Patents

Literature

36results about How to "Faster and cheap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

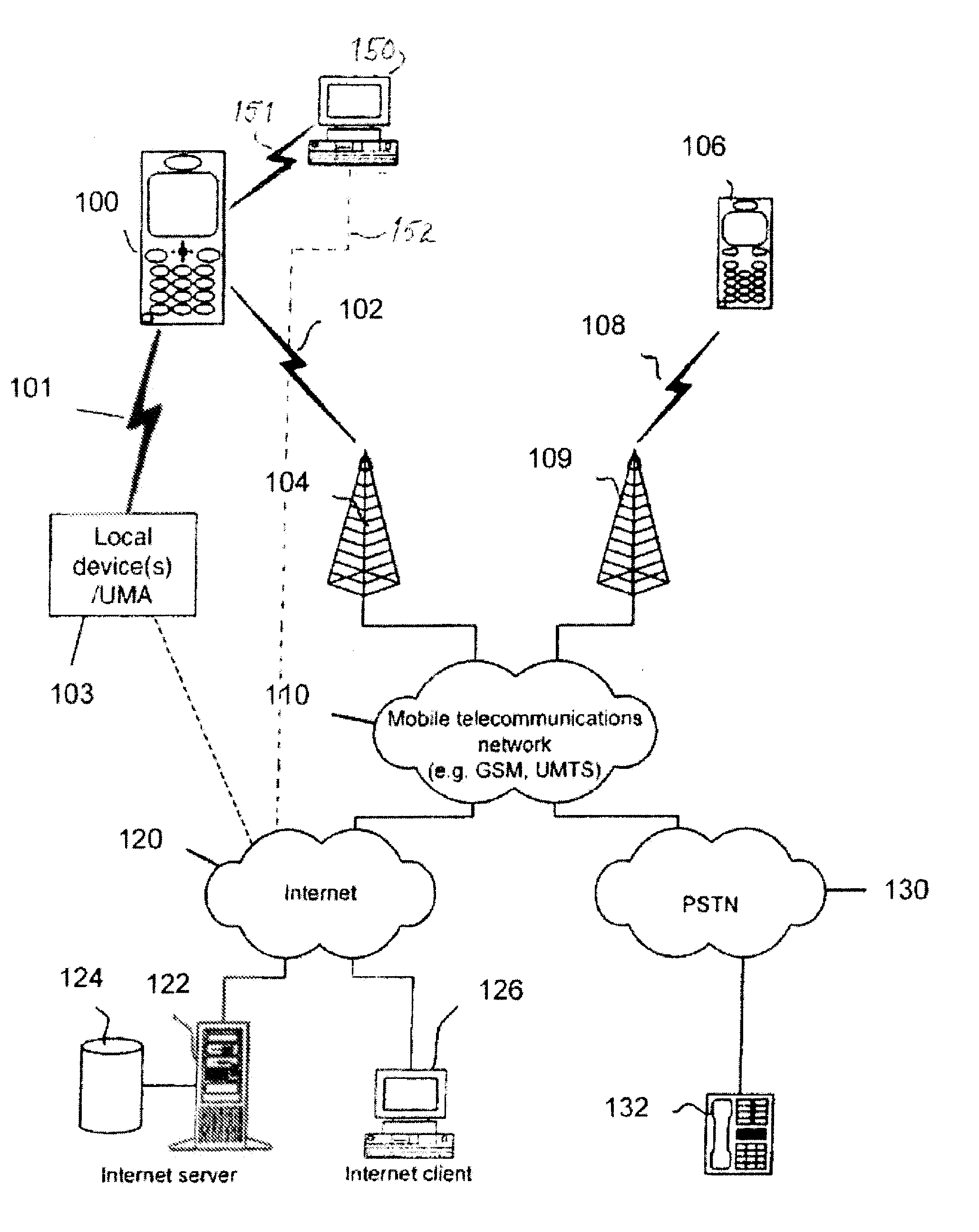

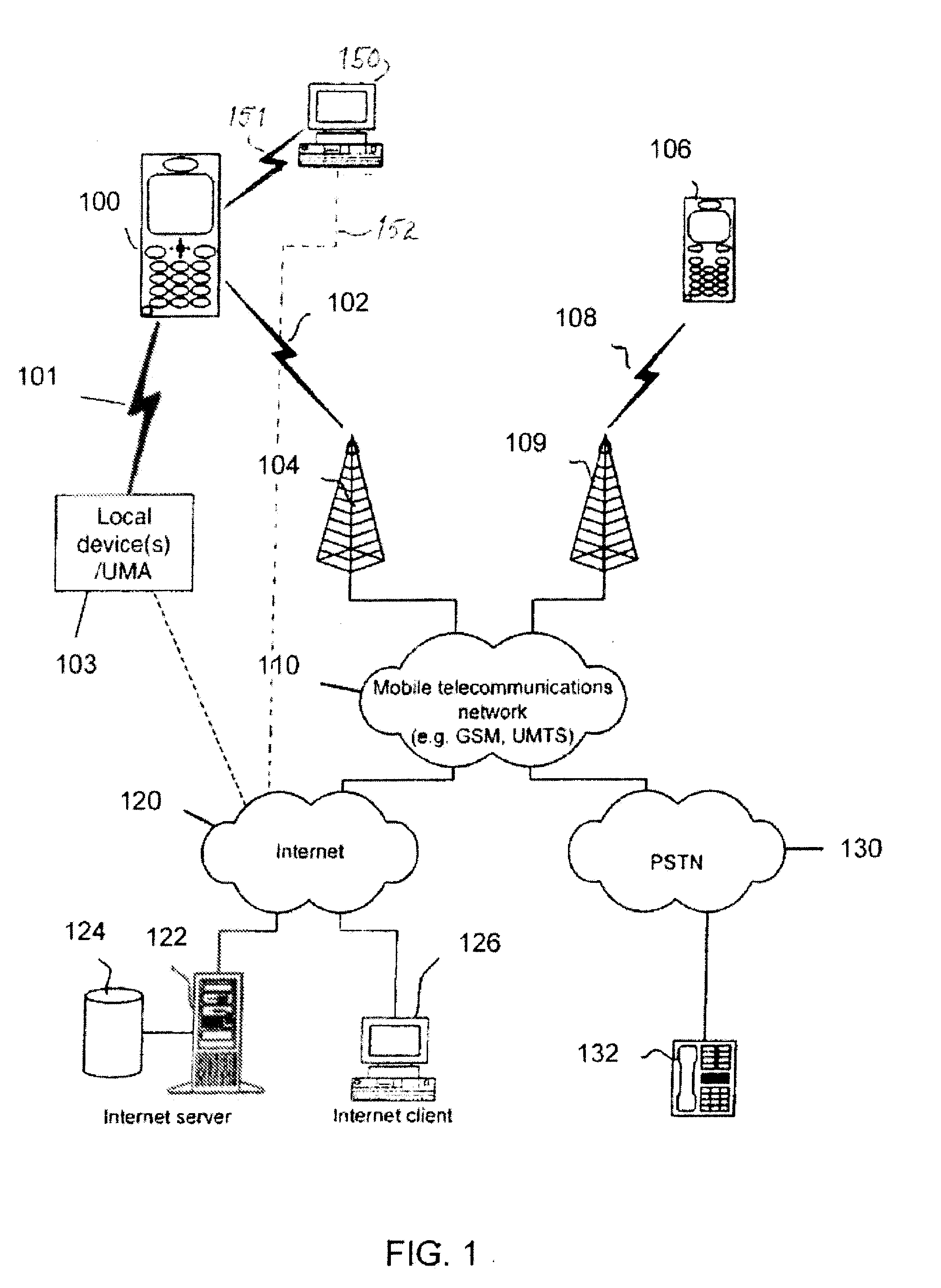

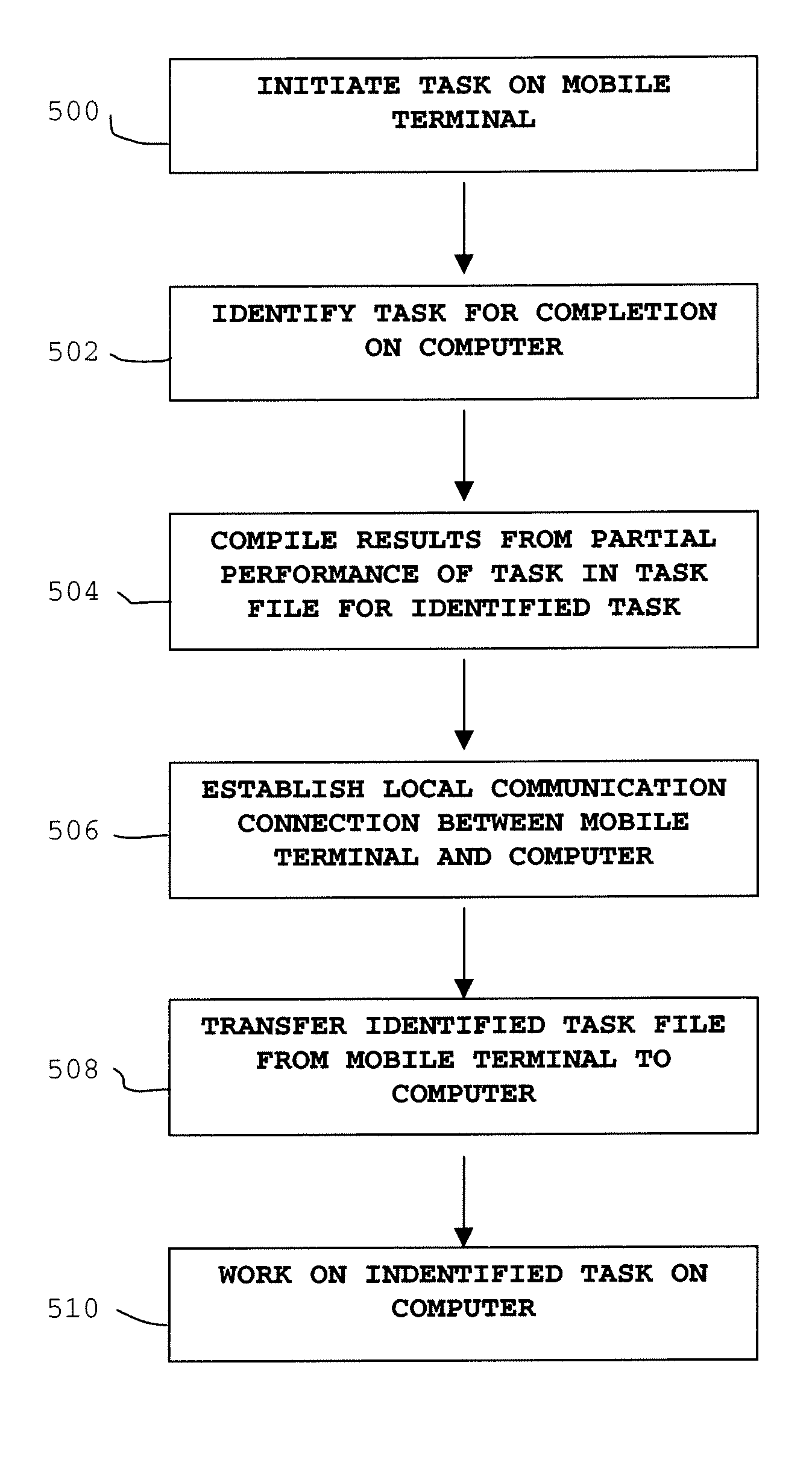

