Patents

Literature

65results about "Tool adjuster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

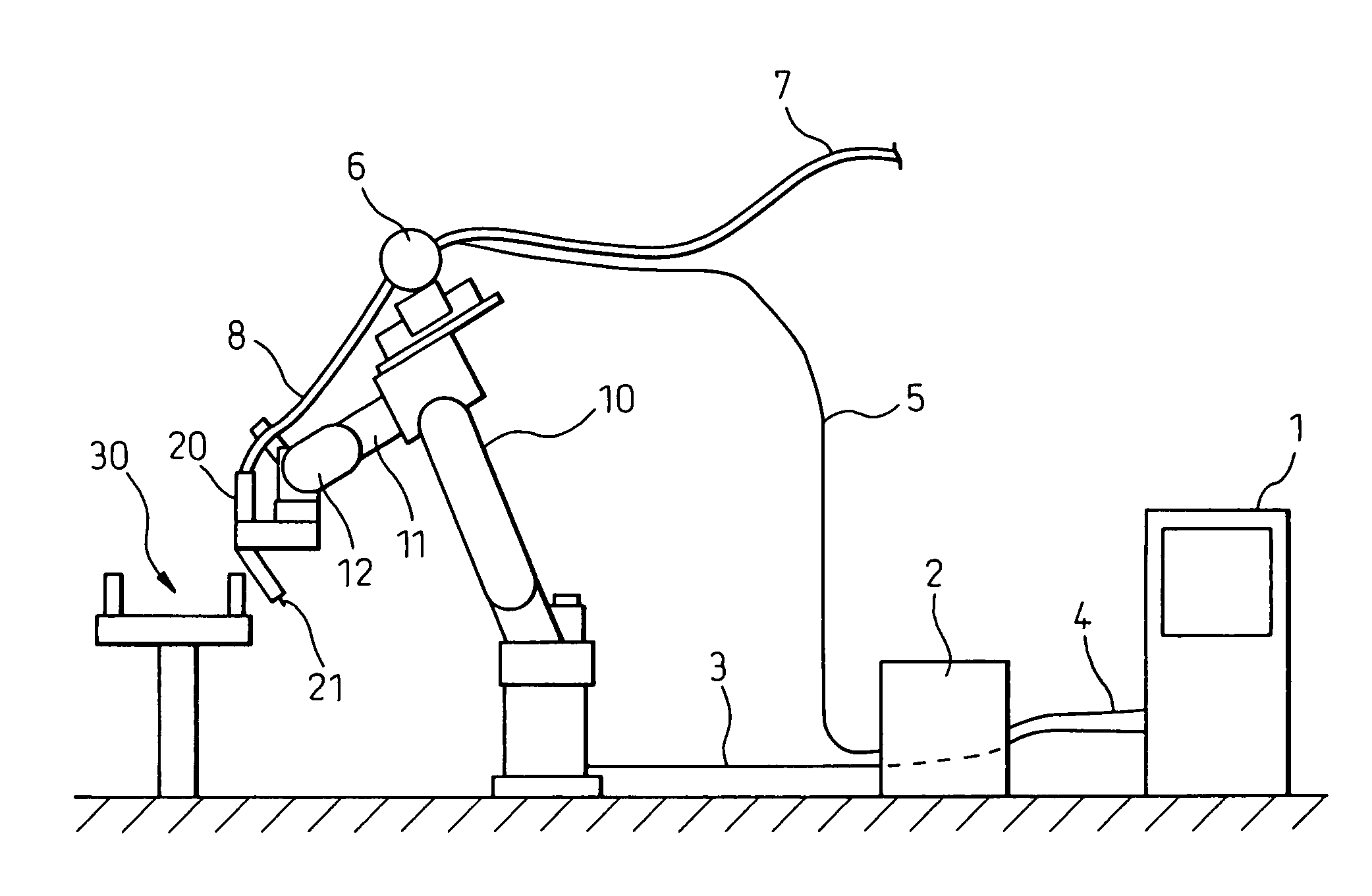

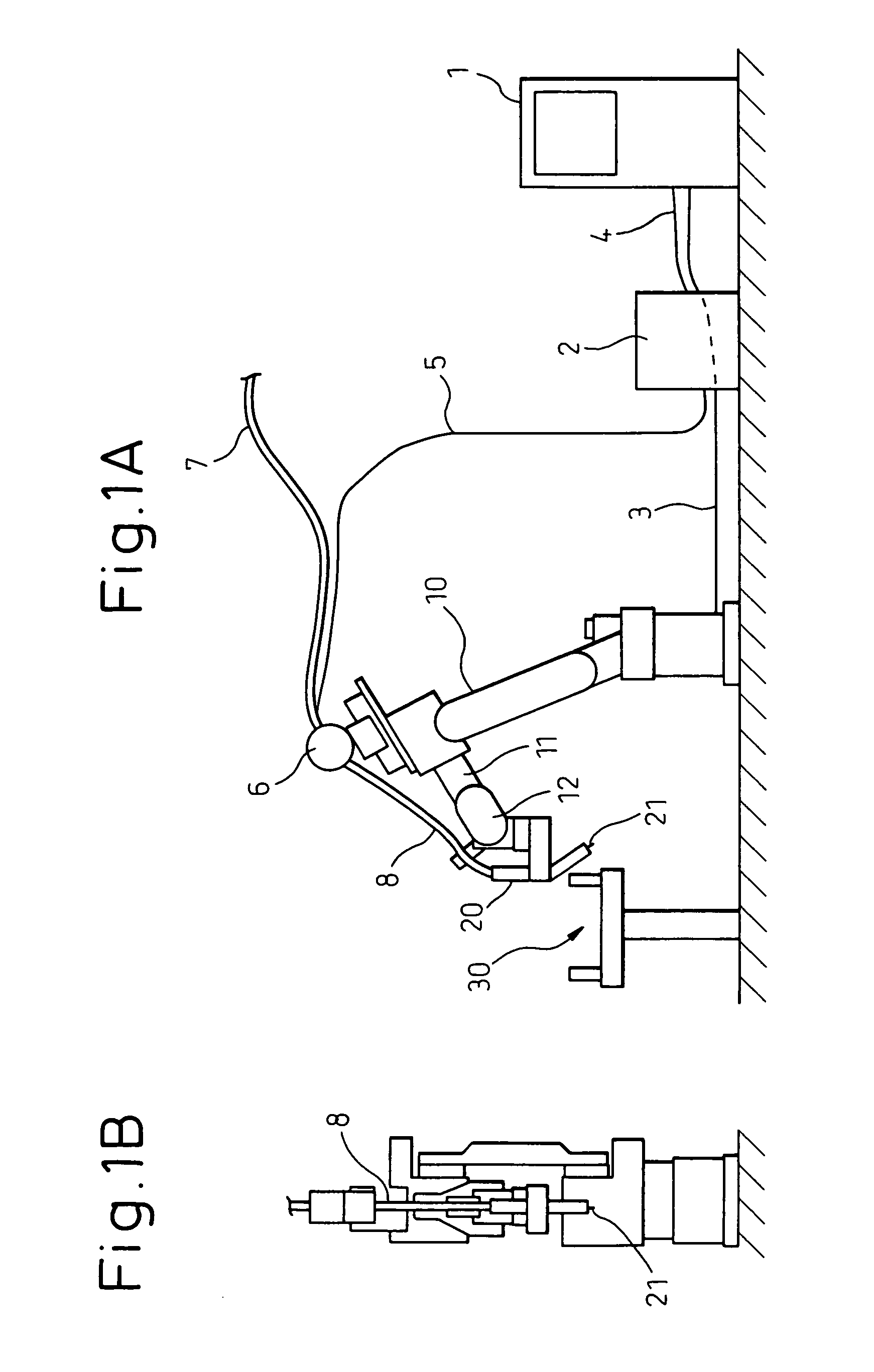

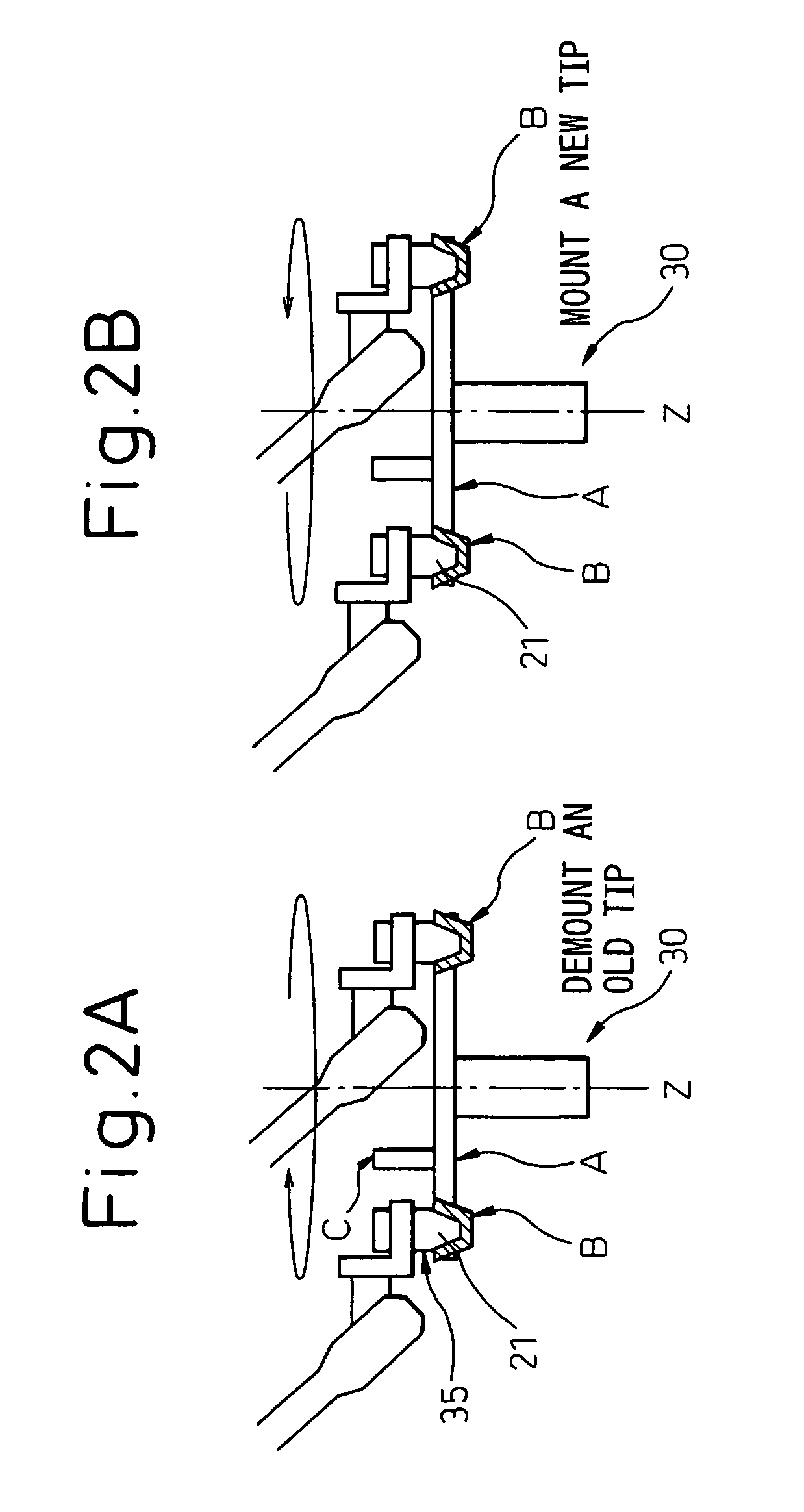

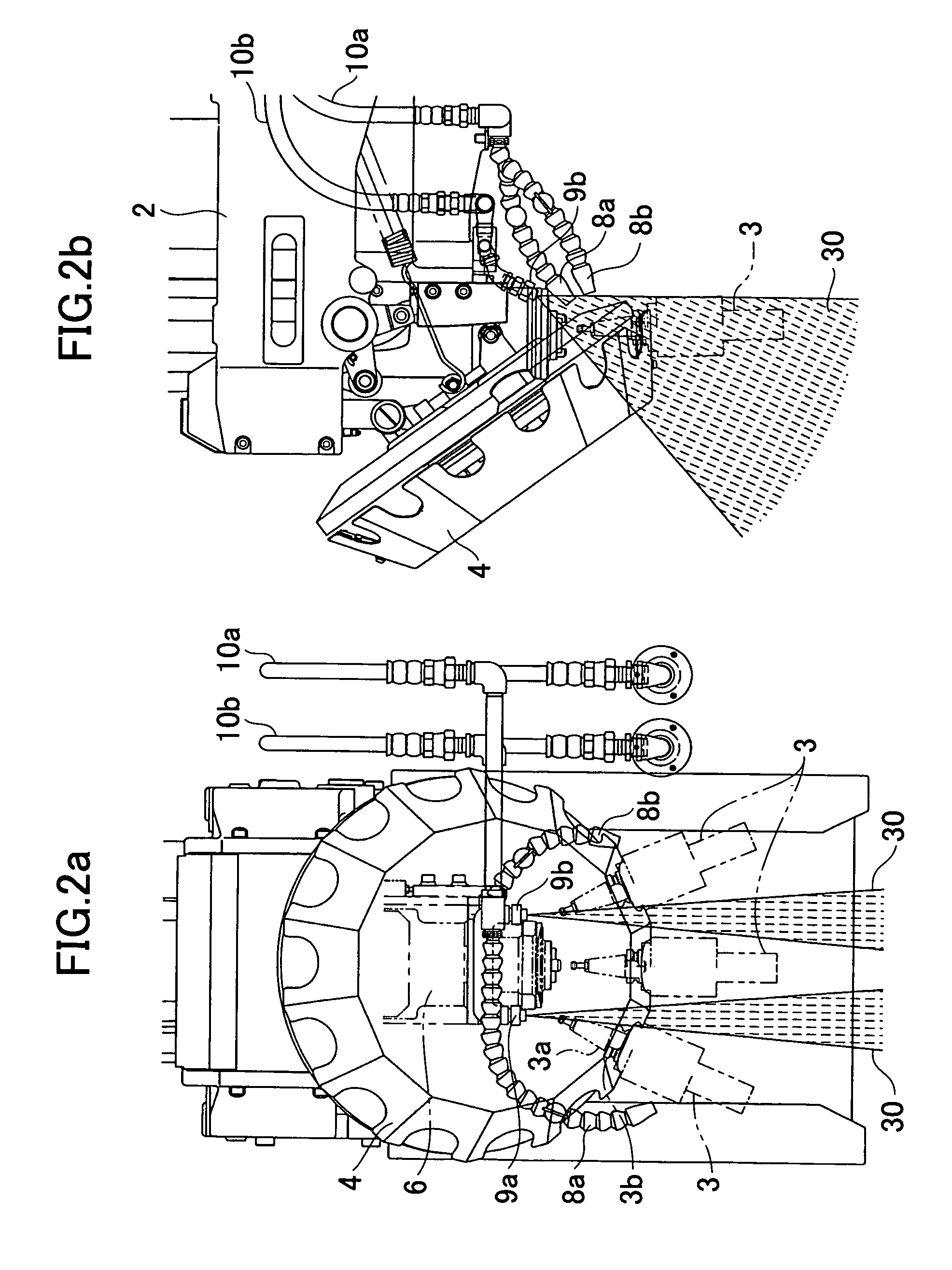

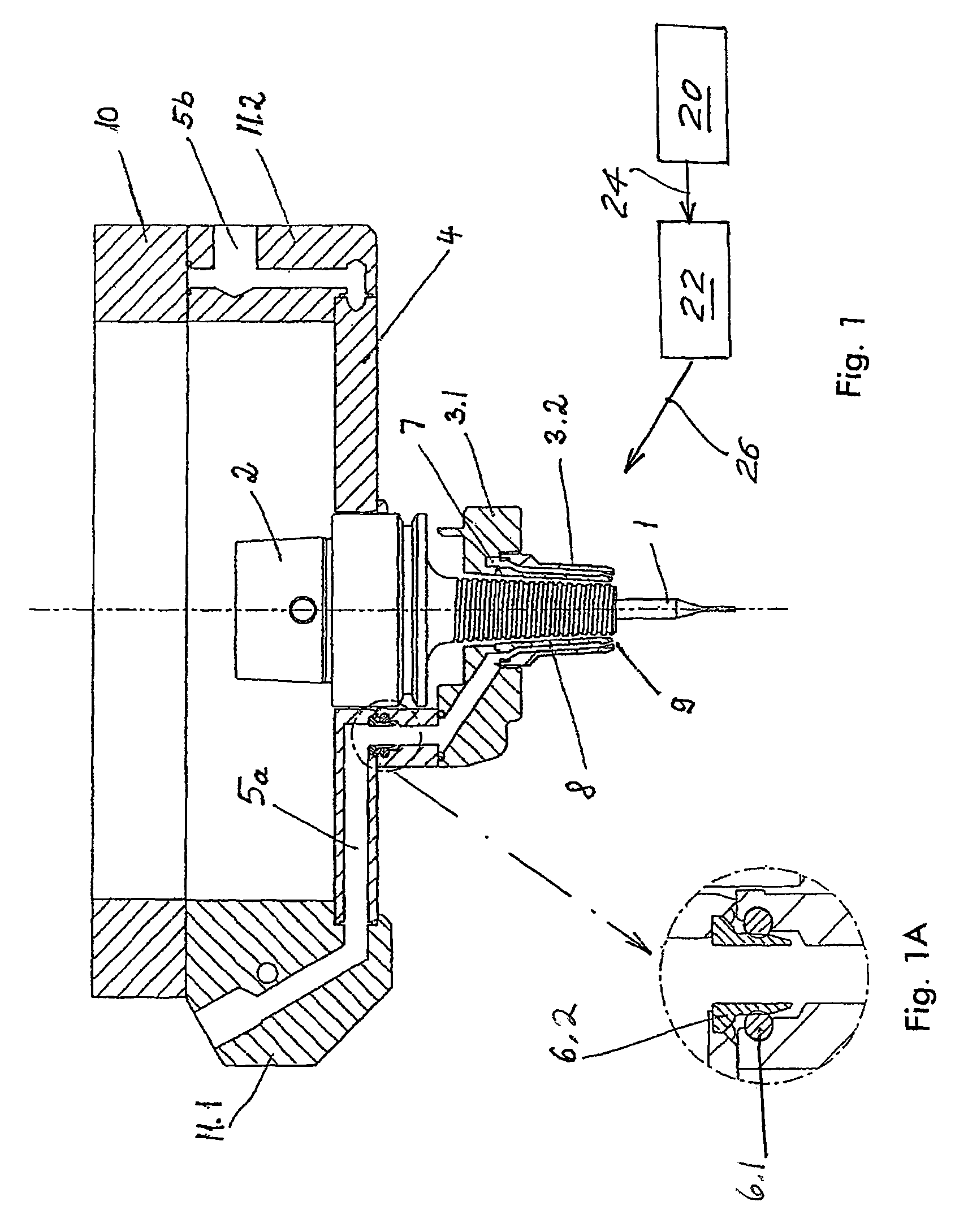

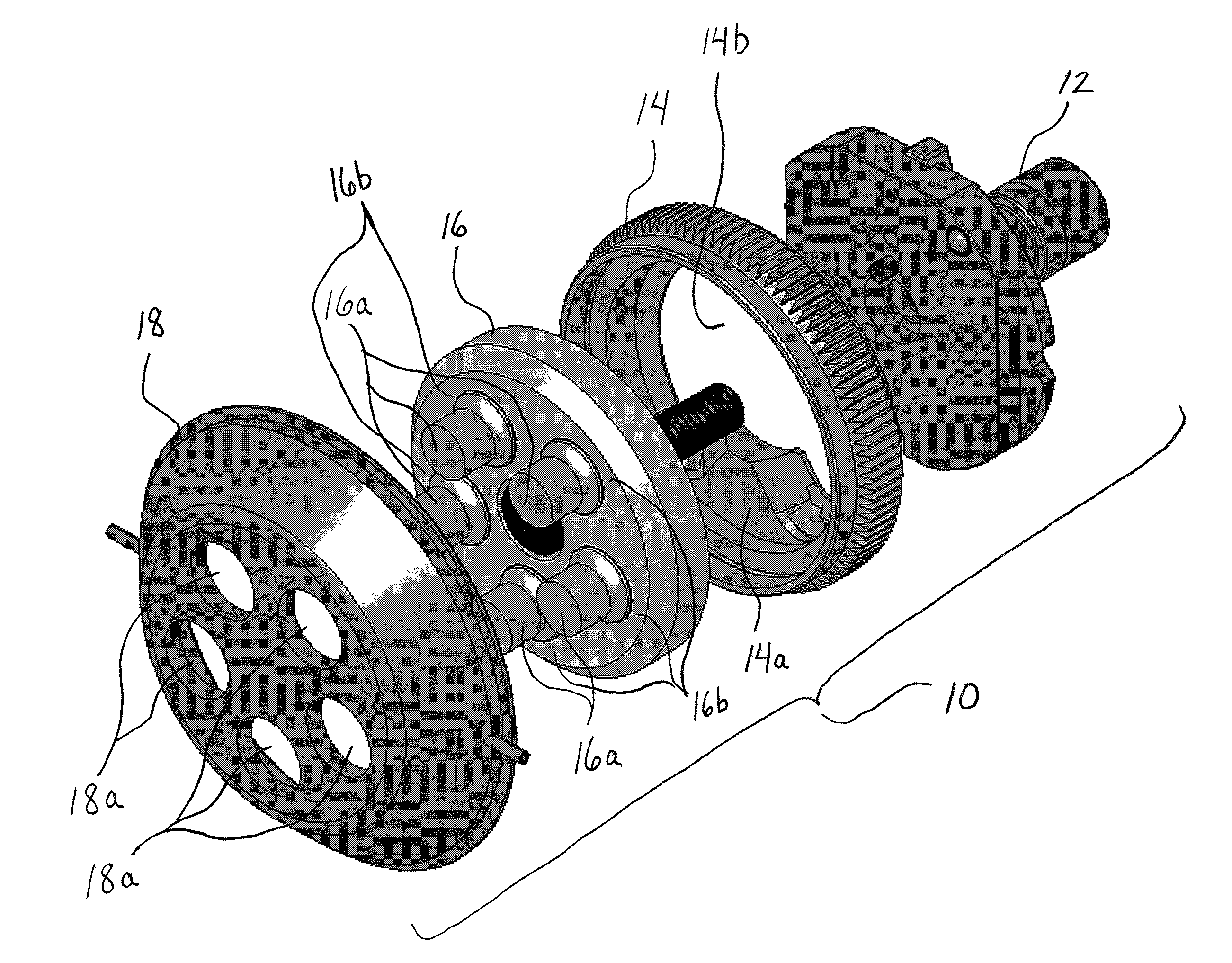

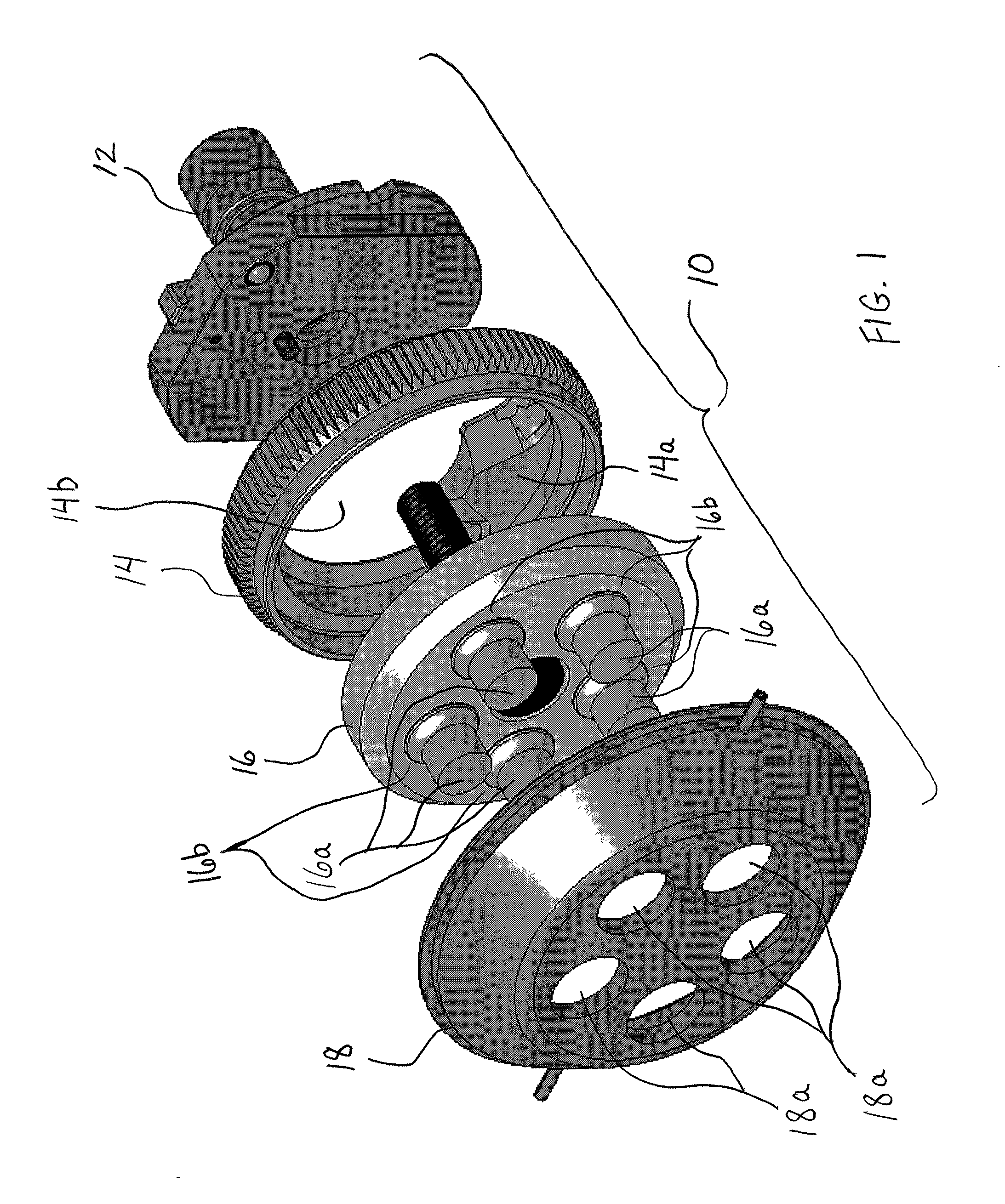

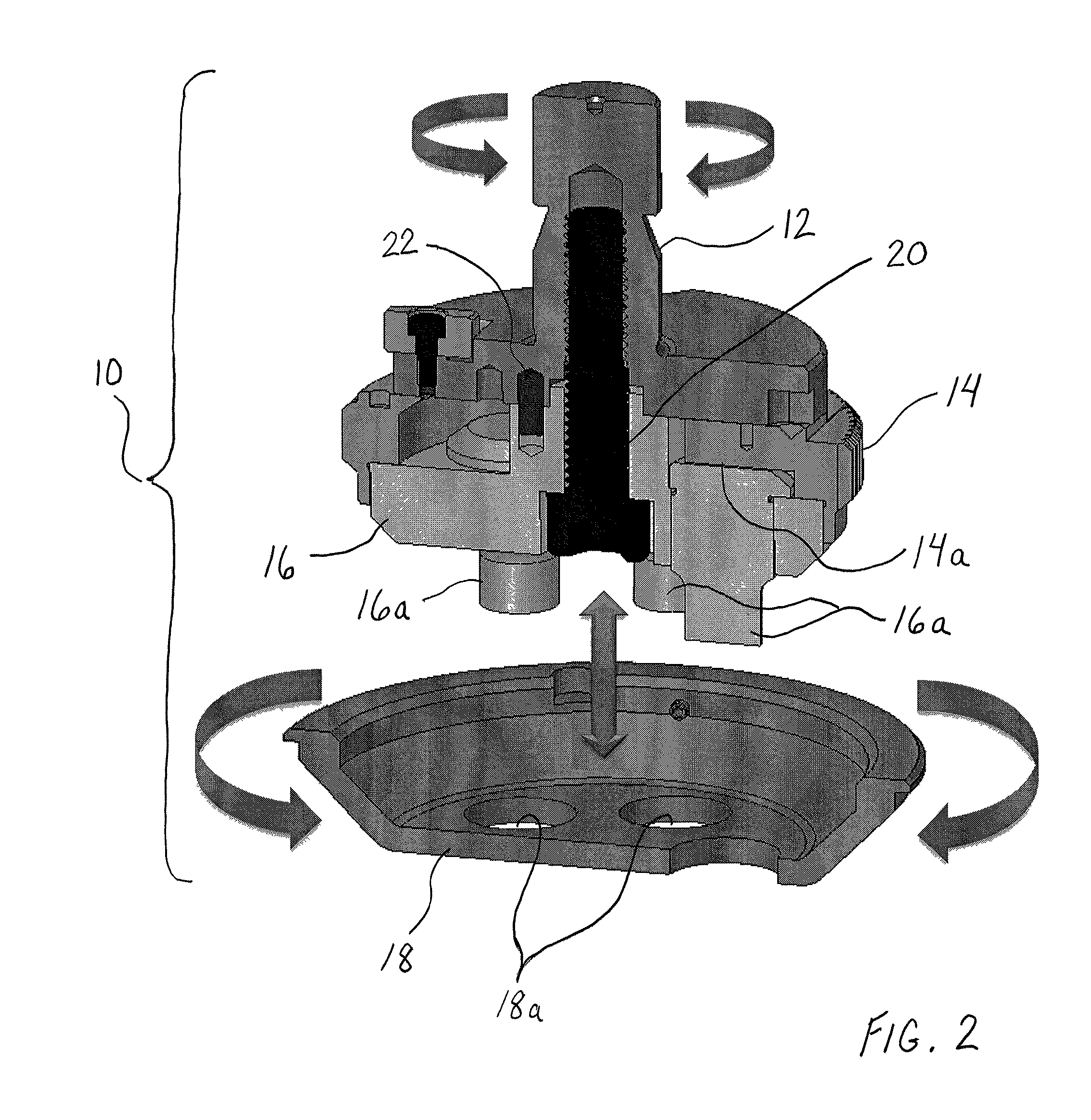

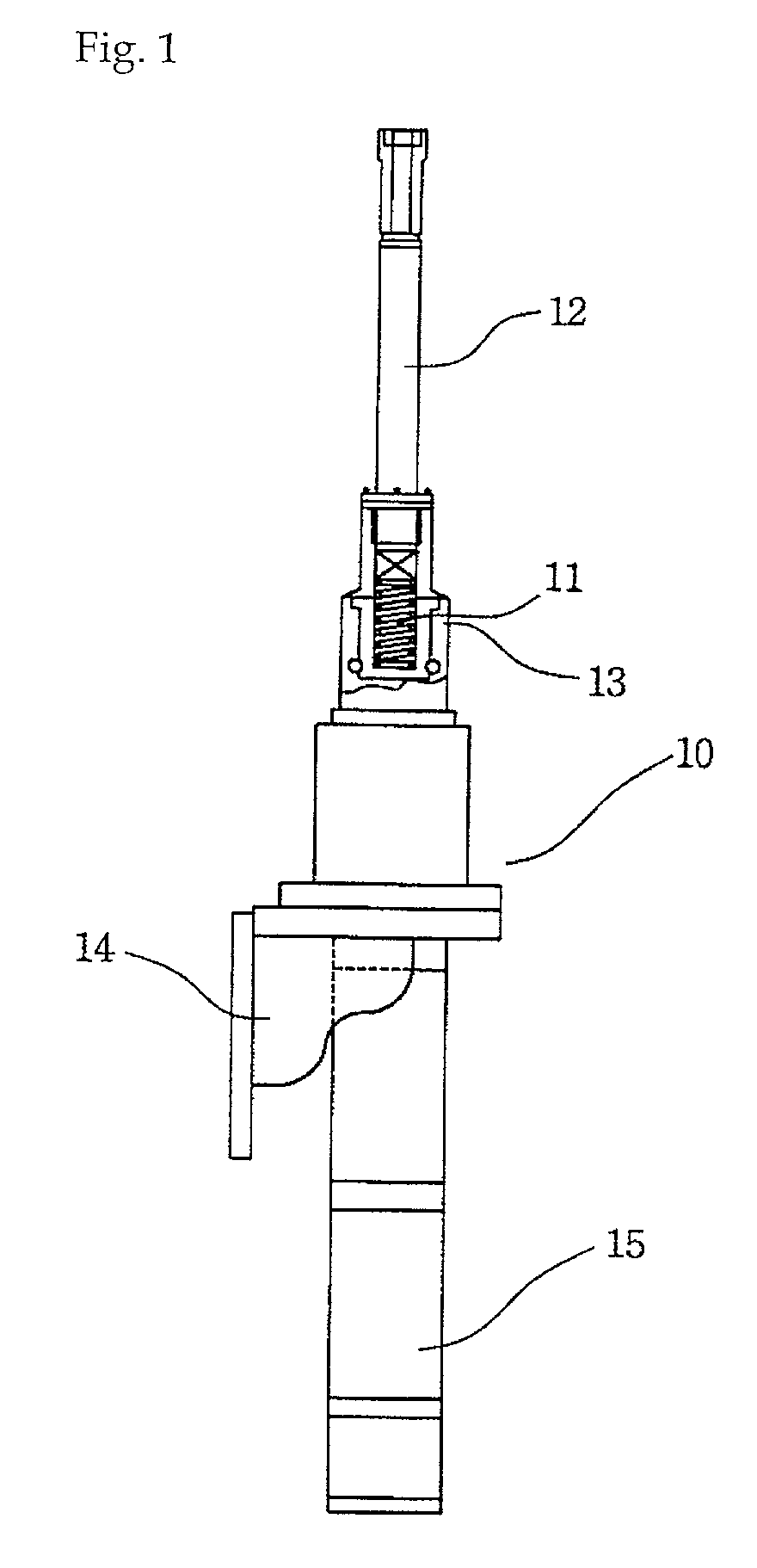

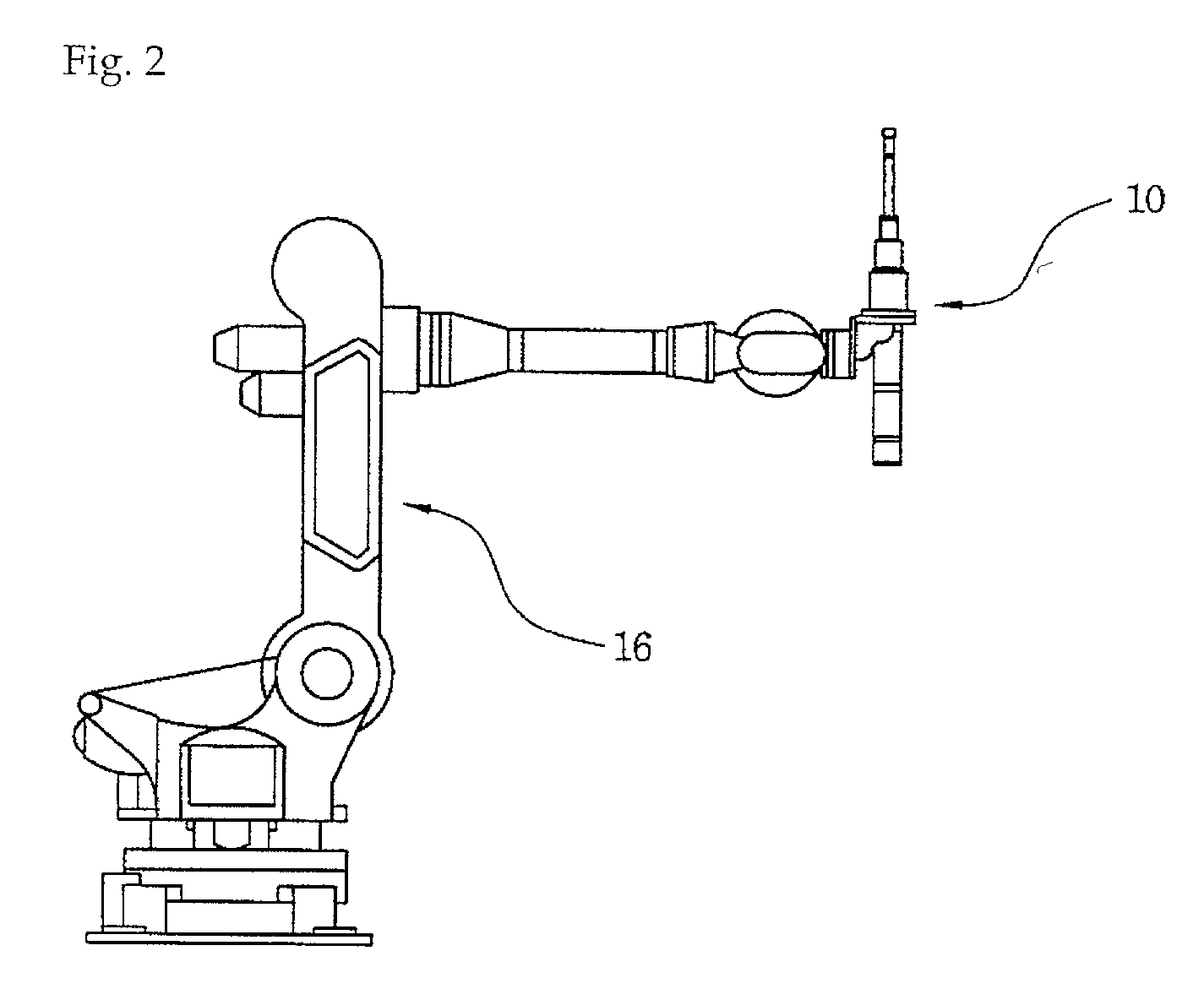

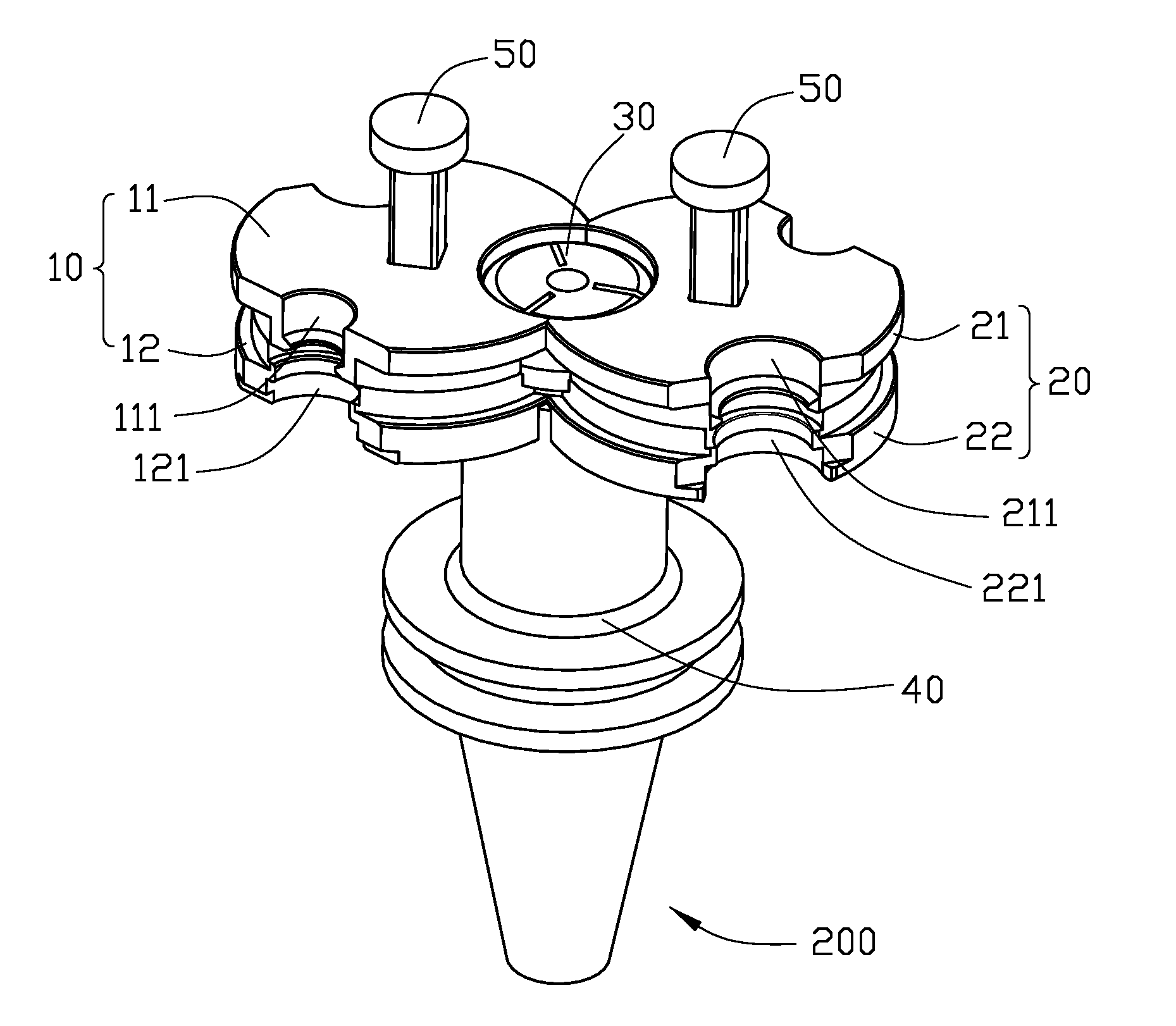

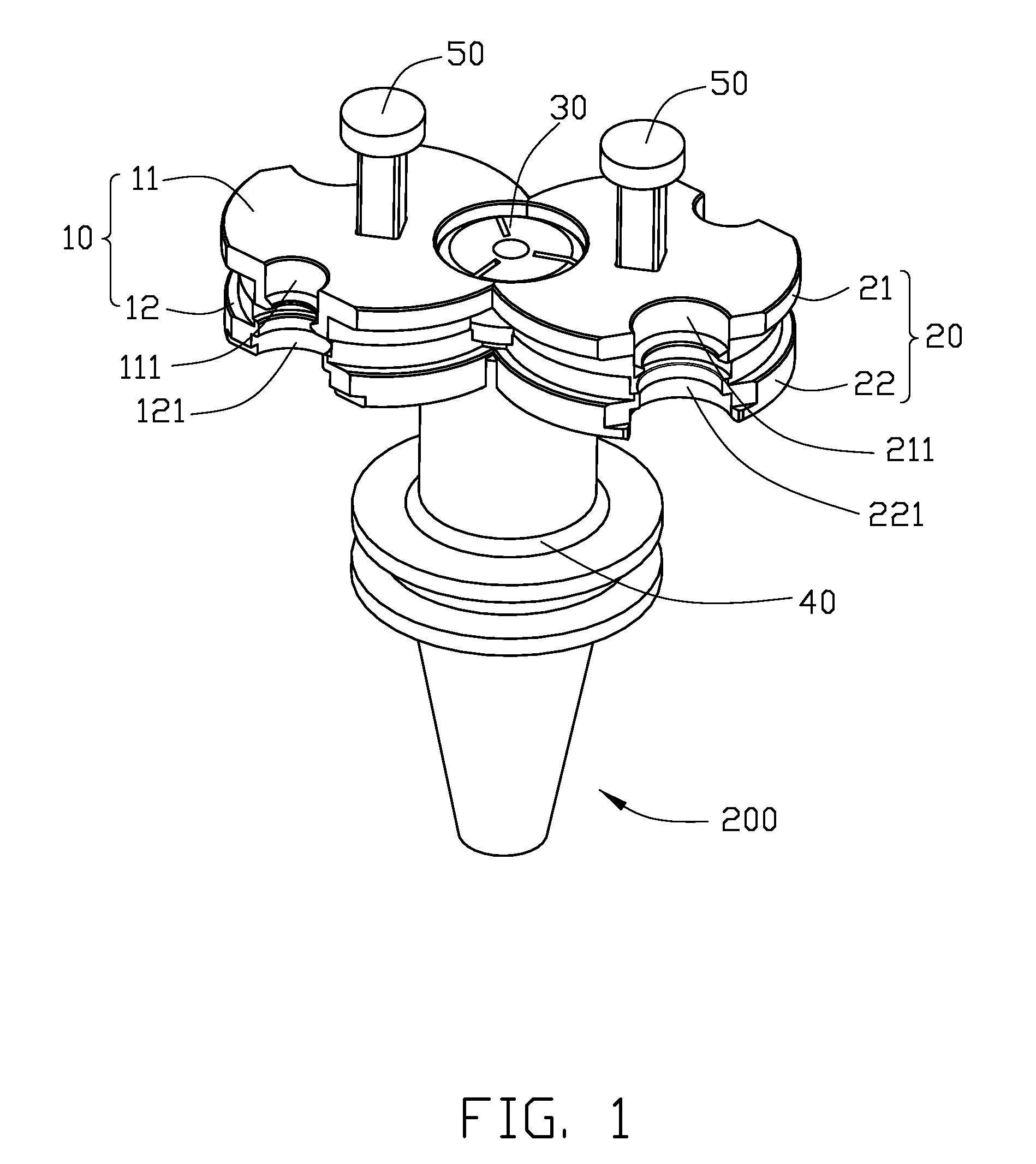

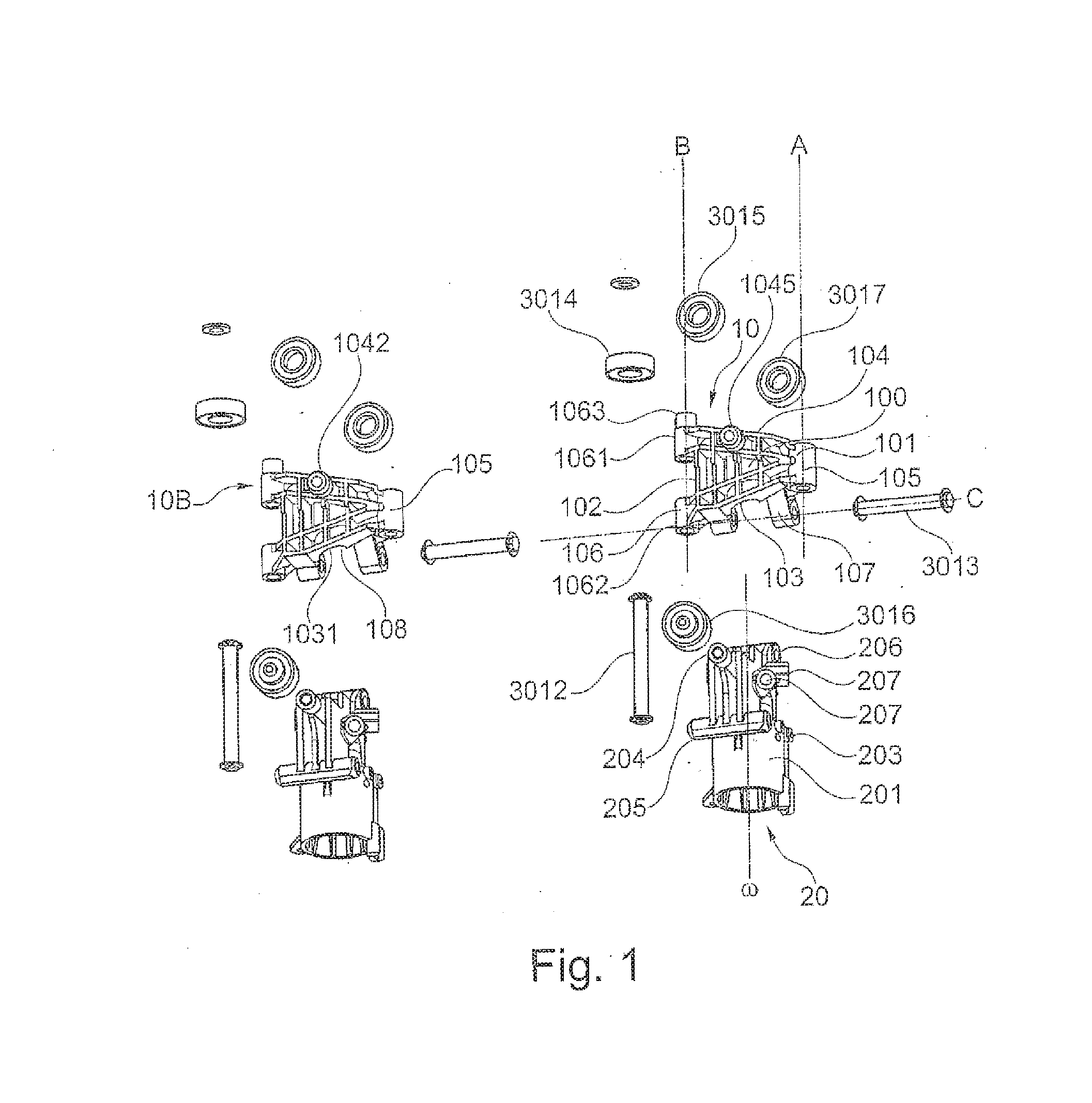

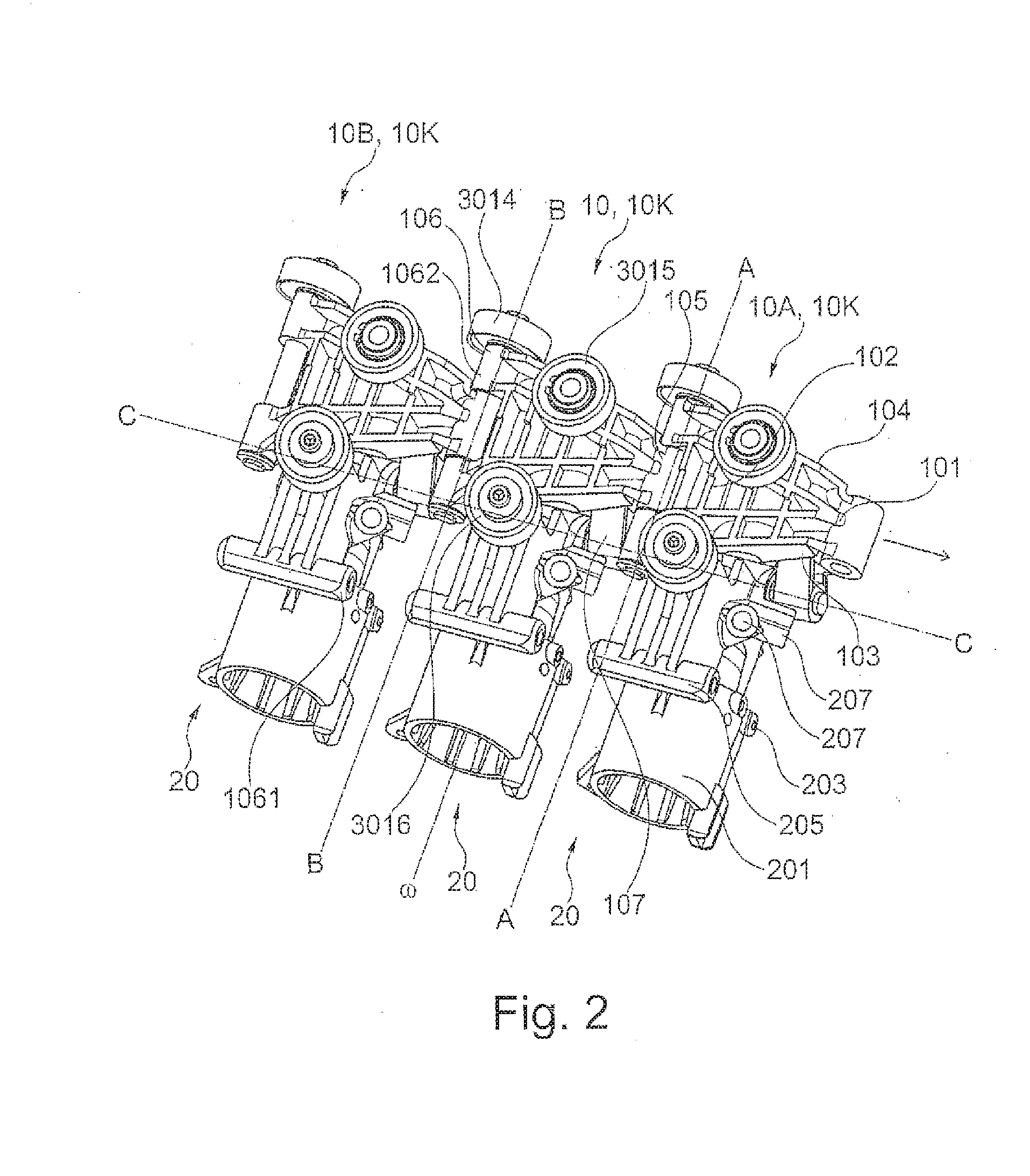

Apparatus for automatically changing a robot tool tip member

ActiveUS7204792B2Simple structureFew stepsPrecision positioning equipmentWeld torches cleaningEngineeringMechanical engineering

An apparatus for automatically changing a tool tip member for a robot includes a tip member changing jig disposed in an operational area of the robot. The tip member changing jig includes a base member, a rotating member supported by the base member so as to be rotatable about a rotation axis, and tip member holding means disposed at positions that are offset from the rotation axis of the rotating member. The tip member holding means holds the tool tip member so that a central axis of relative rotation, for threadedly mounting or demounting the tool tip member on or from the tool body, extends substantially parallel to the rotation axis of the rotating member and so that rotation of the tool tip member, with respect to the rotating member, is locked.

Owner:FANUC LTD

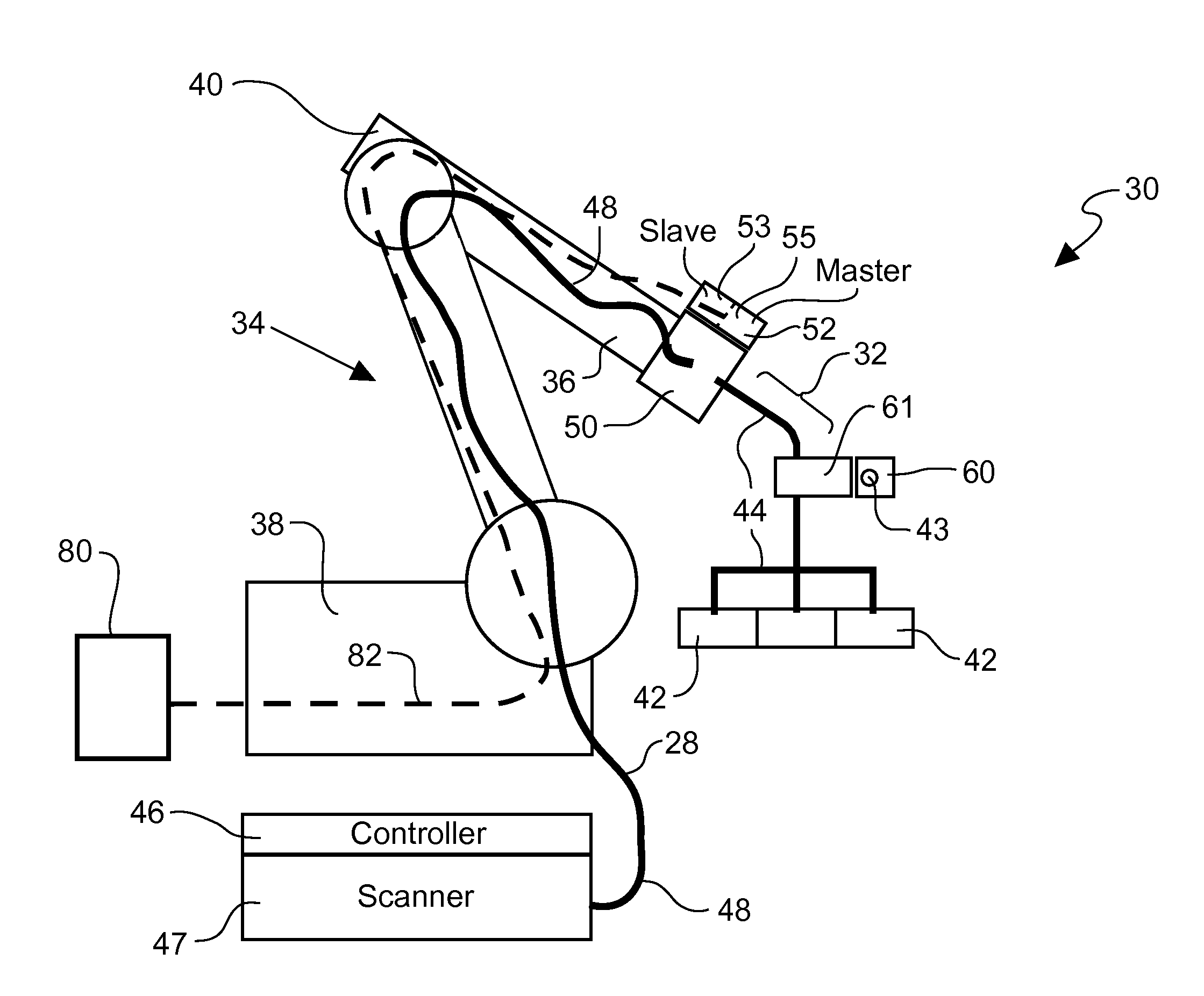

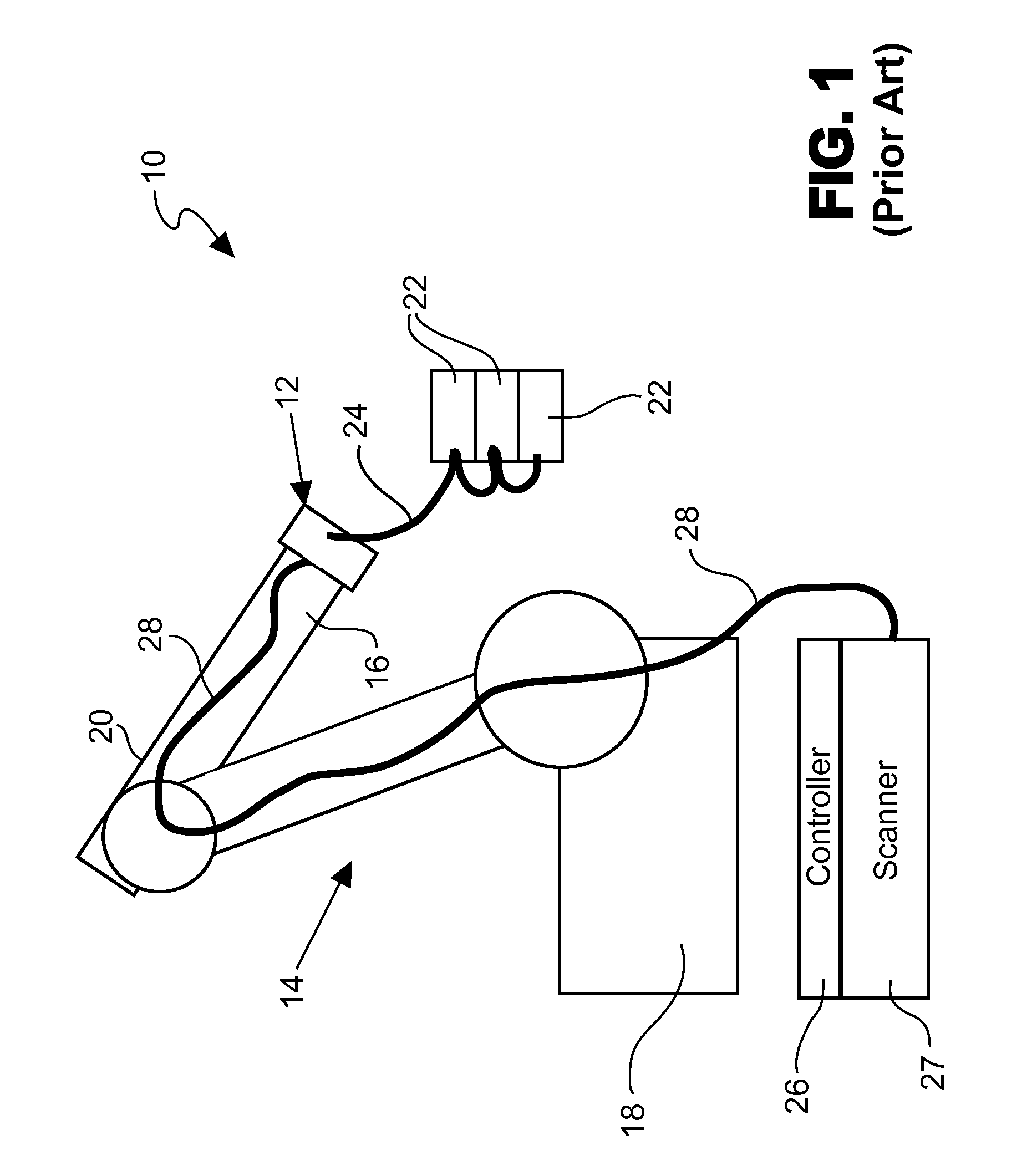

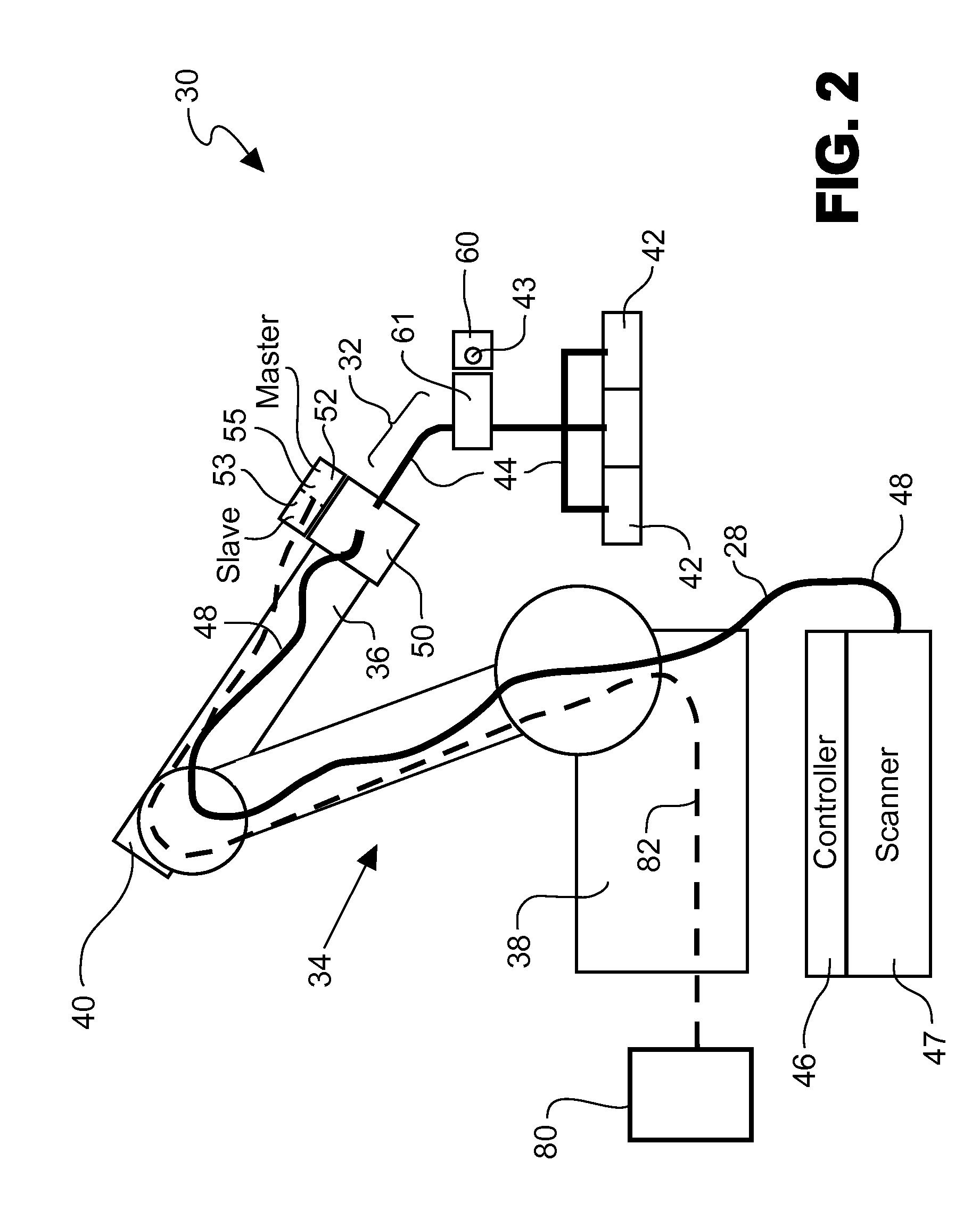

Methods and systems for monitoring the operation of a robotic actuator

InactiveUS20100184575A1Shorten connection timePrecision positioning equipmentGripping headsComputer moduleSupercapacitor

