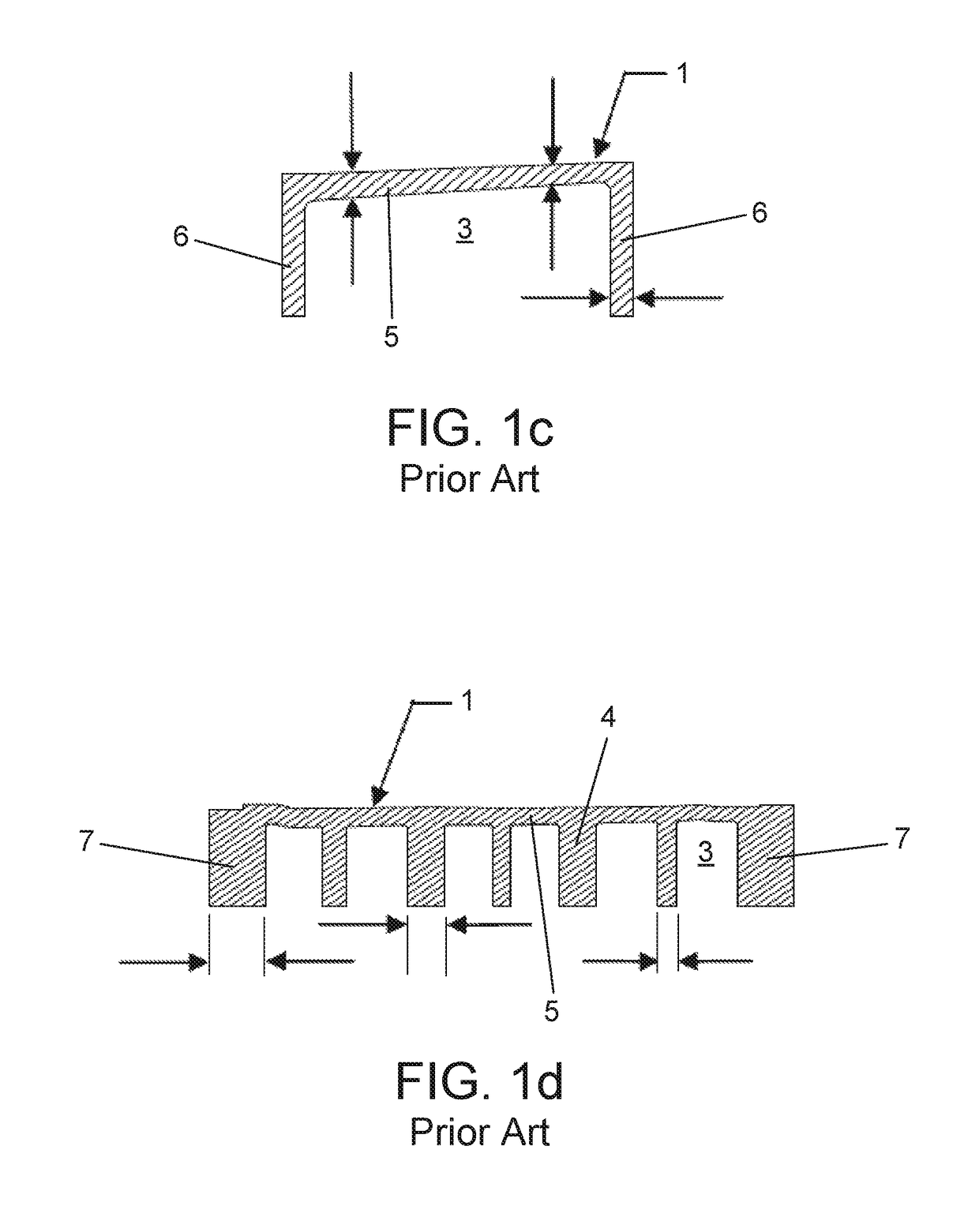

ActiveUS20160339508A1Reduce material usageLess machiningCutting toolsFoundry mouldsEngineeringForging

The present invention provides a casting / hot forging die having a forming surface and an opposing rear surface. The rear surface has a plurality of cavities spaced by a plurality of walls. Each of the plurality of walls has a substantially equal width. At least one transverse wall may also be provided such that the walls define a grid spacing a series of rectangular or triangular cavities.