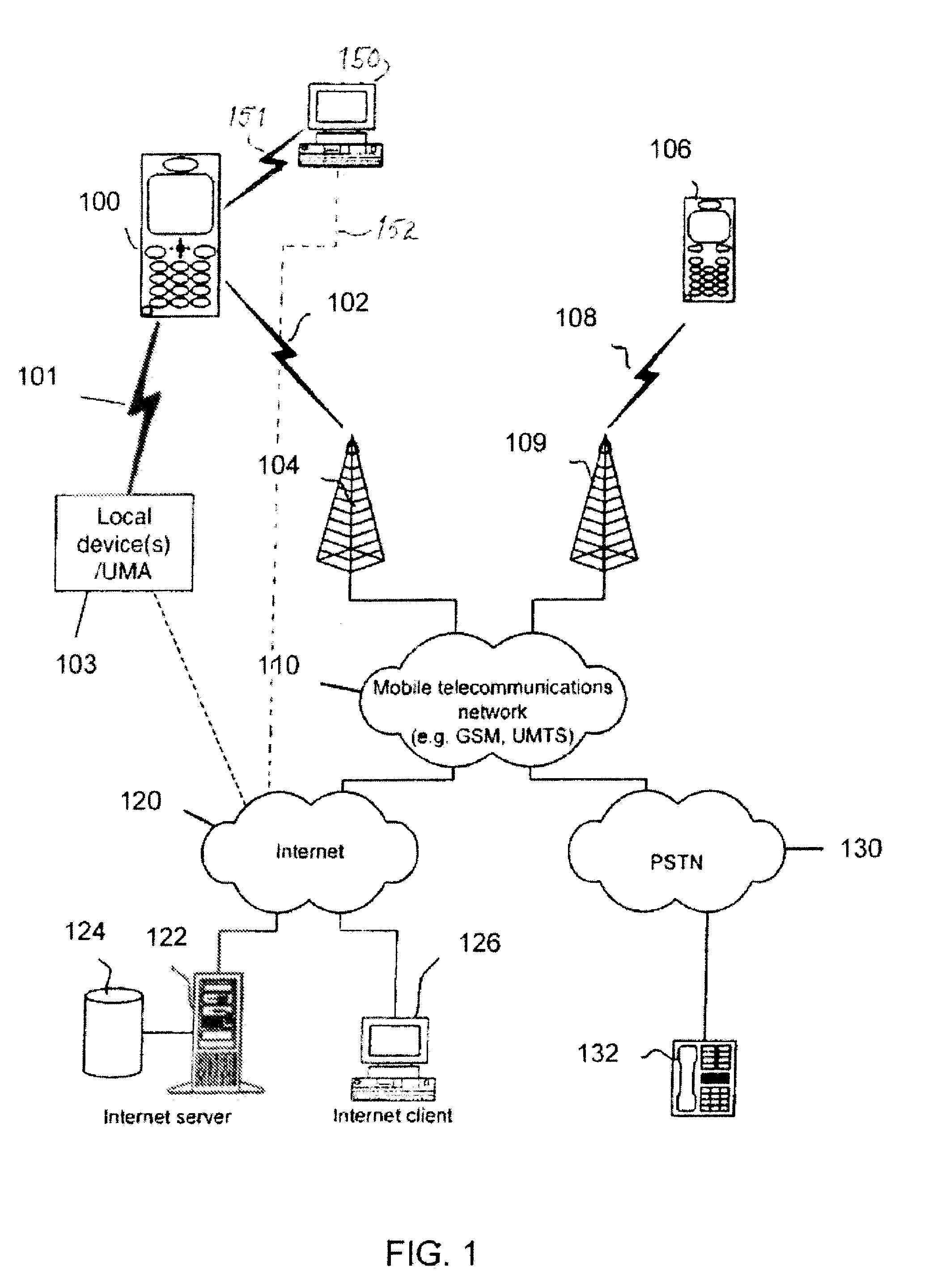

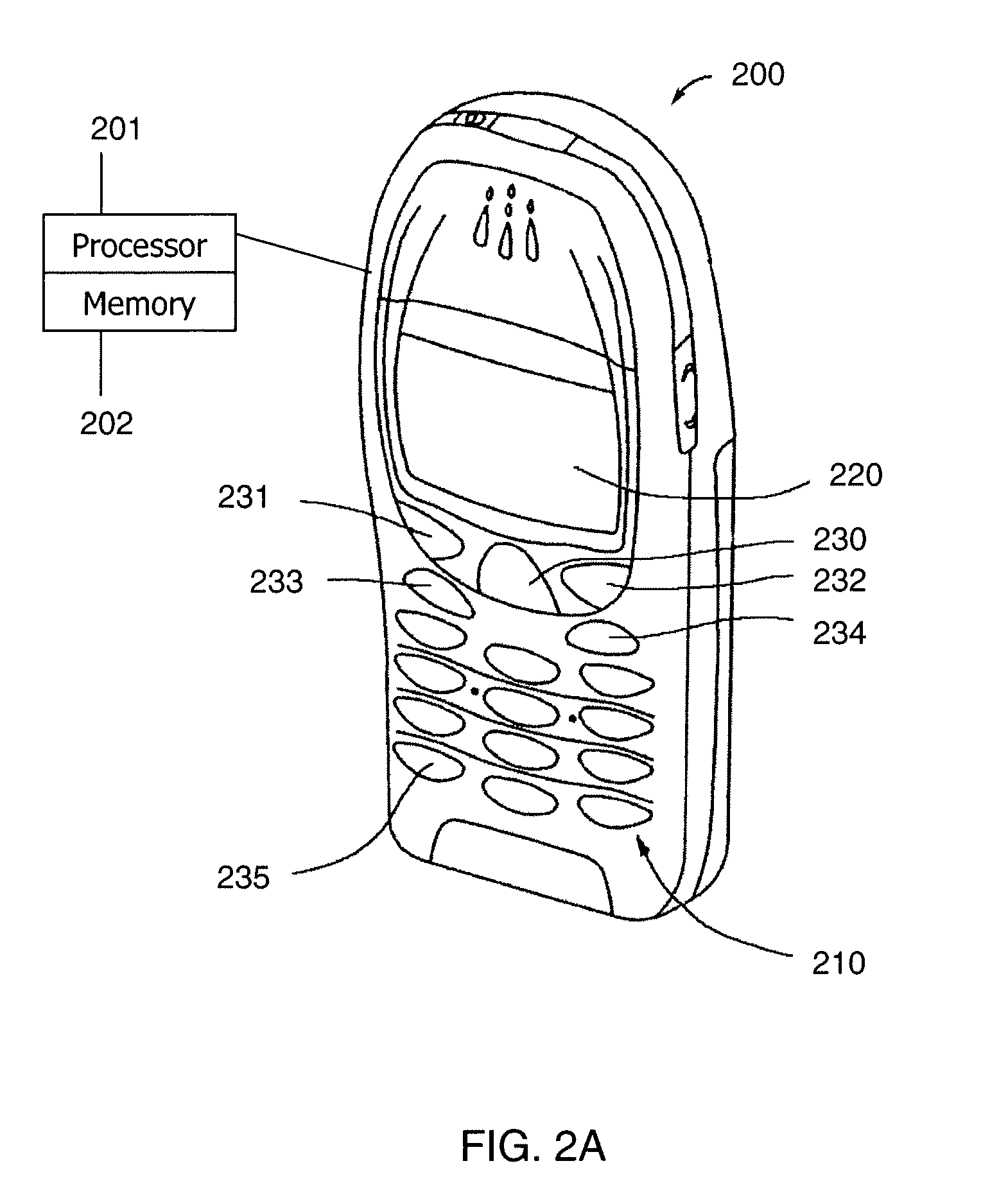

Transferring task completion to another device

ActiveUS20080160974A1Cheap and faster meanUseful and flexible mobile browsing experienceMultiple digital computer combinationsRadio transmission for post communicationTask completionTelecommunications link

A mobile communication device is adapted to identify a task for postponed transfer to a computing device over a local communication link. A similar transfer task function is established on the computing device for receiving the identified task and any required related data. The user is provided with the ability to initiate a task on the mobile communication device and continue or complete the task on a computer.