A robotic tool changer and systems and methods for controlling the operation of a robotic tool changer are provided. The tool changer, methods, and systems include a robot-side component mountable to a robot arm end interface; a tool-side component adapted to engage a tool; a first slave module associated with the robot-side component and adapted to communicate with a first master module; and a second master module associated with the robot-side component and adapted to communicate with a second slave module associated with the tool. The second slave module may include a temporary power supply, for example, a battery or a capacitor, for instance, a super capacitor. Aspects of the invention are advantageous for performing high-speed robotic connections and disconnections, and for providing tool and tool changer performance information gathering.

Owner:APPLIED ROBOTICS

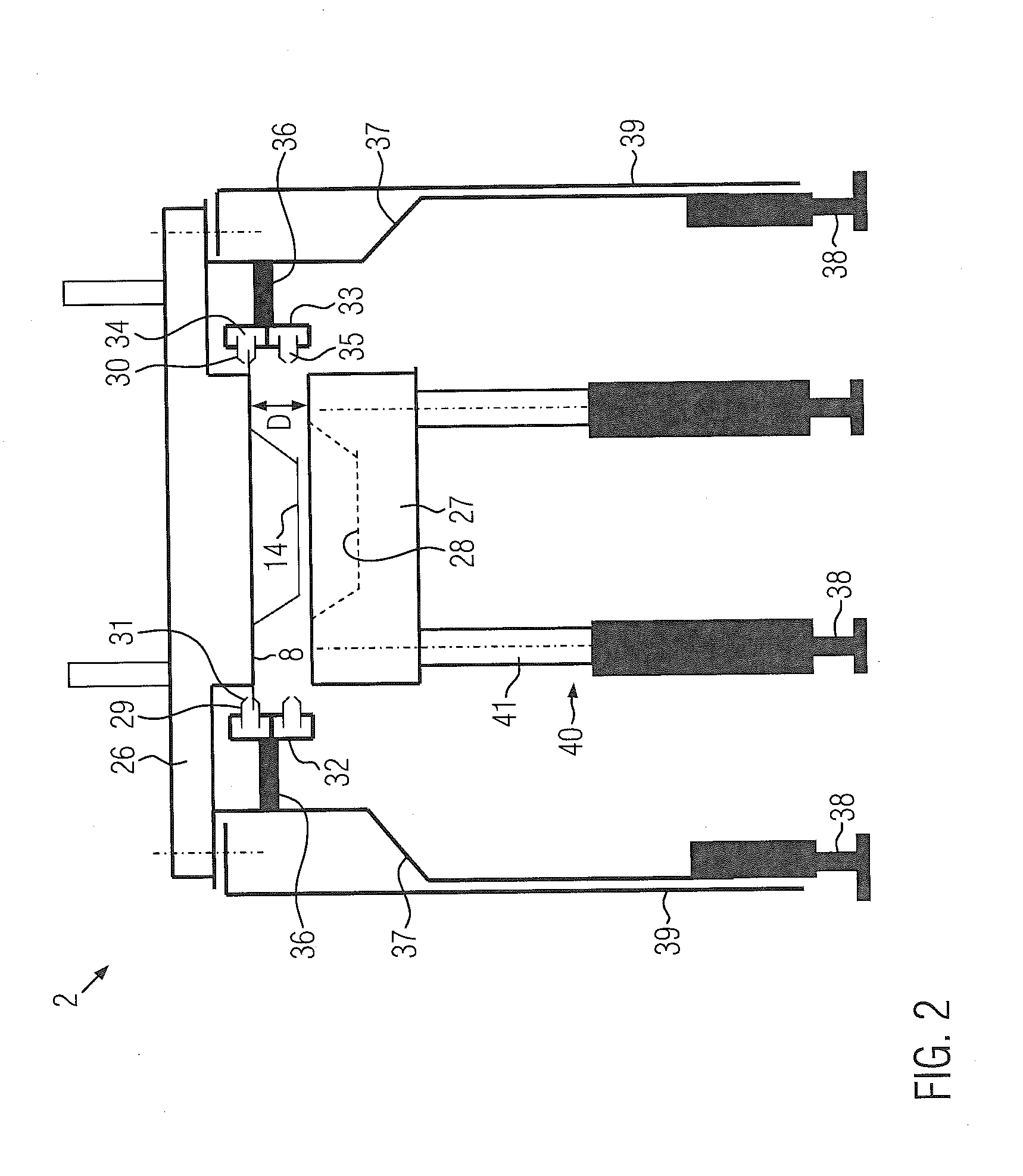

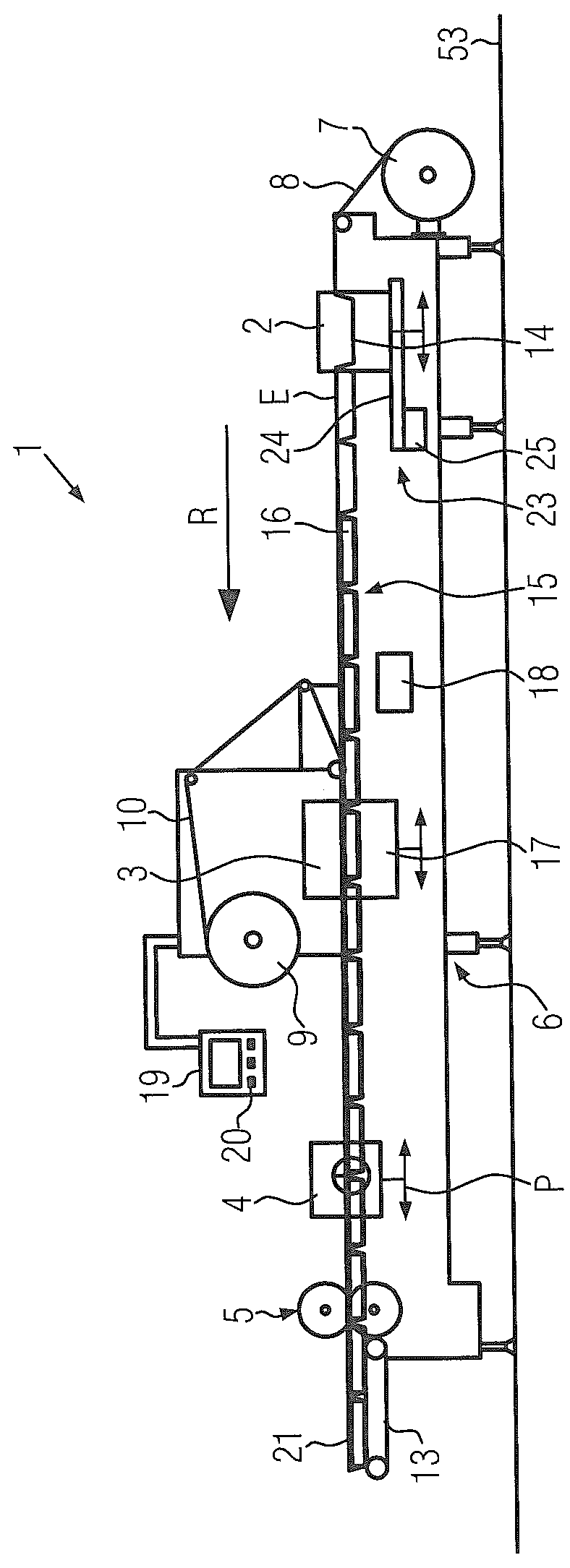

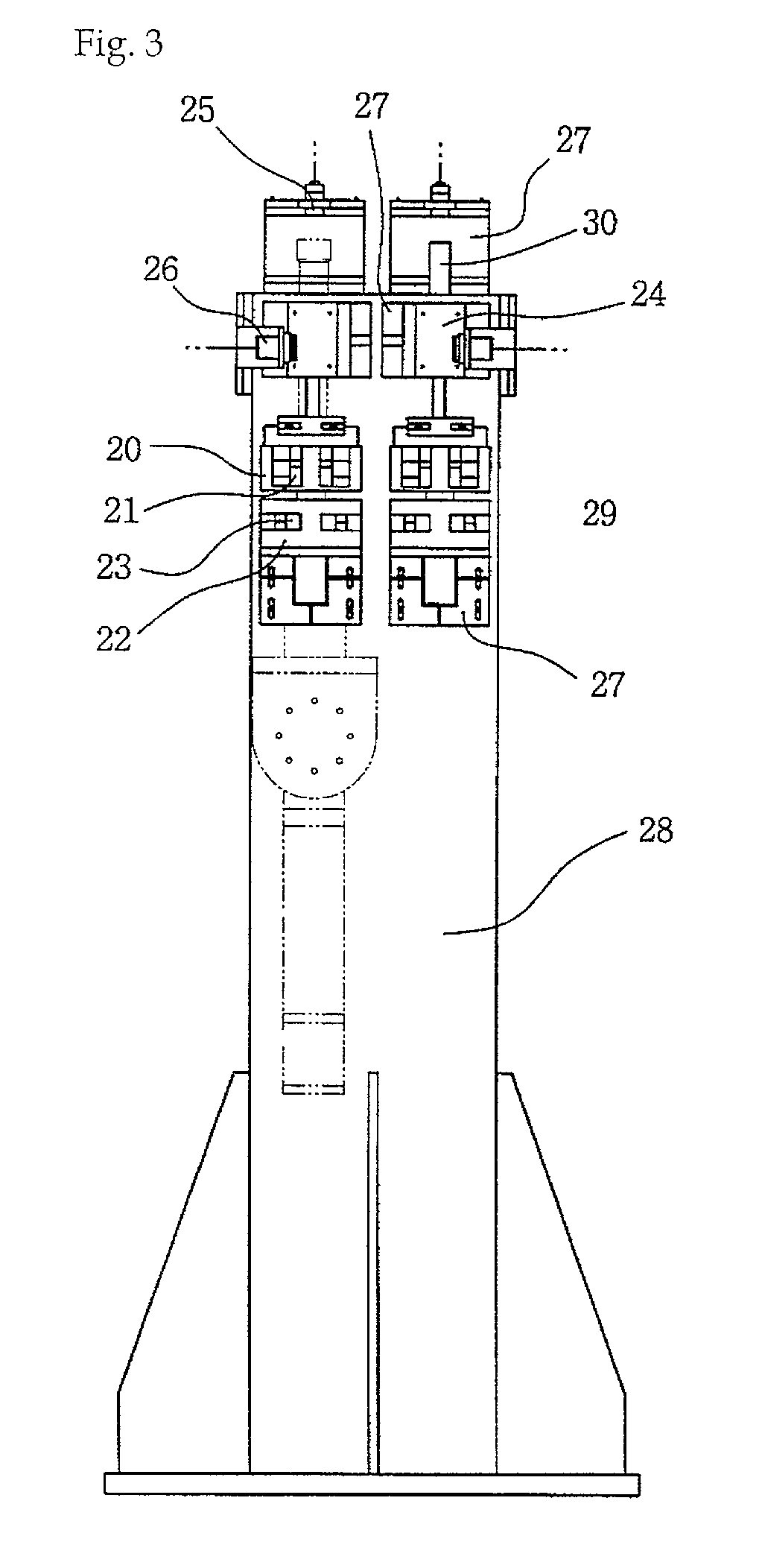

Work station for a packaging machine and tool changing method

ActiveUS20120289388A1Increase displacementPrecise positioningShaping toolsPrecision positioning equipmentCouplingEngineering

The present invention relates to a work station for a packaging machine, comprising an upper tool and a lower tool arranged below the upper tool. These tools are configured for acting on a packaging web. A lifting unit is able to move the upper tool and / or the lower tool such that, at a specific position, the two tools abut on one another or are only spaced apart at a small distance. According to the present invention, the two tools are adapted to be coupled to one another by a releasable coupling at this position so that they can be removed from the work station in common. The invention also relates to a corresponding method for removing a lower tool from a work station, e.g. for the purpose of tool exchange.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

