Precision forming method of large high-strength aluminum alloy forged piece

A precision forming and aluminum alloy technology, applied in the field of aluminum alloy forging, can solve the problems that the size does not meet the requirements of the parts, the forming of forgings is difficult, and the ribs are not high enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

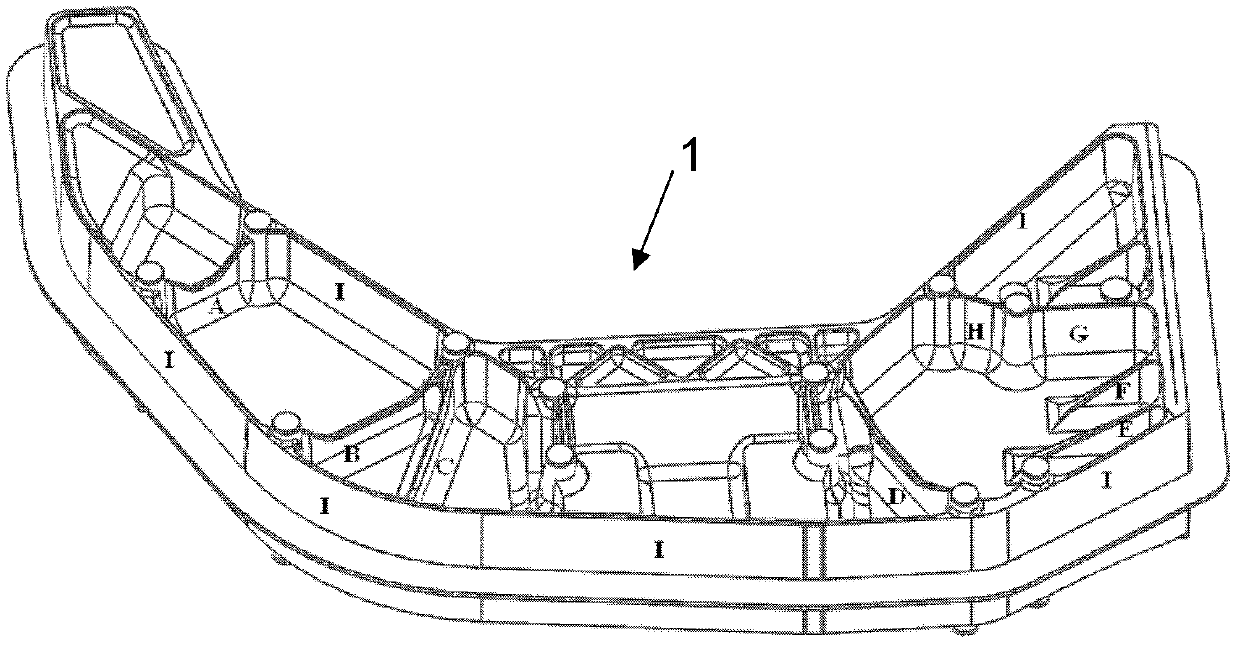

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

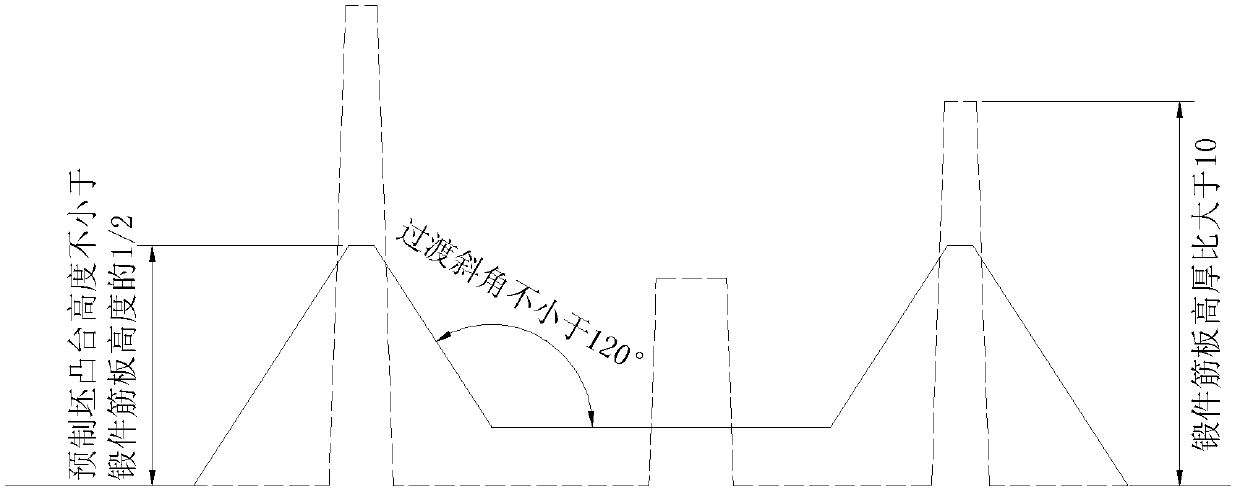

[0033] The precision forming method of the large-scale high-reinforced aluminum alloy forging of the present invention specifically comprises the following steps:

[0034] A. Forging design: According to the part design drawing, leave a machining allowance of 3 to 5 cm at the part that needs to be connected with other parts, set the demoulding angle of the forging to 1 to 2°, and remove the features of the parts that cannot be forged, such as through holes and sides Cavities, etc., the rest of the parts are kept unchanged in size. Die design: According to the forging design, calculate the mold cavity size according to the following formula, and design the forming die. The formula is:

[0035] S 模具 =p×S 锻件 , p=(1+α 锻件 ×ΔT) / (1+α 模具 ×ΔT)

[0036] In the formula, S 模具 is the mold cavity size, S 锻件 is the corresponding siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com