Owner:WSOU INVESTMENTS LLC

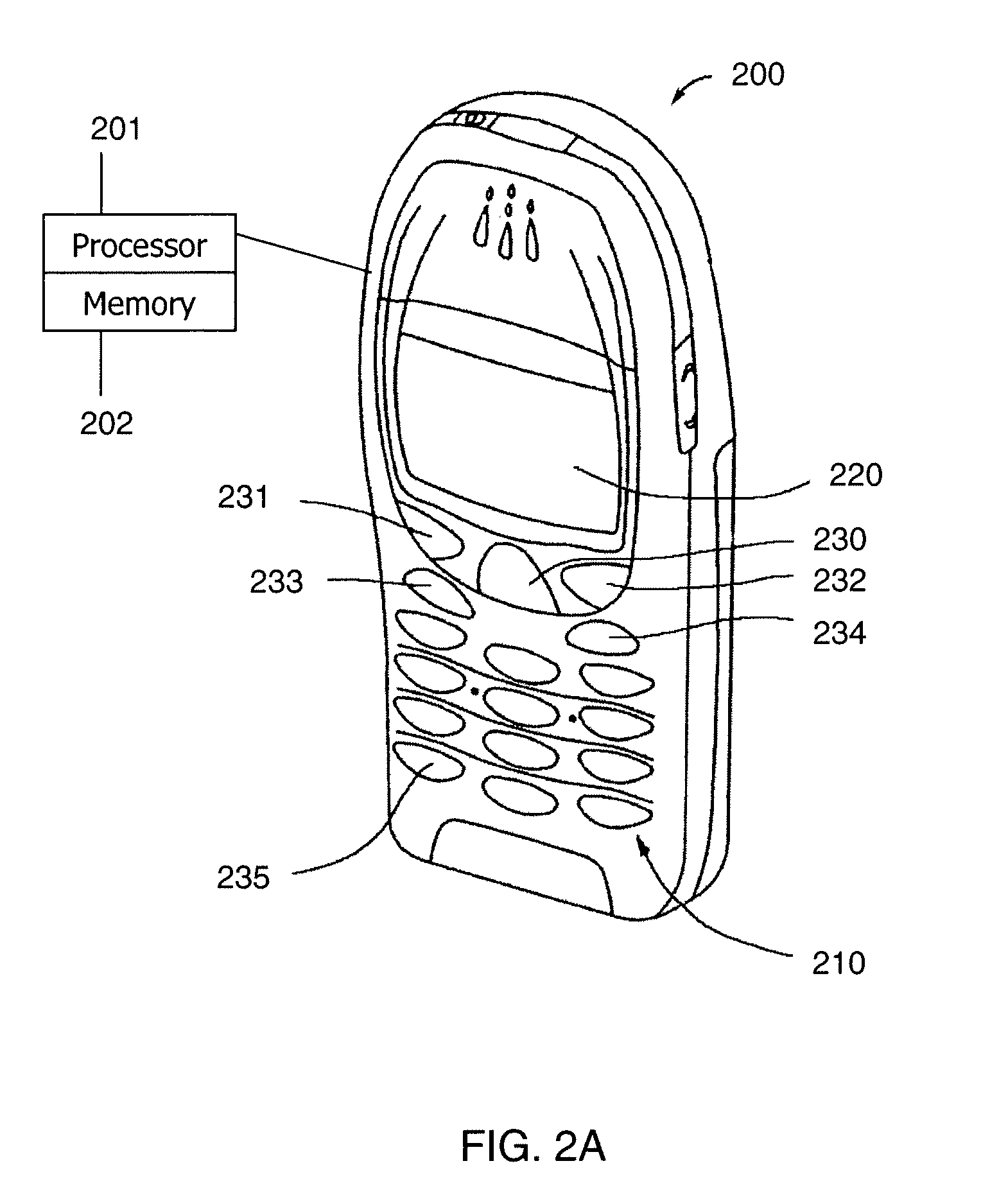

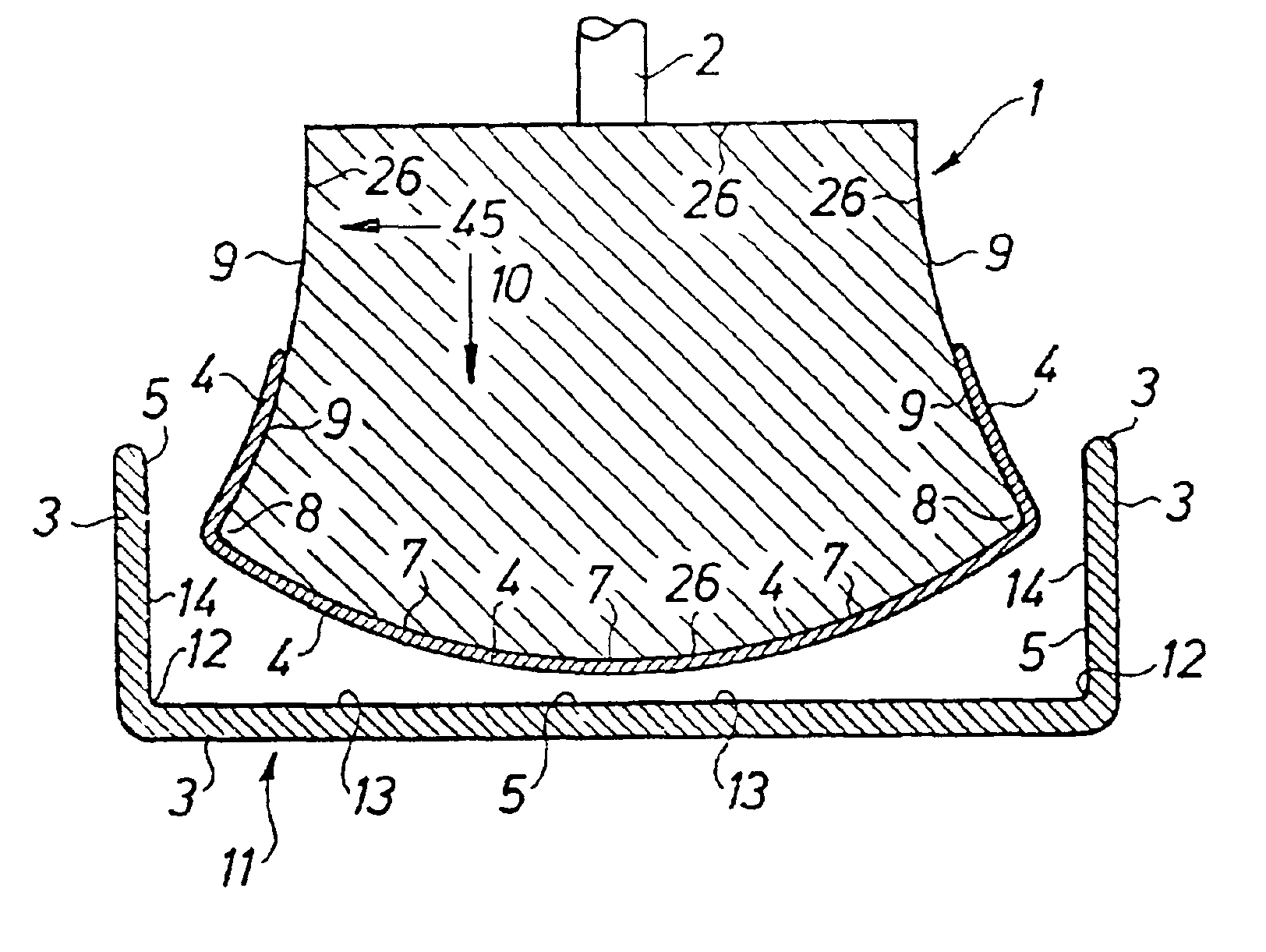

Method for making an absorbent binder composition and application thereof to a substrate