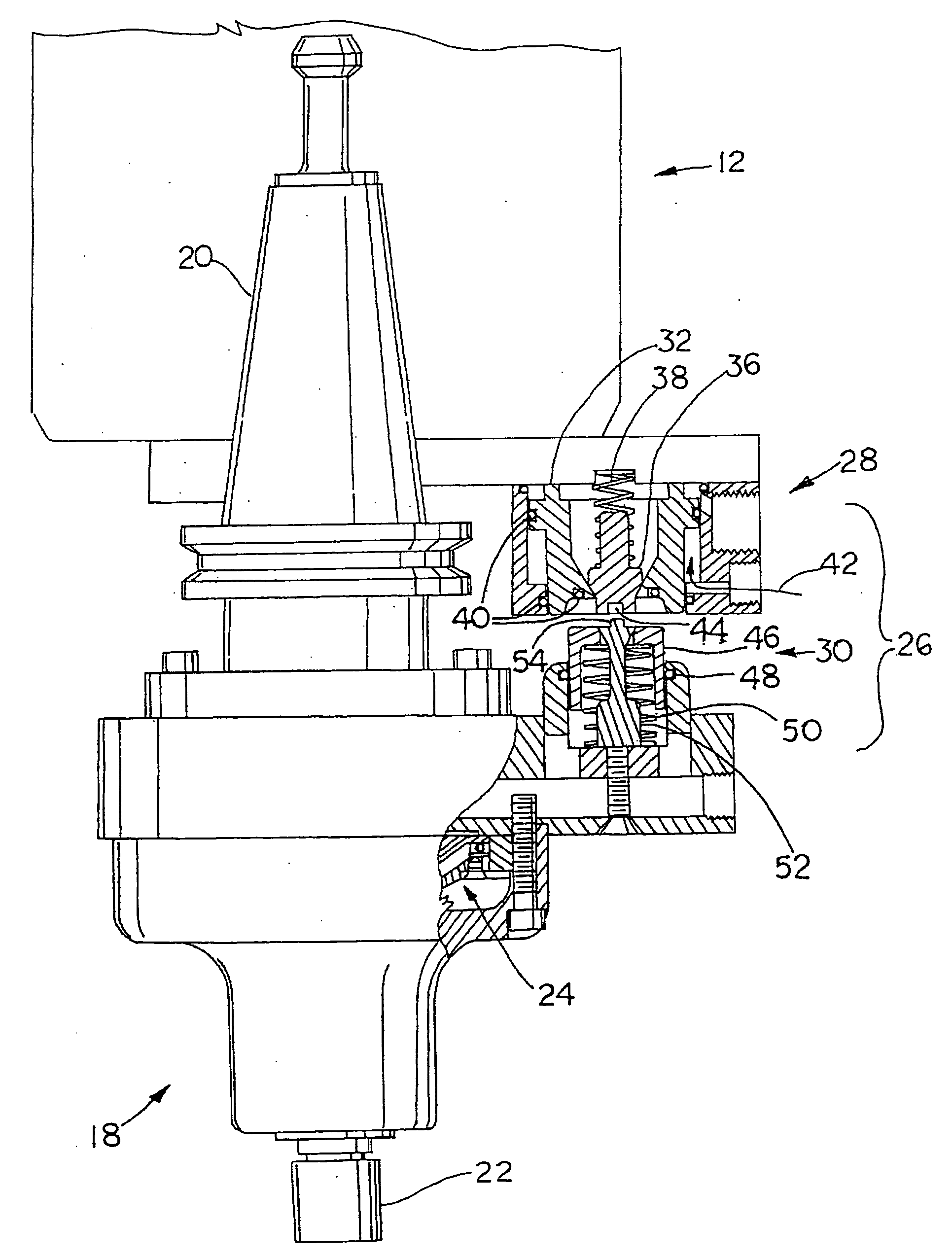

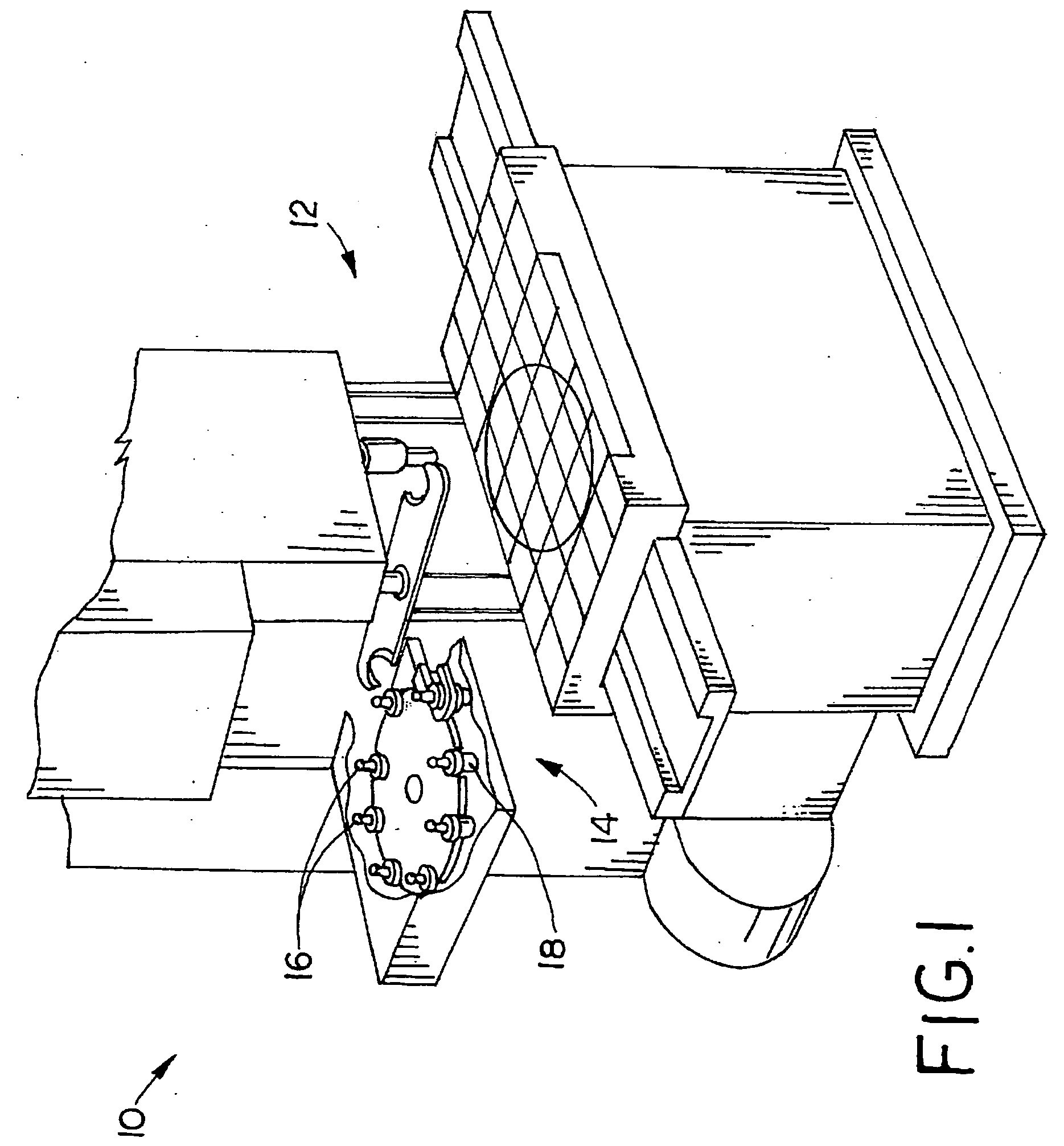

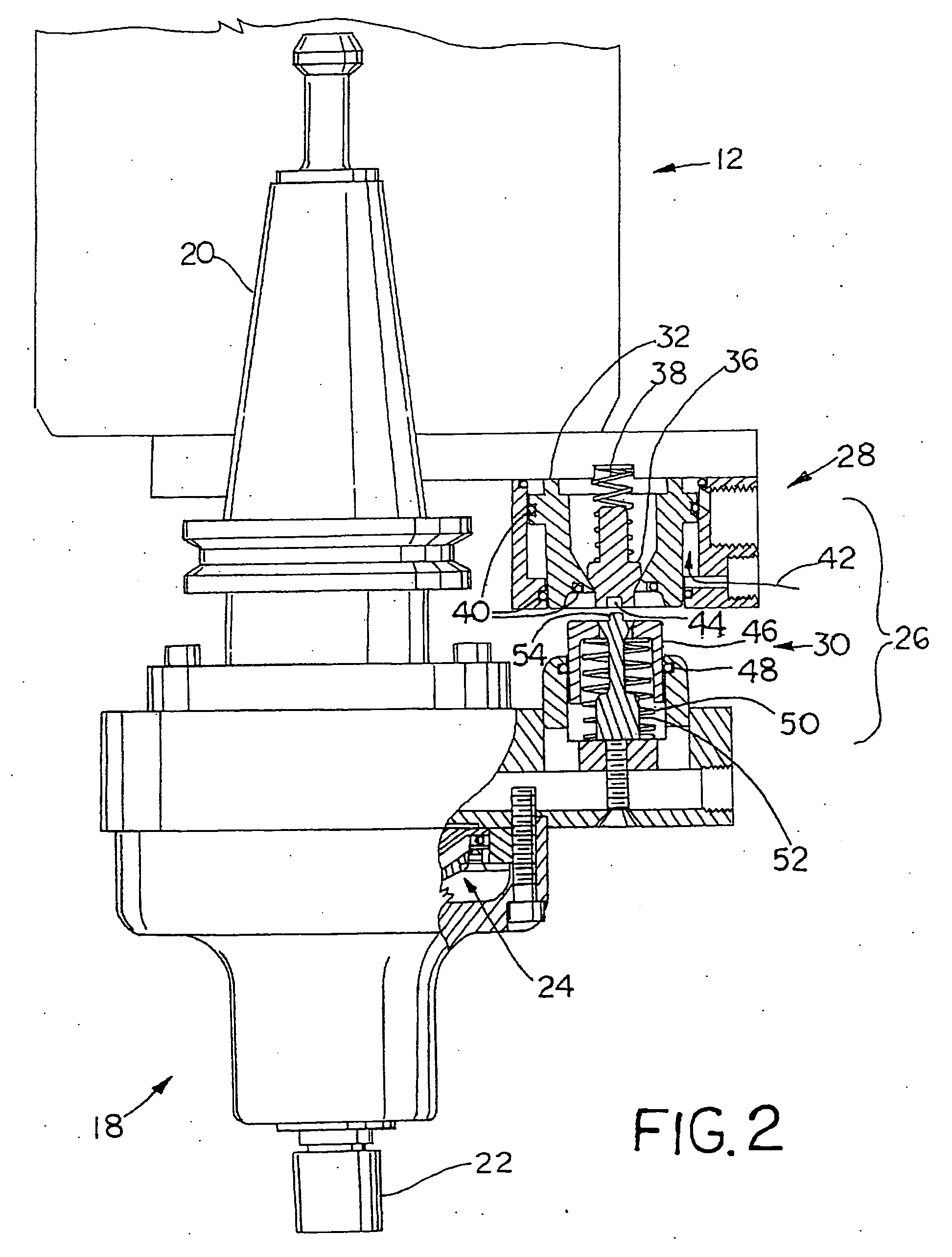

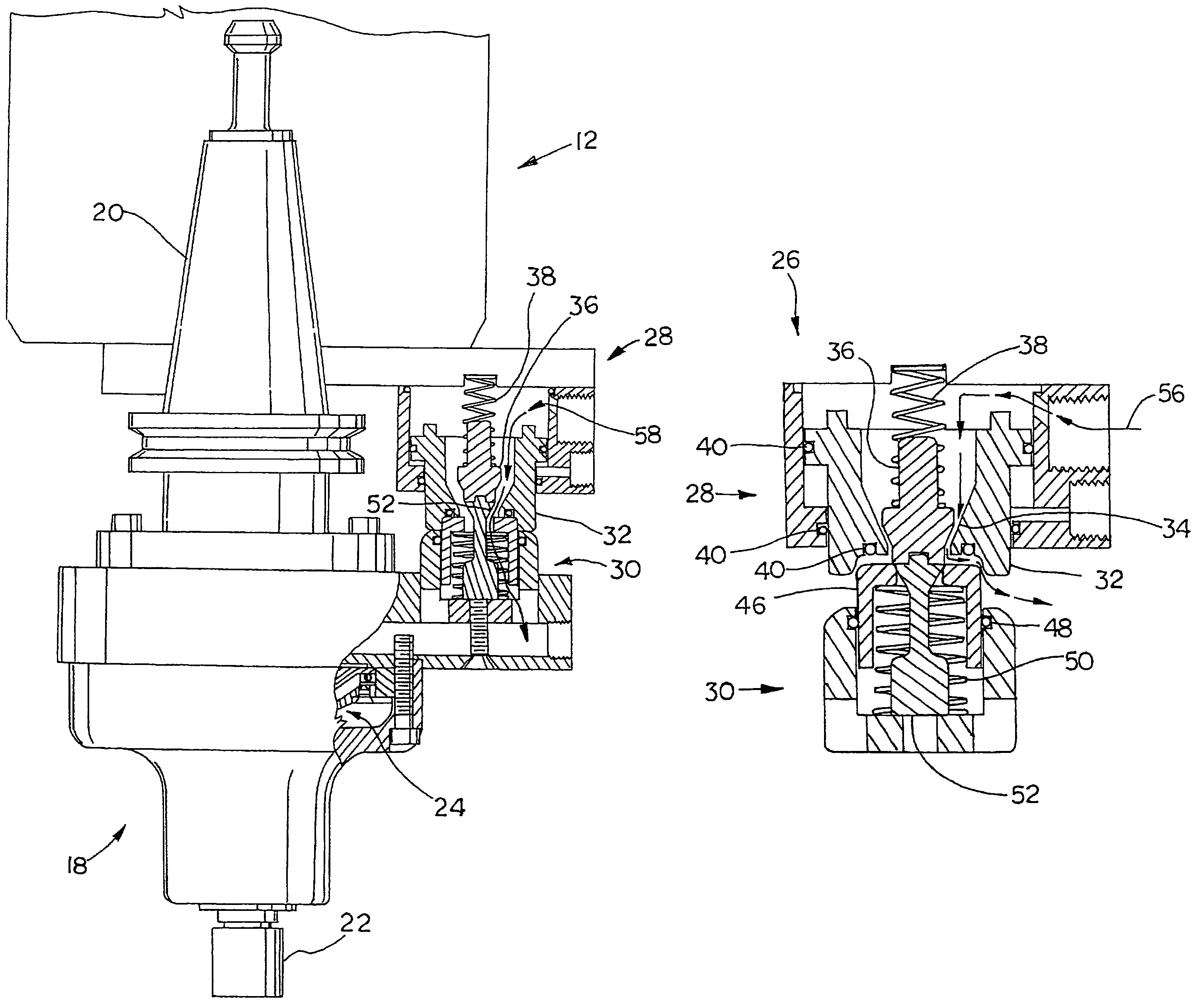

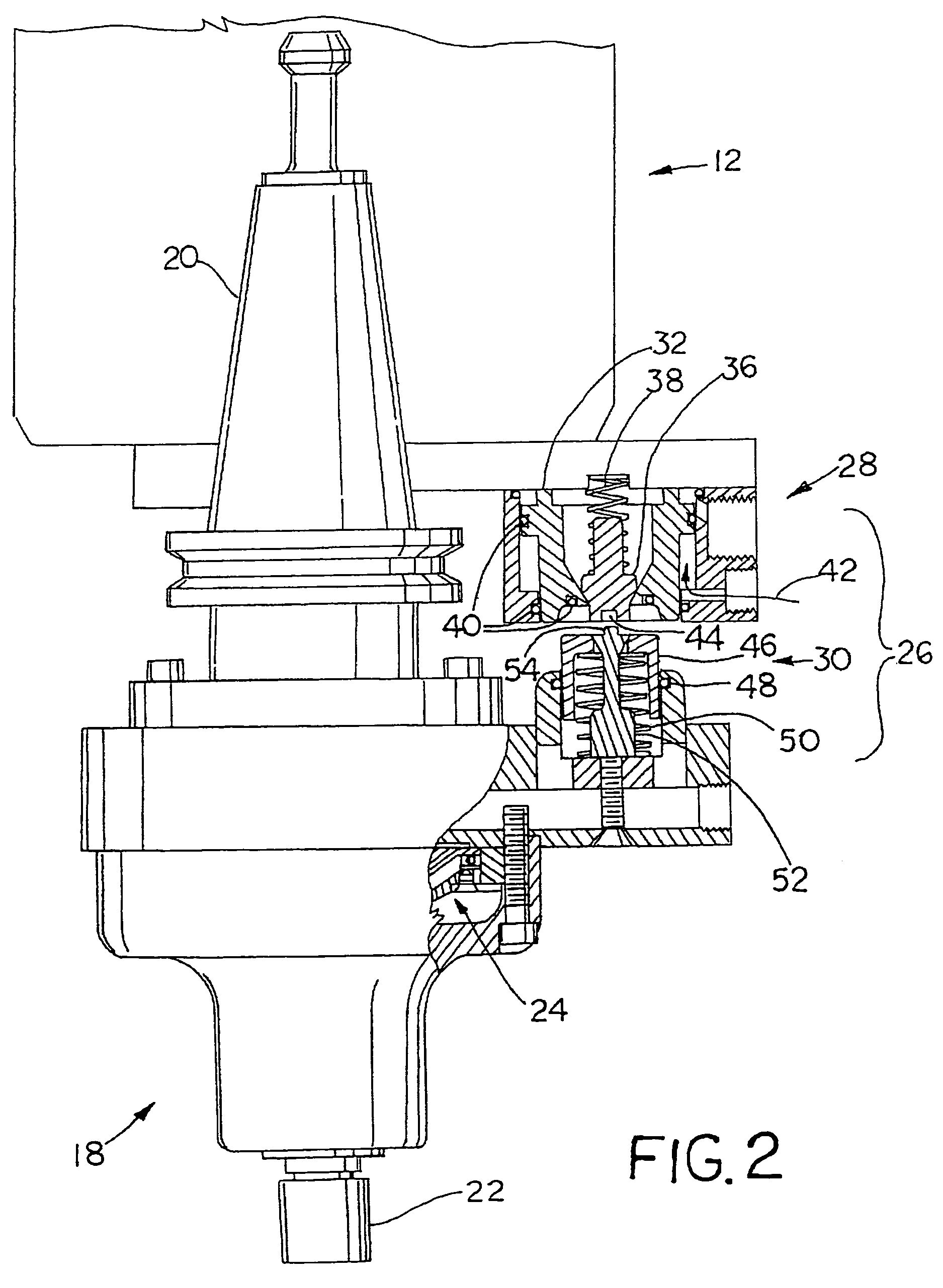

Air valve coupling method and apparatus

A machining center including a machining head, a tool changer, an air driven tool and an air valve system. The air driven tool is connectable to the machine head by action of the tool changer. The air valve system has a first portion associated with the machining head and a second portion associated with the air driven tool. The first portion and the second portion include a connection therebetween having an airflow across the connection before the connection seals.

Owner:BRYAN STEVE M

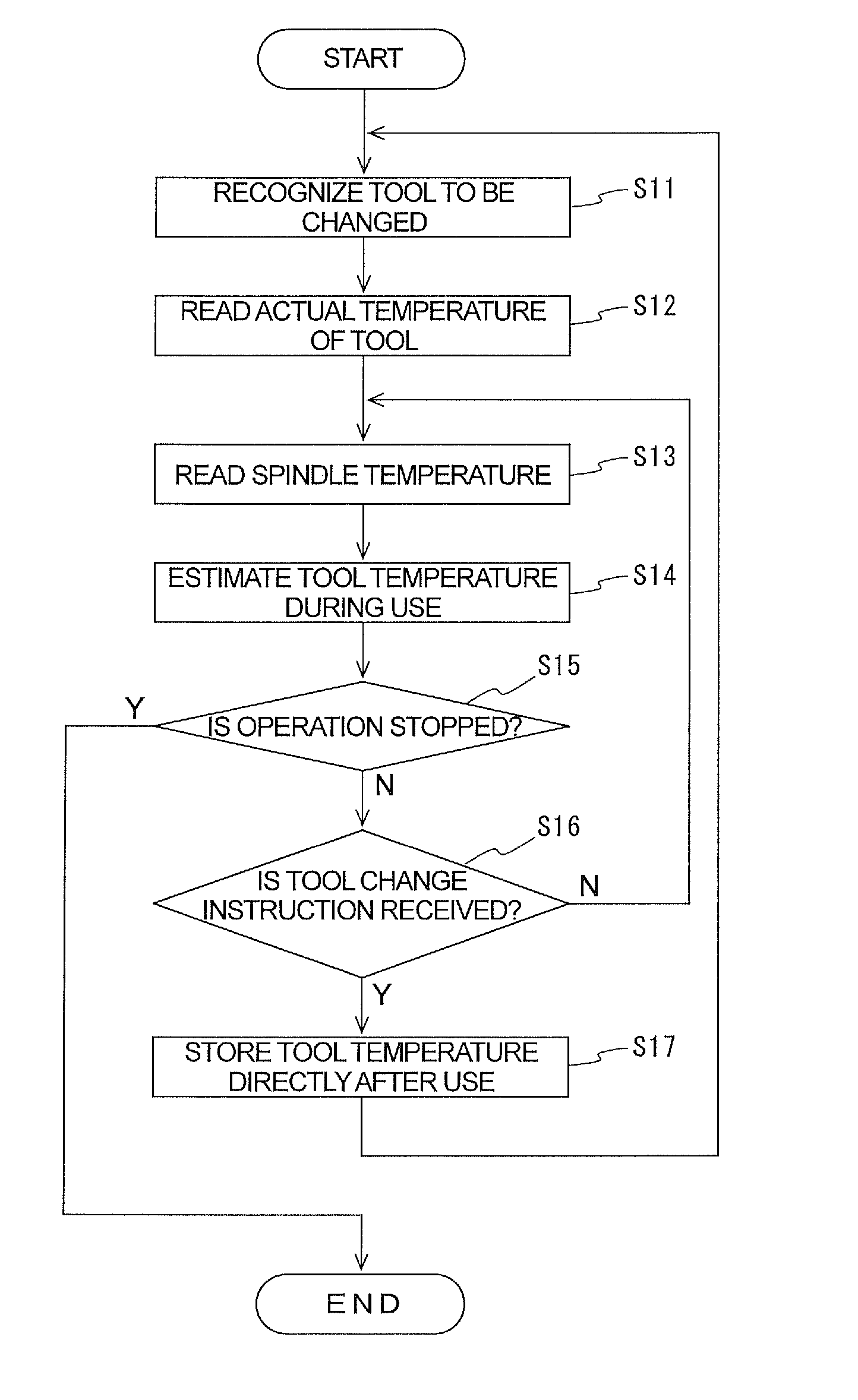

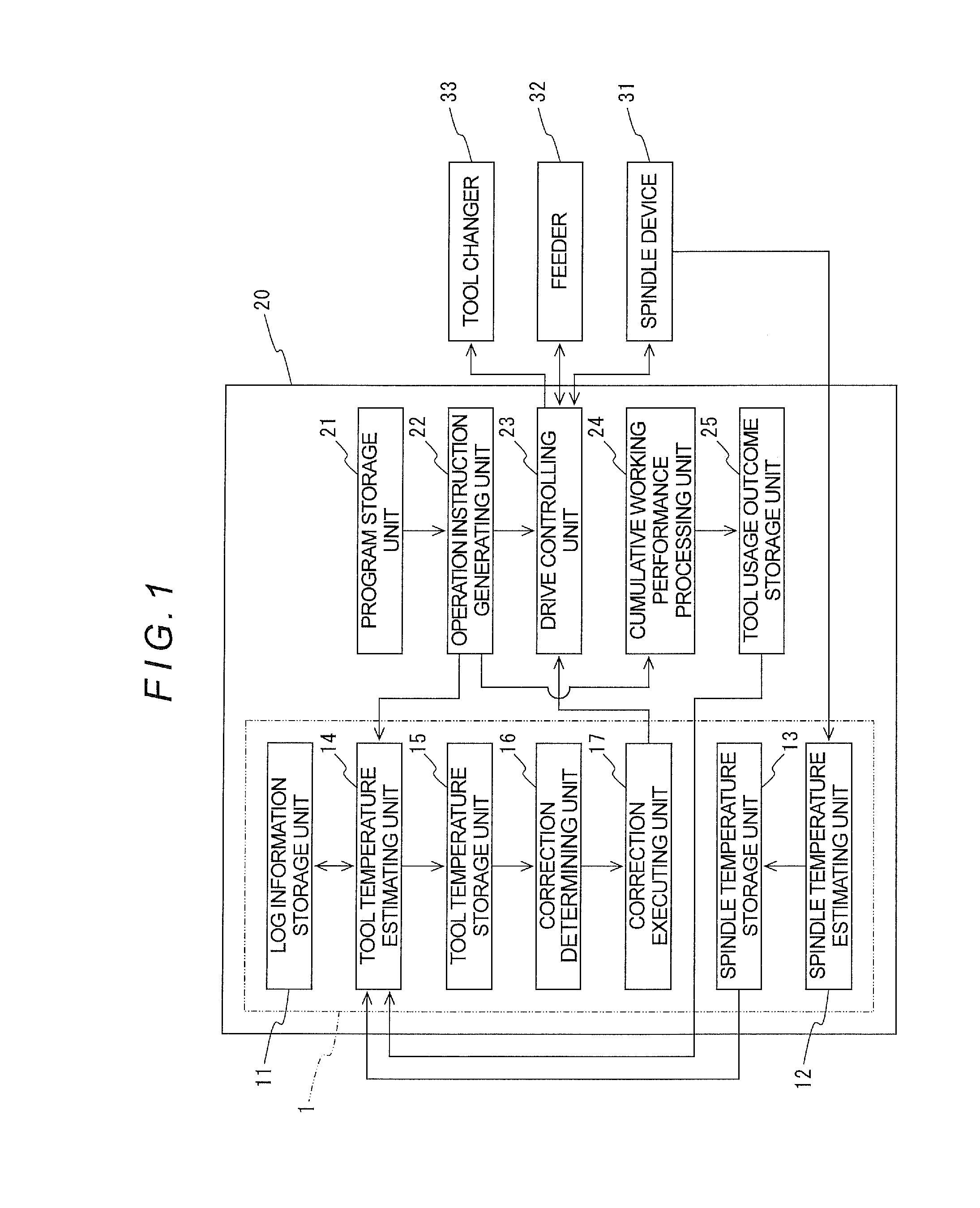

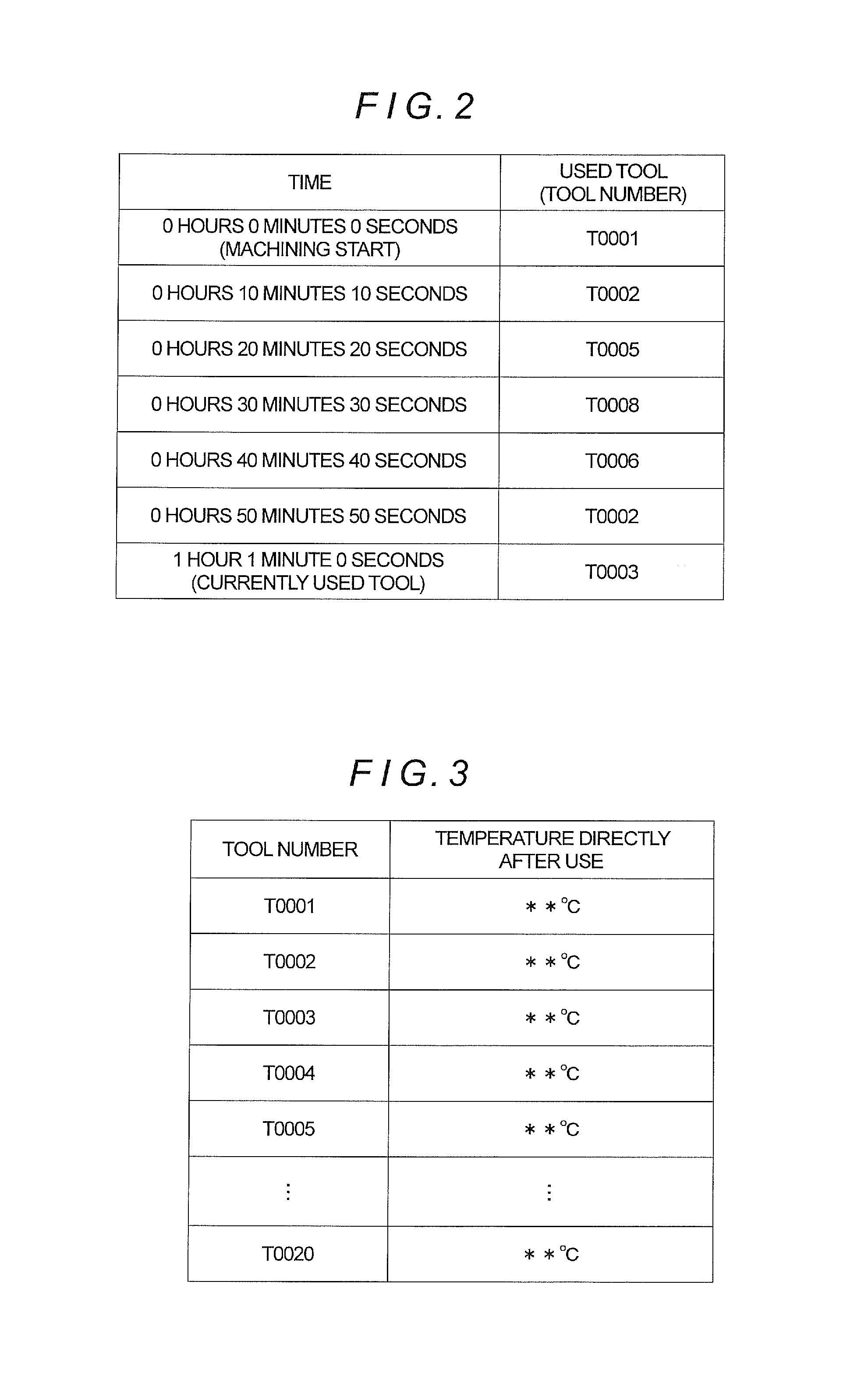

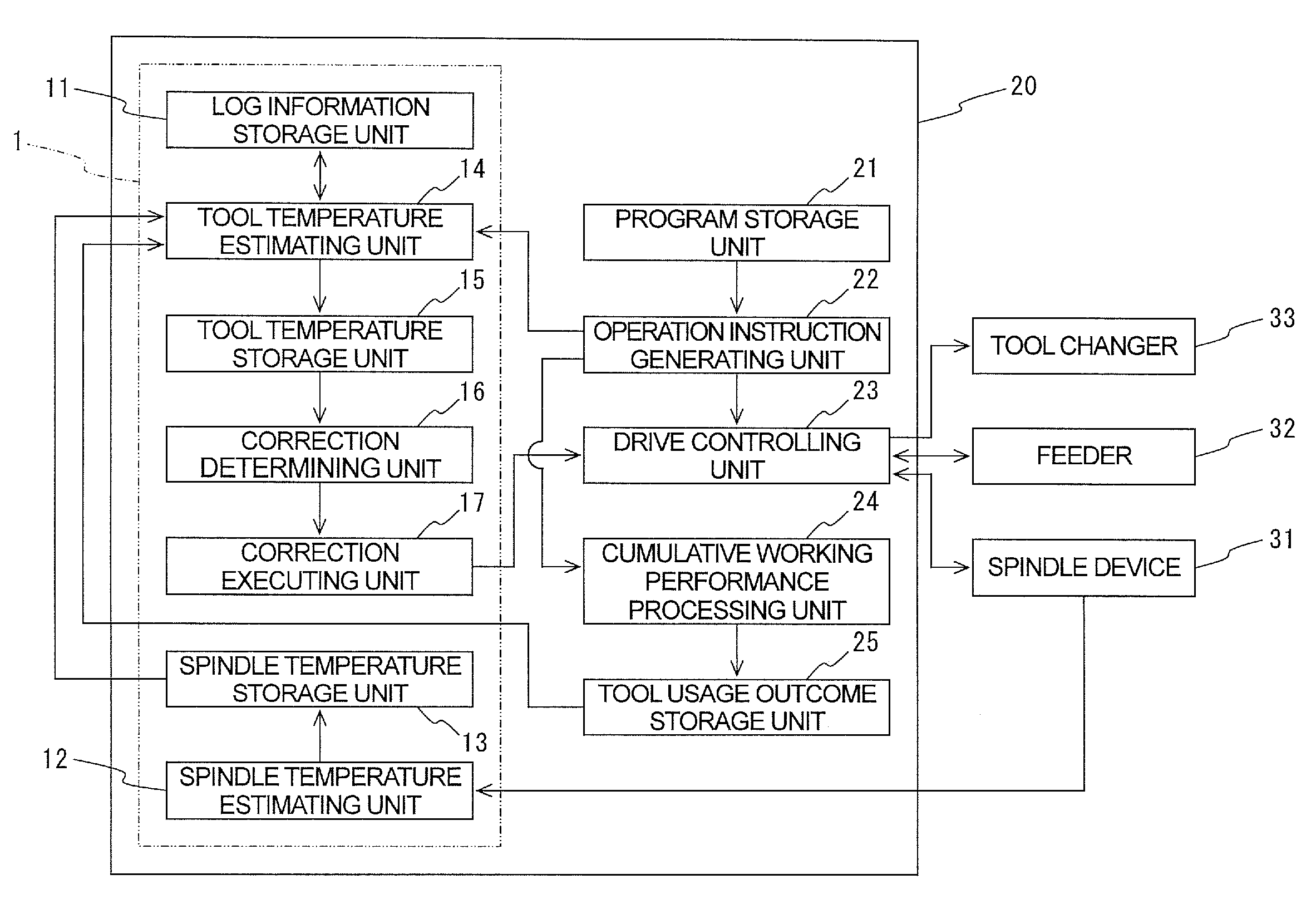

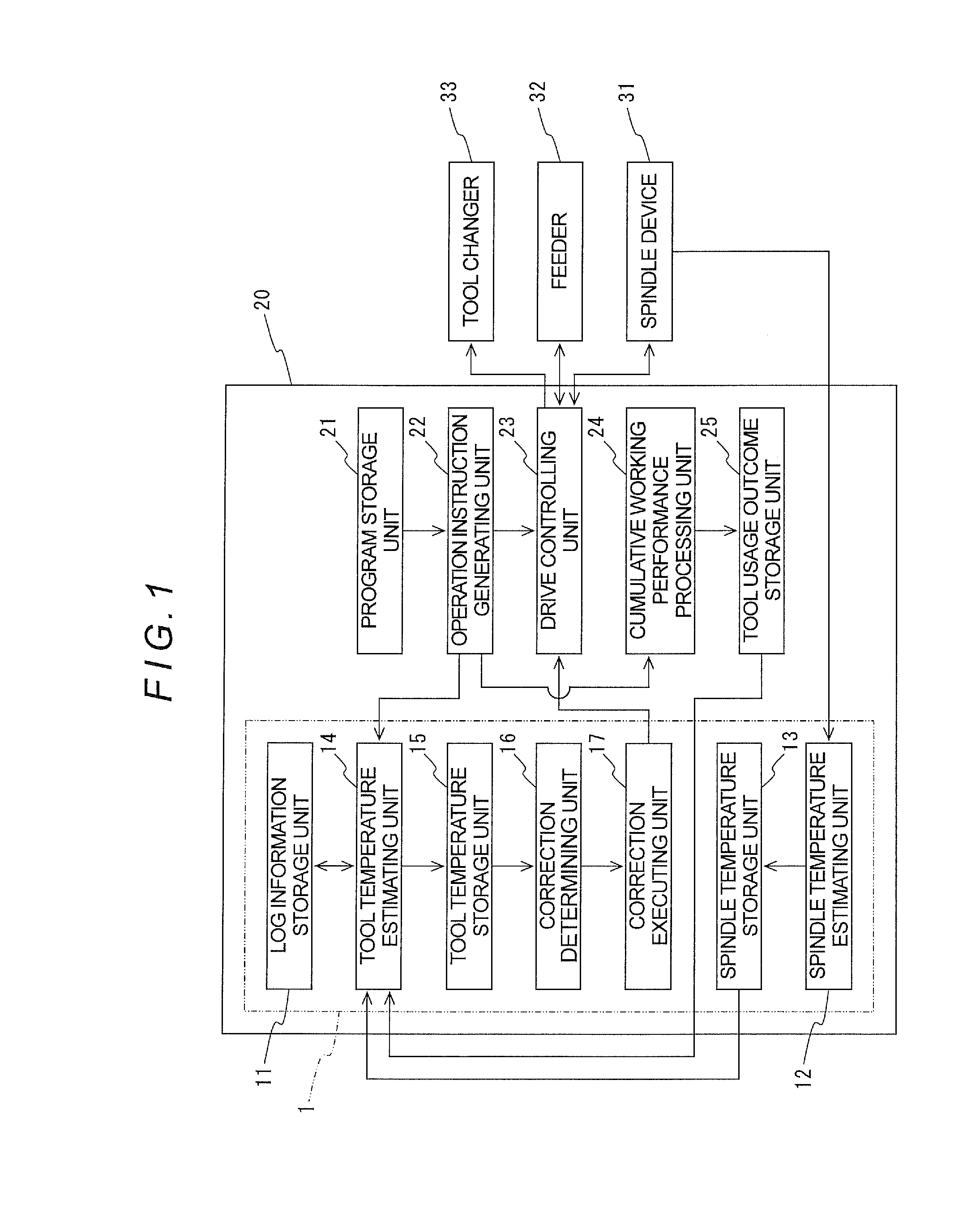

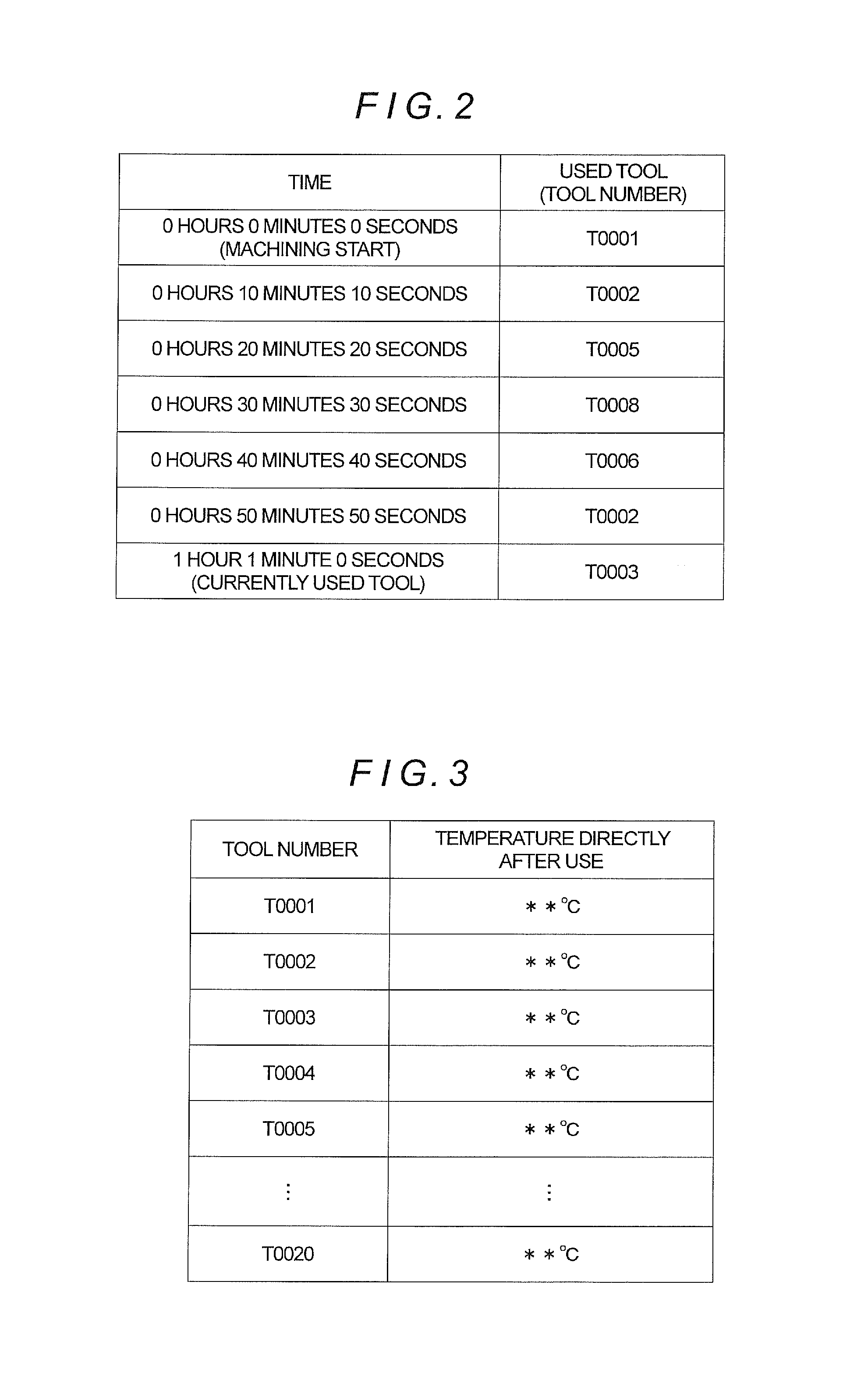

Thermal Displacement Correcting Device

InactiveUS20070105697A1Improve accuracyEliminate needAutomatic control devicesPrecision positioning equipmentLapse timeEngineering

Machine-tool thermal displacement correcting device having: a tool-temperature estimating unit for recognizing—based on identification data obtained from a controller for designating, out of tools stowed in the tool-changer tool magazine, an exchange-target tool—the directly-after-use temperature of the ID'd tool, and estimating the tool temperature directly before use, based on the recognized directly-after-use tool temperature and on lapsed time, obtained from the controller, since previous use of the ID'd tool, and for estimating, based on the estimated directly-before-use tool temperature and on the spindle temperature, during-use temperature of the tool; a correction determining unit for estimating, based on the estimated during-use tool temperature, axial thermal displacement of the tool, and determining a correction amount for canceling out the displacement; and a correction executing unit for carrying out correction based on the determined correction amount.