Owner:ROLLS ROYCE PLC

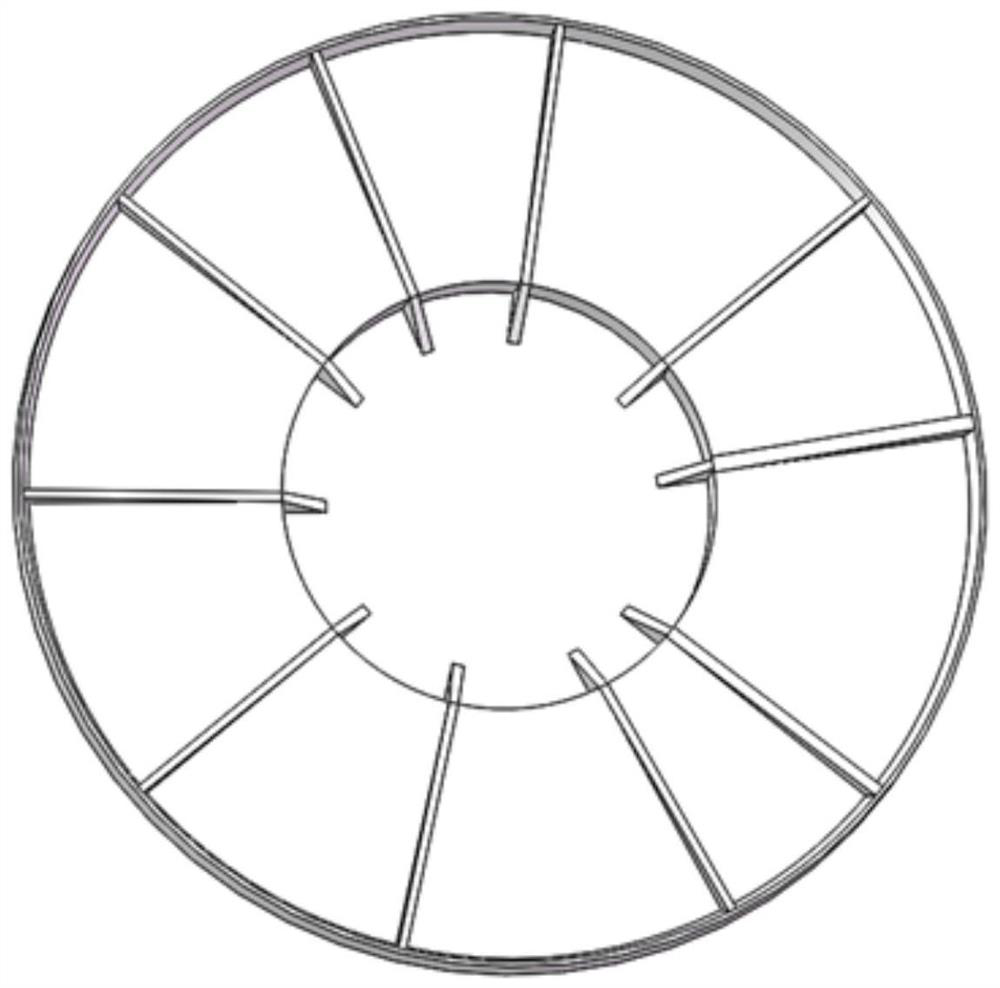

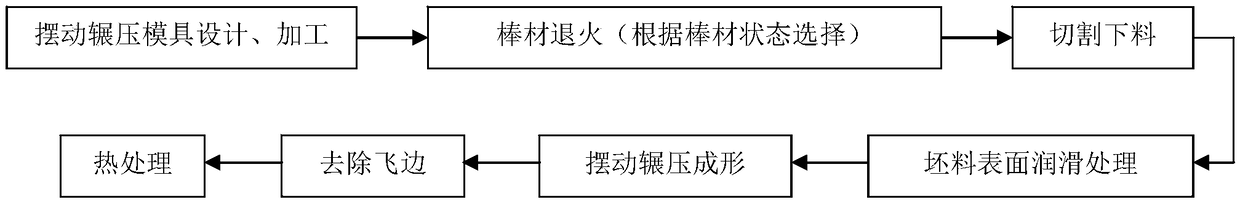

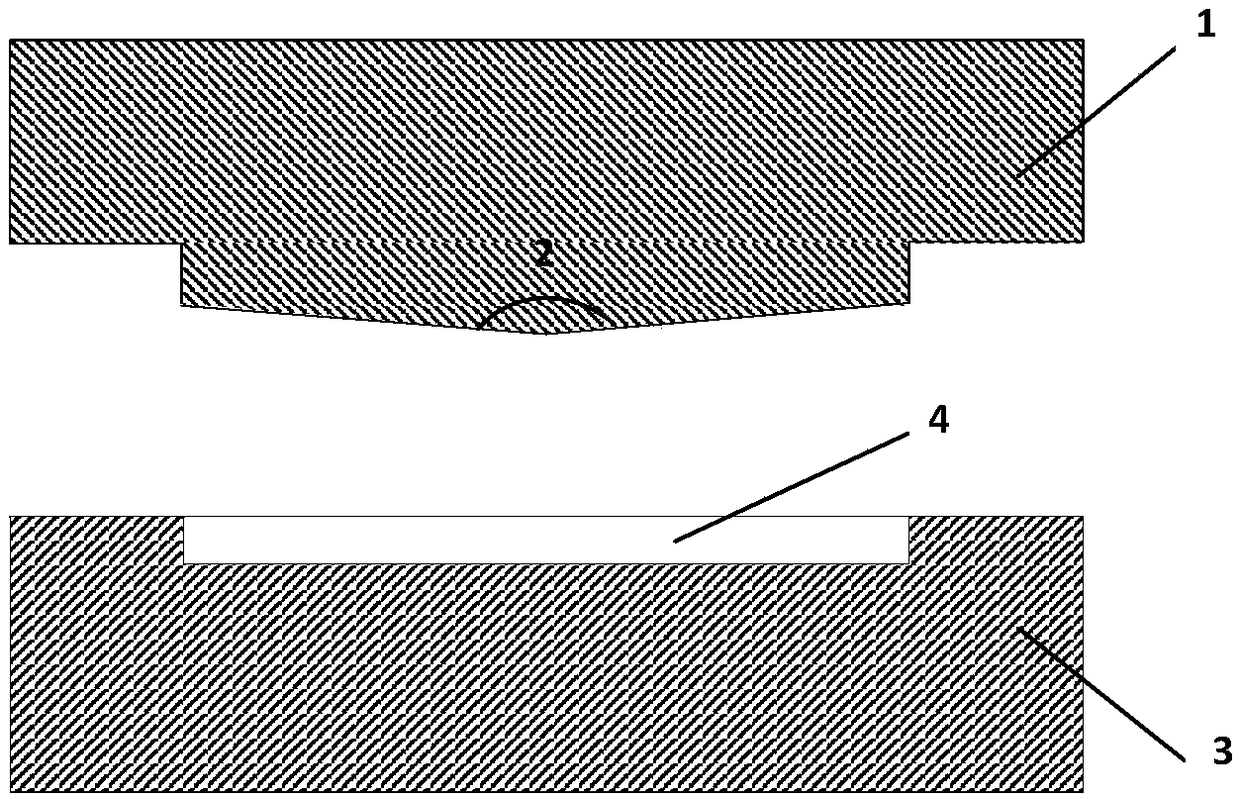

A metal circular plate swing rolling forming processing method

The invention belongs to the technical field of metal plastic deformation and particularly relates to a rotary forging forming method for a metal circular plate. The method comprises the steps of rod annealing, cutting and blanking, blank surface lubricating, rotary forging forming, trimming removal, thermal treatment, obtaining of the finished circular plate and the like. According to the rotary forging forming method for the metal circular plate, large deformation machining of the metal circular plate can be conducted through a small-tongue rotary forging machine, the manufactured metal circular plate has the excellent structure property, the blank deformation is uniform, the metal streamline is complete and radial, the aeolotropism of the rolled plate is avoided, generation of a great amount of leftover materials is avoided, the material utilization rate is high, small or zero cutting machining can be achieved, metal materials are saved, the production efficiency is high, the production process is easy to operate, and the rotary forging forming method is suitable for batch production.

