Compression molding process machining method for large composite reinforced thin-wall support structure

A composite material and support structure technology, applied in the field of thin-walled castings, can solve the problems of poor fluidity of fiber-reinforced composite materials, affecting product performance, and high production and maintenance costs, achieving good corrosion resistance, low production costs, and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Based on the equivalent modulus and tensile strength of the material, and the convenience of purchasing domestic materials, PA66 and short fiber T300 are used in this embodiment. The performance parameters of PA66 are: density 1.14g / m 3 , The modulus of elasticity is 3.21GPa, and the strength is 68.3MPa. The performance parameters of short fiber are: density 1.76g / m 3 , The elastic modulus is 230MPa, the strength is 2330MPa, and the diameter is 6μm. The parameters in the manufacturing process are raw material drying temperature 100°C, drying time 4h, melt temperature 255-303°C, mold temperature 120-140°C.

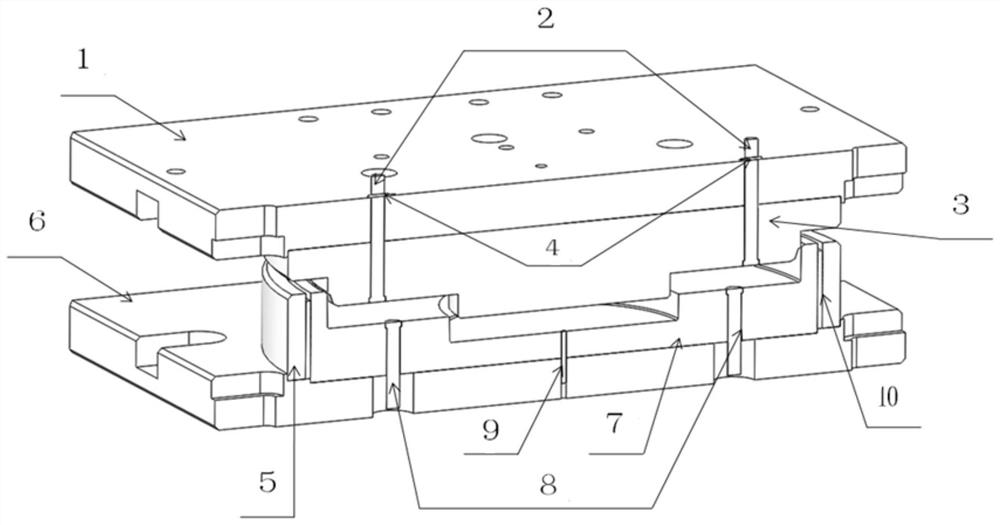

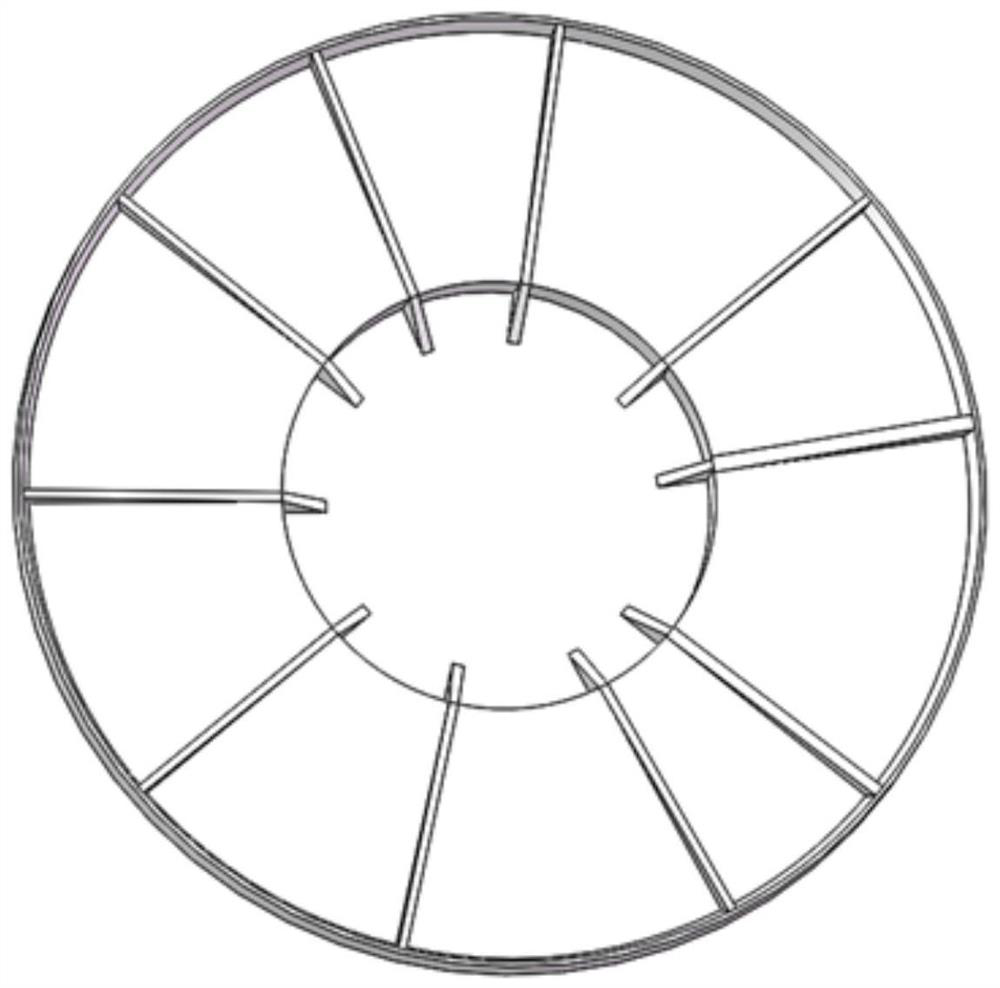

[0035] Such as figure 1 As shown, the present embodiment discloses the mold of the above-mentioned compression molding process method, and the products produced are as figure 2 As shown, the mold includes an upper template 1 and an upper mold 3 connected thereto, a lower template 6 and a lower mold 7 connected thereto, and a manufacturing space for products to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com