Owner:DMG MORI SEIKI CO LTD

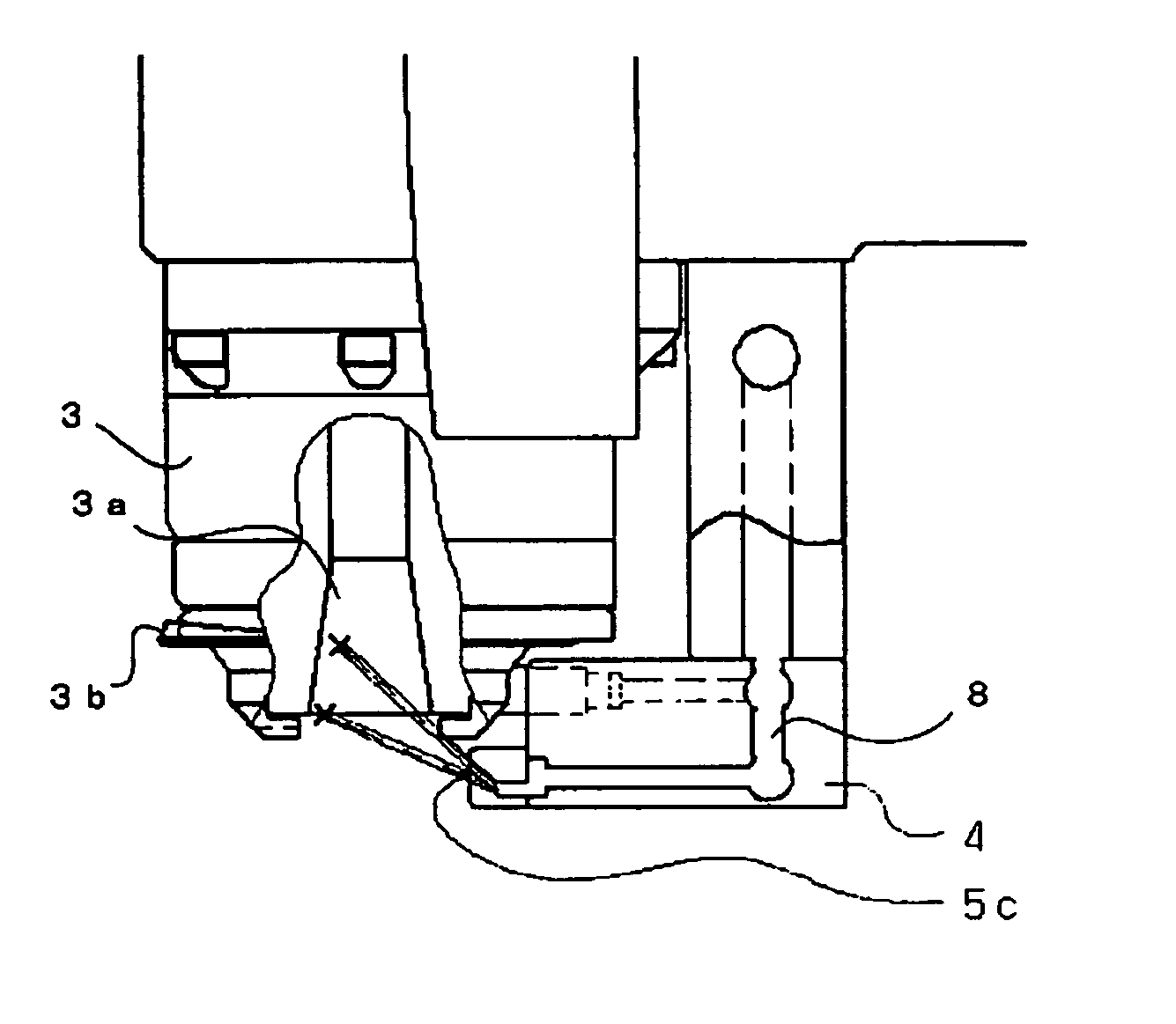

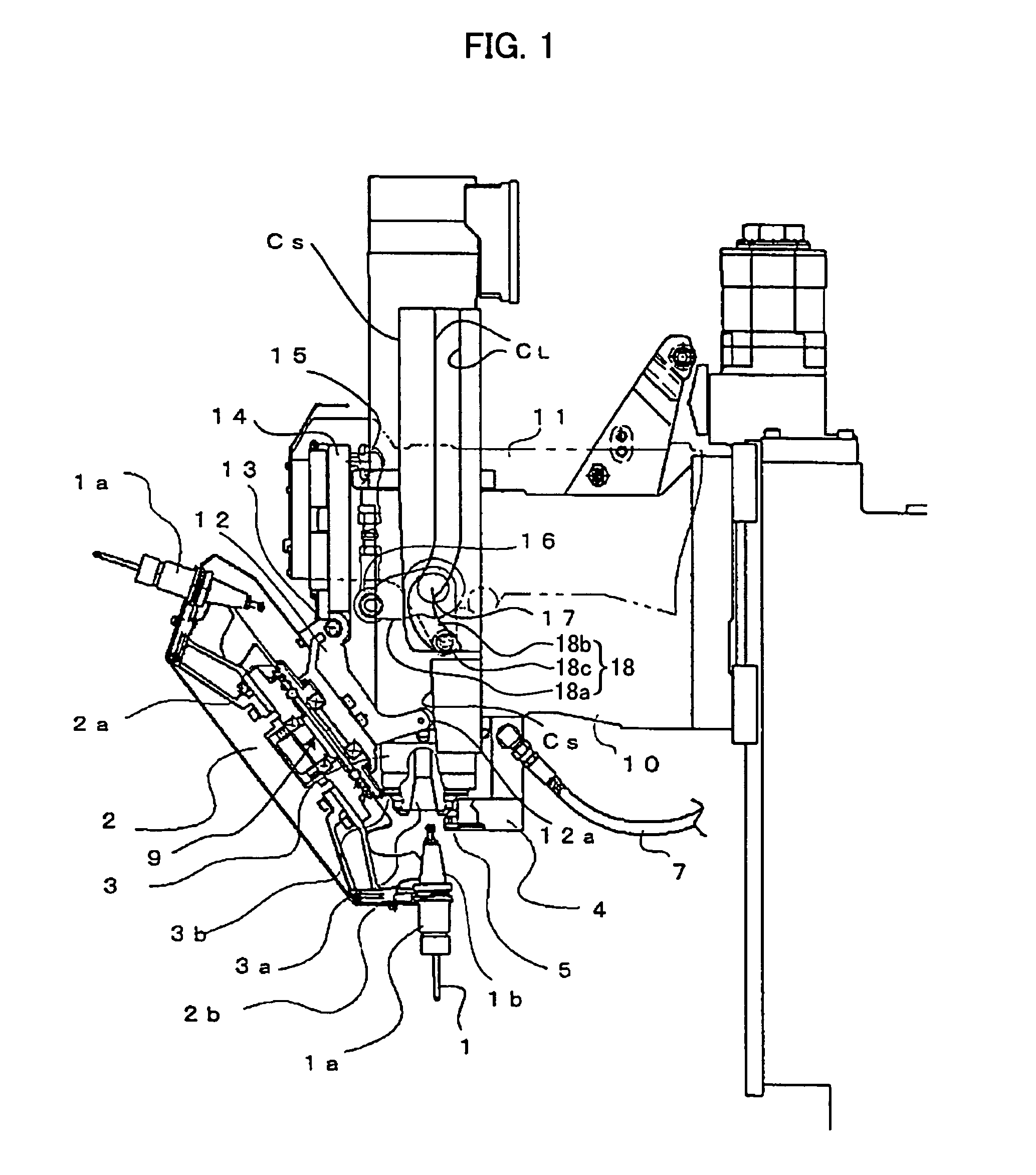

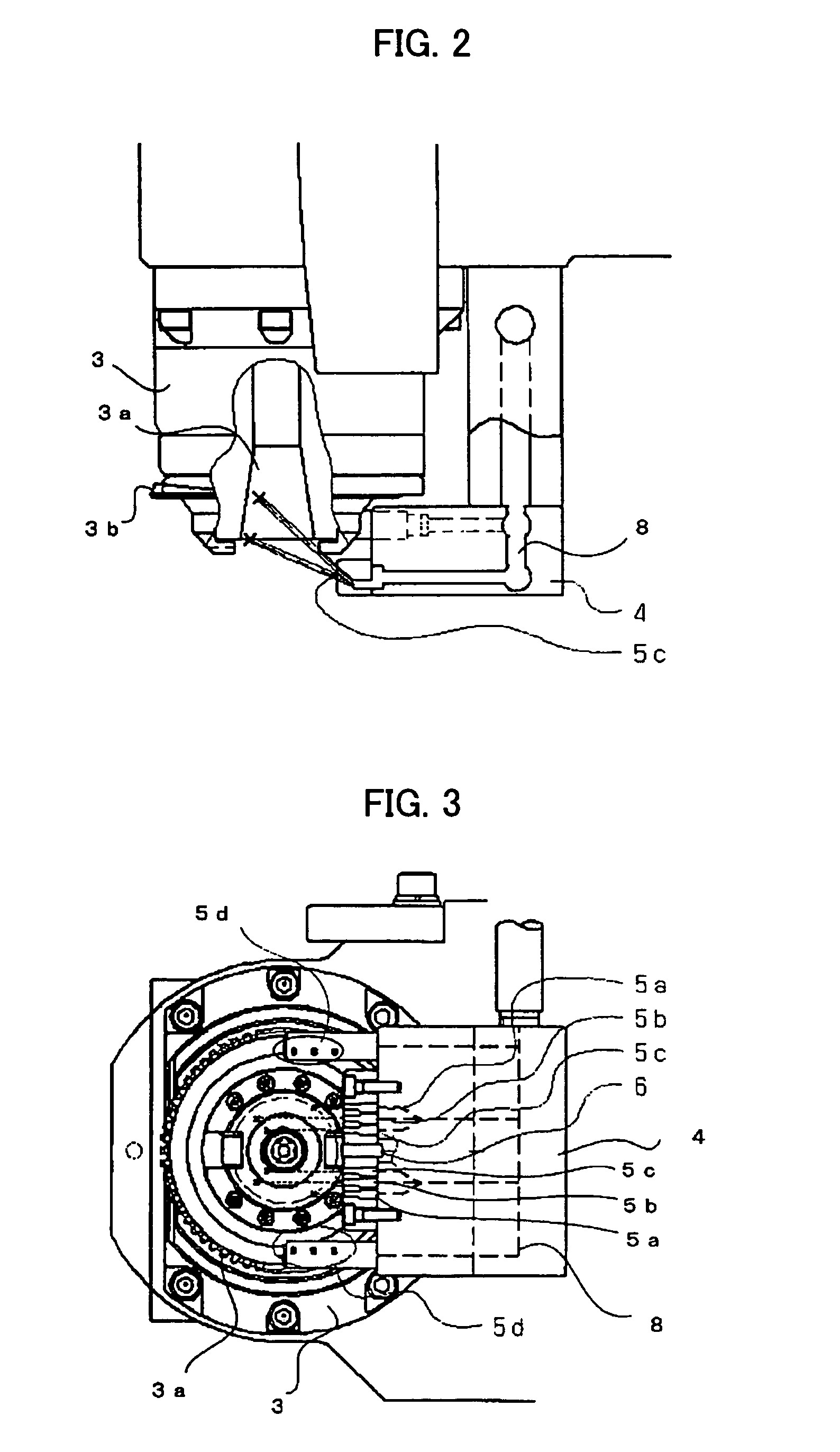

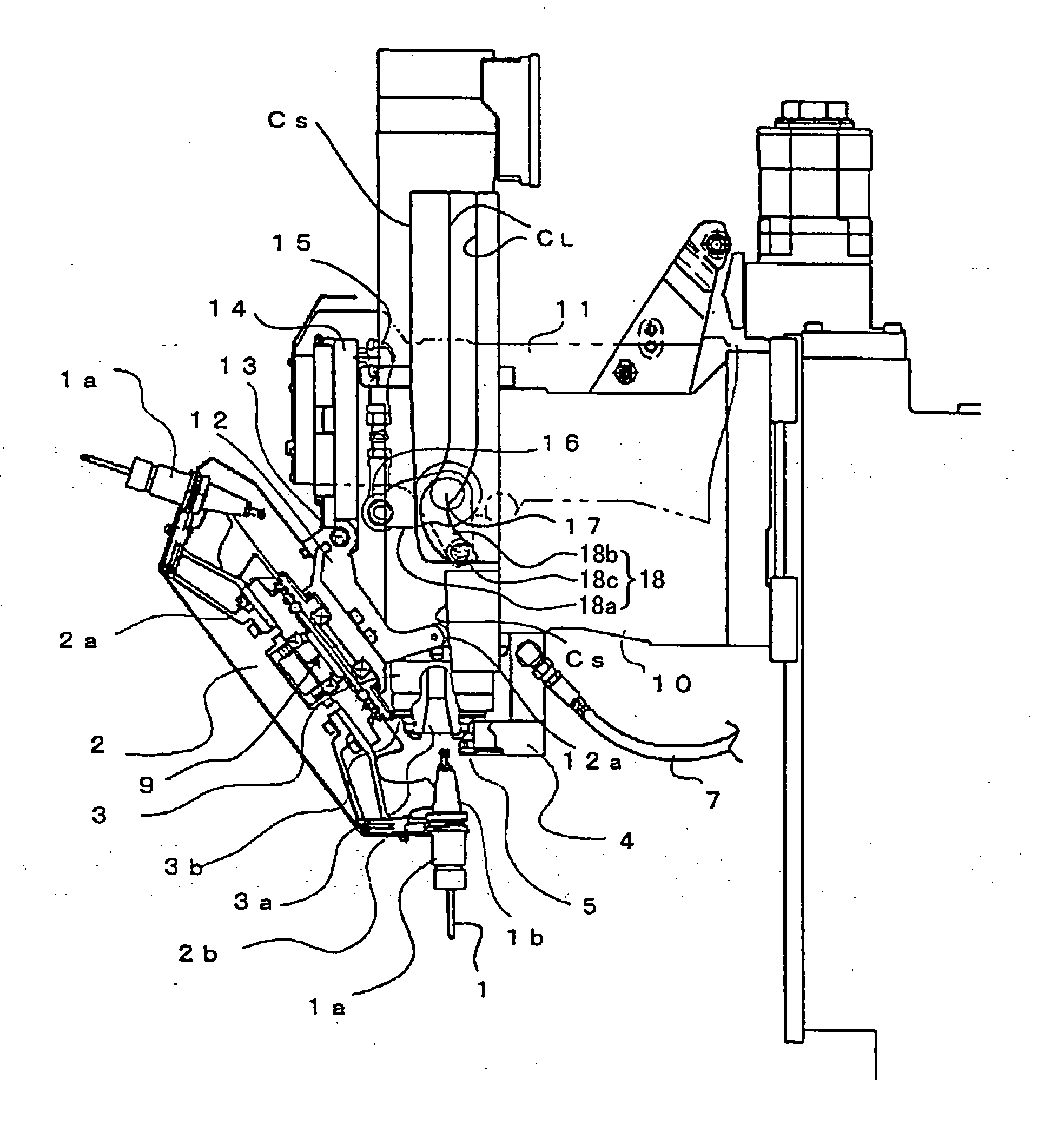

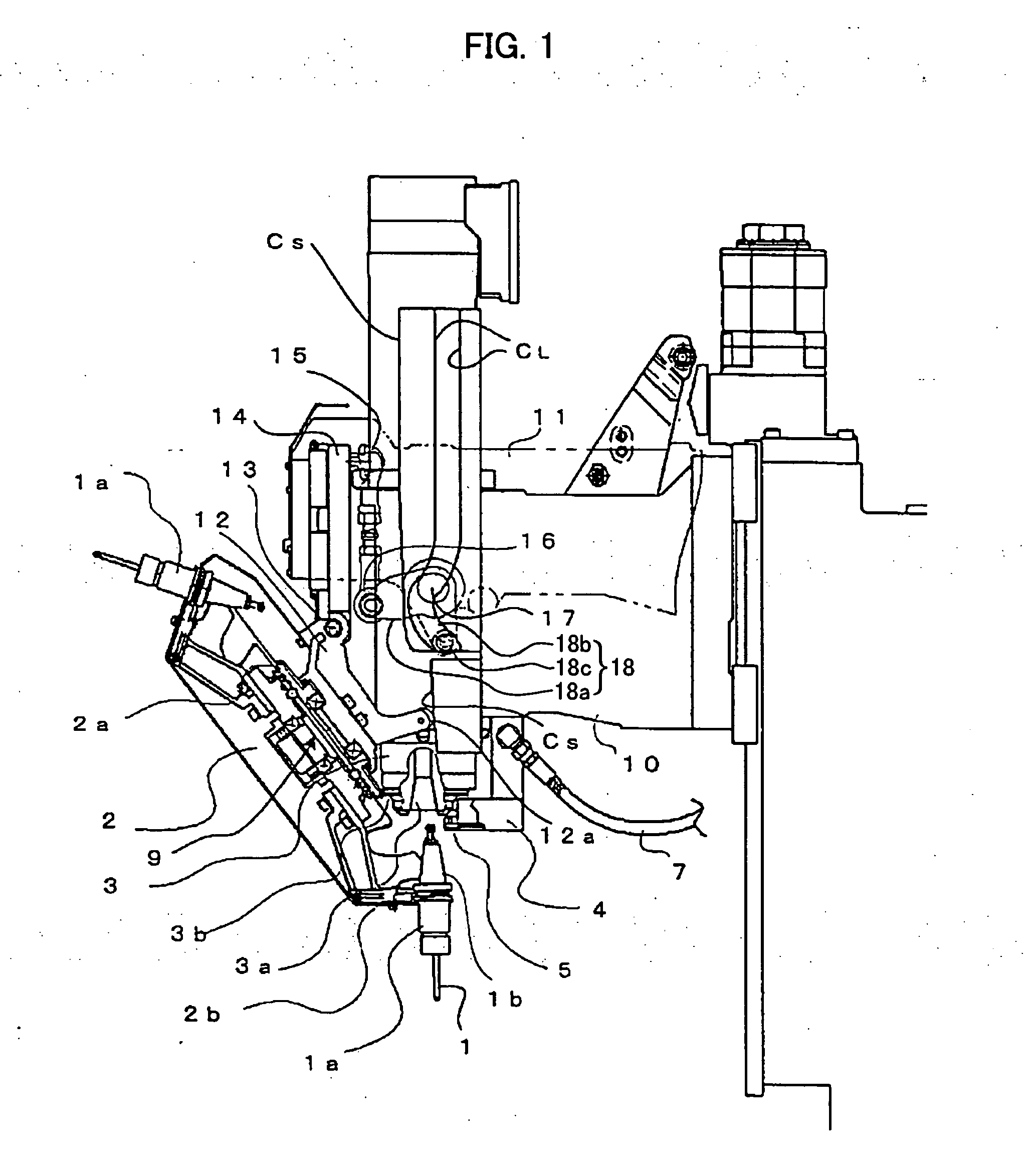

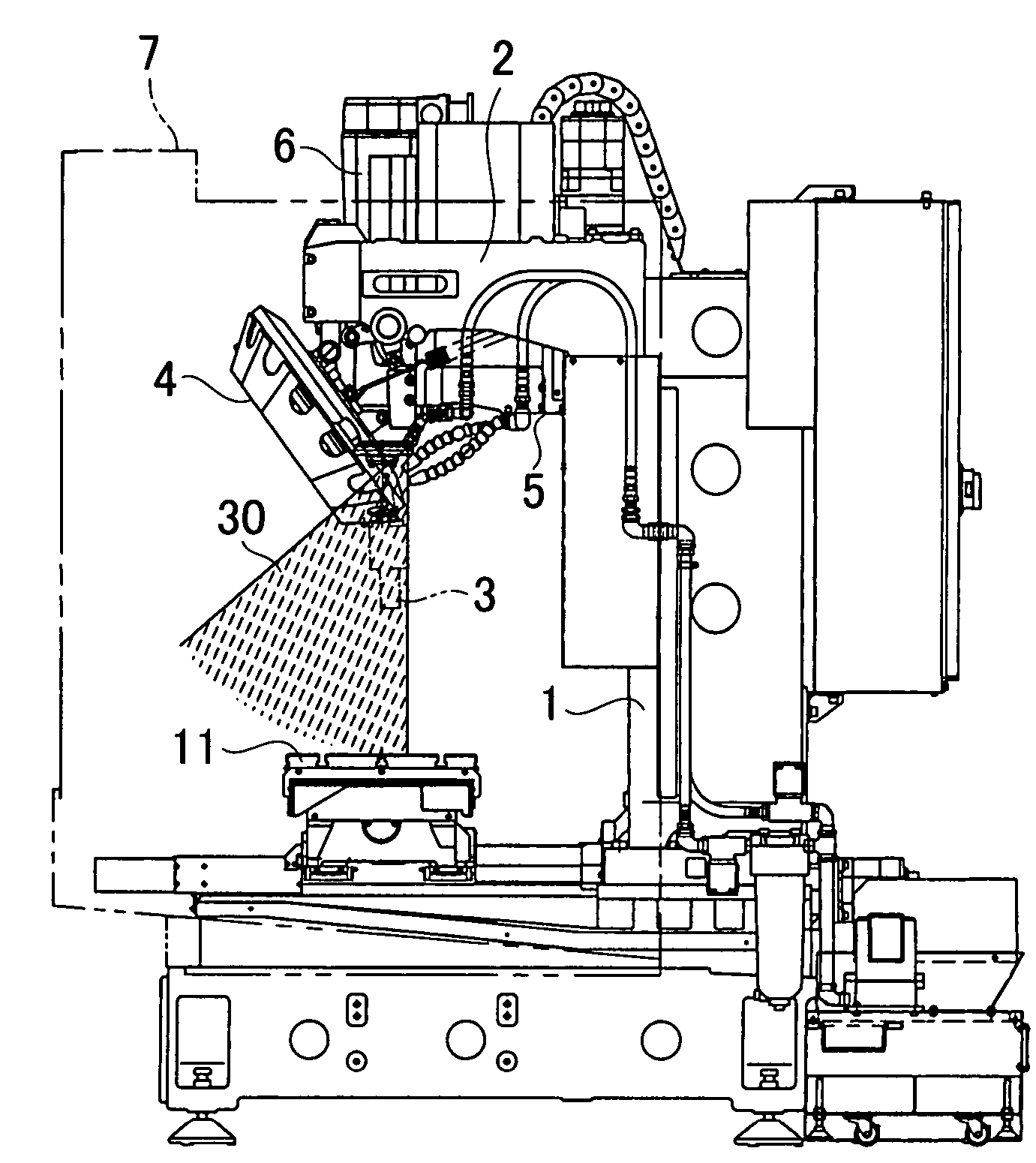

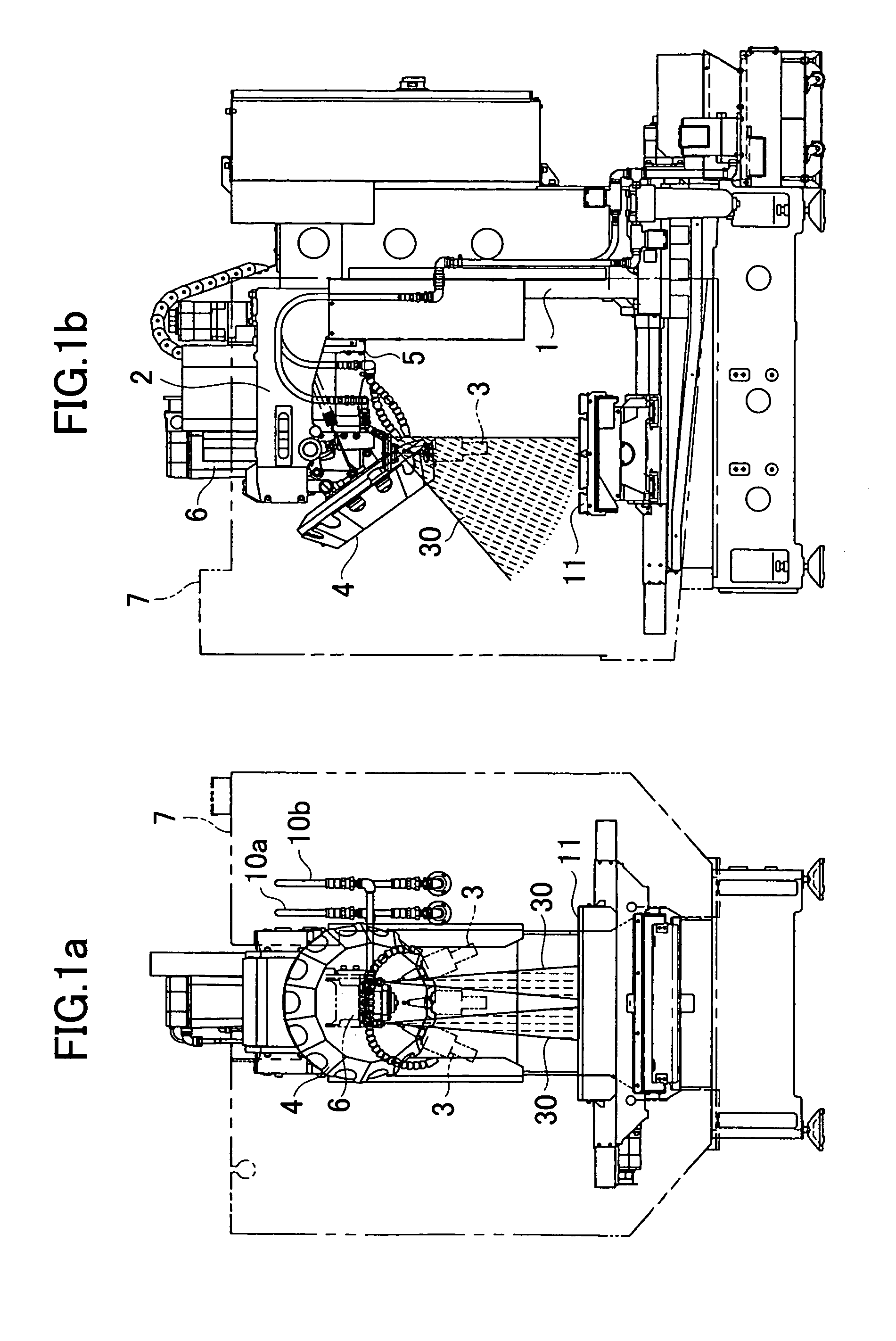

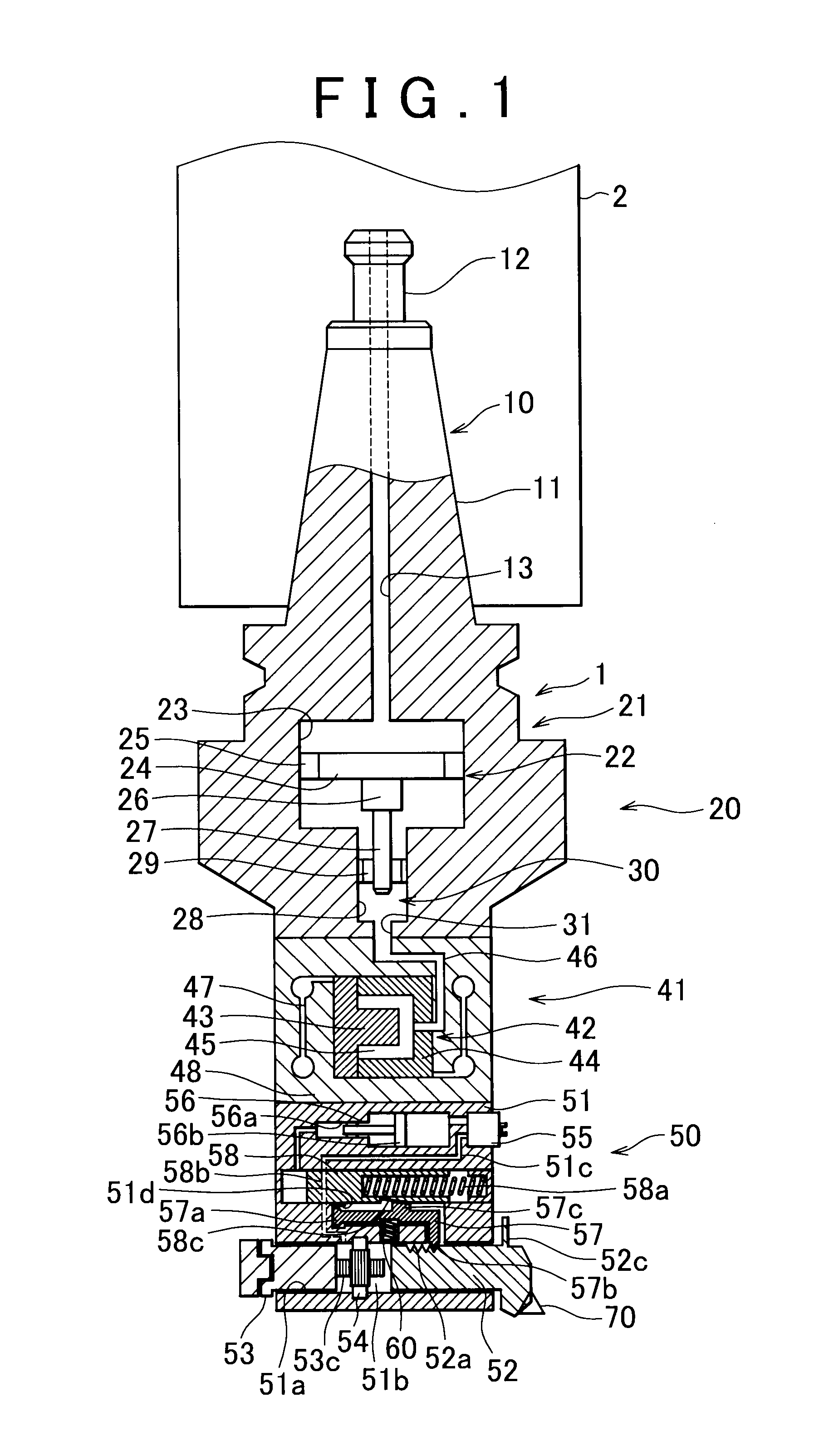

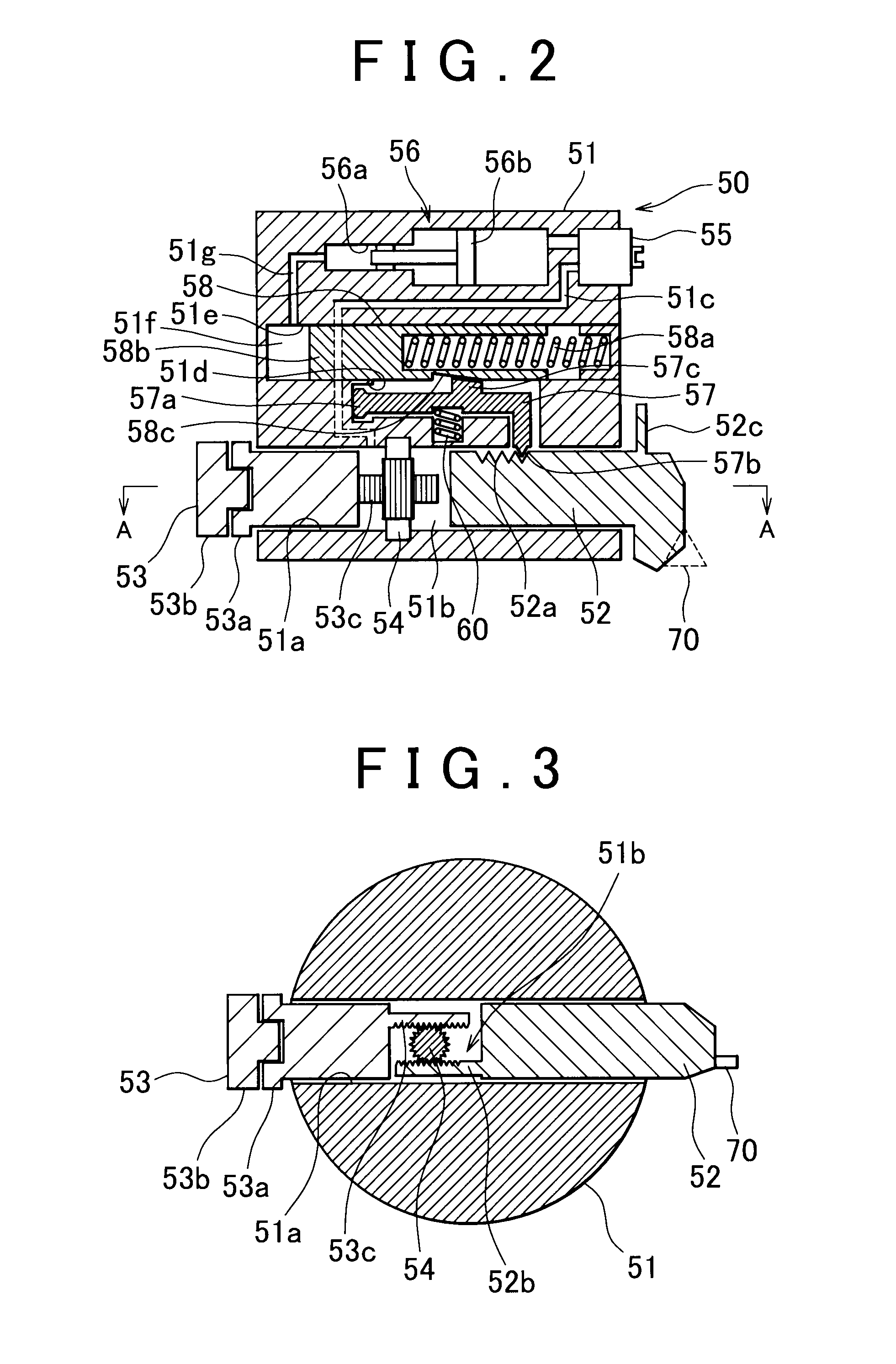

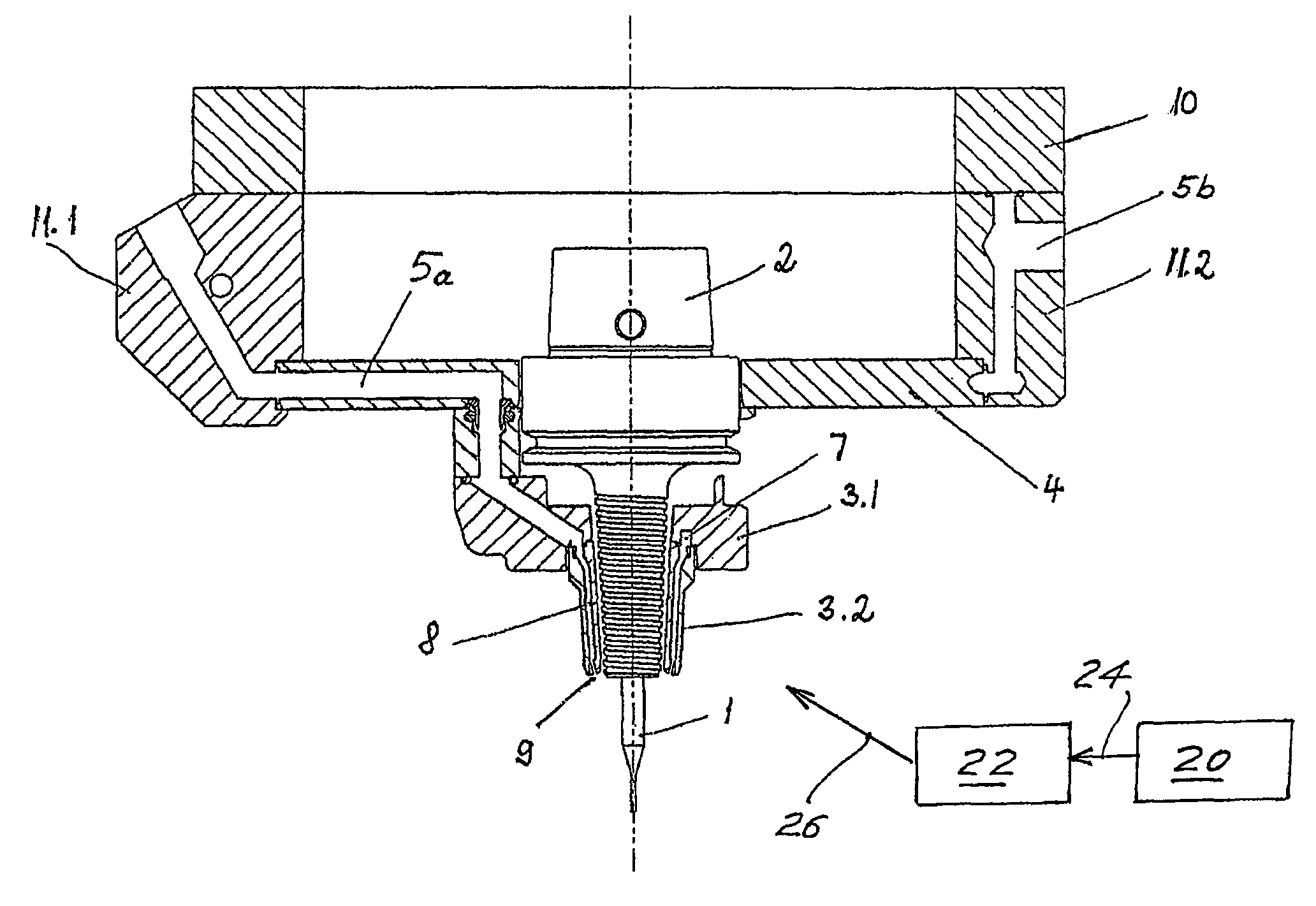

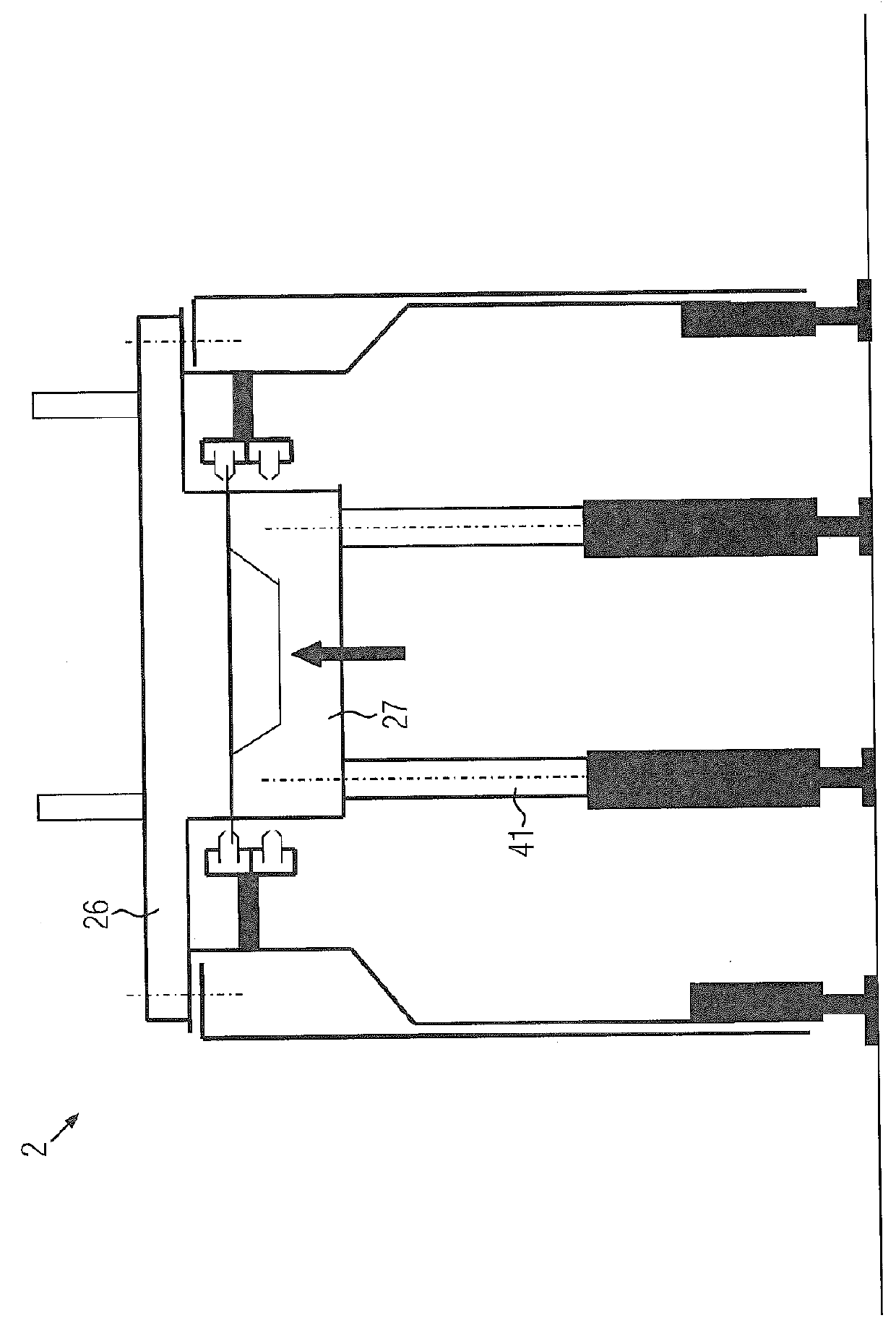

Automatic tool changing device for machine tool

ActiveUS7033308B2Accurate measurementAccurate detectionPrecision positioning equipmentProtection and storage accessoriesEngineeringMachine tool

An automatic tool changing device capable of cleaning a contact surface of a spindle, which is to be in contact with a tool holder, with a simple structure. The device includes a turret having a plurality of grippers on its outer circumference and holding the tool holder by means of the grippers. At the time of tool change, the grippers grip and pull out the tool holder fixed to the spindle. Rotation of the spindle causes the turret to rotate through a spindle gear, a turret gear, and a decelerating device, to thereby select a tool. At this moment, a coolant is spouted from a nozzle portion of a manifold toward a spindle taper hole in which the tool holder is interfitted and washes the taper hole. Due to the rotation of the spindle, the coolant is spouted onto the whole circumference of the taper hole, and the surface to be in contact with the tool holder is surely washed. Therefore, it is possible to perform the cleaning with a simple structure in which the nozzle portion is arranged near the spindle without machining the spindle and the tool holder.

Owner:FANUC LTD

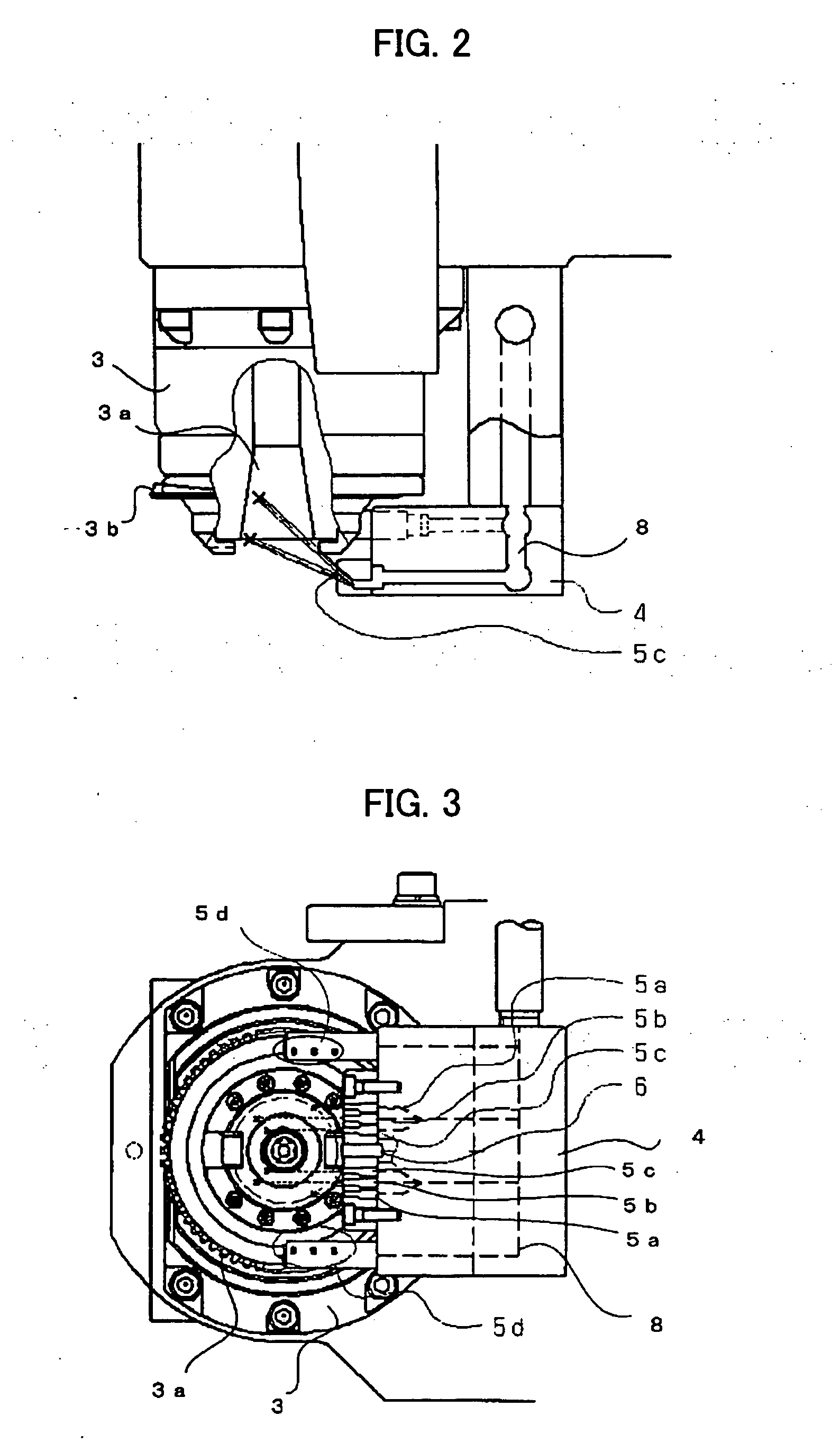

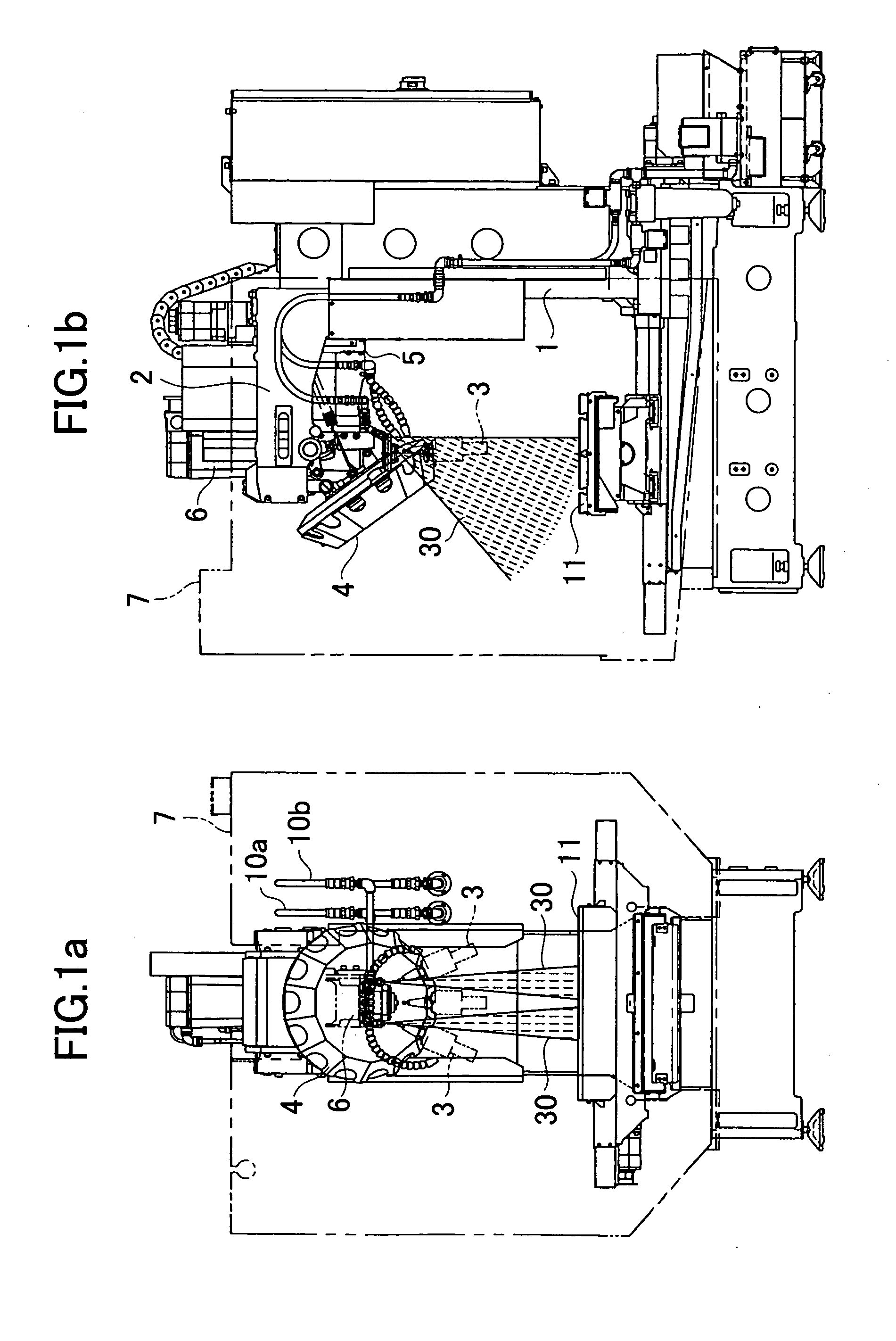

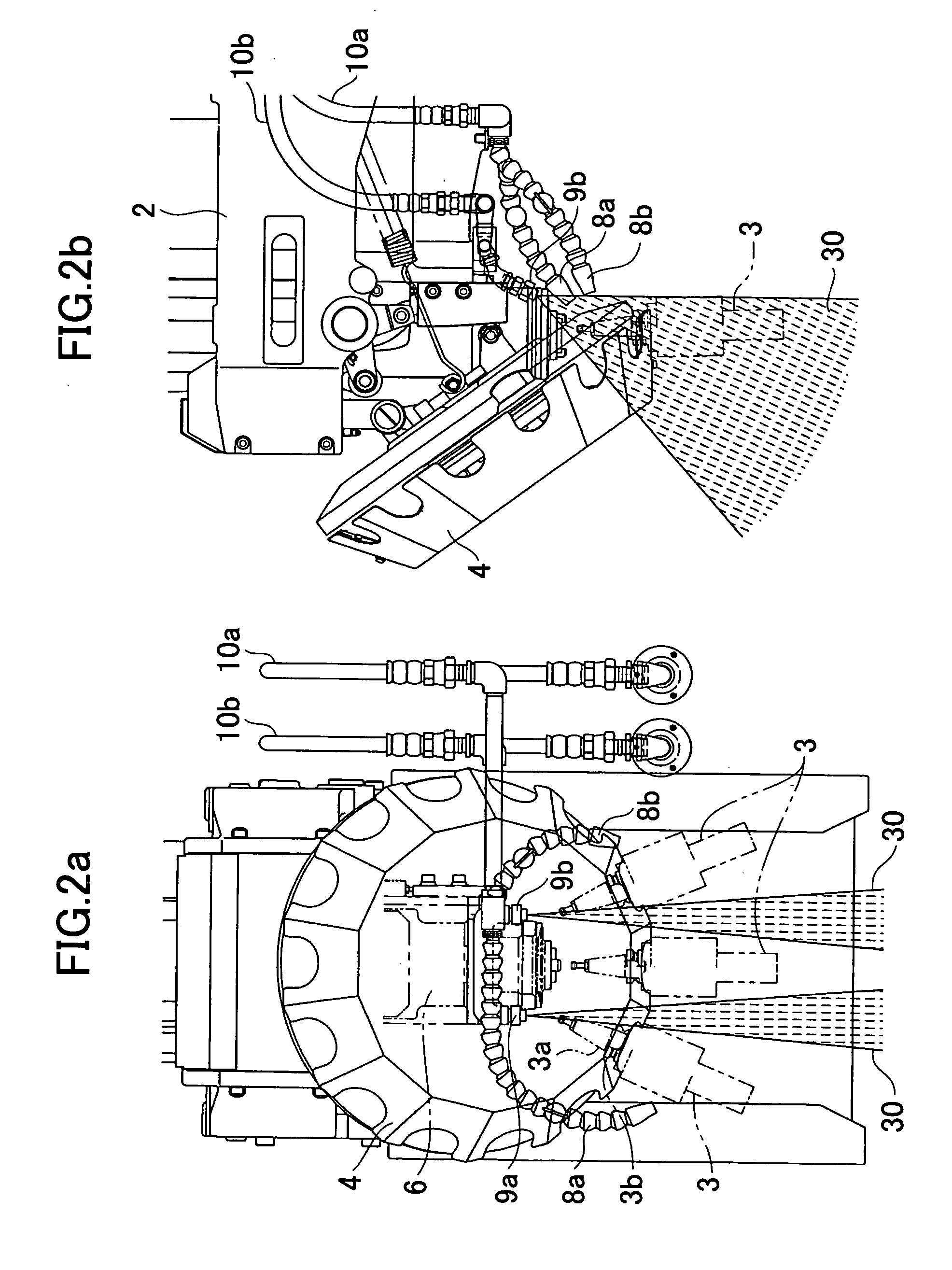

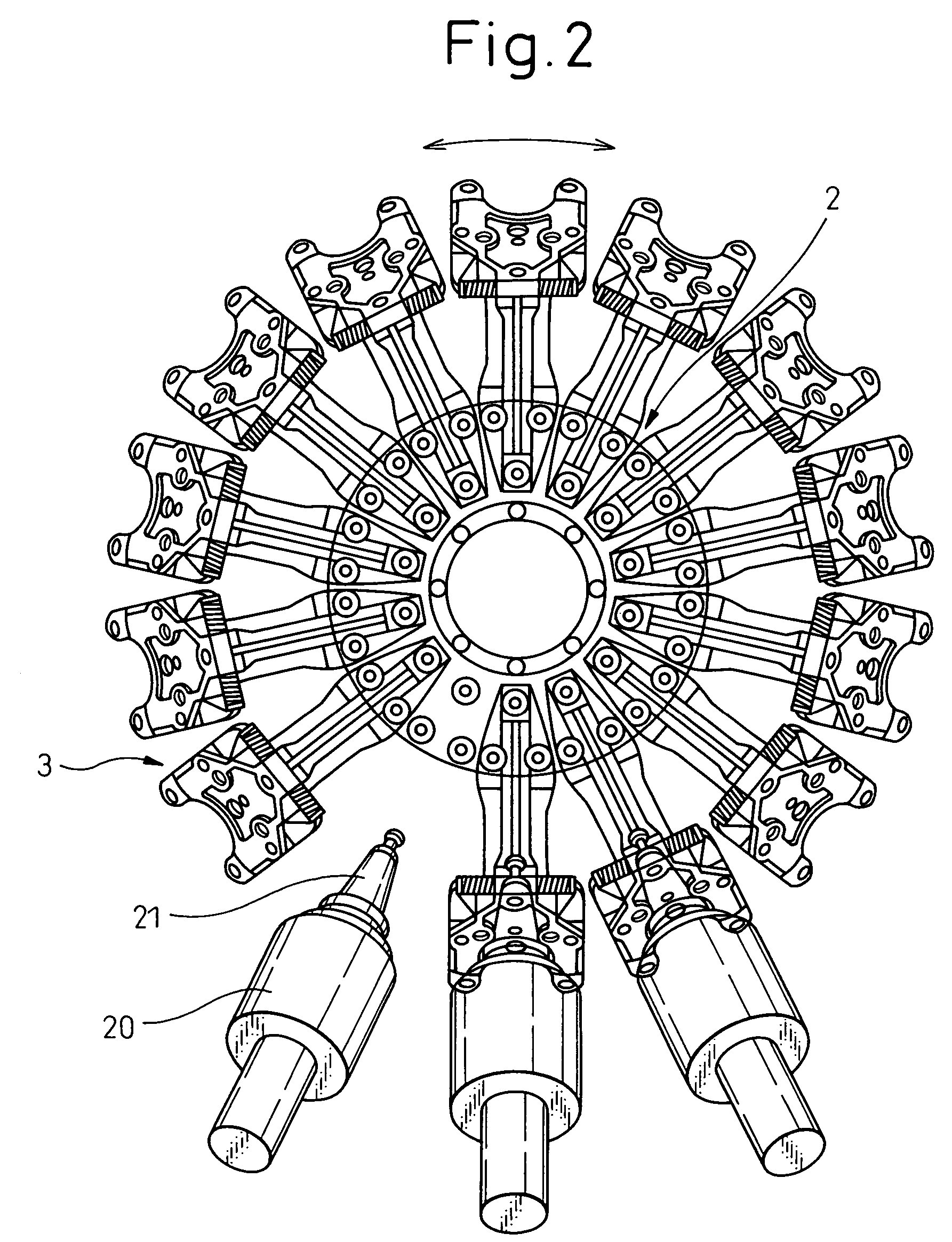

Automatic tool changing device for machine tool

ActiveUS20050009679A1Accurate measurementAccurate detectionPrecision positioning equipmentProtection and storage accessoriesGear wheelEngineering

An automatic tool changing device capable of cleaning a contact surface of a spindle, which is to be in contact with a tool holder, with a simple structure. The device includes a turret having a plurality of grippers on its outer circumference and holding the tool holder by means of the grippers. At the time of tool change, the grippers grip and pull out the tool holder fixed to the spindle. Rotation of the spindle causes the turret to rotate through a spindle gear, a turret gear, and a decelerating device, to thereby select a tool. At this moment, a coolant is spouted from a nozzle portion of a manifold toward a spindle taper hole in which the tool holder is interfitted and washes the taper hole. Due to the rotation of the spindle, the coolant is spouted onto the whole circumference of the taper hole, and the surface to be in contact with the tool holder is surely washed. Therefore, it is possible to perform the cleaning with a simple structure in which the nozzle portion is arranged near the spindle without machining the spindle and the tool holder.

