Automatic chuck jaw change system in combined machining lathe

A compound processing and automatic replacement technology, which is applied to tool changing devices, chucks, lathes, etc., can solve the problems of insufficient positioning accuracy and mechanical positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

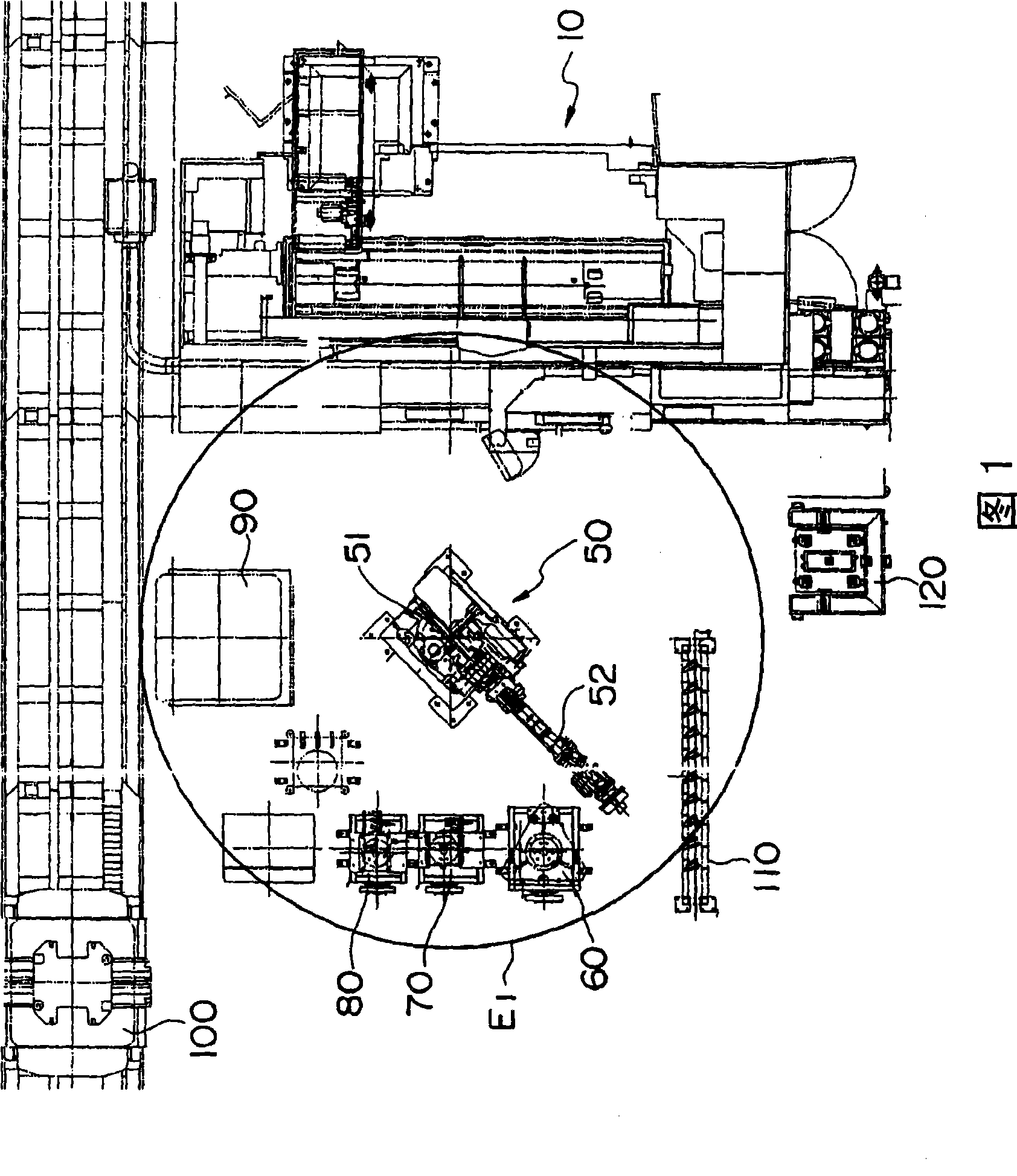

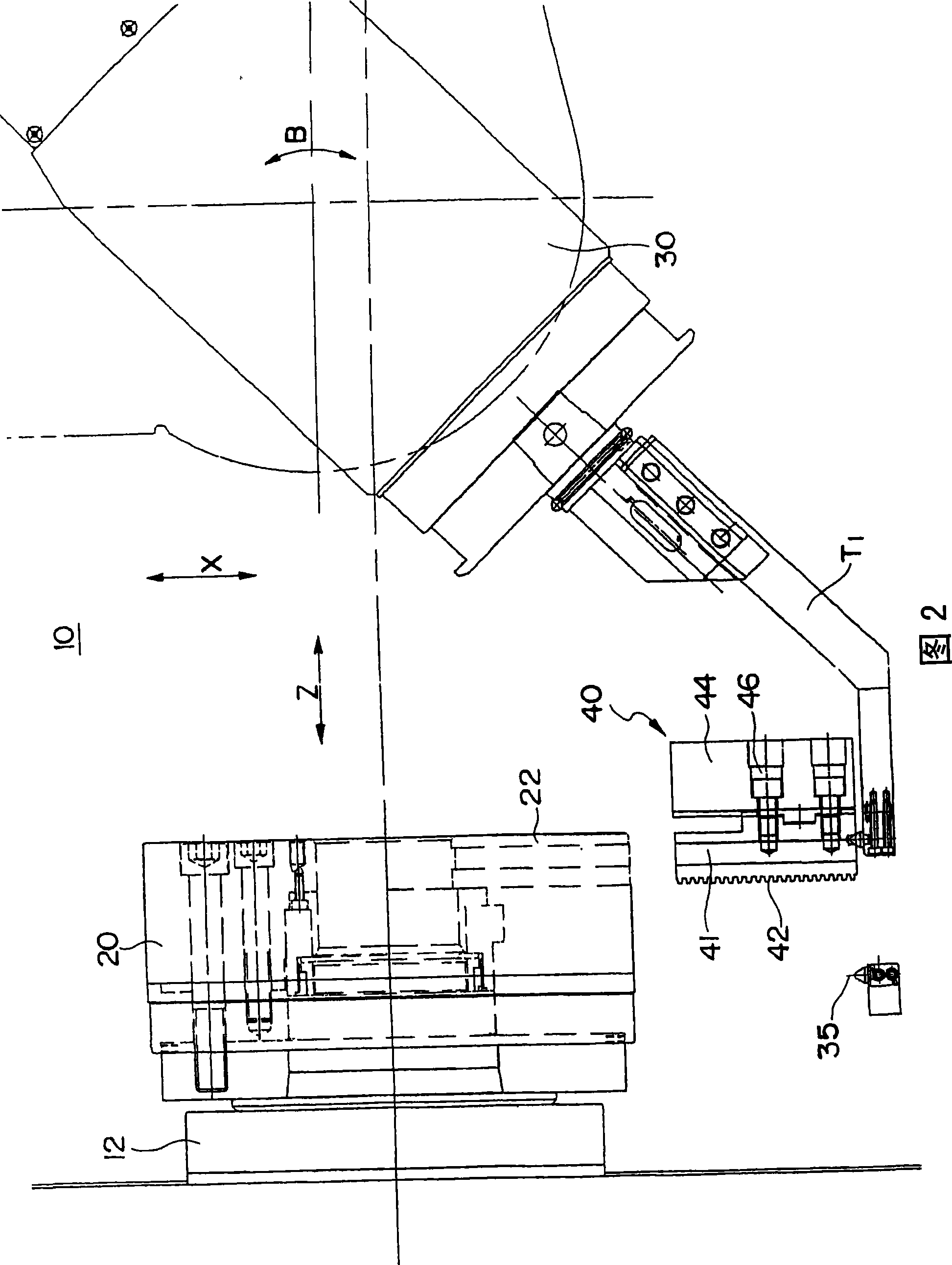

[0029] FIG. 1 is a plan view showing the overall configuration of a chuck jaw replacement system of a combined machining lathe according to the present invention.

[0030] This system has a multi-joint robot 50 equipped in front of a compound machining lathe 10 .