Owner:GRIMAT ENG INST CO LTD

Positioning method for wrapped sand core and positioning structure for foundry sand core

InactiveCN102873274BPrecise positioningUniform wall thicknessFoundry mouldsFoundry coresFoundryMaterials science

The invention discloses a positioning method for a wrapped sand core and a positioning structure for a foundry sand core, aiming at providing a positioning method for a wrapped sand core and a positioning structure for a foundry sand core which have reliable and steady sand core positioning, high production efficiency, realize casting with a complex cavity inner structure easily and improve the qualified rate of castings effectively. The positioning structure comprises a main sand core and a sub sand core, wherein product molding parts and embedding par are arranged on the main sand core and the sub sand core; the positioning method comprises the following steps of: firstly, dividing the main sand core into a first main sand core and a second main sand core; forming dividing surfaces on the first main sand core and the second main sand core; then arranging limiting slots for containing the embedding part of the sub sand core on the dividing surfaces of the first main sand core and the second main sand core; and finally, clamping the embedding part of the sub sand core in the limiting slot through the first main sand core and the second main sand core, and positioning the first main sand core, the second main sand core and the sub sand core on a mould through the embedding part of the main sand core.

Owner:MAIN PLAN NINGBO BATHROOM COLLECTIONS

High-strength hot-spinning precision plastic forming method for hollow train axle blanks

ActiveCN105081041BReduce processing workloadHigh forming precisionVehicle componentsNumerical controlMaterials preparation

The invention relates to a method for powerful hot spinning precision plastic forming of hollow train axle blanks, which belongs to the technical field of plastic forming of long shaft parts, and mainly solves the problems of difficulty in manufacturing hollow train axle molds and complicated manufacturing processes. The invention includes several steps of material preparation, heating, feeding, spinning, and finishing. The powerful hot spinning technology is used to control the rotation speed of the workpiece, the feed speed of the rotary wheel, and the axial movement of the rotary wheel frame through the numerical control technology. Speed, spinning out high-precision hollow train axle blanks, realizing rapid and precise plastic forming of hollow train axle blanks. The invention has the advantages of simple manufacturing process, good metal fiber flow direction, small machining allowance, high material utilization rate, dieless forging and low manufacturing cost, and is suitable for mass production of various types of hollow train axles.

Owner:QINGDAO ZHONGTIANPENG FORGING MFG CO LTD

Tool changing method and tool changer

ActiveUS10252385B2Change timeExtension of timeTool adjusterPositioning apparatusEngineeringDrive motor

Owner:DMG MORI CO LTD

Manufacture of hollow aerofoil

ActiveUS9879545B2Accurate locationTolerance errors is reduced/minimizedBlade accessoriesEfficient propulsion technologiesStructural engineeringGas turbines

A method of manufacturing a hollow aerofoil component for a gas turbine engine includes using a capping panel to cover a pocket in a pocketed aerofoil body. During manufacture, the outer surface of the capping panel is located relative to the pocketed aerofoil body. This ensures that the outer surface of the capping panel is located as accurately as possible. This means that the capping panel can be made to be as thin as possible, which in turn reduces weight and material wastage. Once the capping panel has been located in position, it may be welded to the aerofoil body in order to produce the hollow aerofoil component.

Owner:ROLLS ROYCE PLC

Casting die

The present invention provides a casting / hot forging die having a forming surface and an opposing rear surface. The rear surface has a plurality of cavities spaced by a plurality of walls. Each of the plurality of walls has a substantially equal width. At least one transverse wall may also be provided such that the walls define a grid spacing a series of rectangular or triangular cavities.