Owner:FANUC LTD

Air valve coupling method and apparatus

A machining center including a machining head, a tool changer, an air driven tool and an air valve system. The air driven tool is connectable to the machine head by action of the tool changer. The air valve system has a first portion associated with the machining head and a second portion associated with the air driven tool. The first portion and the second portion include a connection therebetween having an airflow across the connection before the connection seals.

Owner:BRYAN STEVE M

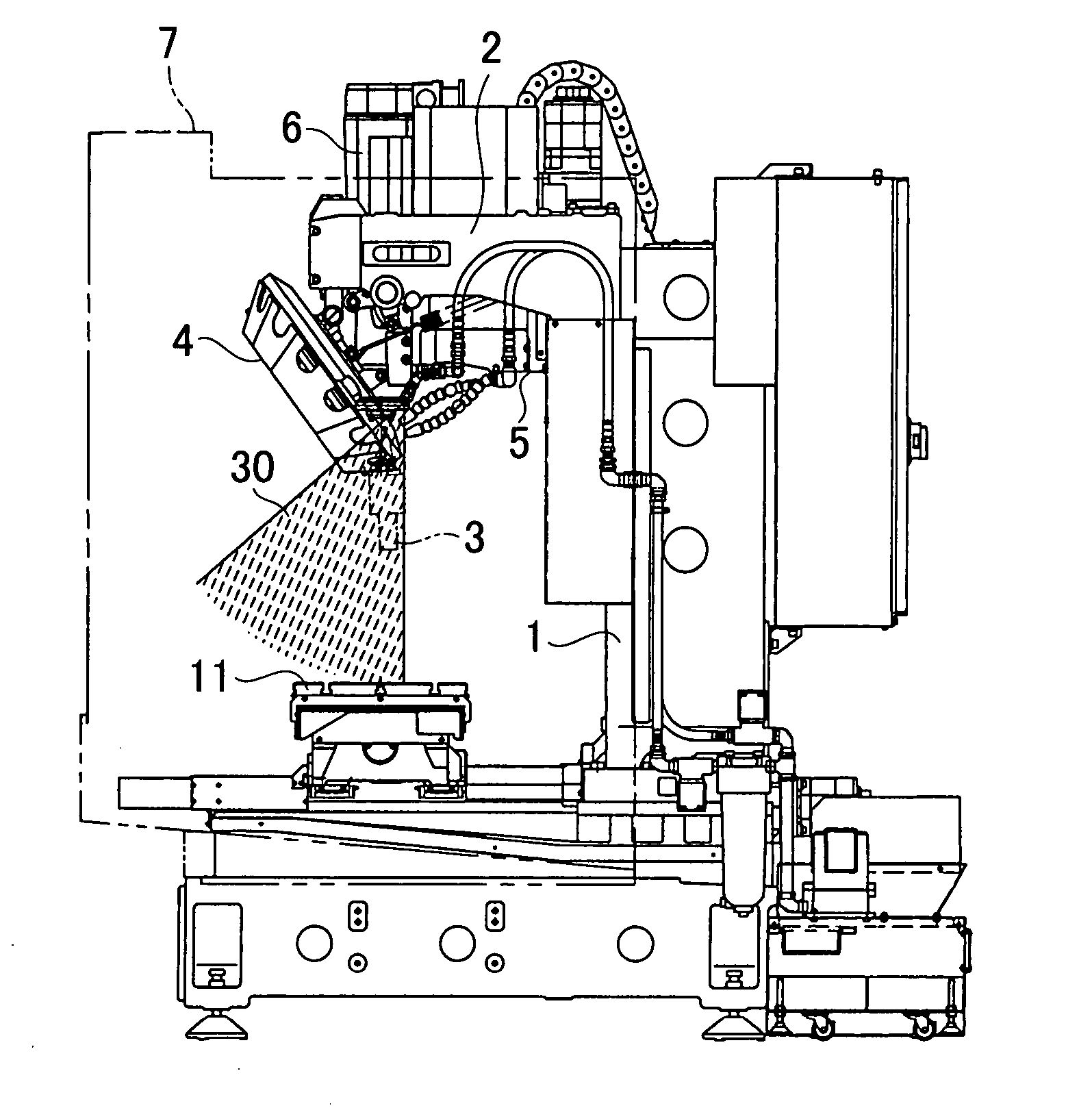

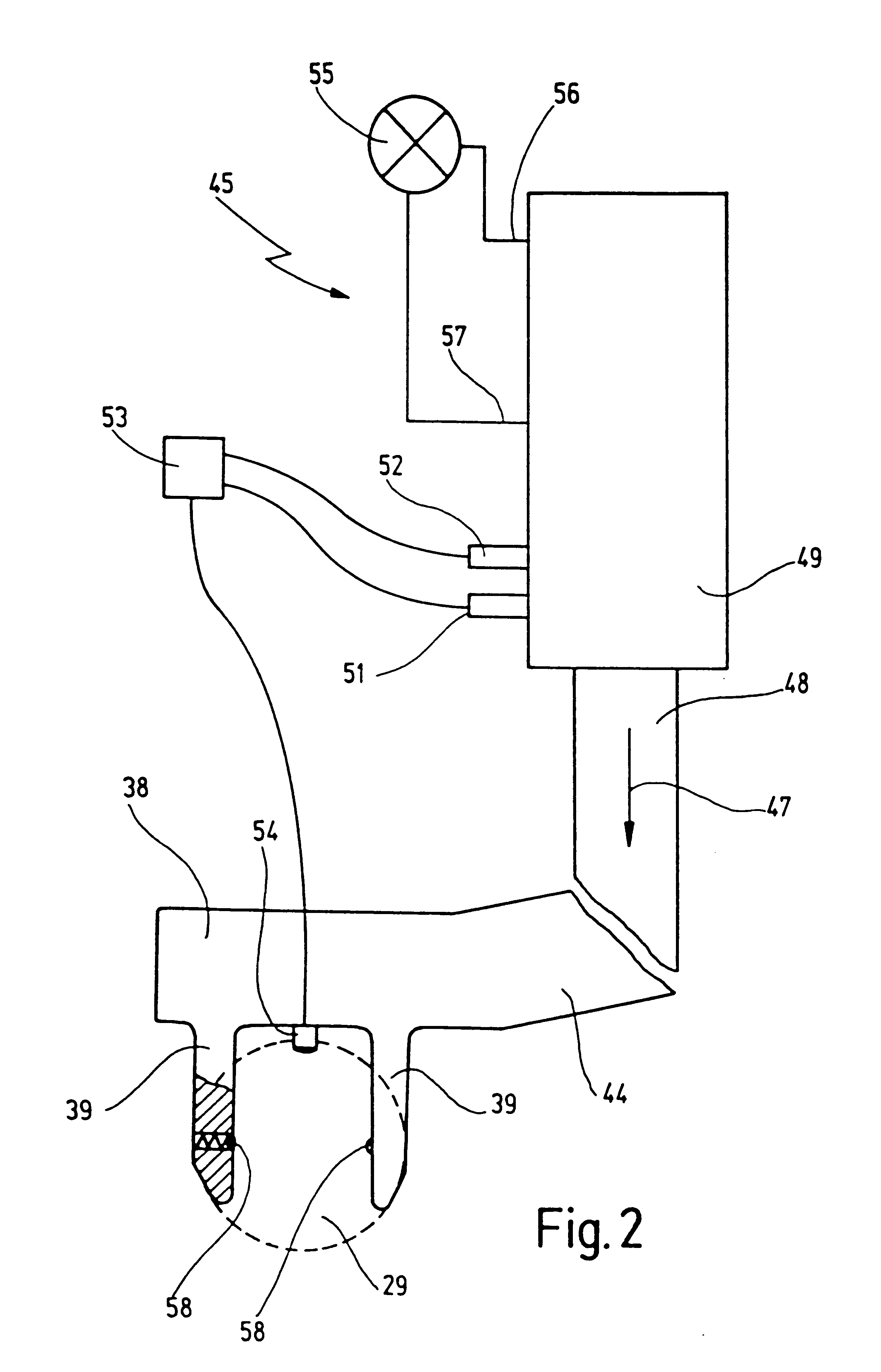

Tool changing device and tool cleaning method

InactiveUS7172542B2Reliable removalAutomatic/semiautomatic turning machinesPrecision positioning equipmentForeign matterCleaning methods

A tool changing device and a tool cleaning method capable of surely removing foreign matter such as swarf adhered to tapered portions and / or flange portions of tools, which serve as contact faces to be in contact with a spindle. There is arranged tool cleaning nozzles for spouting coolant on both sides of the spindle in the rotating position of a turret. The tool cleaning nozzle has a position and a posture such that the coolant spouted from the nozzle hits against the tapered portions and / or the flange portions of the tools held by the turret. The coolant is spouted from the tool cleaning nozzle with the rotation of the turret at the time of tool selection. Each time the turret rotates, the tapered portions and / or the flange portions of the tools held by the turret are cleaned by the coolant. Even if foreign matter, such as swarf, is adhered to the standby tools held by the turret, it is possible to surely remove the foreign matter, such as swarf, since the tools are cleaned during the rotation of the turret.

Owner:FANUC LTD

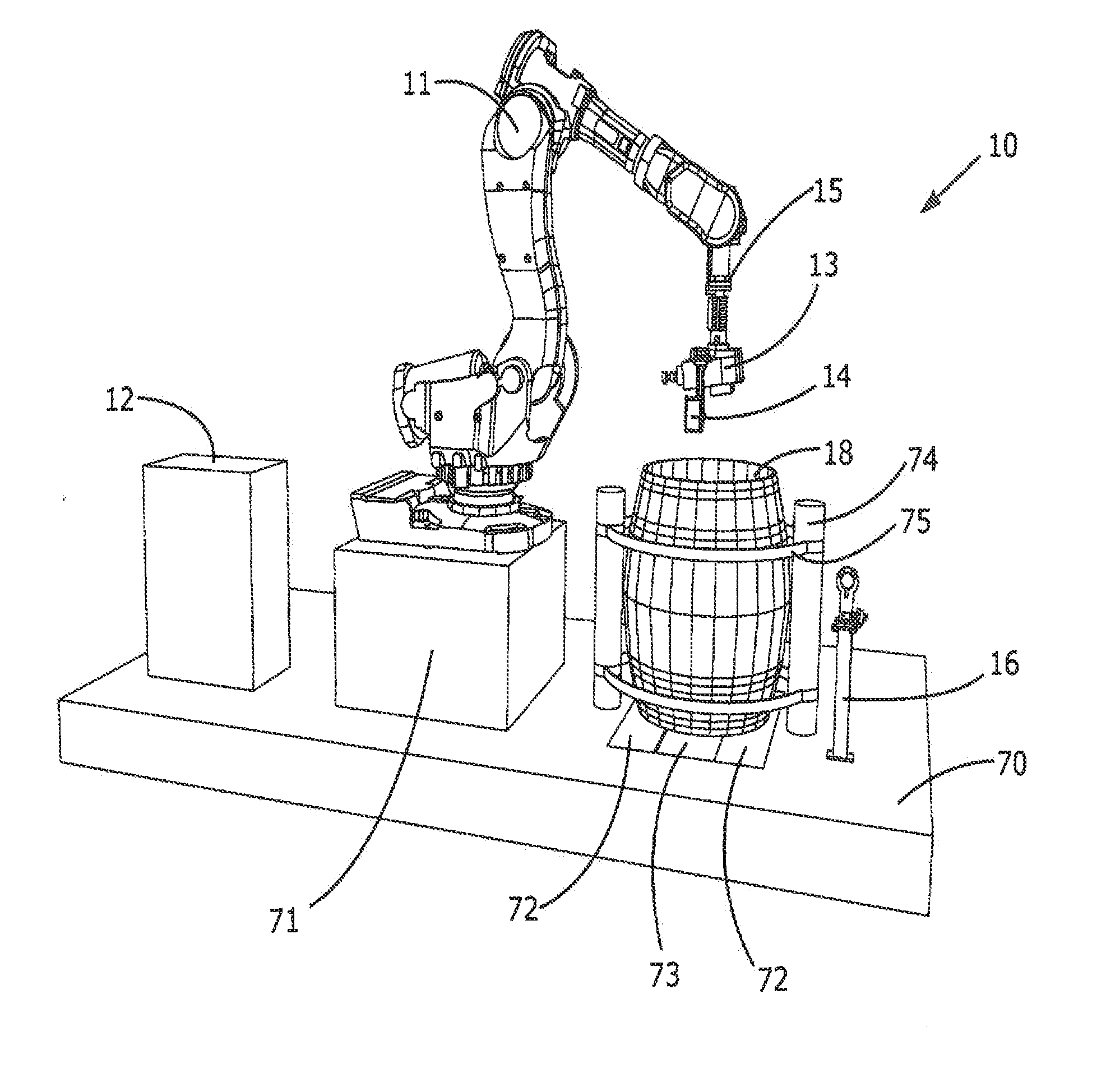

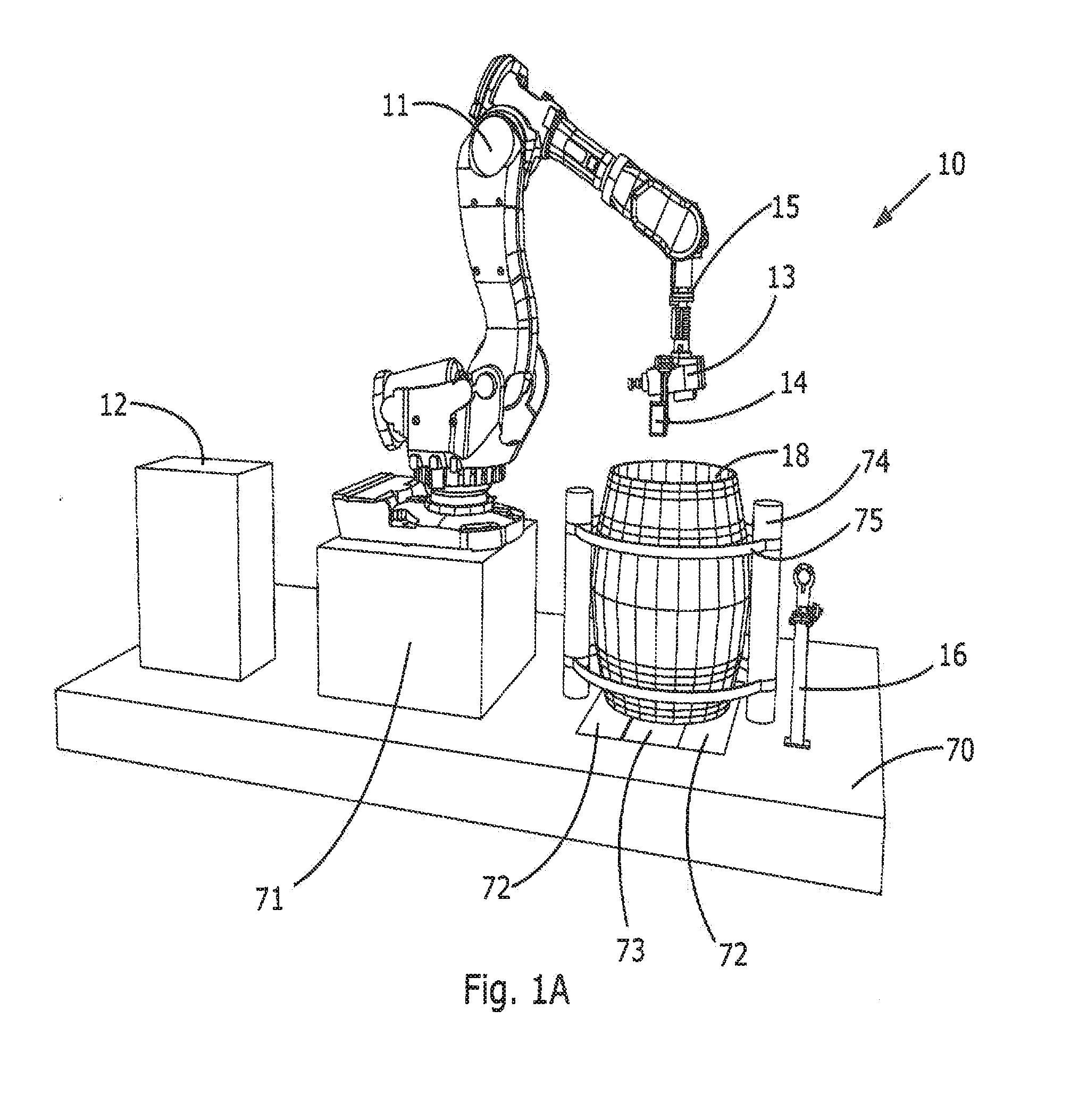

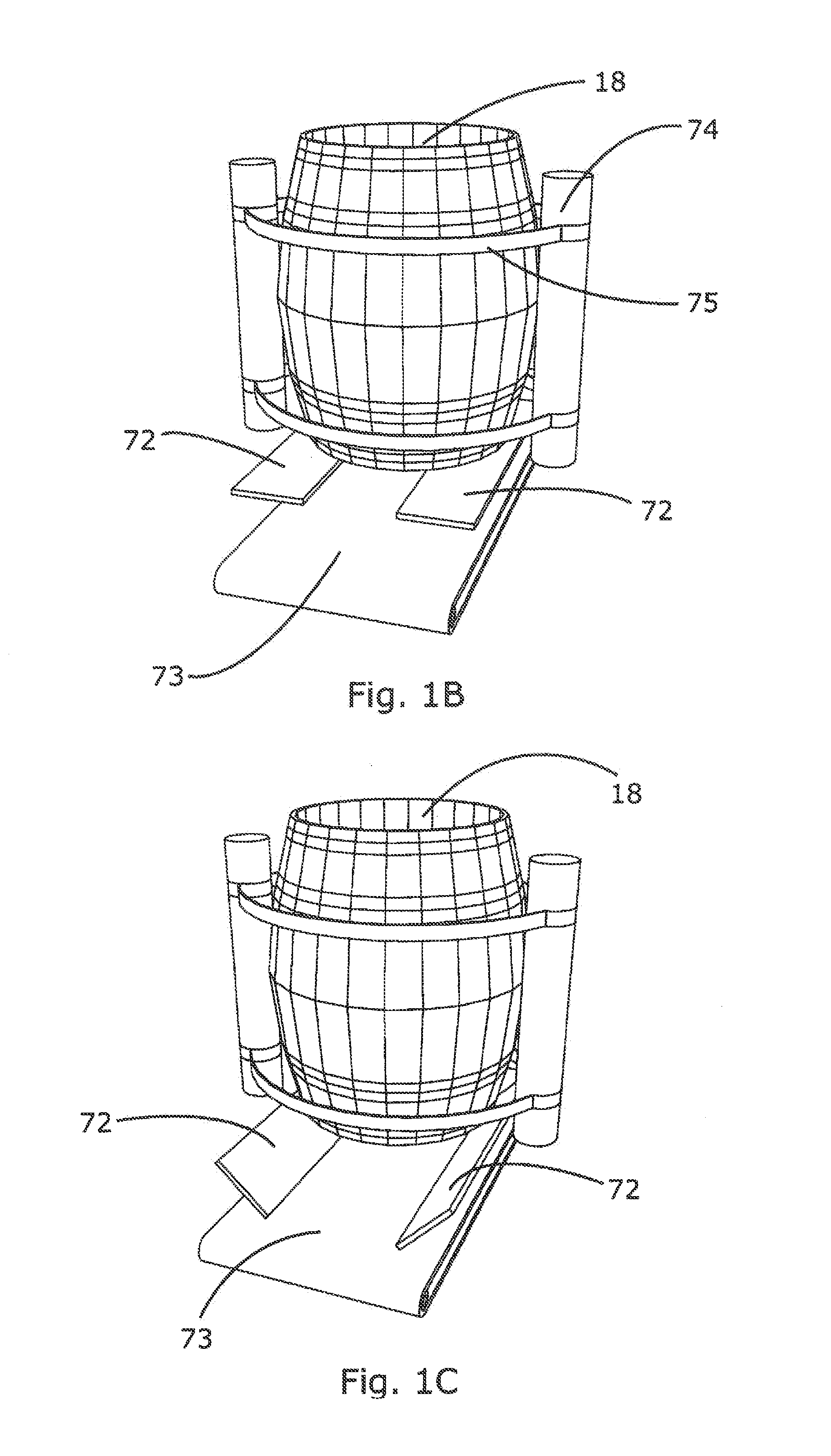

System and method for the reconditioning of barrels including a robotic arm with a removable laser module

A system for reconditioning barrels comprising: a robot arm; a router assembly for routing the inside surface of a barrel; and a laser assembly for measuring the inside profile of a barrel, wherein: the router assembly is fixedly attached to the robot arm; and the laser assembly is removably attached to the router assembly thus allowing the laser assembly to be removed whilst the barrel is being routed in order to protect the laser from airborne particles and vibrations from the router.

Owner:DIVERSE BARREL SOLUTIONS

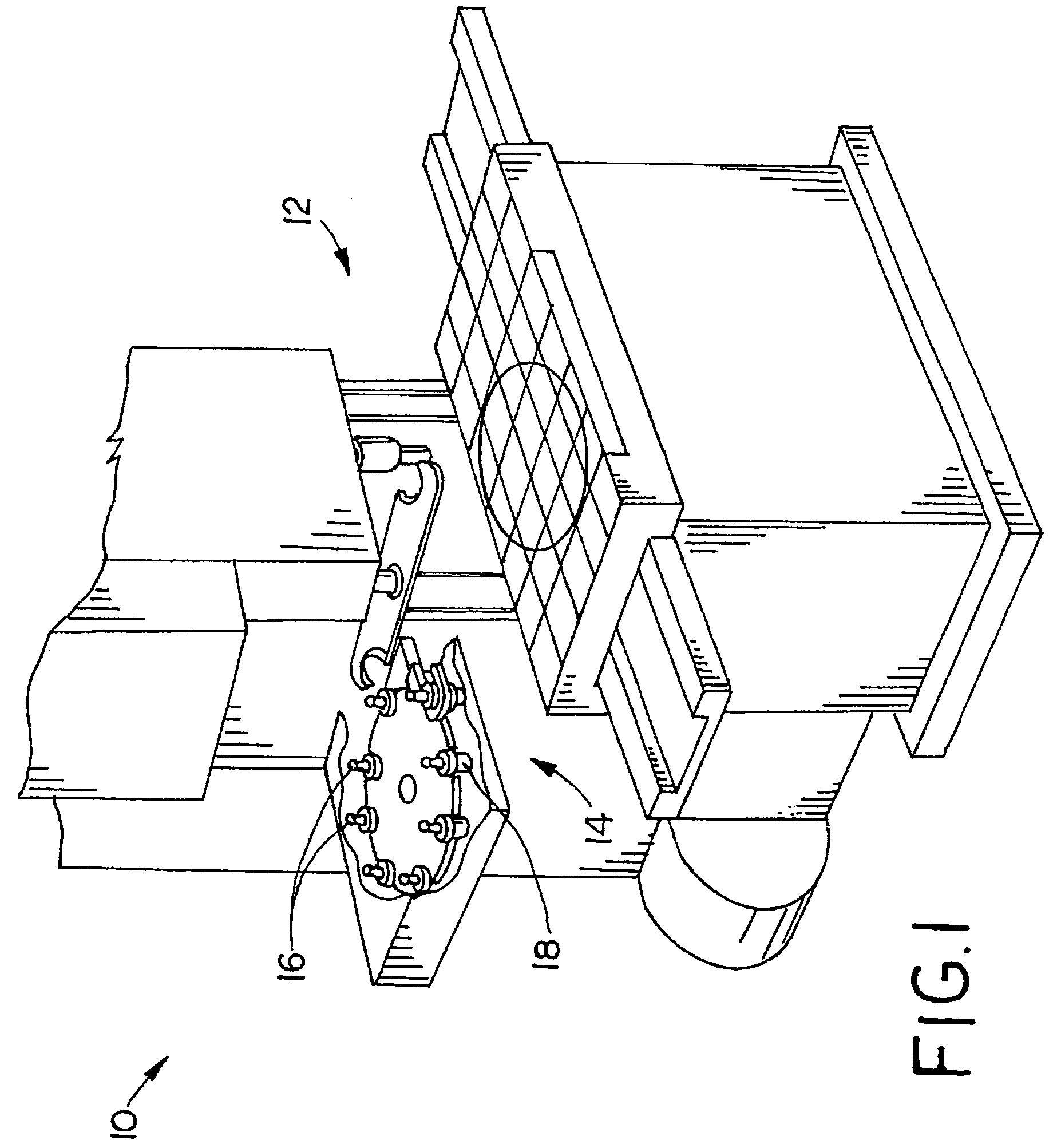

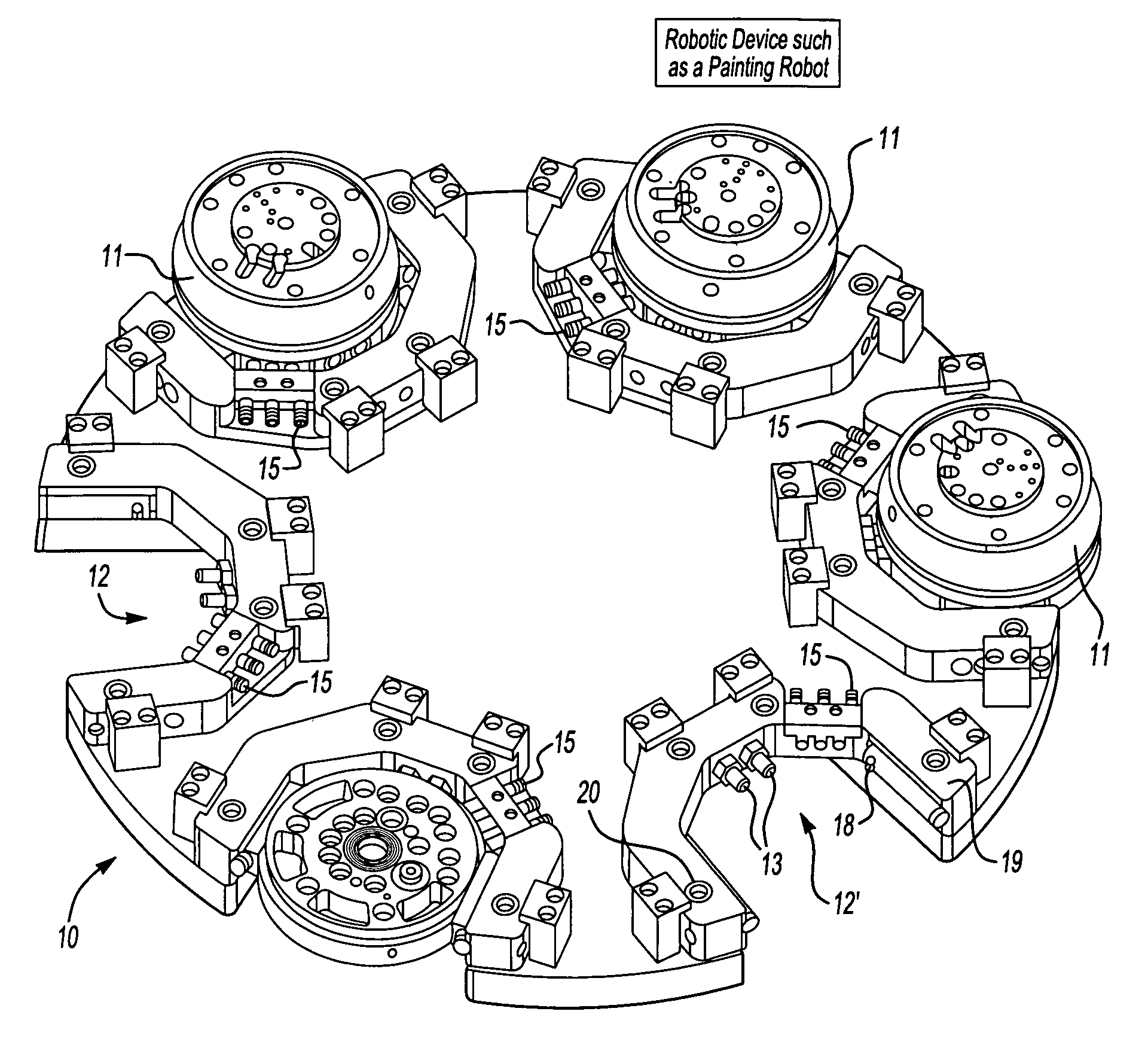

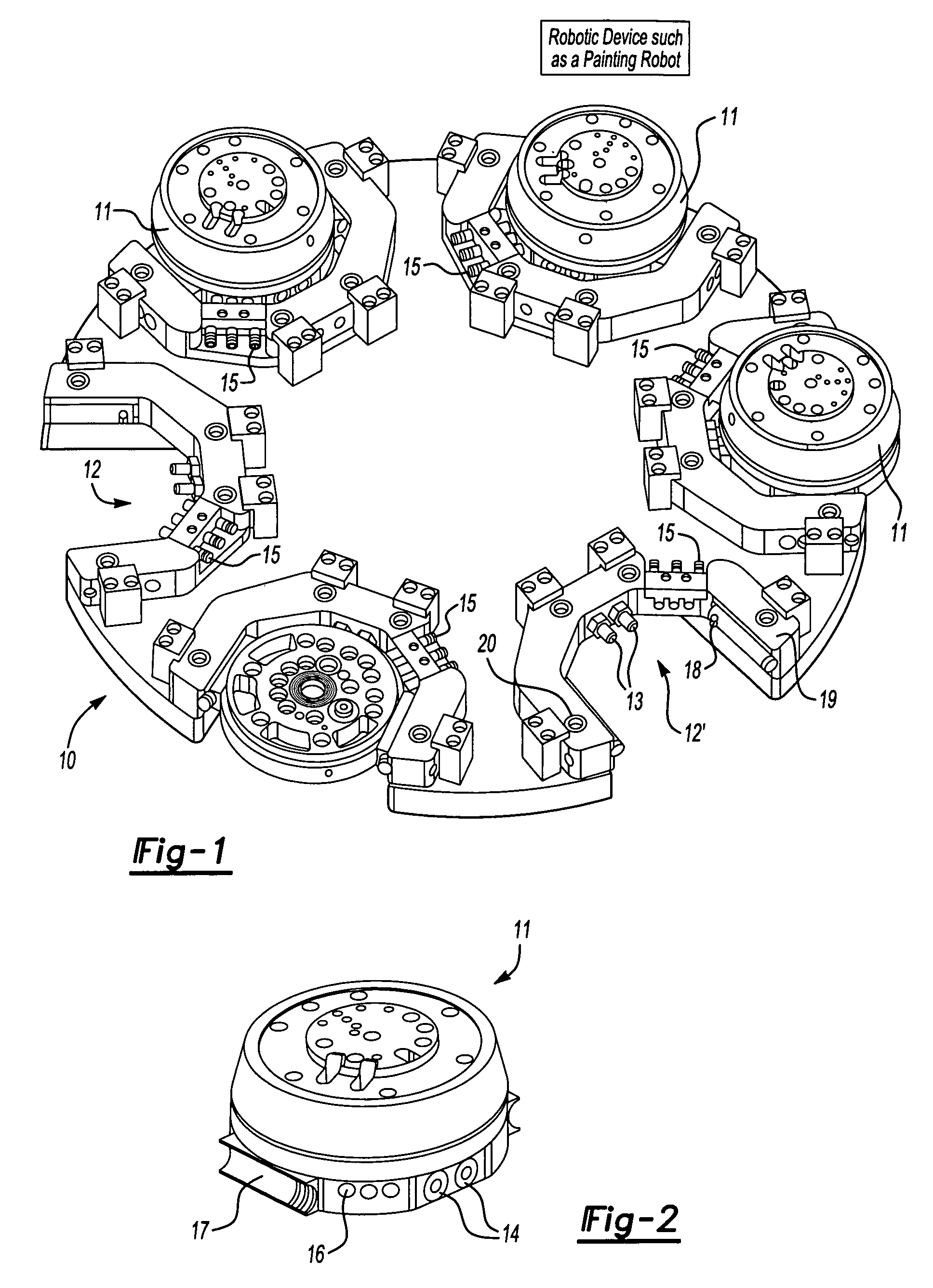

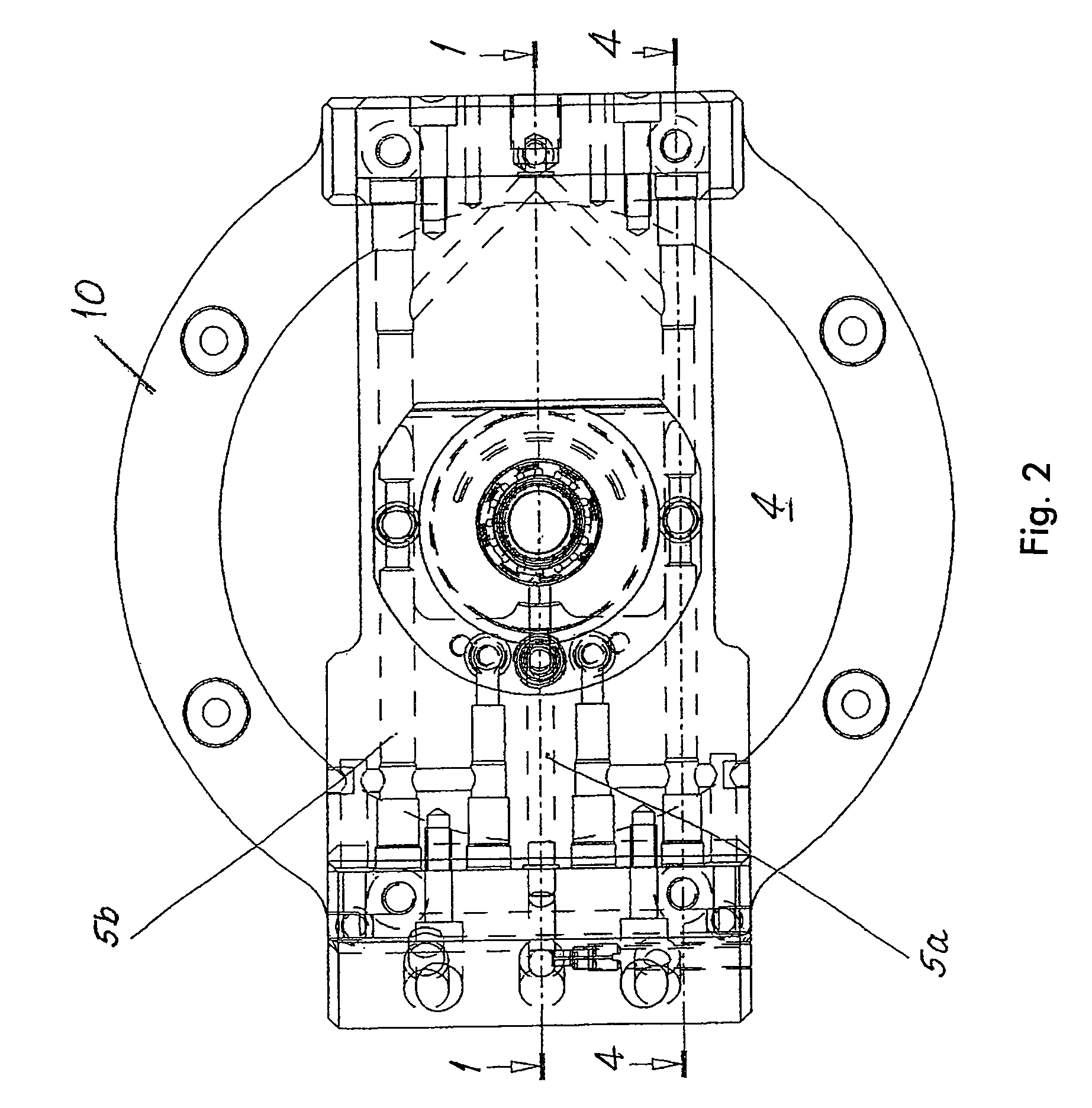

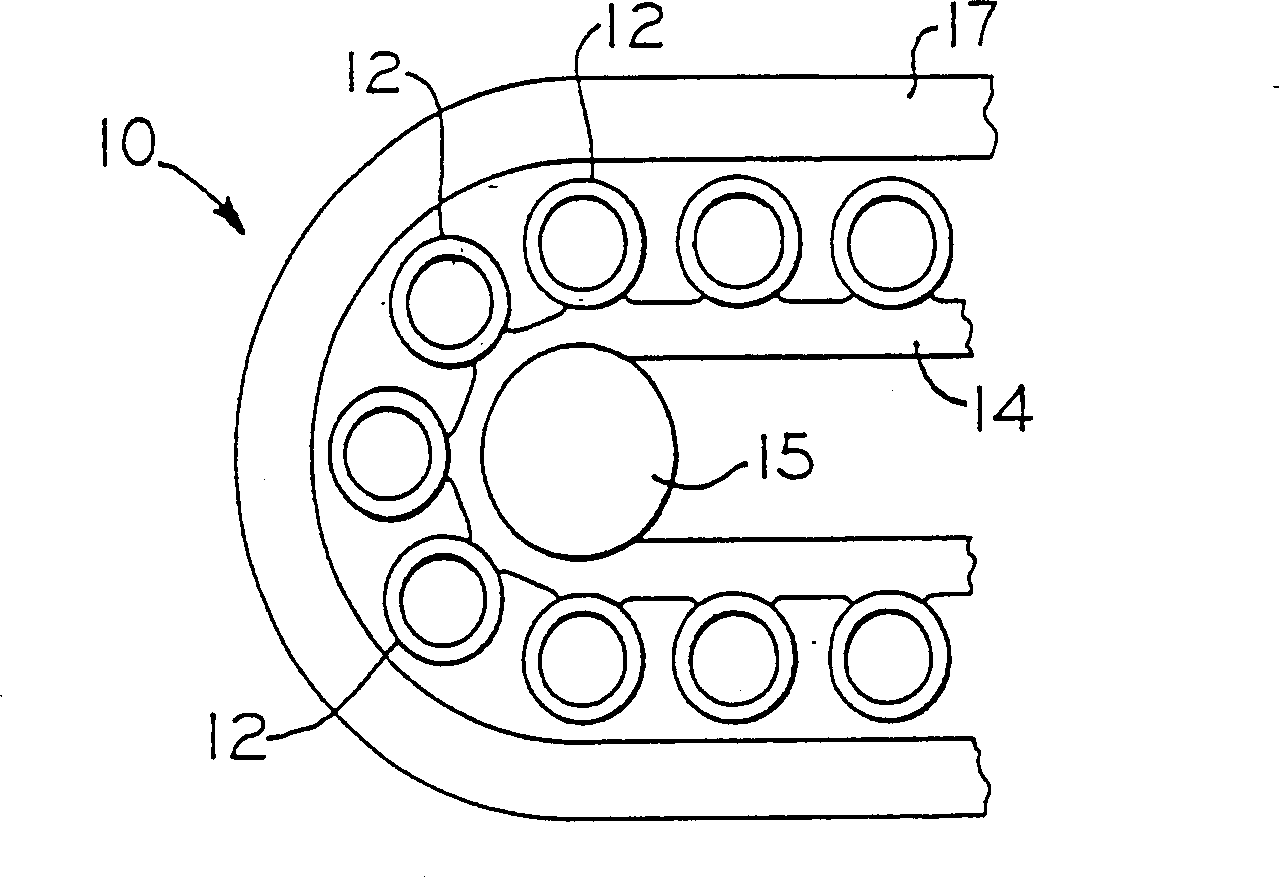

Tool change system for a machine

A plurality of atomizers or other tools are disposed in a mounting plate (10) in storage places (12), respectively. The mounting plate (10) is rotatable relative a paint robot of a coating installation and has a pneumatic lock or a tool holder (19) that can only be released automatically during storage of the atomizers by an external control device of the mounting plate.