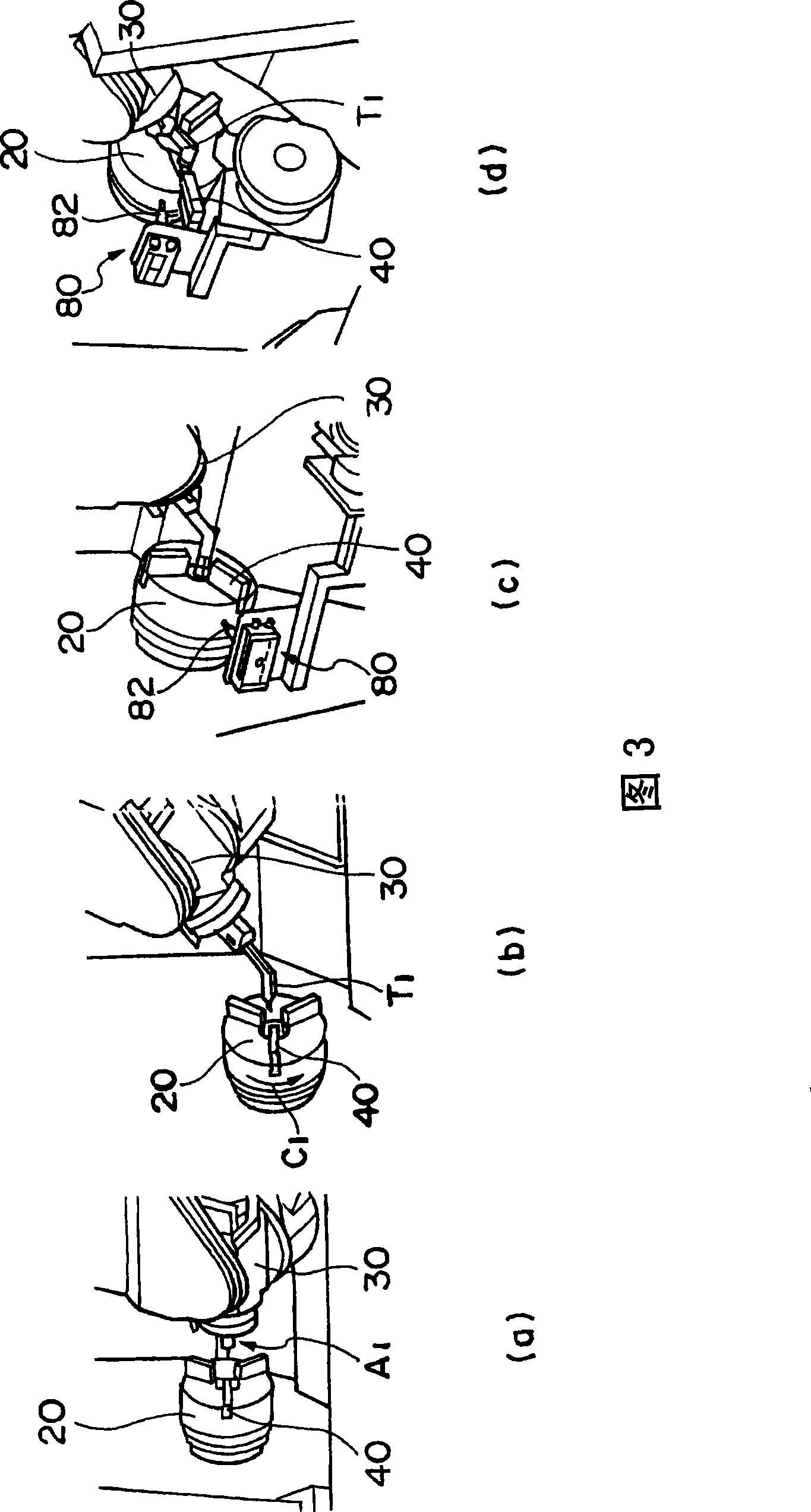

[0031] The robot 50 has a body 51 and an arm 52 extending from the body 51. A workpiece hand 60 for holding a workpiece and a pliers 70 for holding a chuck jaw are selectively installed on the front end of the arm 52 to release the spindle from the compound processing lathe 10. Lock the nut wrench 80 on the chuck. Each hand is placed on its own stage.

[0032] A workpiece supply station 90 , a pallet conveying device 100 for conveying pallets to the workpiece supply station 90 , and the like are installed on the side of the composite machining lathe 10 .

[0033] In addition, a shelf-shaped claw storage room 110 is also arranged.

[0034] The robot 50 is represented by symbol E in FIG. 1 1 The area shown as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com