Owner:ROLLS ROYCE PLC

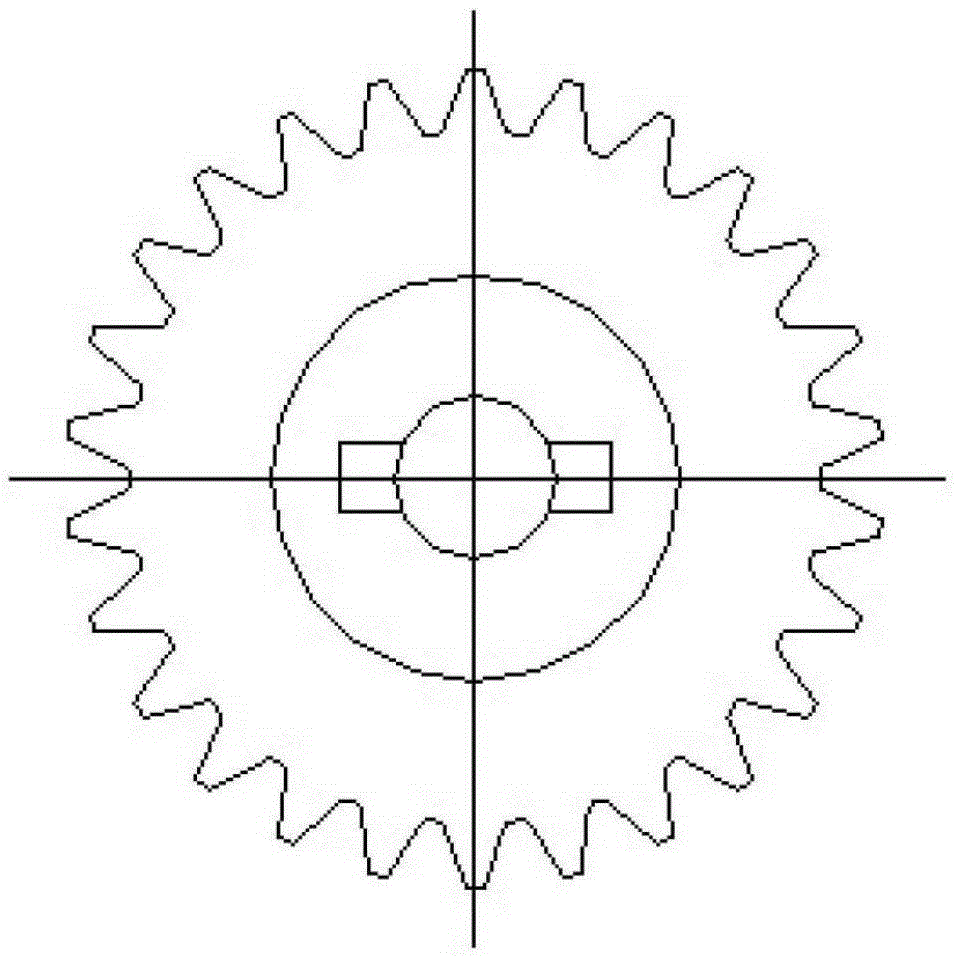

Method for manufacturing motorcycle cooling pump gear

ActiveCN103846439BHigh hardnessHigh strengthShaping pressCompression moldingHigh volume manufacturing

A method for manufacturing a motorcycle cooling pump gear, characterized in that: metal powder is used as a raw material and filled into a motorcycle cooling pump gear mould, pressed and formed and then sintered. The invention uses metal powder as raw material to alloy the metal powder into alloy steel through pressing and sintering, which not only avoids the waste of steel, saves steel resources greatly, but also produces motorcycle cooling pump gears with the mechanical properties of steel, further It improves its mechanical performance and overall product quality, and also greatly improves production efficiency. The invention has the advantages of simple production process, high product precision and good consistency, and ensures the stability of product quality in mass production.

Owner:重庆聚能粉末冶金股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com