Owner:DURR SYST INC

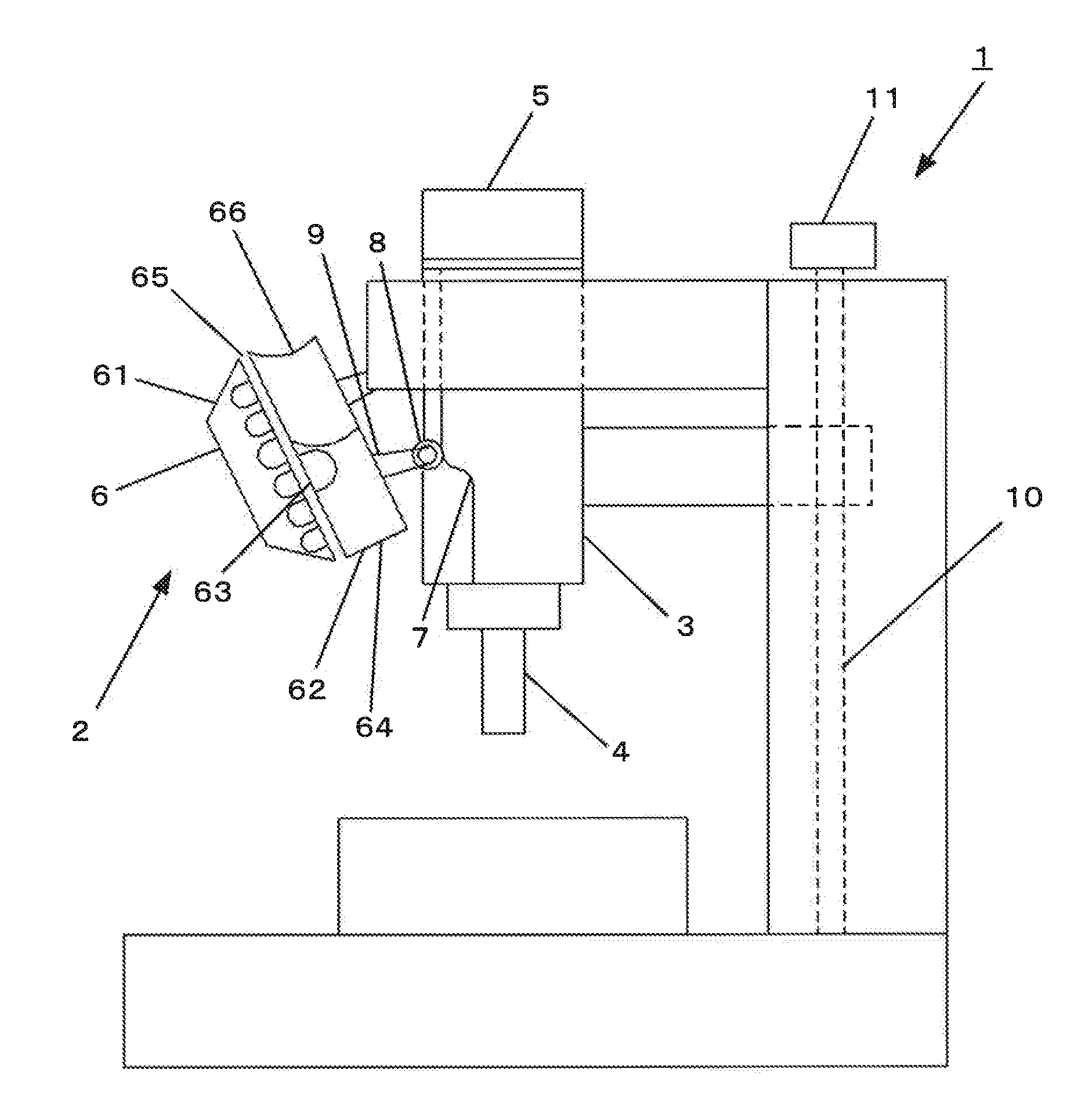

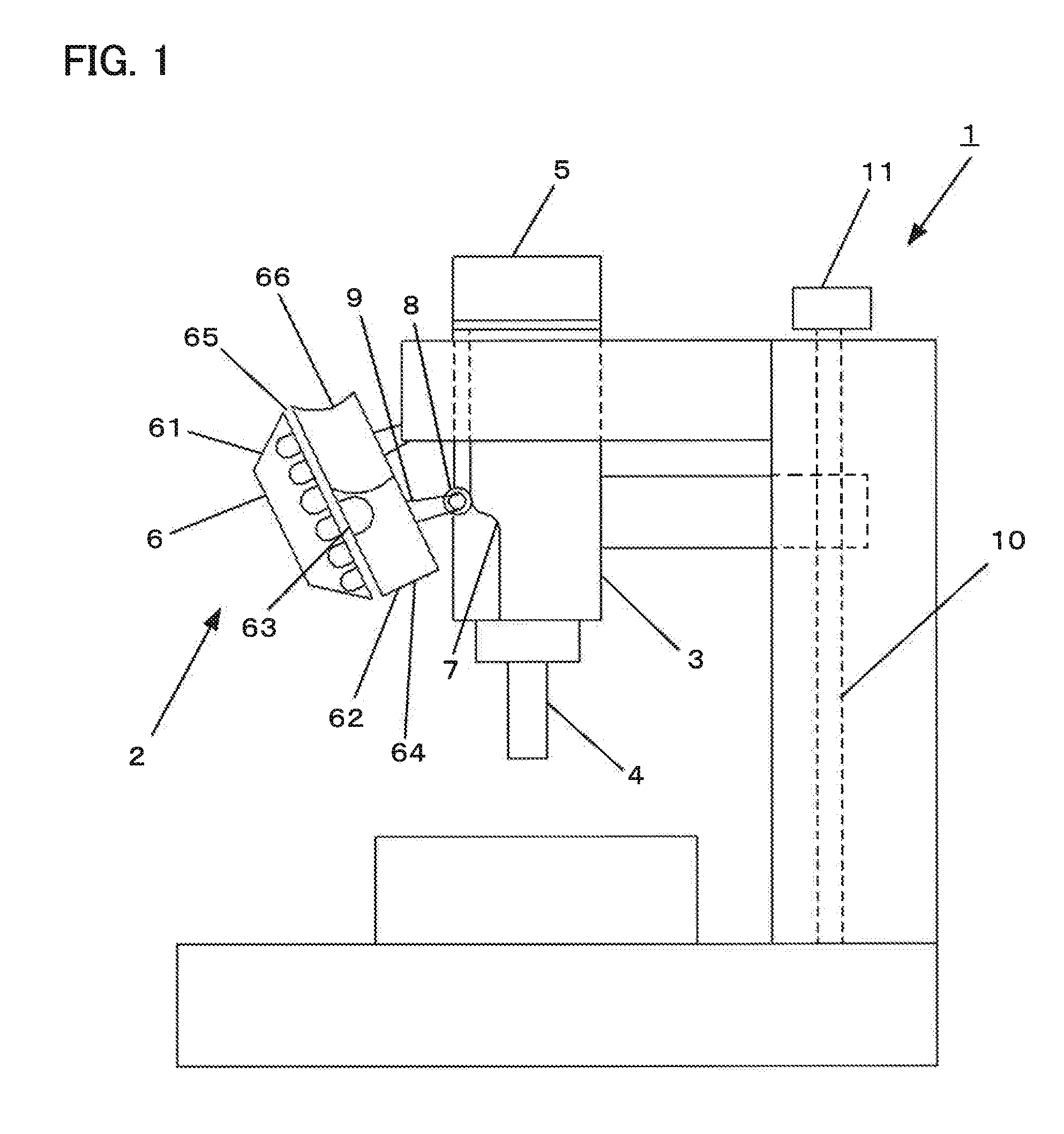

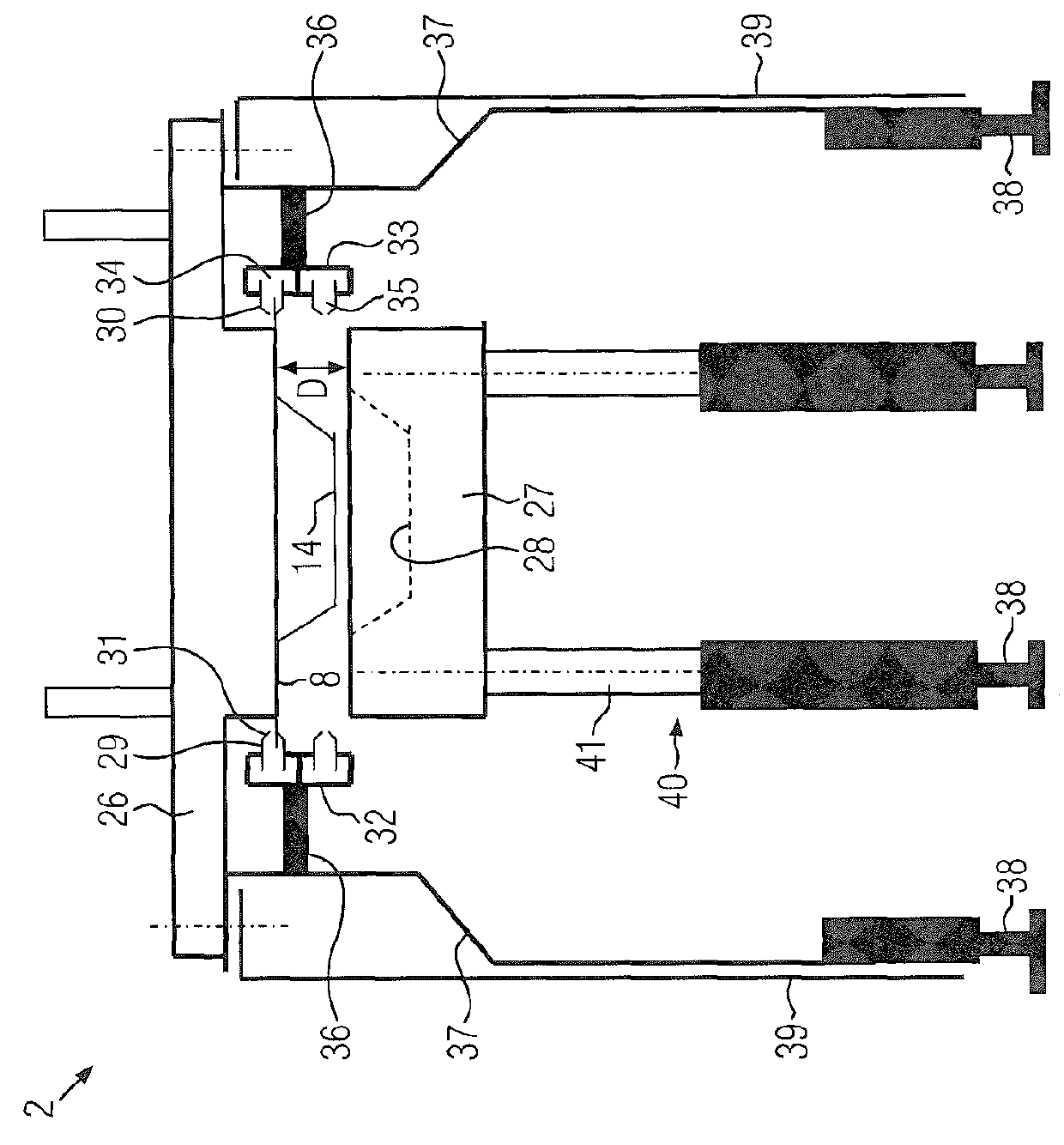

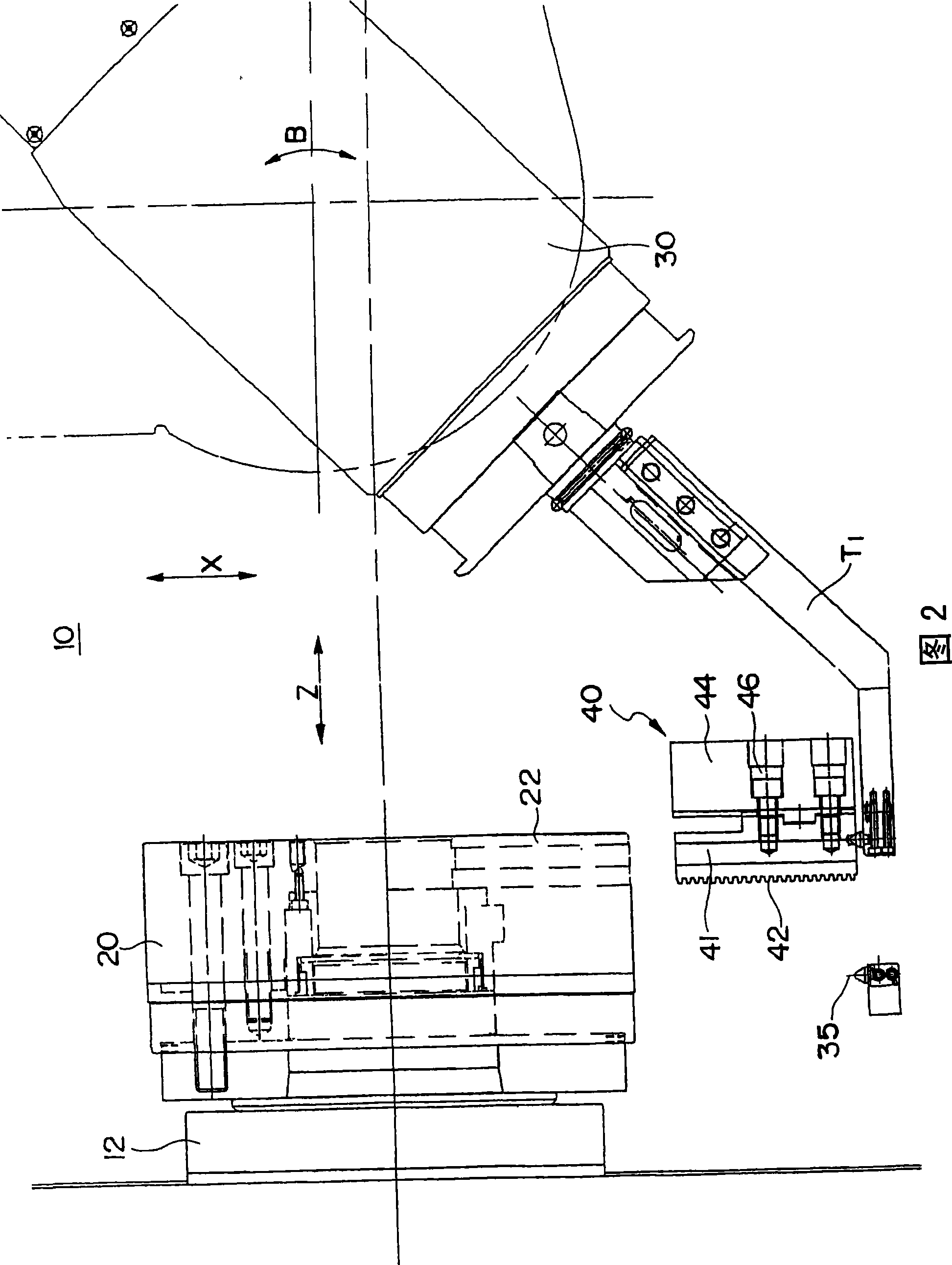

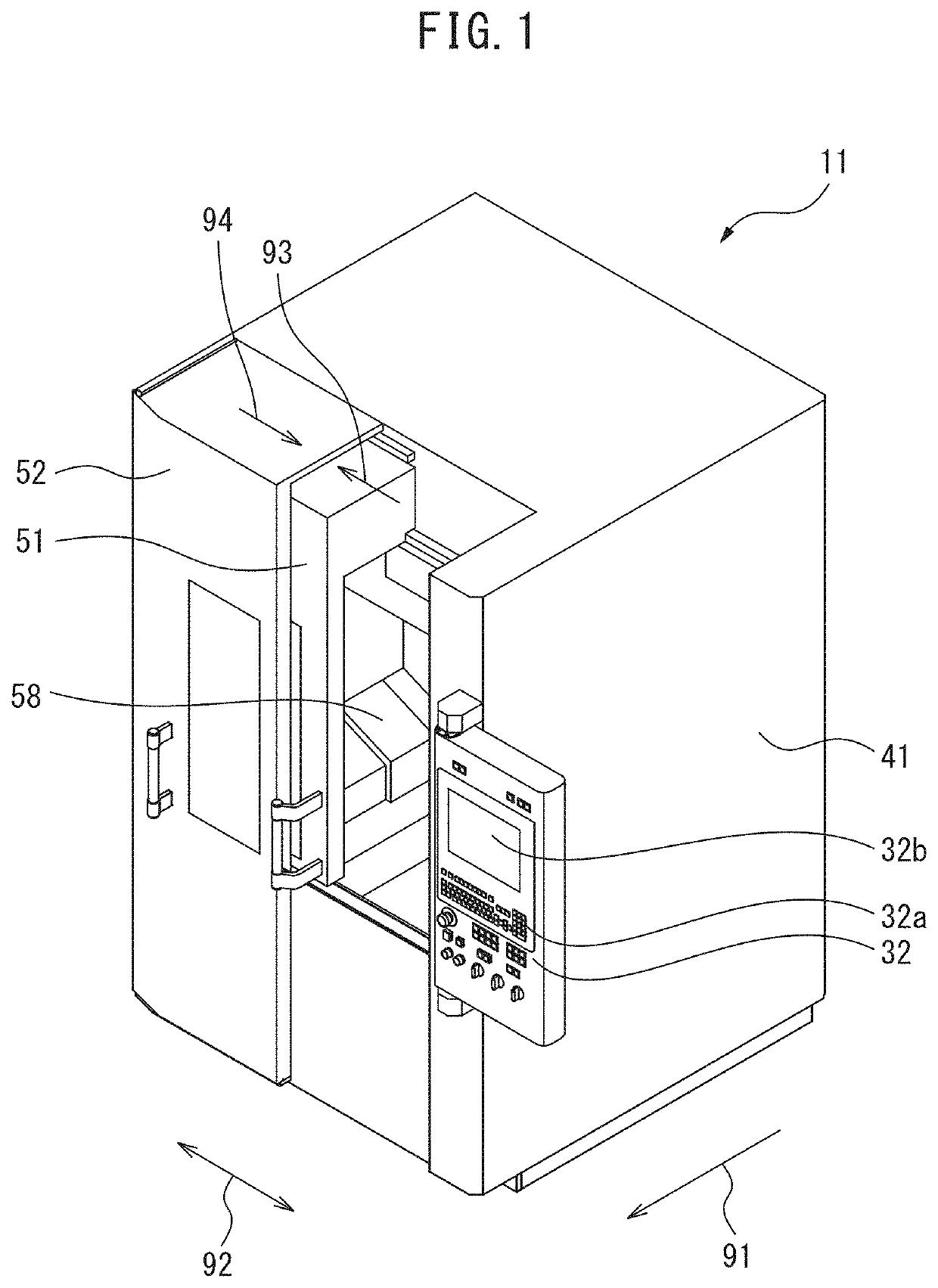

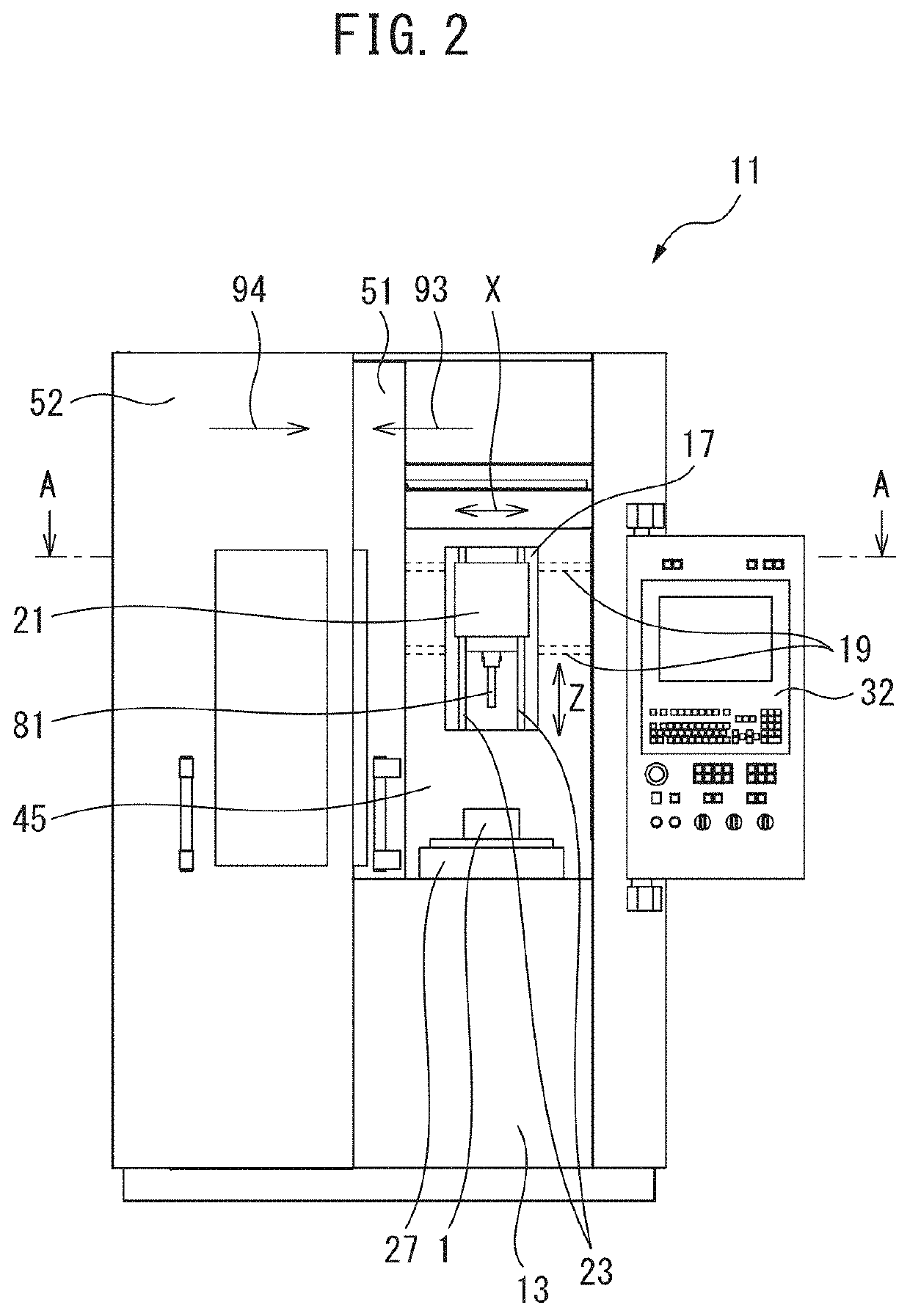

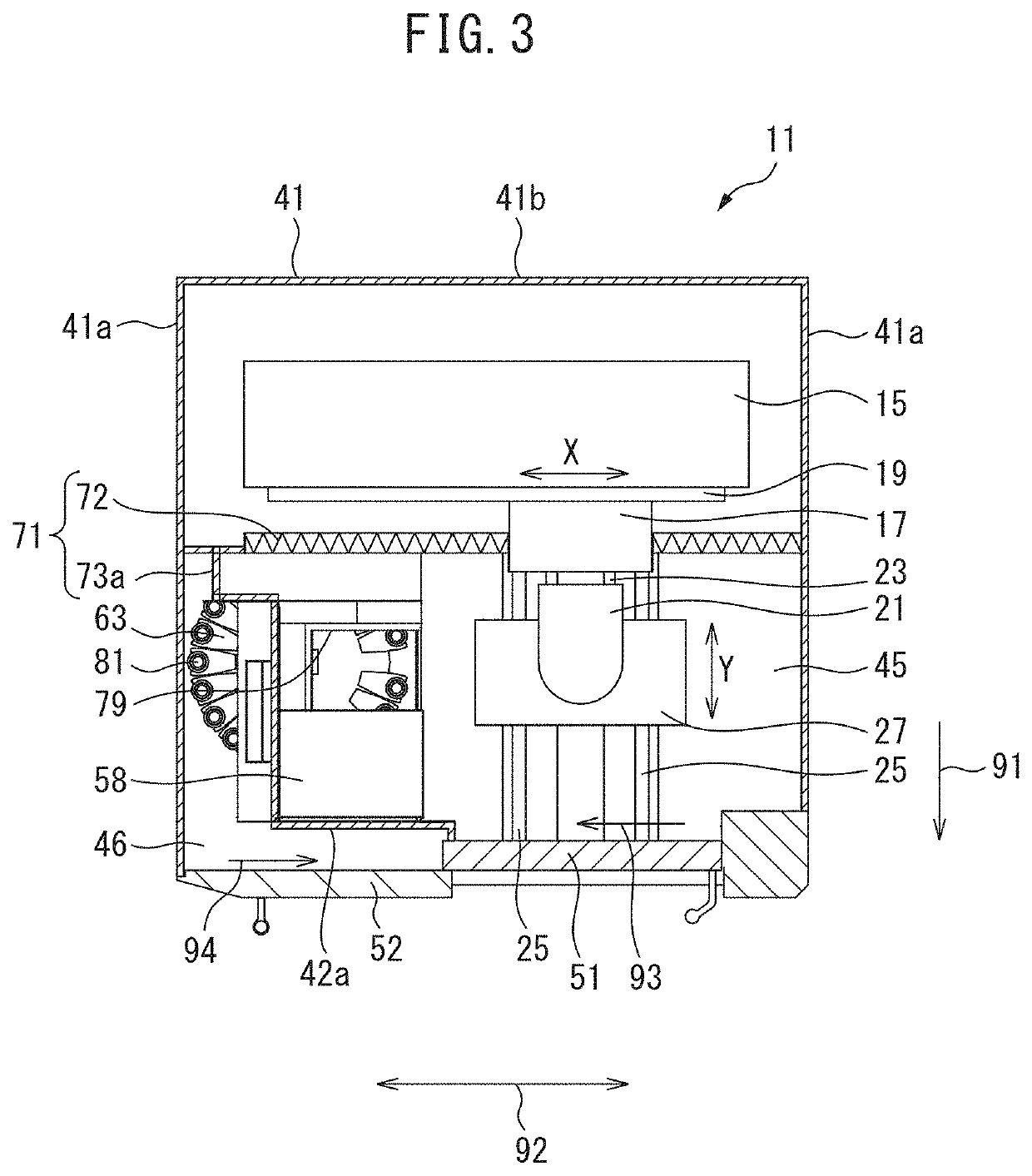

Machine tool including tool radius adjusting device

ActiveUS20120058871A1Reduce machining cycle timeInhibitionThread cutting toolsPrecision positioning equipmentEngineeringMachine tool

A tool radius adjusting device executes an operation for adjusting the tool radius of a boring holder in parallel with execution of a machining program for executing an operation of a spindle head and an operation of a tool changer. A carrier control unit determines whether the tool changer is executing a tool changing process. When the tool changing process is not being executed, the carrier control unit allows the carrier device to execute an operation for picking the boring holder out from the tool magazine and an operation for returning the boring holder, of which the tool radius has been adjusted, to the tool magazine.

Owner:JTEKT CORP

Tool changing device and tool cleaning method

InactiveUS20050032615A1Reliable removalAutomatic/semiautomatic turning machinesPrecision positioning equipmentForeign matterEngineering

A tool changing device and a tool cleaning method capable of surely removing foreign matter such as swarf adhered to tapered portions and / or flange portions of tools, which serve as contact faces to be in contact with a spindle. There is arranged tool cleaning nozzles for spouting coolant on both sides of the spindle in the rotating position of a turret. The tool cleaning nozzle has a position and a posture such that the coolant spouted from the nozzle hits against the tapered portions and / or the flange portions of the tools held by the turret. The coolant is spouted from the tool cleaning nozzle with the rotation of the turret at the time of tool selection. Each time the turret rotates, the tapered portions and / or the flange portions of the tools held by the turret are cleaned by the coolant. Even if foreign matter, such as swarf, is adhered to the standby tools held by the turret, it is possible to surely remove the foreign matter, such as swarf, since the tools are cleaned during the rotation of the turret.

Owner:FANUC LTD

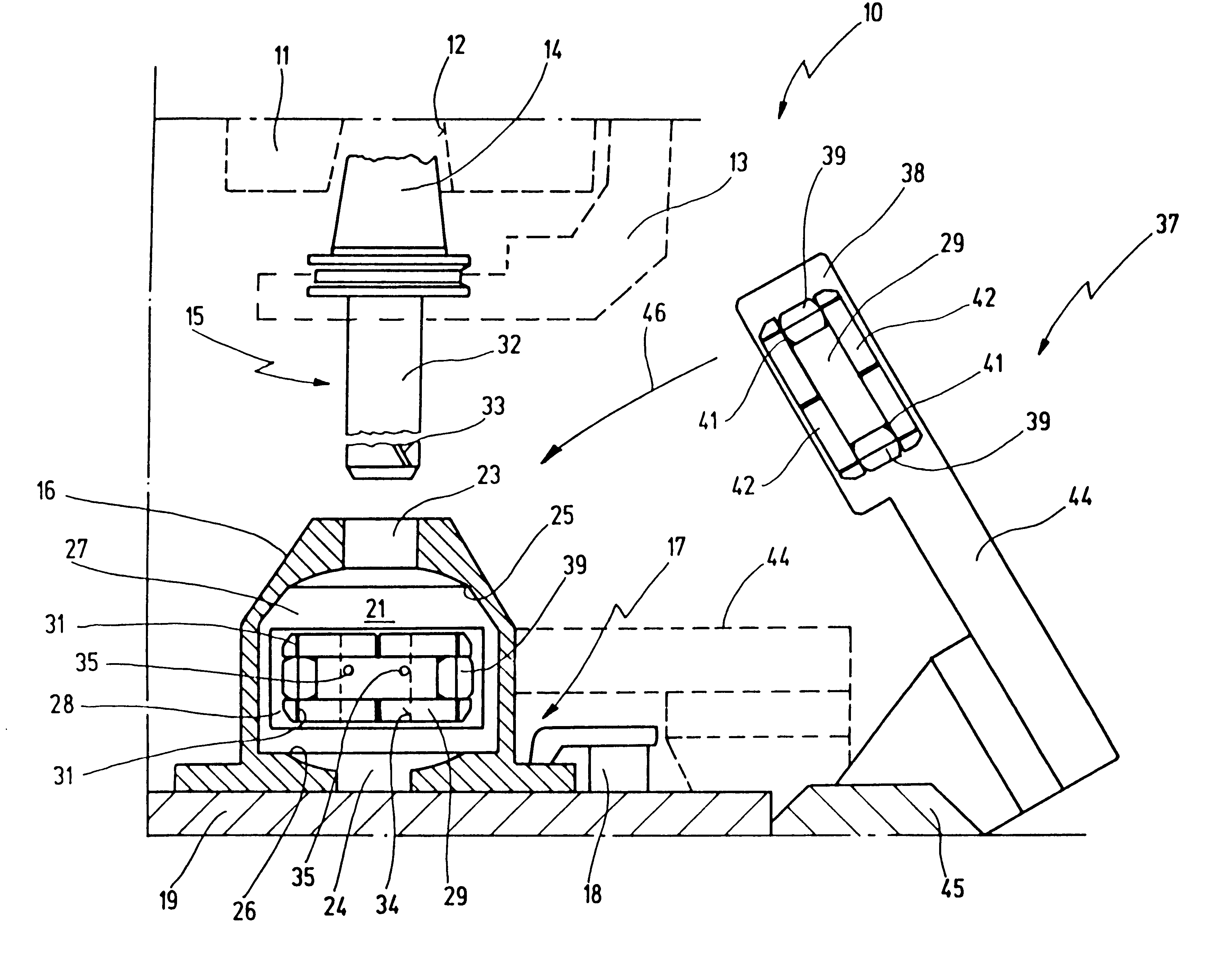

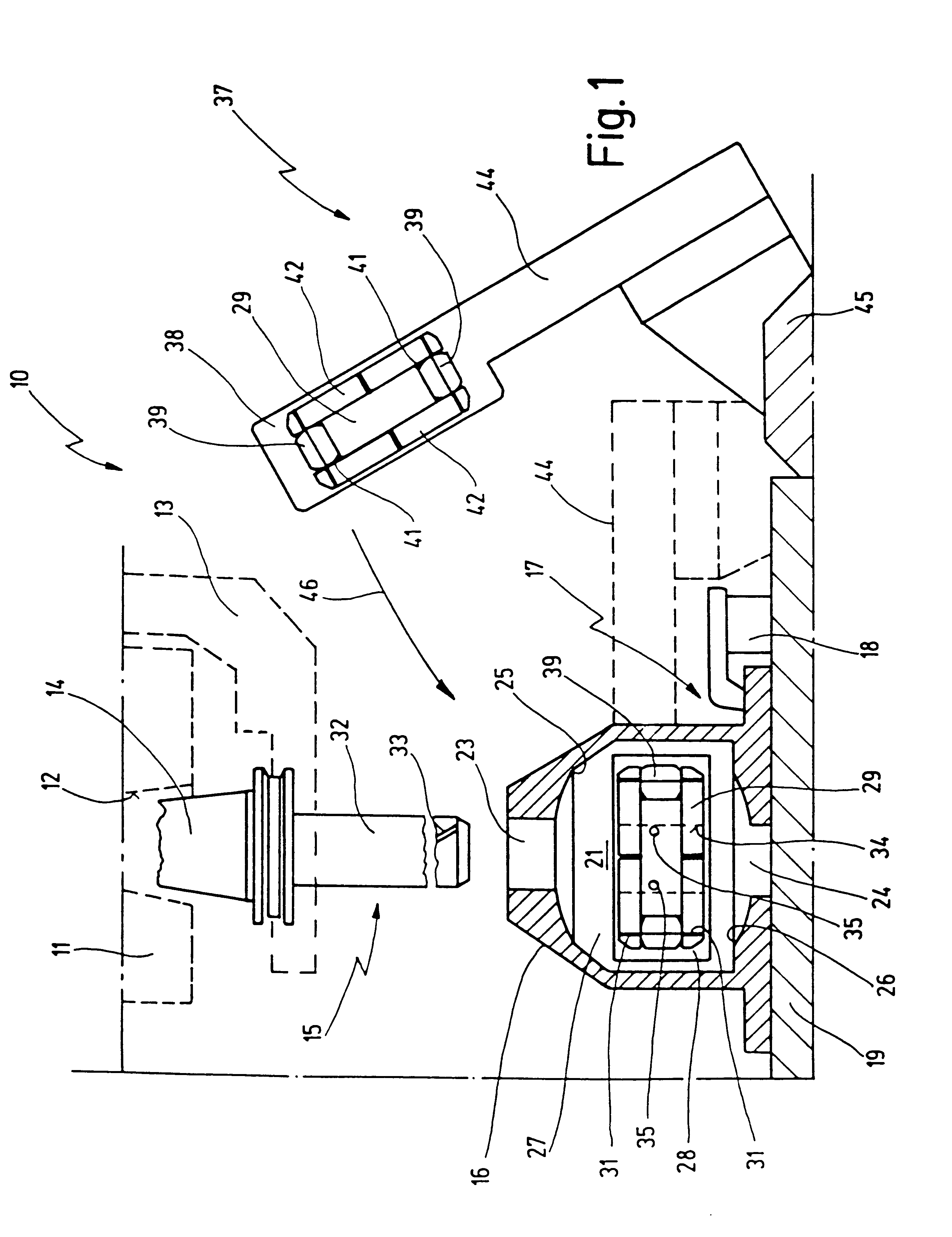

Machine tool for machining cavities in workpieces

A machine tool (10) has a spindle (11) for receiving a tool (15) for machining a workpiece (16). A mechanism (17) for clamping the workpiece (16) is also provided. Also provided is a changing mechanism (37) for a machining tool (29), which holds the machining tool (29) in a gripper hand (38) which it introduces laterally into a workpiece cavity (21) in such a way that it can be automatically coupled there to an adapter tool (32) carried by the spindle (11).

Owner:CHIRON WERKE

Method and device for fitting a machine tool with tools

The invention relates to a method of fitting a machine tool with tools which are cooled by a free-flowing medium during operation of the machine tool, comprising the following method steps: a plurality of various tools are provided in order to carry out successive machining operations on a workpiece; a plurality of various nozzle devices are provided, each of which can be fitted together with a specific tool and connected to a medium source and has such a medium jet geometry that the respective medium jets strike locations where the machining takes place; a specific nozzle device is in each case fitted together with a specific tool and connected to the medium source before the operation of the machine tool is started.

Owner:RICHARD BAHR GMBH FORMEN UND WERKZEUGBAU

Tool changer provided with covers

A tool changer configured so that a turret is turned to index a desired tool to change the tool is provided with front and rear covers that cover front and rear surfaces, respectively, of the turret. A projection or a recess, which defines a passage for chips or a cutting fluid, is formed on or in an outer peripheral portion of the rear cover. Thus, the chips produced during machining and the cutting fluid used in the machining can be prevented from getting into the turret through a gap between the front and rear covers.

Owner:FANUC LTD

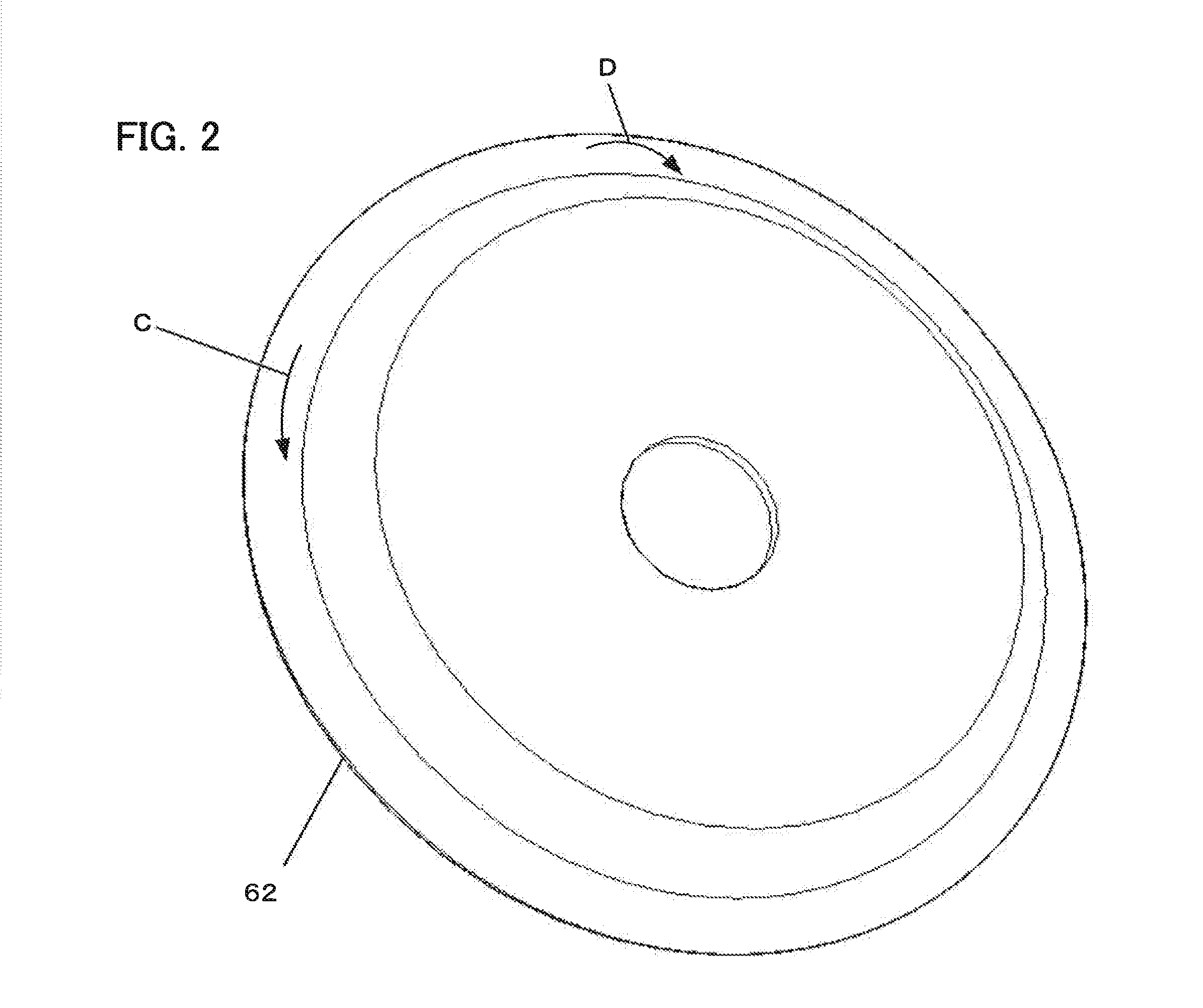

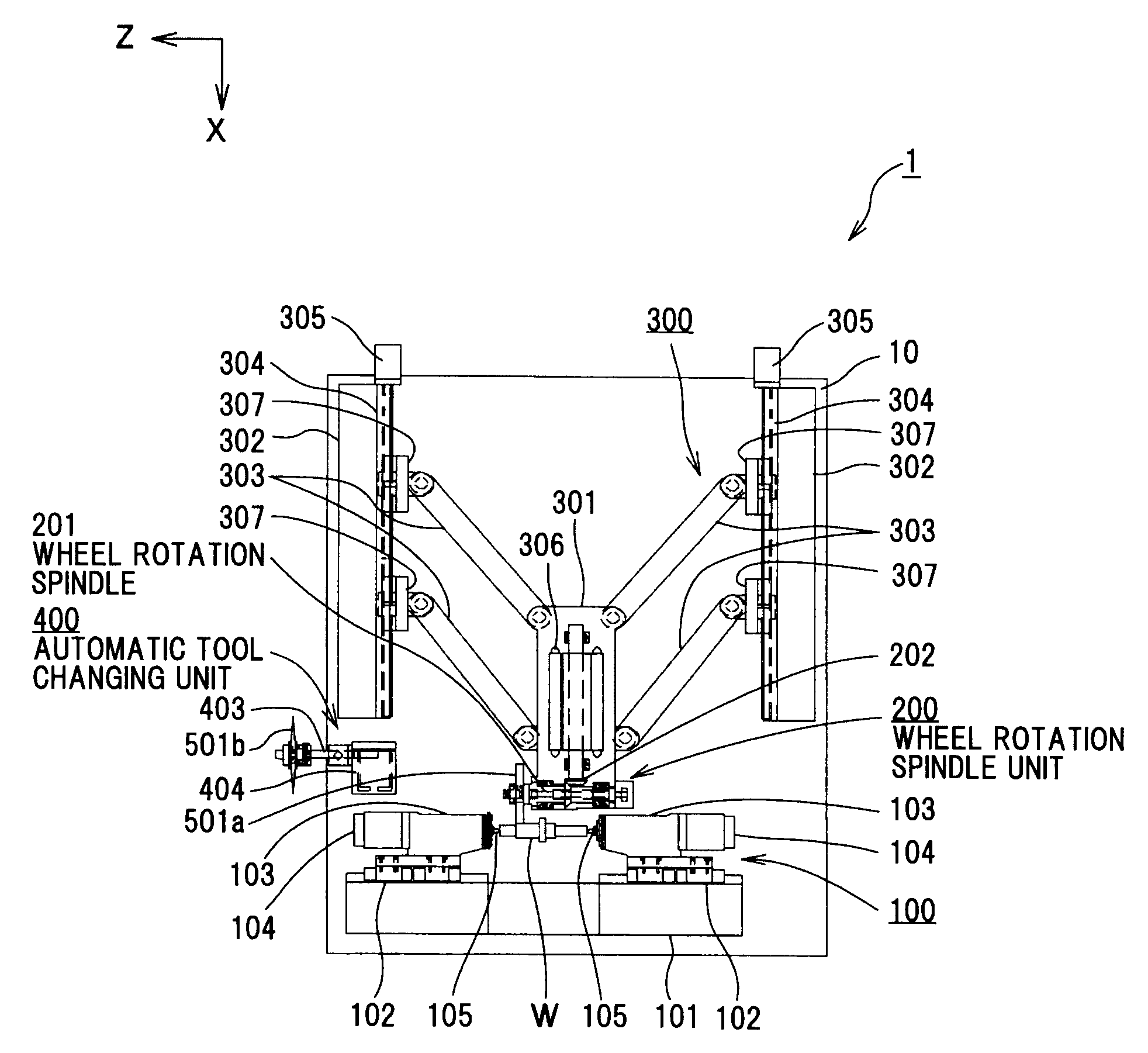

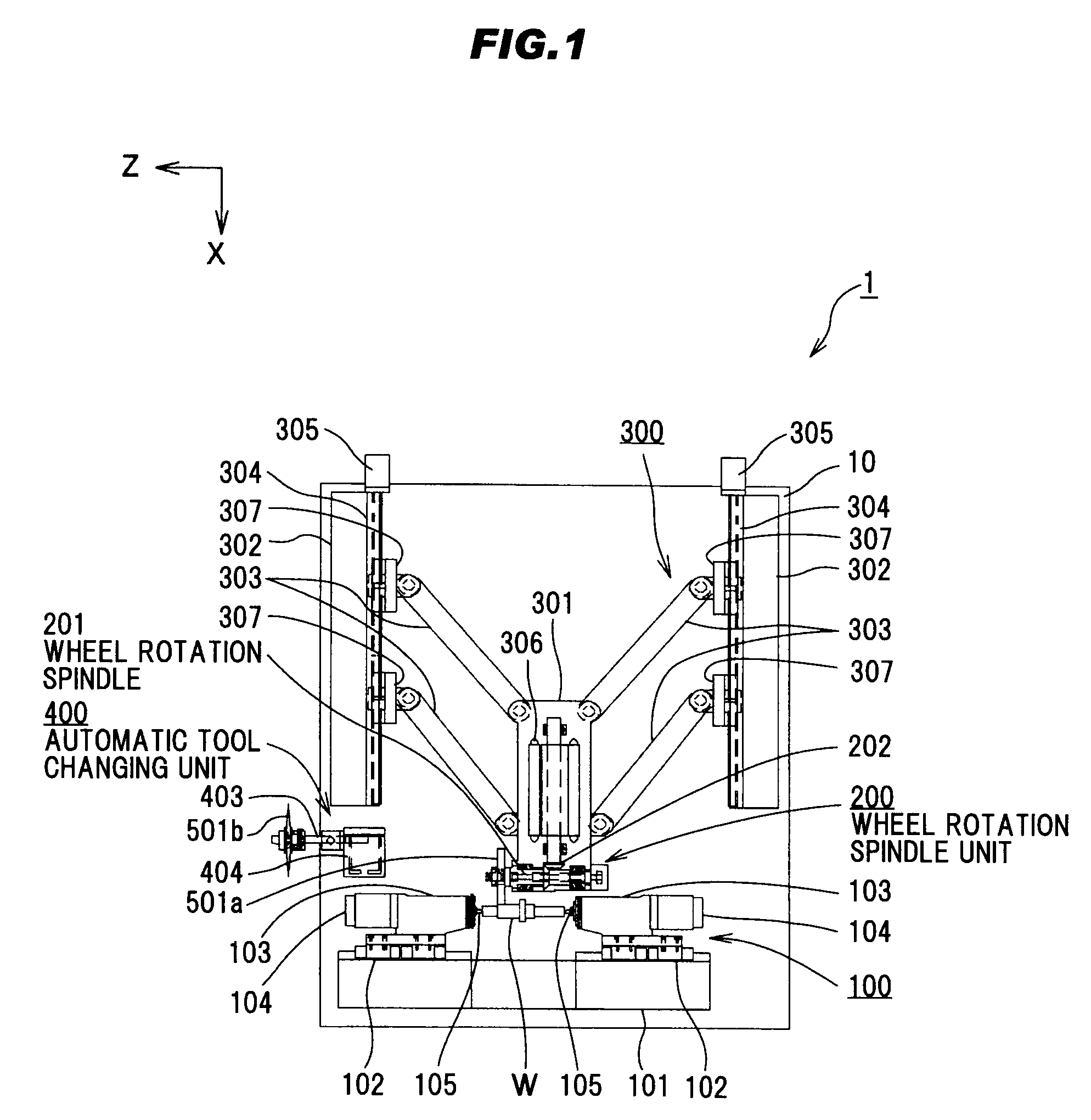

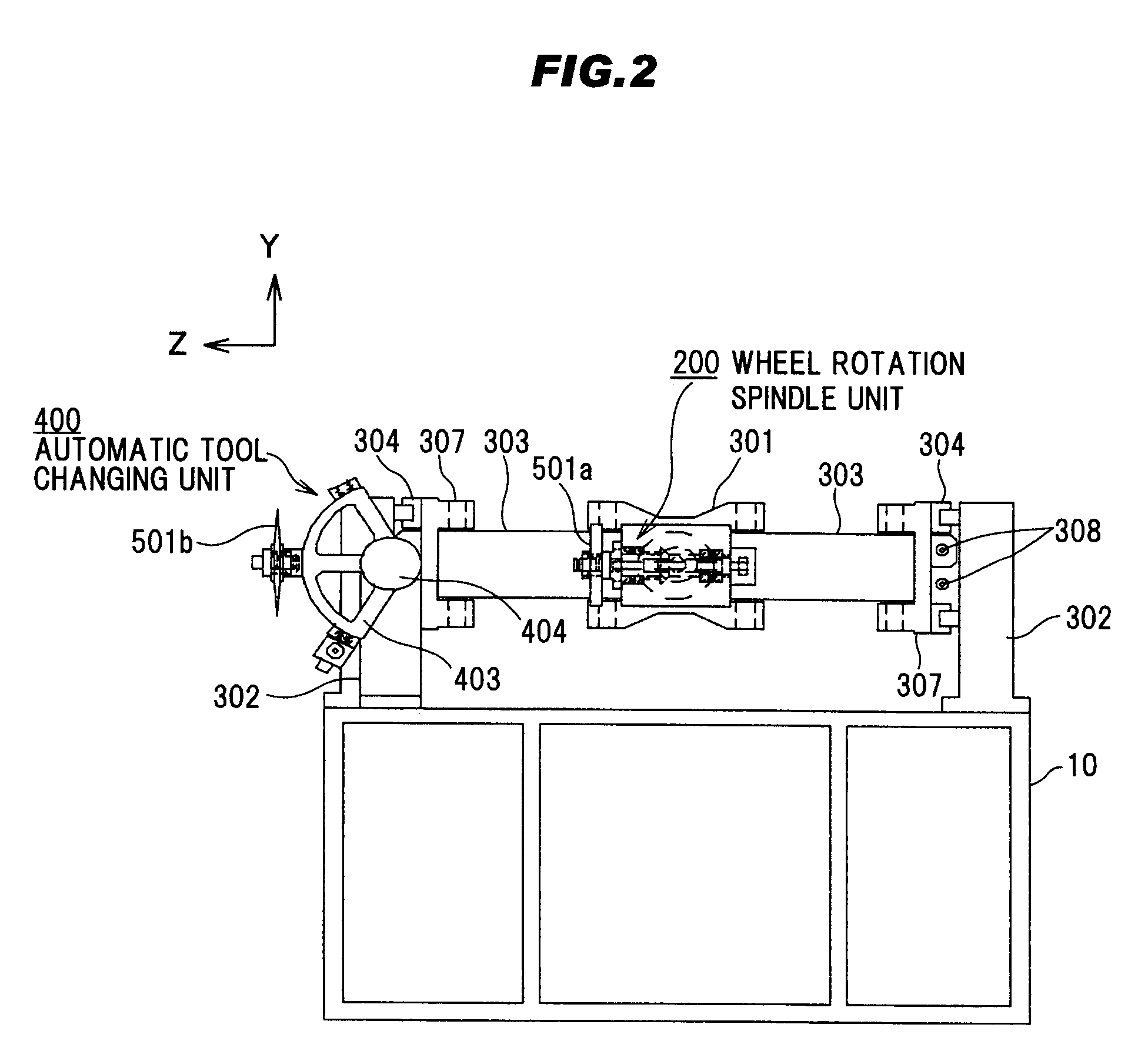

Machine tool and control method therefor

InactiveUS20080214374A1Short timeGrinding machine componentsPrecision positioning equipmentMachine toolEngineering

A machine tool includes a wheel rotation spindle supported rotatably for holding a tool for processing a work by rotation; a tool changing unit for exchanging a tool provided at a predetermined position for the tool held on the side of the wheel rotation spindle; a rotation balance adjustment device for adjusting the balance due to the rotation of the wheel rotation spindle; a tool information memory section for storing the tool information including the balance data of the tool held on the side of the wheel rotation spindle; and a control section for actuating the rotation balance adjustment device on the basis of the tool information of the tool held on the wheel rotation spindle stored in the tool information memory section thereby to implement the control of the rotation balance adjustment.

Owner:JTEKT CORP

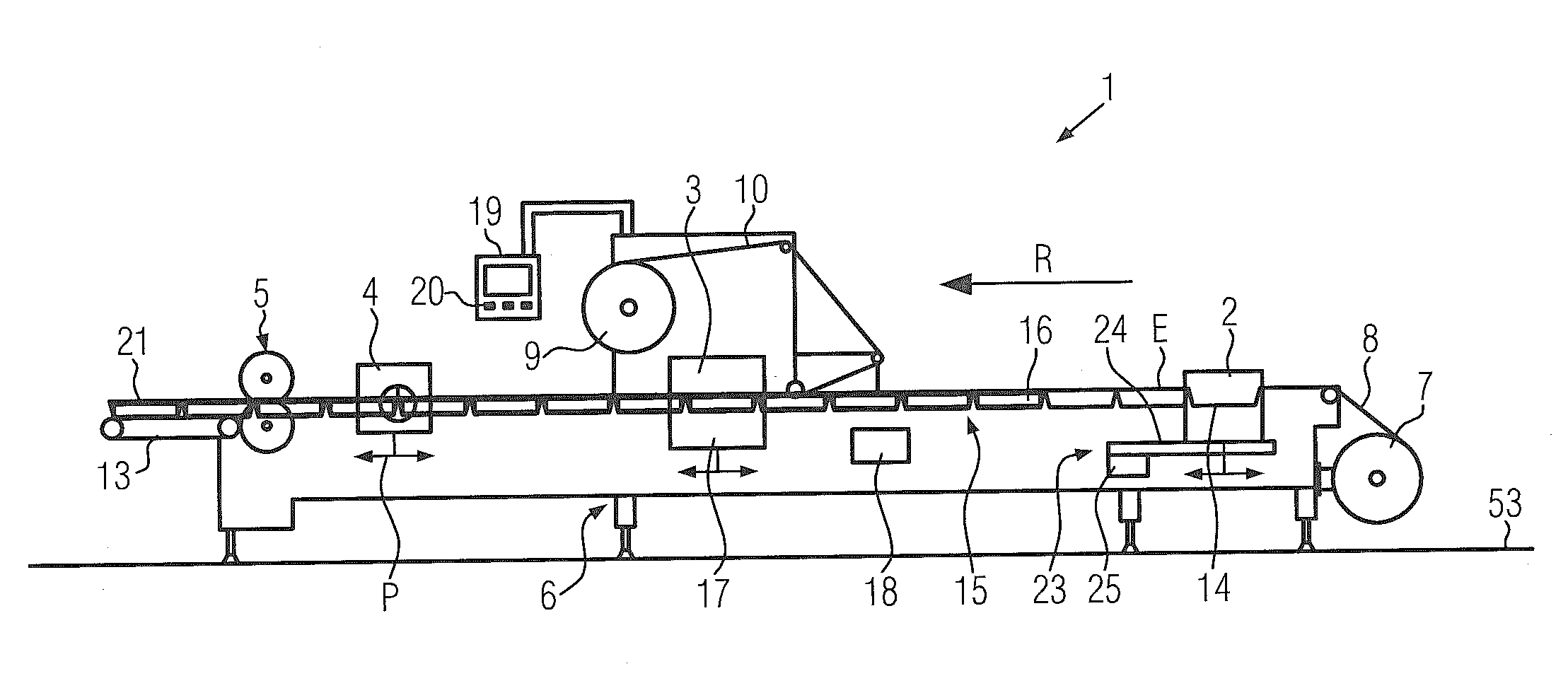

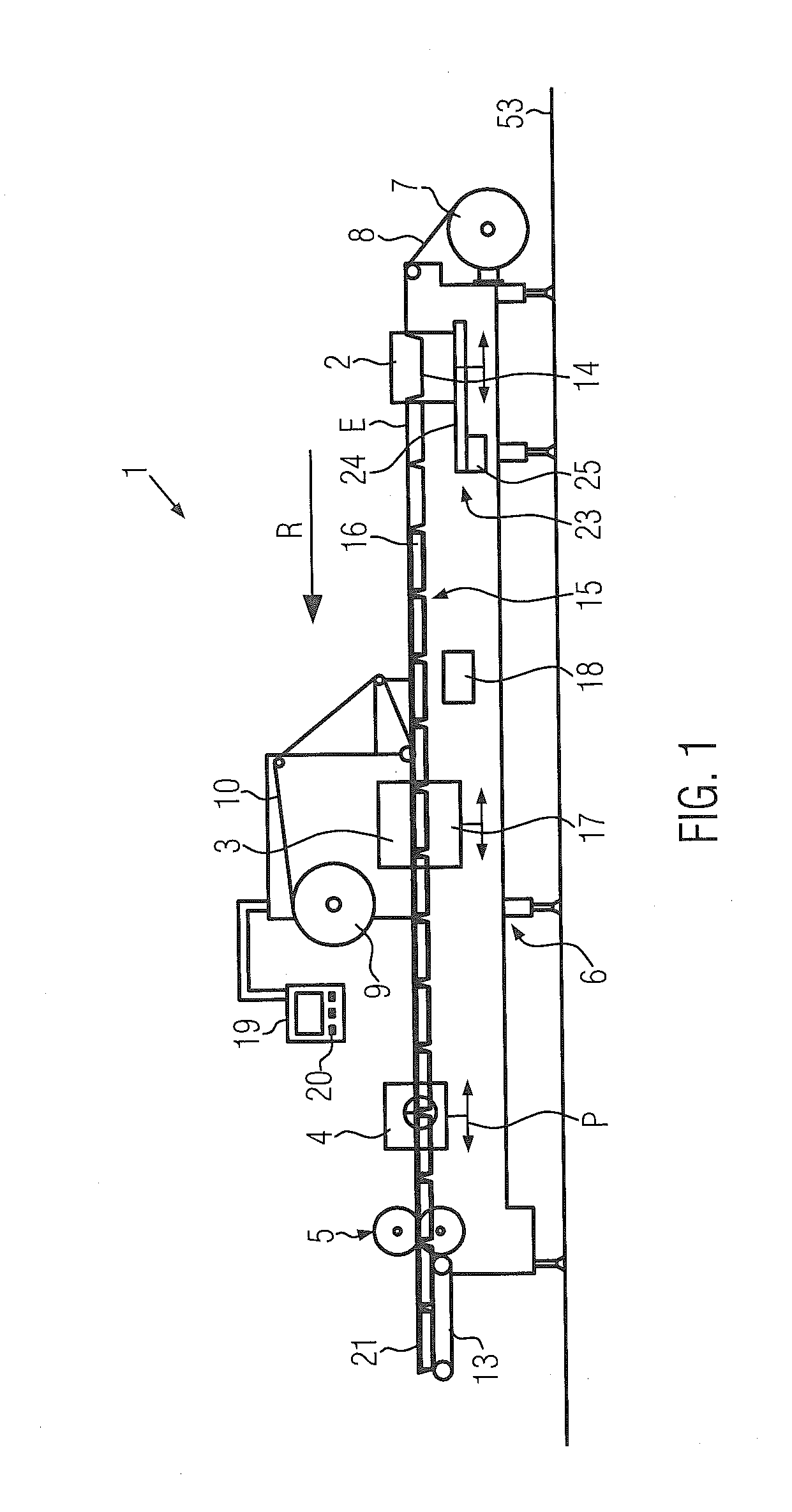

Work station for a packaging machine and tool changing method

ActiveUS9248929B2Simple structural designReduce the amount requiredShaping toolsPrecision positioning equipmentCouplingEngineering

The present invention relates to a work station for a packaging machine, comprising an upper tool and a lower tool arranged below the upper tool. These tools are configured for acting on a packaging web. A lifting unit is able to move the upper tool and / or the lower tool such that, at a specific position, the two tools abut on one another or are only spaced apart at a small distance. According to the present invention, the two tools are adapted to be coupled to one another by a releasable coupling at this position so that they can be removed from the work station in common. The invention also relates to a corresponding method for removing a lower tool from a work station, e.g. for the purpose of tool exchange.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Thermal displacement correcting device

InactiveUS7354386B2Improve accuracyEliminate needAutomatic control devicesPrecision positioning equipmentLapse timeExecution unit

Machine-tool thermal displacement correcting device having: a tool-temperature estimating unit for recognizing—based on identification data obtained from a controller for designating, out of tools stowed in the tool-changer tool magazine, an exchange-target tool—the directly-after-use temperature of the ID'd tool, and estimating the tool temperature directly before use, based on the recognized directly-after-use tool temperature and on lapsed time, obtained from the controller, since previous use of the ID'd tool, and for estimating, based on the estimated directly-before-use tool temperature and on the spindle temperature, during-use temperature of the tool; a correction determining unit for estimating, based on the estimated during-use tool temperature, axial thermal displacement of the tool, and determining a correction amount for canceling out the displacement; and a correction executing unit for carrying out correction based on the determined correction amount.

Owner:DMG MORI CO LTD

Multi-tool adaptor

Owner:WILSON TOOL INT

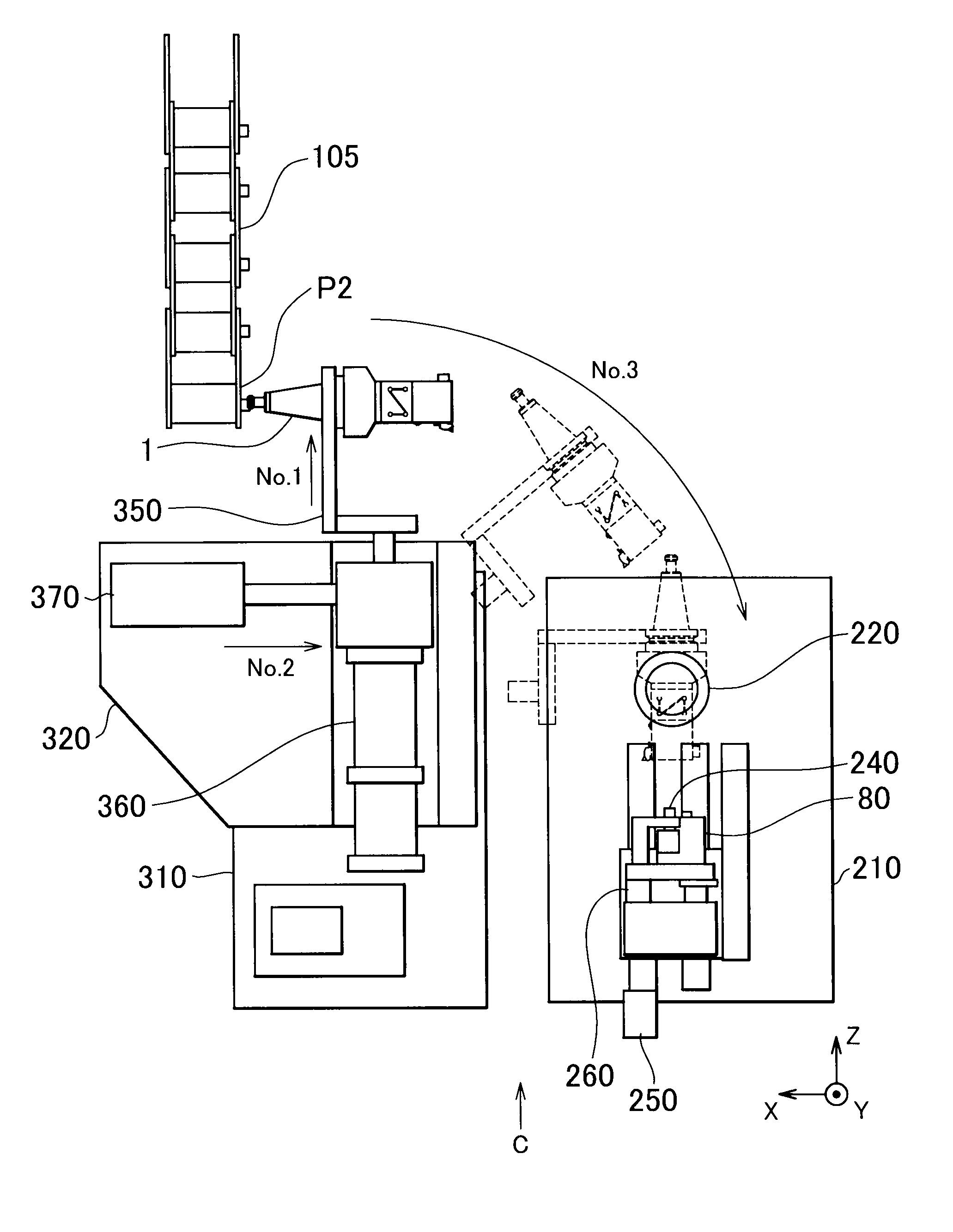

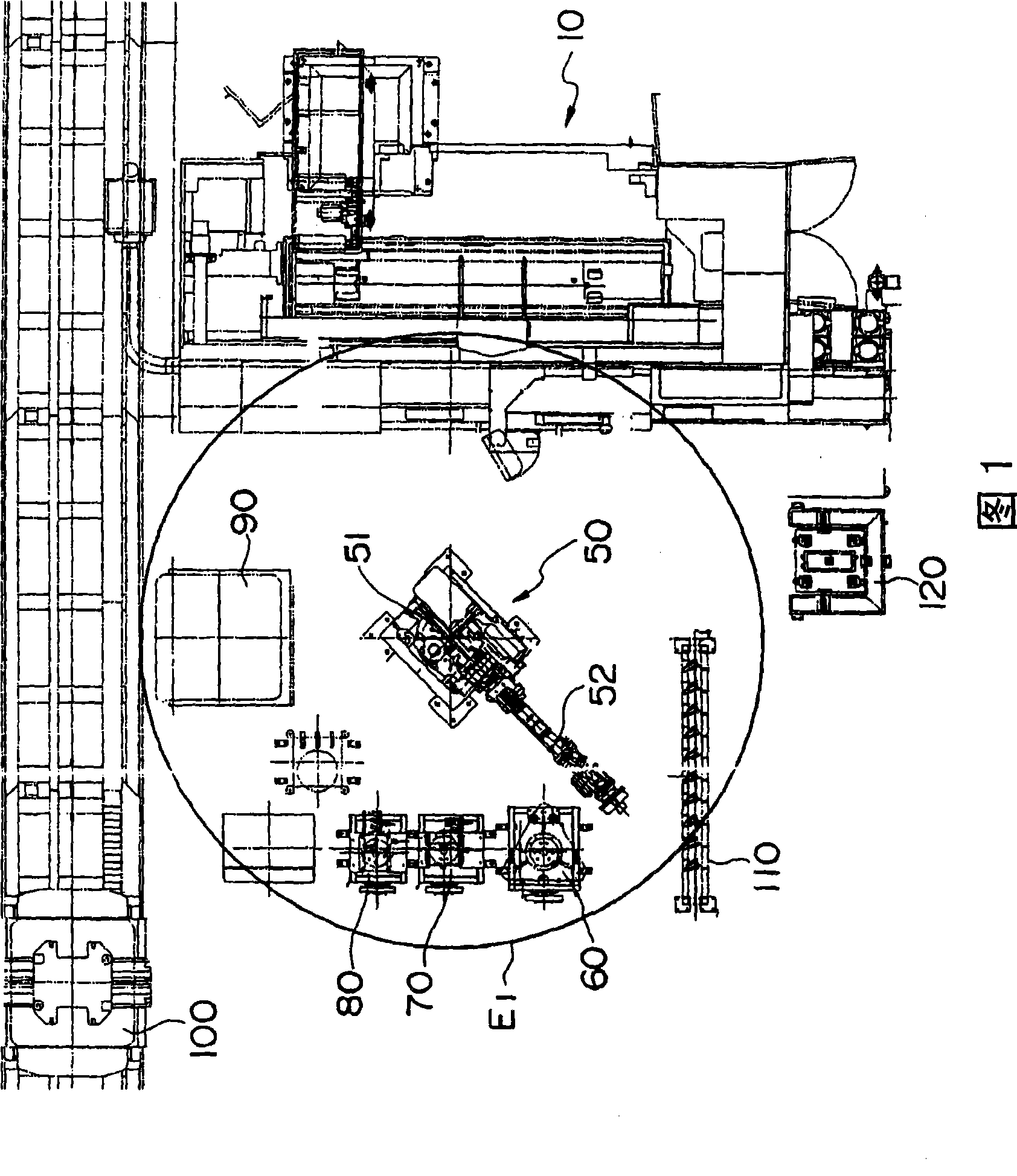

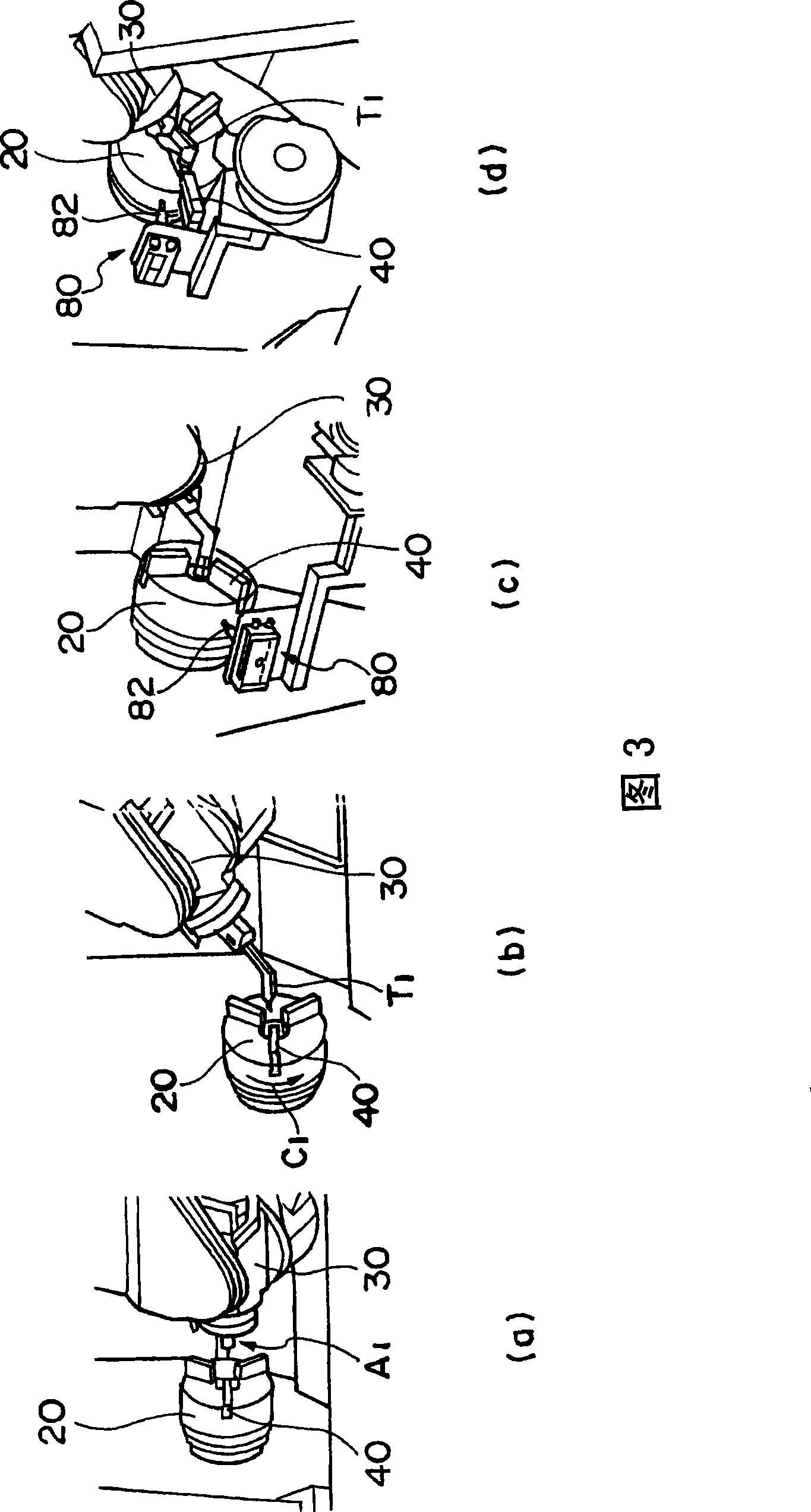

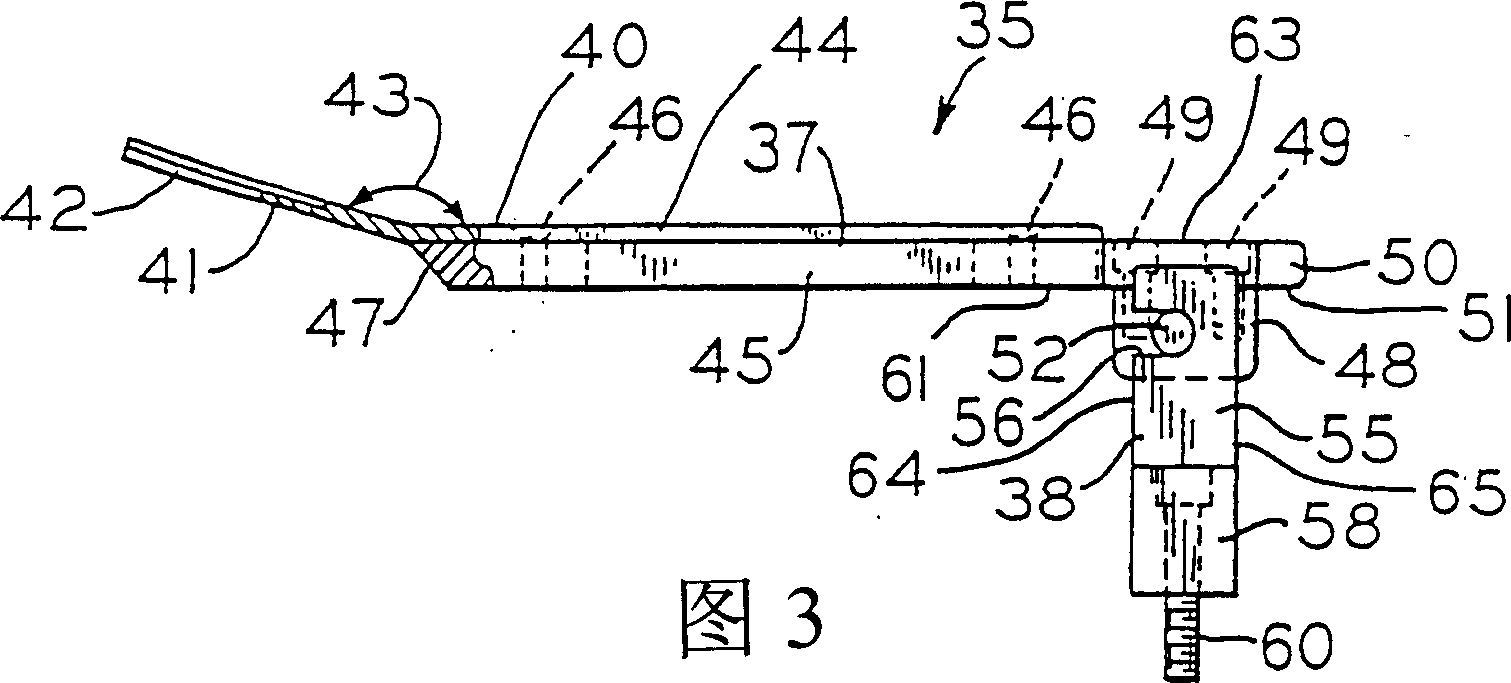

Automatic chuck jaw change system in combined machining lathe

ActiveCN101444848AAutomatic replacementAutomated cleaningLathesSleeve/socket jointsEngineeringMachining

In an automatic chuck jaw change system, a combined machining lathe capable of positioning with high precision and a robot with lower positioning precision than the combined machining lathe cooperate to automatically change a chuck jaw. The system includes a robot (50) disposed in front of the combined machining lathe, and the robot (50) can be selectively mounted on a front end of an arm (52) thereof with a work hand for operating a work (60), a chuck jaw (70), and a nut runner hand (80) for operating a drive mechanism of the chuck. The robot cooperates with a tool for jaw mounted on a tool spindle of the combined machining lathe to automatically change a chuck jaw of a main spindle.

Owner:YAMAZAKI MAZAK KK

Tool changing device which prevents chips adhering to tool

A tool changing device of a machine tool which prevents chips adhering to a tool. By using a drive motor with which a tool changing device of the machine tool is usually provided, to vibrate the tool, the chips are prevented from adhering to the tool, especially to a tapered portion of the tool, and / or the chips adhered to the tool are removed, without using any additional device.

Owner:FANUC LTD

Floating tool changer for an automobile

InactiveUS20010016545A1Easy to useImprove operationPrecision positioning equipmentGripping headsProduction rateAssembly line

The present invention relates to a floating tool changer for an automobile and more particularly, to a floating tool changer for an automobile which can set at least two different floating tools simultaneously and exchange a socket portion of the floating tool by using a desirable grip means automatically so that the floating tool changer is applicable to in assembly lines for variety kinds of automobiles and thus, a productivity and an operation efficiency can be enhanced.

Owner:HYUNDAI MOTOR CO LTD

Machine tool

This machine tool is provided with: a partition that partitions a machining chamber and a tool storage chamber and that has an opening; a shutter; and a receiving member that is formed so as to receive cutting fluid. The partition includes a sidewall member that extends in the vertical direction and an inclined wall member inclined in such a manner so as to become lower from the sidewall member to the interior of the machining chamber. At least part of the opening is formed in the inclined wall member. The receiving member is positioned beneath the shutter, and in such a position so as to receive cutting fluid that drops down along the sidewall member when the shutter is opened.

Owner:MAKINO MILLING MASCH CO LTD

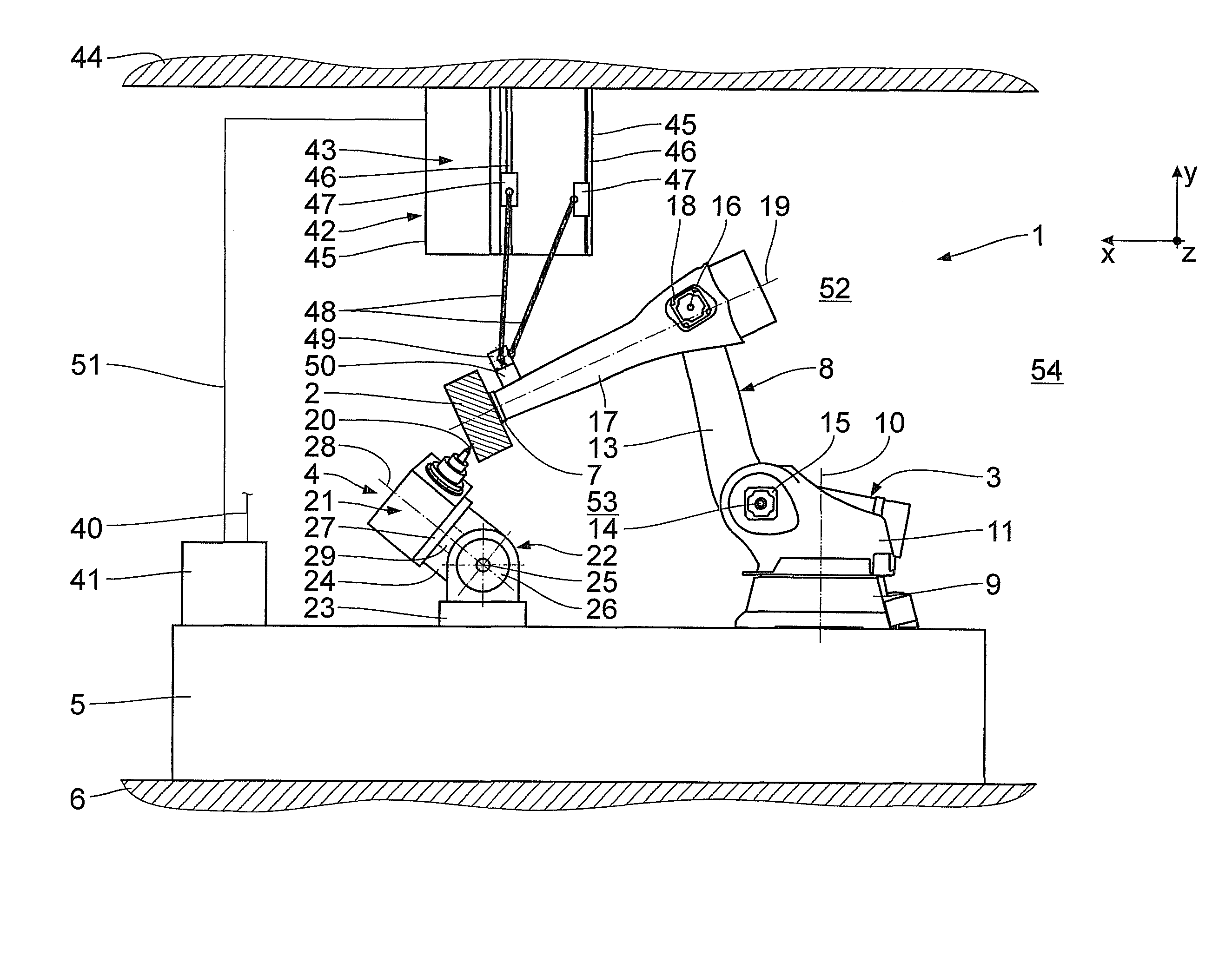

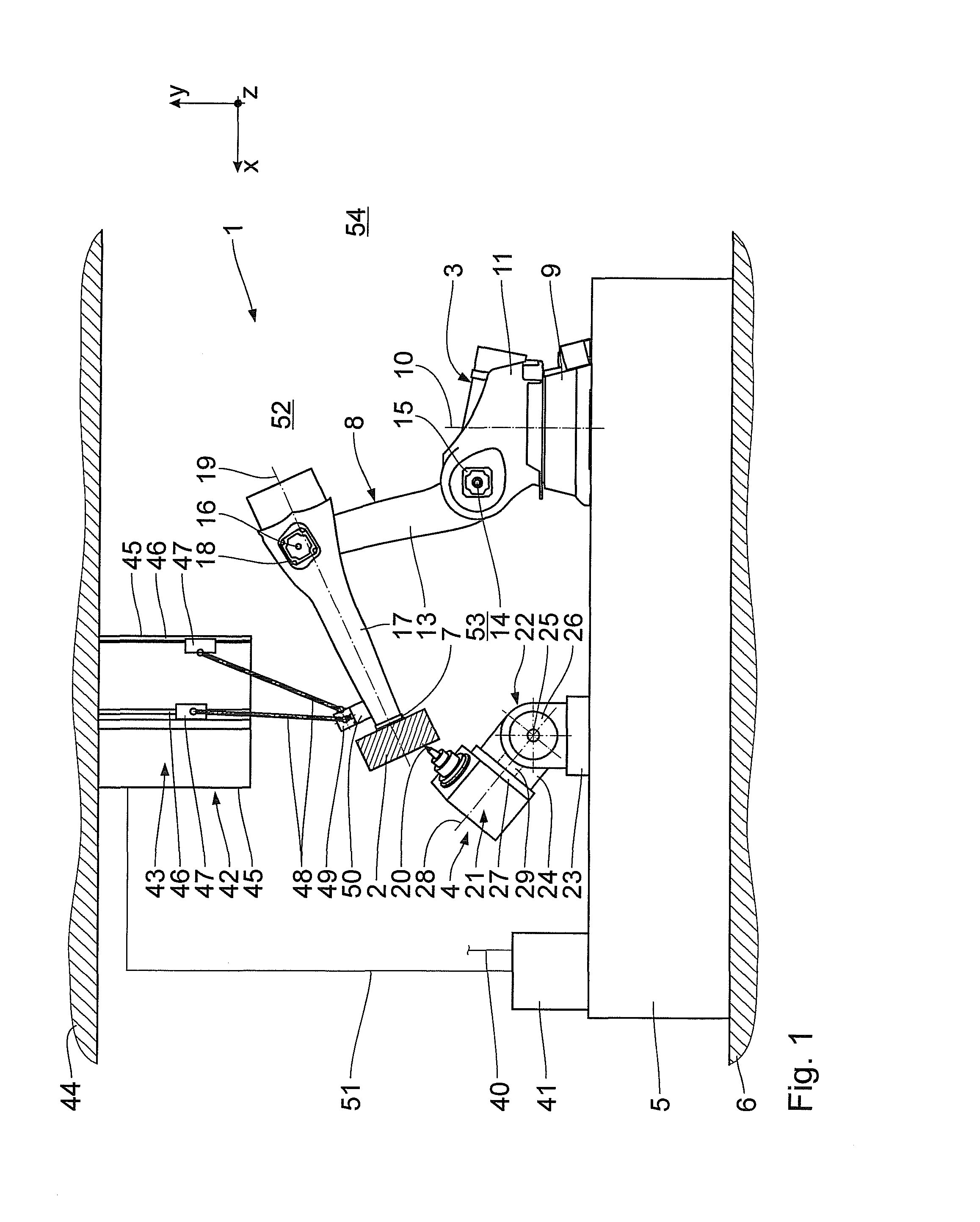

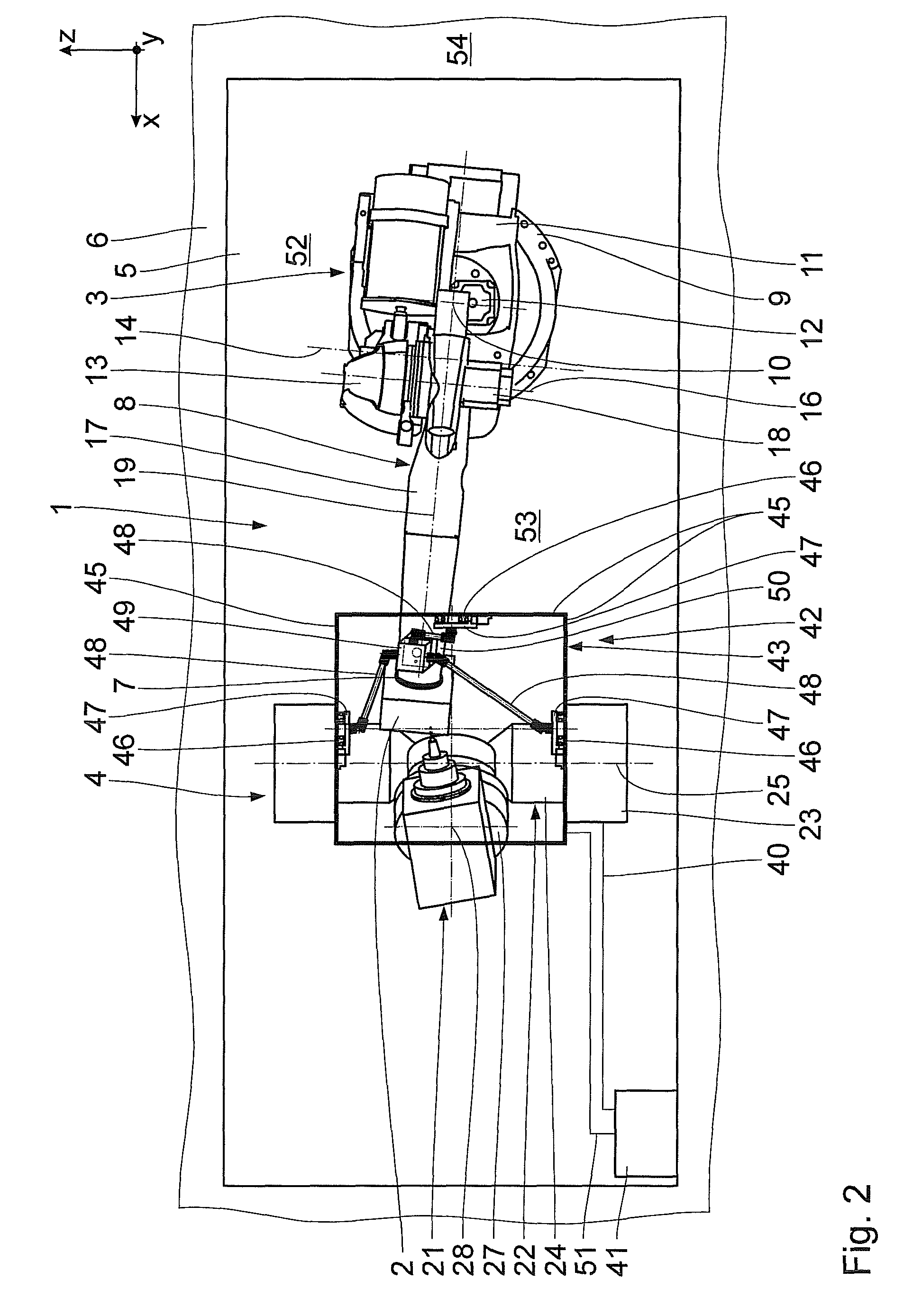

Machining installation for workpieces

InactiveUS8694150B2Simple designFlexible and accurate machiningProgramme-controlled manipulatorGrinding drivesMachiningTool holder

A machining installation for workpieces comprises a workpiece positioning device comprising a workpiece holder pivot unit as well as a tool positioning device comprising a tool holder pivot unit. The workpiece holder pivot unit is designed such that a workpiece holder is pivotable about at least three and no more than four workpiece holder pivot axes. Moreover, the tool holder pivot unit is designed such that a tool holder is pivotable about no more than two tool holder pivot axes. The machining installation has a simple design and ensures flexible and accurate machining of workpieces.

Owner:MAG IAS

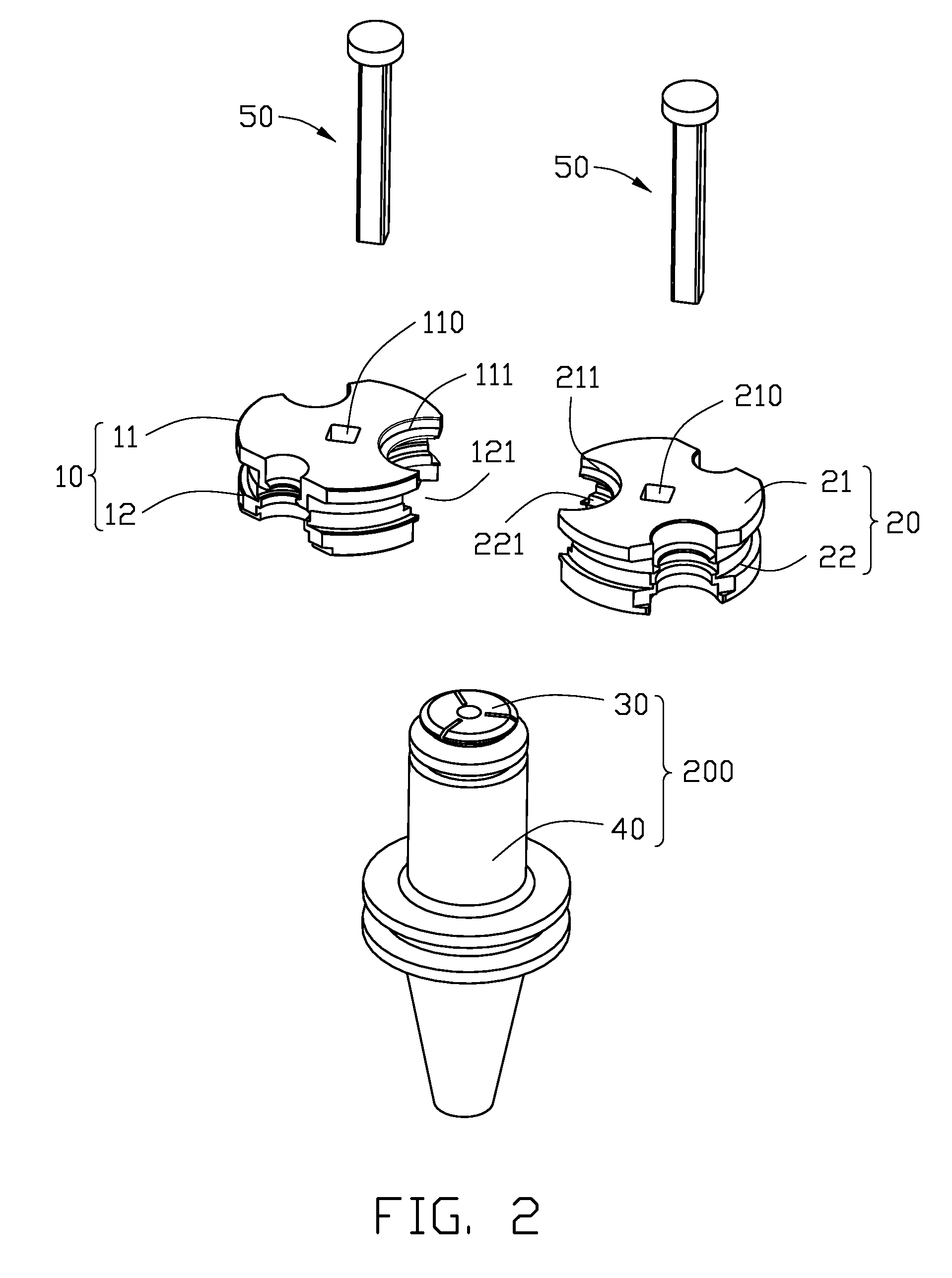

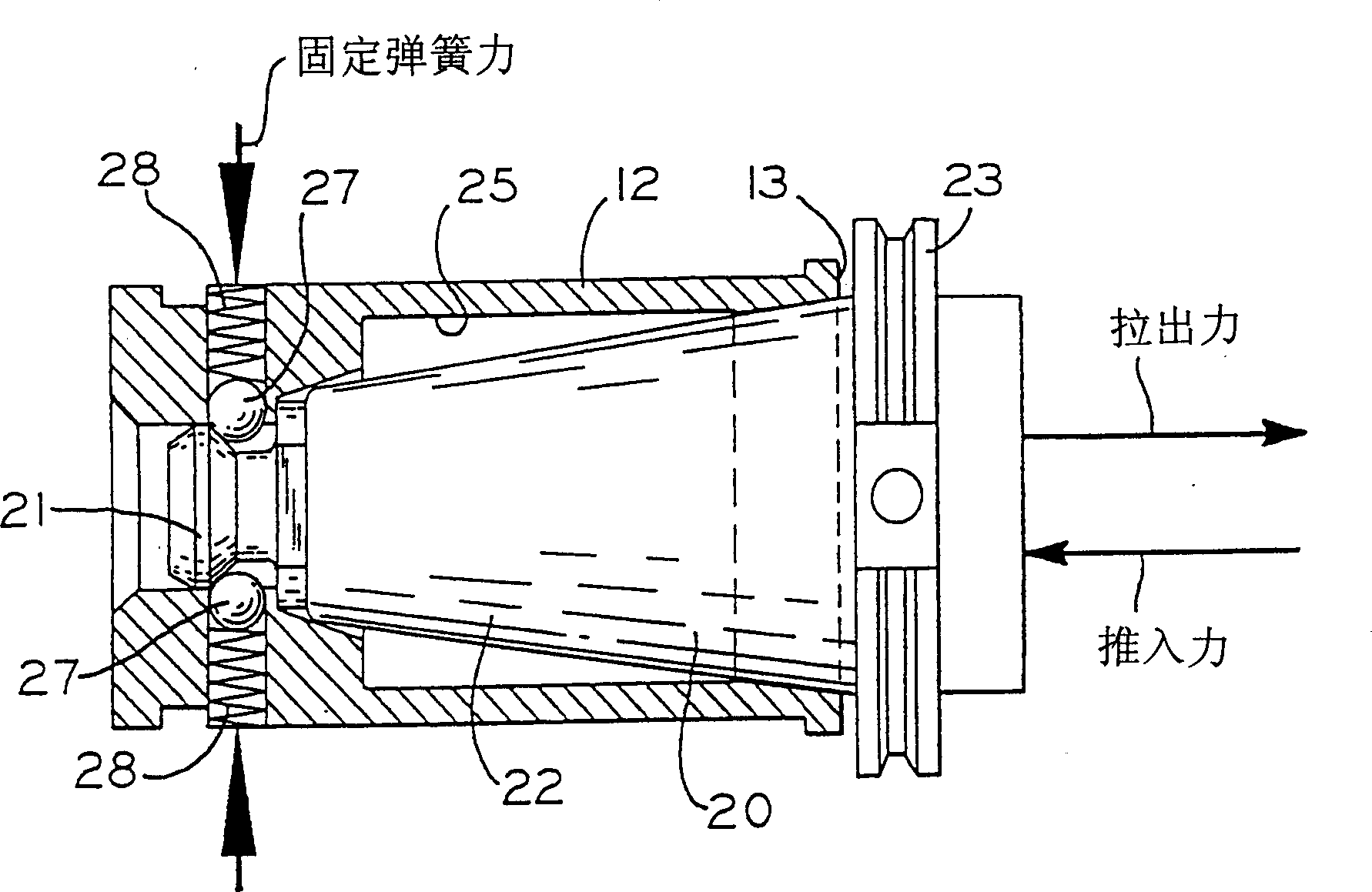

Pressing device for latching and releasing chucking device

InactiveUS20080290614A1Sleeve/socket jointsPrecision positioning equipmentMechanical engineeringEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

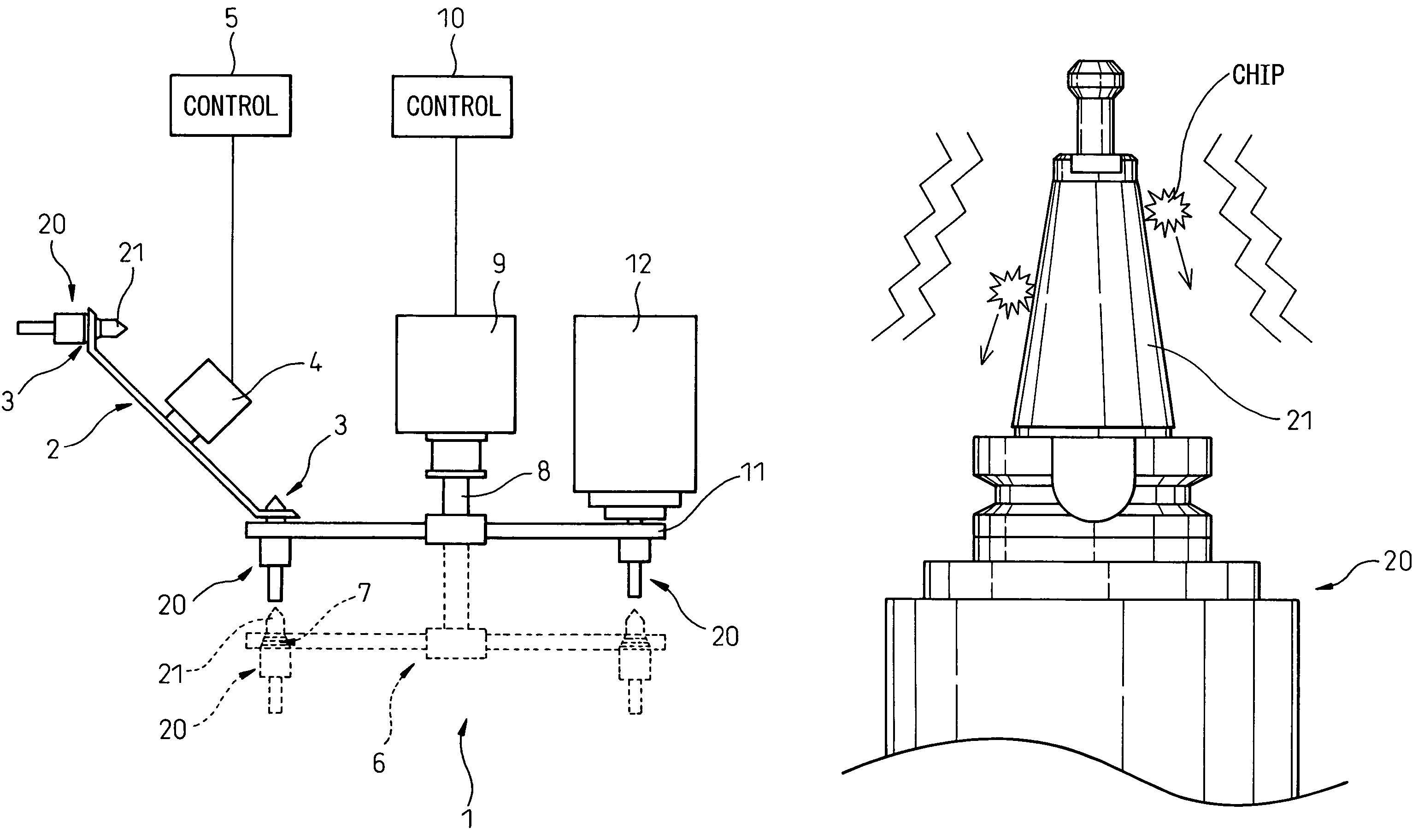

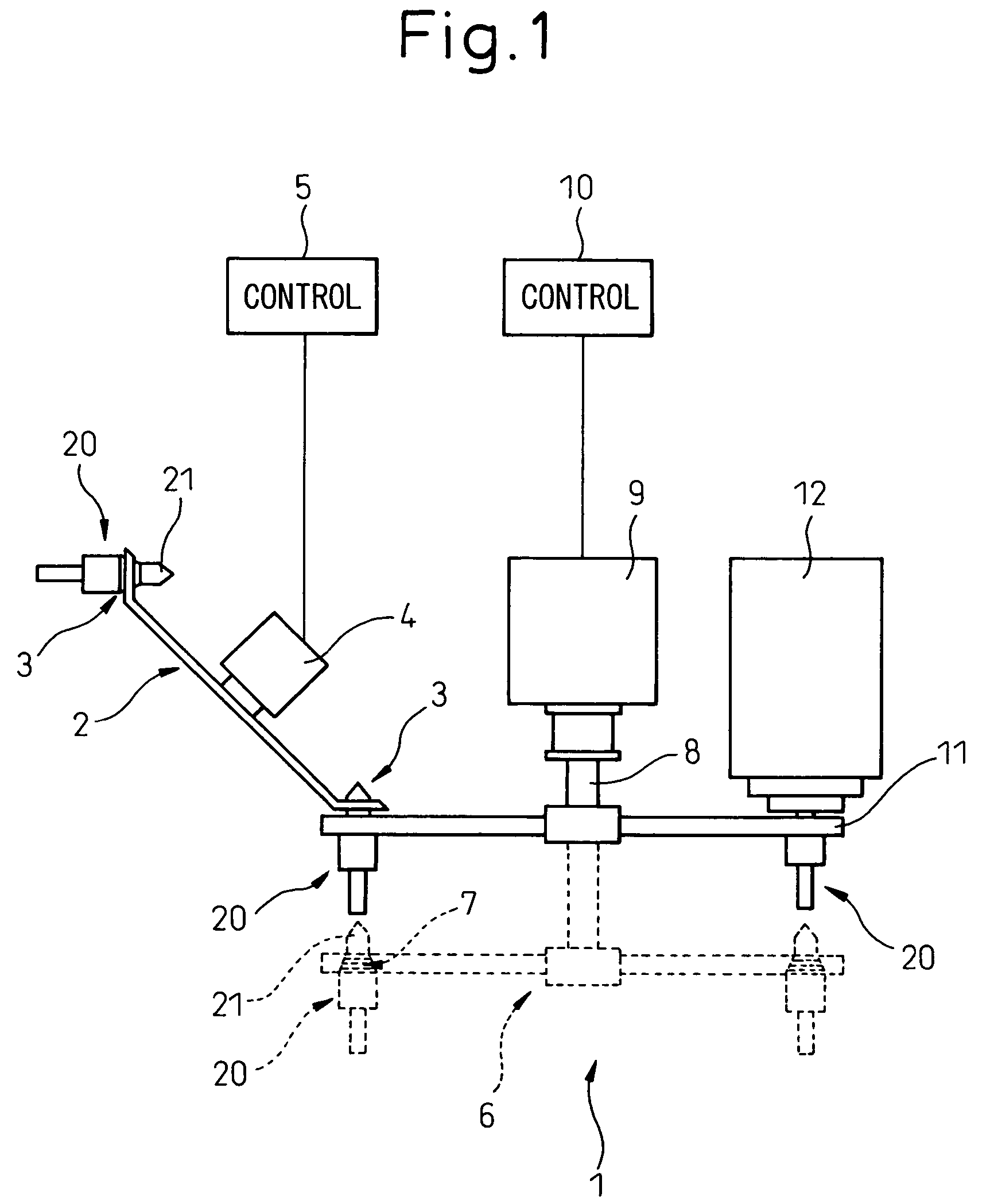

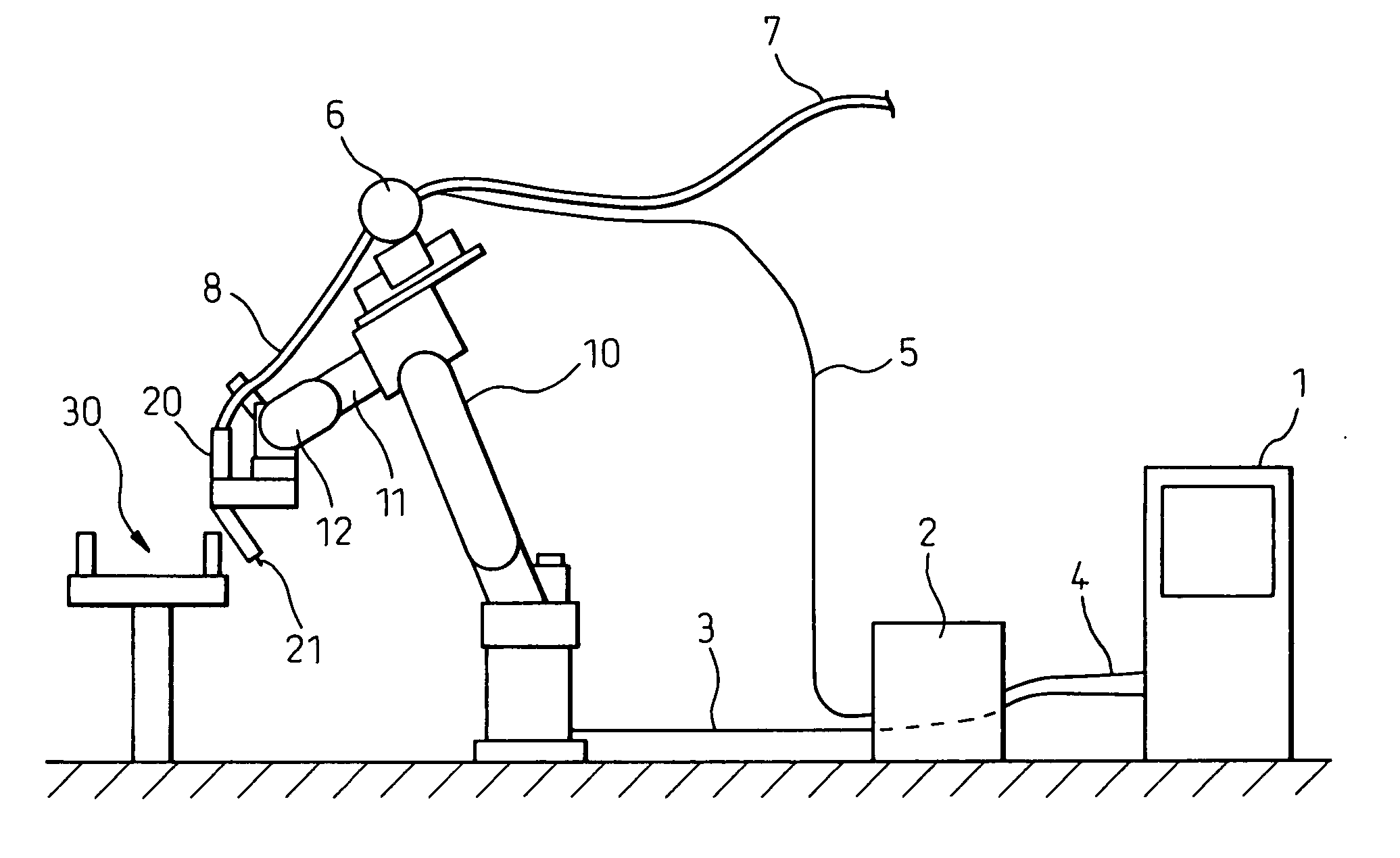

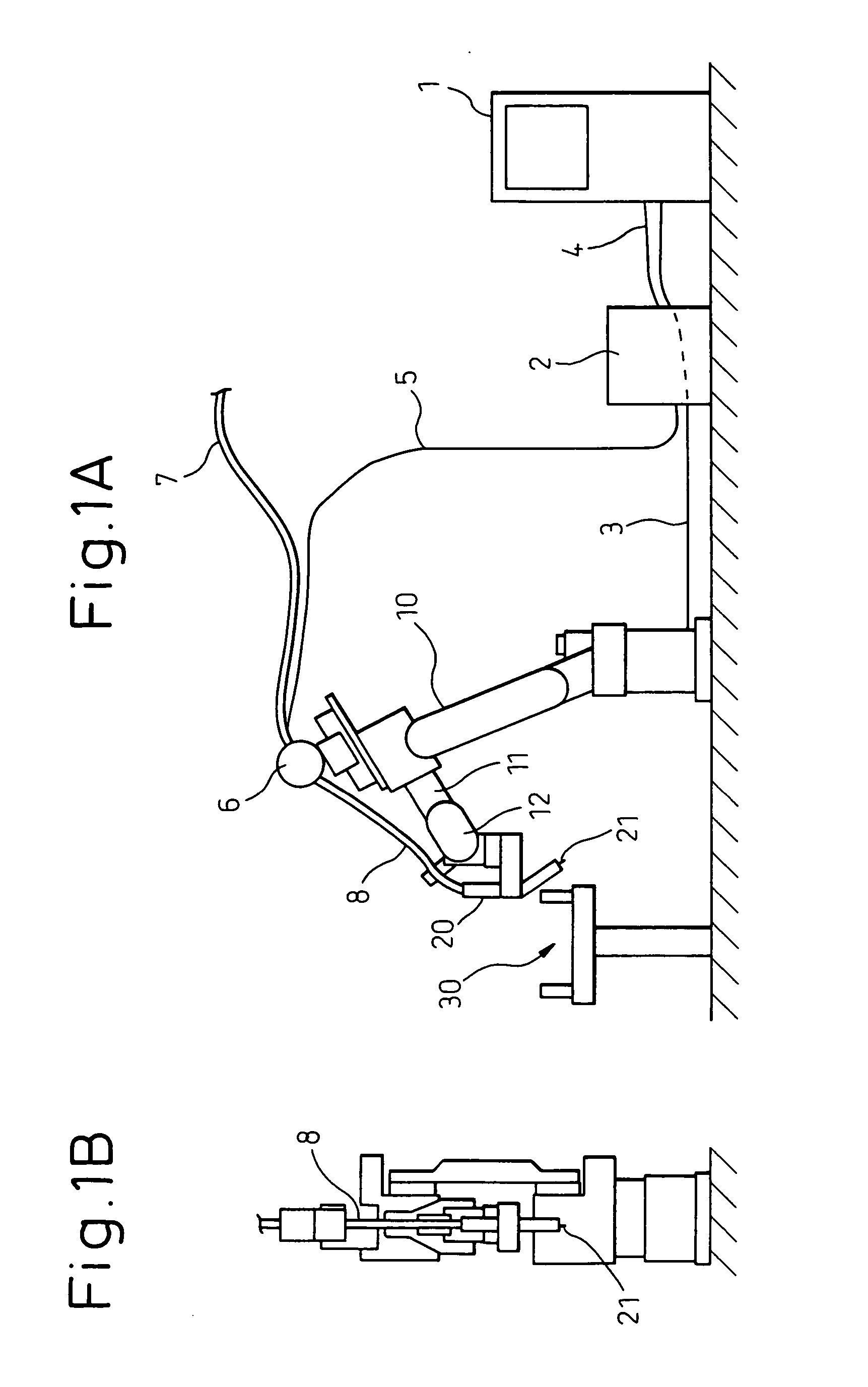

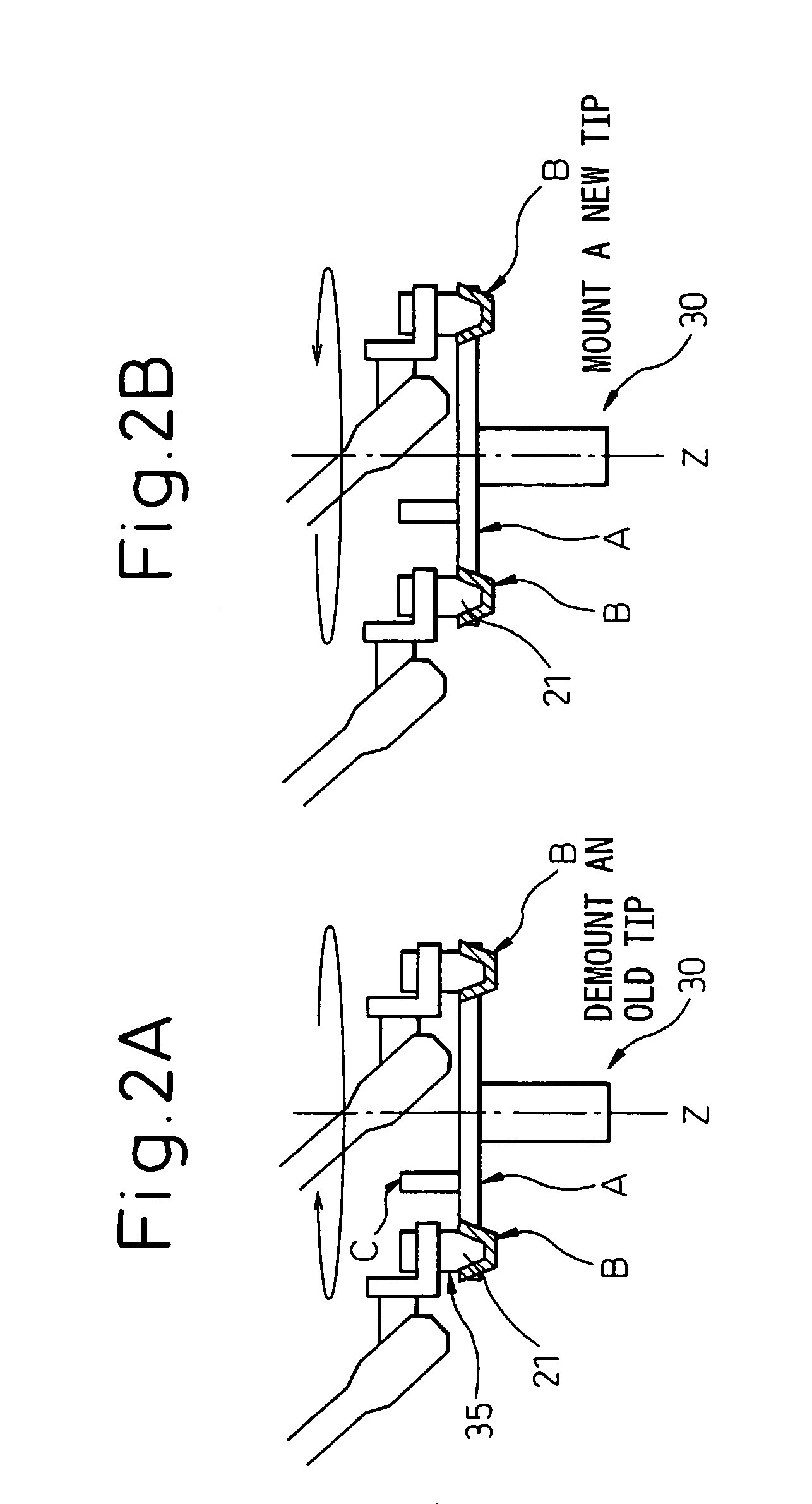

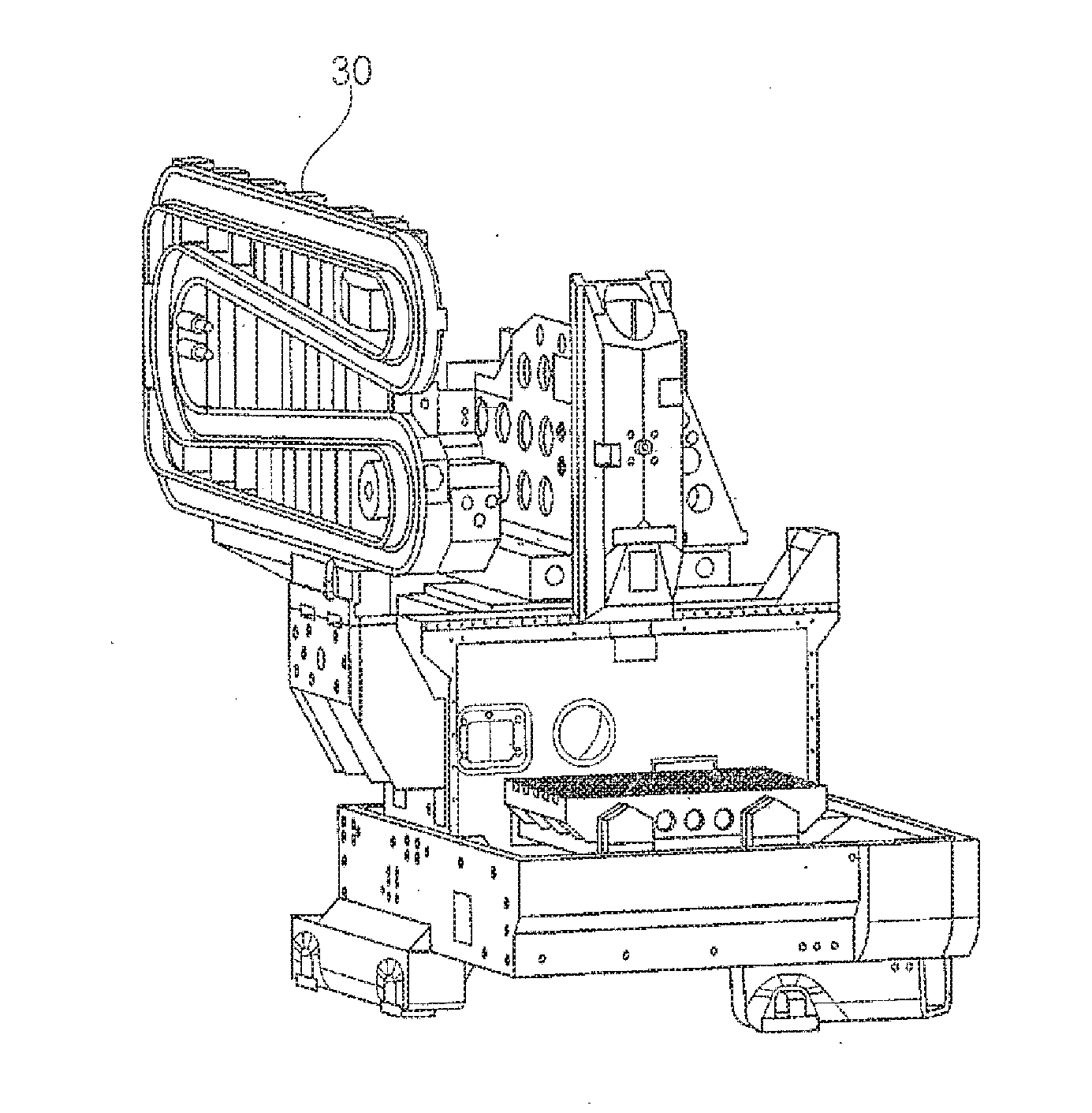

Apparatus for automatically changing a robot tool tip member

ActiveUS20060240961A1Additional running costMinimum setup stepPrecision positioning equipmentWeld torches cleaningCentre of rotationEngineering

An apparatus for automatically changing a tool tip member for a robot includes a tip member changing jig disposed in an operational area of the robot. The tip member changing jig includes a base member, a rotating member supported by the base member so as to be rotatable about a rotation axis, and tip member holding means disposed at positions that are offset from the rotation axis of the rotating member. The tip member holding means holds the tool tip member so that a central axis of relative rotation, for threadedly mounting or demounting the tool tip member on or from the tool body, extends substantially parallel to the rotation axis of the rotating member and so that rotation of the tool tip member, with respect to the rotating member, is locked.

Owner:FANUC LTD

Manual tool changing apparatus

A manually operated apparatus for removal and insertion of a tool holder to and from a tool pocket of a magazine includes two components-a multi-function insertion / removal tool, and a pivot bracket. The multi-function tool generally comprises an elongated bar having a tool holder removal element at one end and an insertion element at the opposite end. The removal element can constitute a known pry tool having a fork portion configured to facilitate insertion between the rim of the tool pocket and the underside of the circumferential flange of the tool holder. The insertion element of the multi-function insertion / removal tool comprises a pivot block and a pressure plate. The pivot block includes a pivot pin projecting therefrom that is configured for pivoting engagement within a channel defined in the pivot bracket. The pivot bracket is mounted to the housing of the tool magazine at a manually accessible location relative to the tool pockets with the open end of the channel facing away from the tool pocket. When the pivot pin of the insertion / removal tool is disposed within the channel of the pivot bracket, the pressure plate is situated over a portion of the circumferential flange of the tool holder when the holder is loosely disposed within the tool pocket. The elongated bar of the tool can be used as a lever arm to pivot the tool about the fulcrum point defined by the pivot pin and pivot bracket. As the elongated bar is manipulated, the pressure plate is pivoted downward, bearing against the circumferential flange of the tool holder with sufficient force to overcome the pocket spring force operating against the knob of the tool holder.

Owner:HURCO

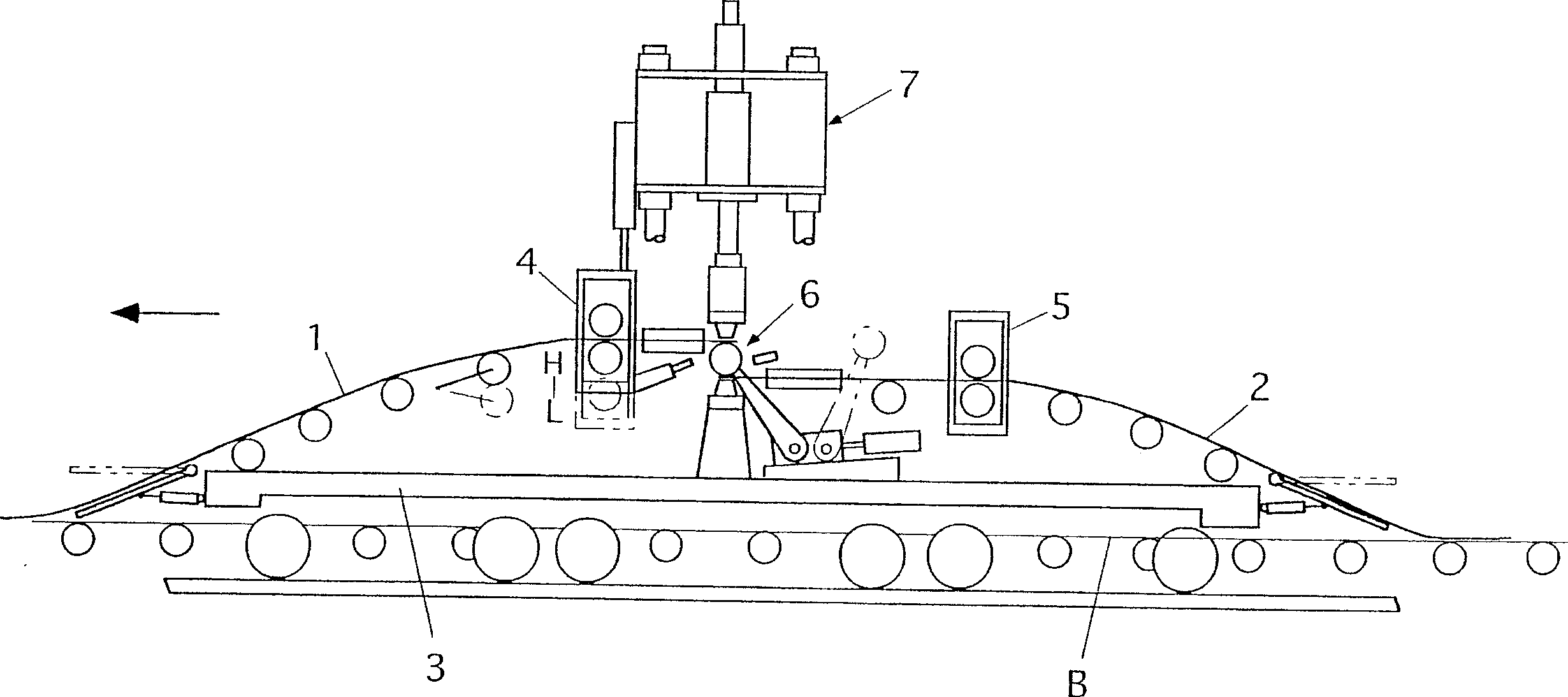

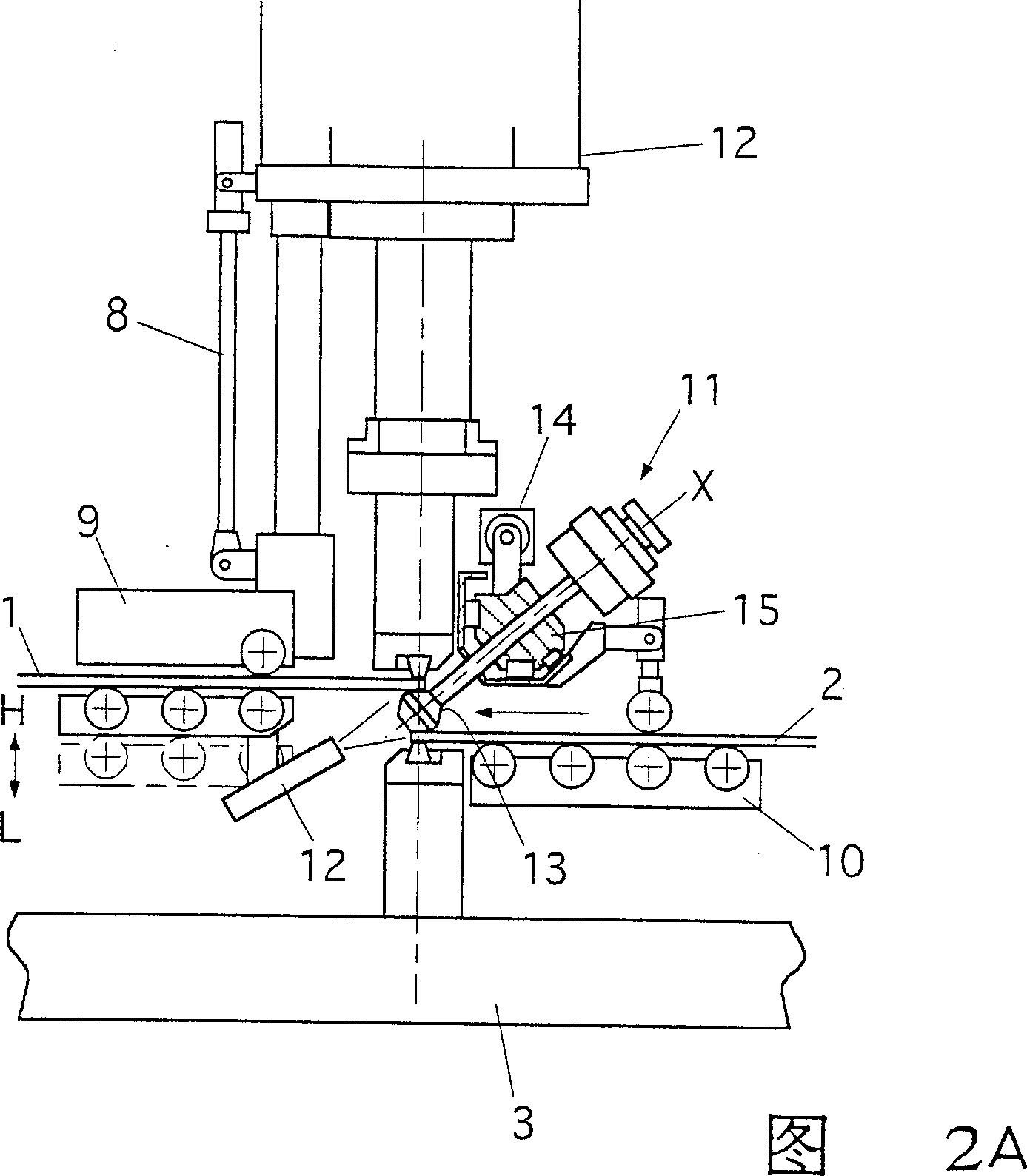

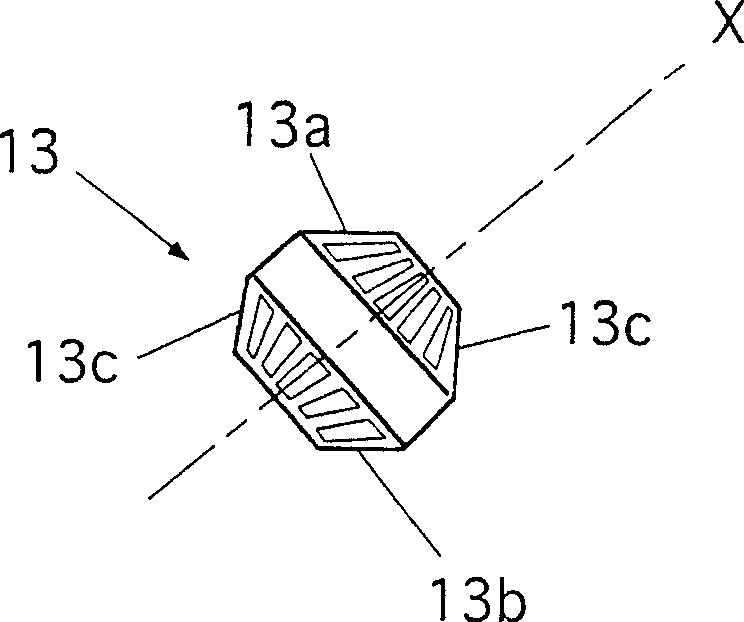

Chain link for a link chain and tool magazine with link chain

ActiveUS20160221137A1Large capacityImprove stabilityChain linksTool adjusterRotational axisEngineering

Owner:DECKEL MAHO SEEBACH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com