InactiveUS6849685B2Faster and cheapLess-expensive to prepareLayered productsDispersed particle separationPhosphoric acidChemistry

A method of making an absorbent binder composition includes combining a first aqueous monomer solution including a reducing polymerization initiator with a second aqueous monomer solution including an oxidizing polymerization initiator to form a binder composition having post application, moisture-induced crosslinking capability. The first aqueous monomer solution includes a monoethylenically unsaturated monomer and an ethylenically unsaturated monomer that contains an alkoxysilane functionality. The second aqueous monomer solution includes a monoethylenically unsaturated monomer. The monoethylenically unsaturated monomer included in the first and second aqueous monomer solutions may be carboxylic, sulphonic, or phosphoric acids or salts or a combination thereof. The ethylenically unsaturated monomer may be an acrylate or methacrylate. Crosslinking of the resulting binder composition is induced by removal of water. The polymerization of the monomer solutions to form an absorbent binder composition may be carried out in about 100 minutes or less.

Owner:KIMBERLY-CLARK WORLDWIDE INC

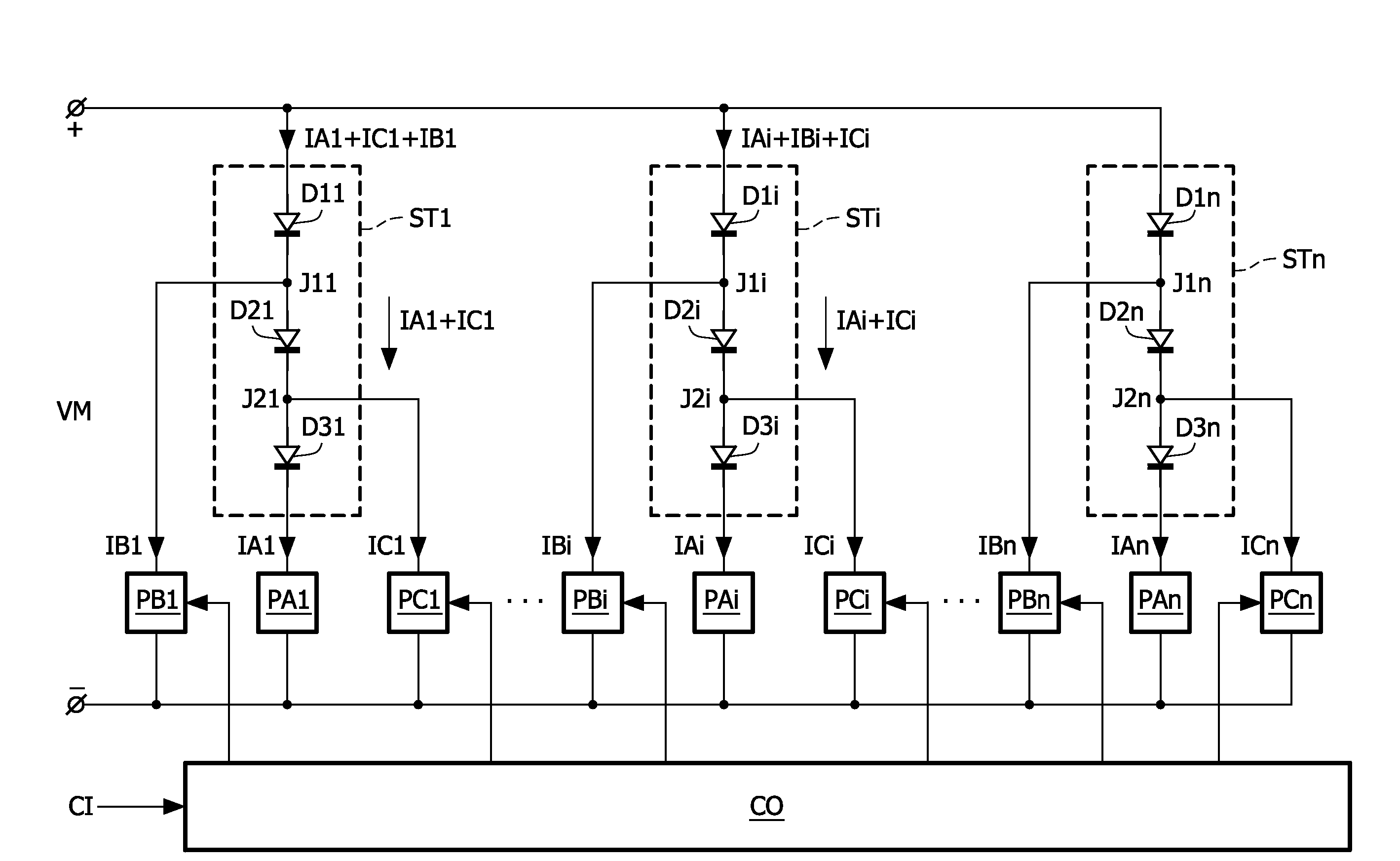

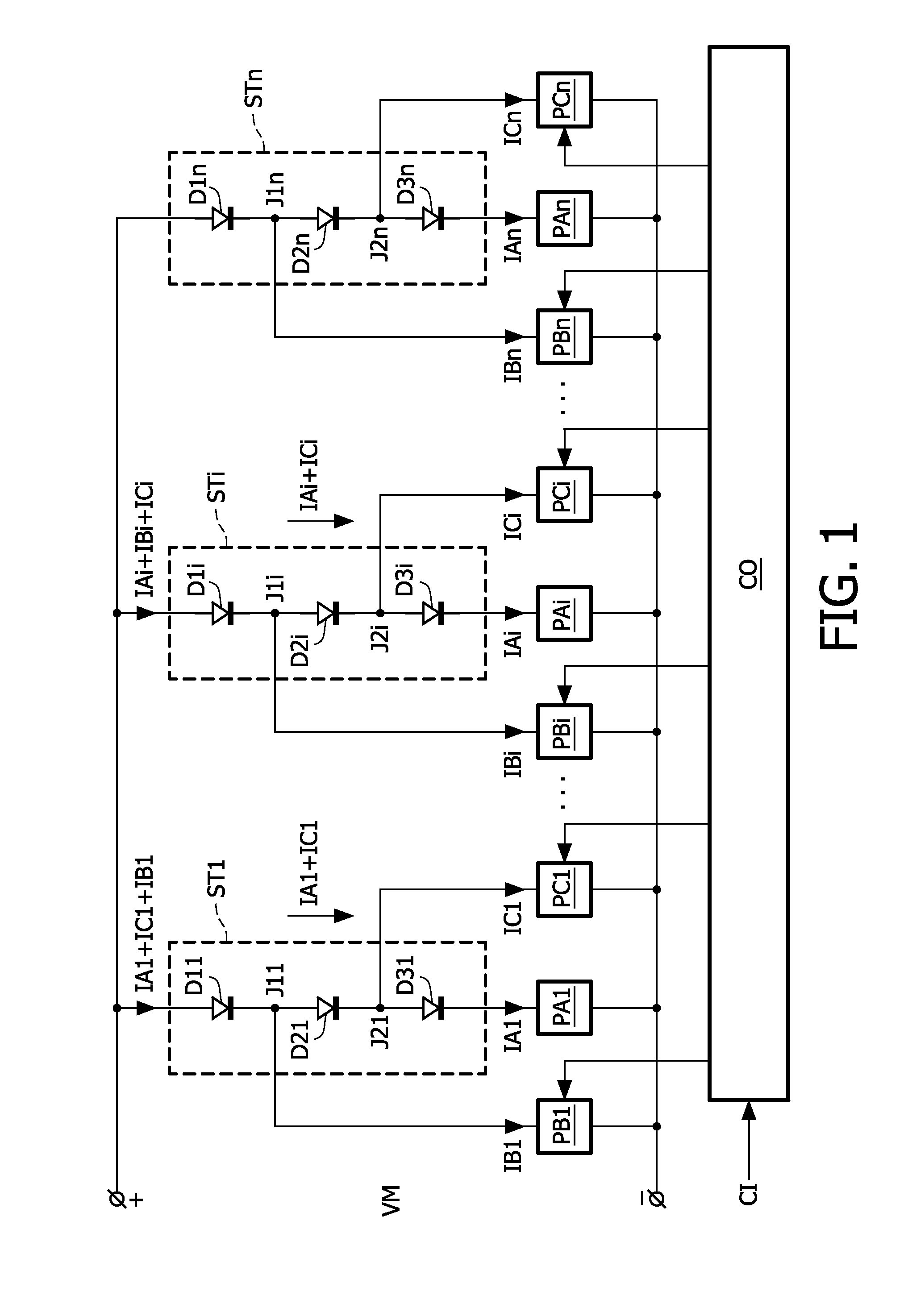

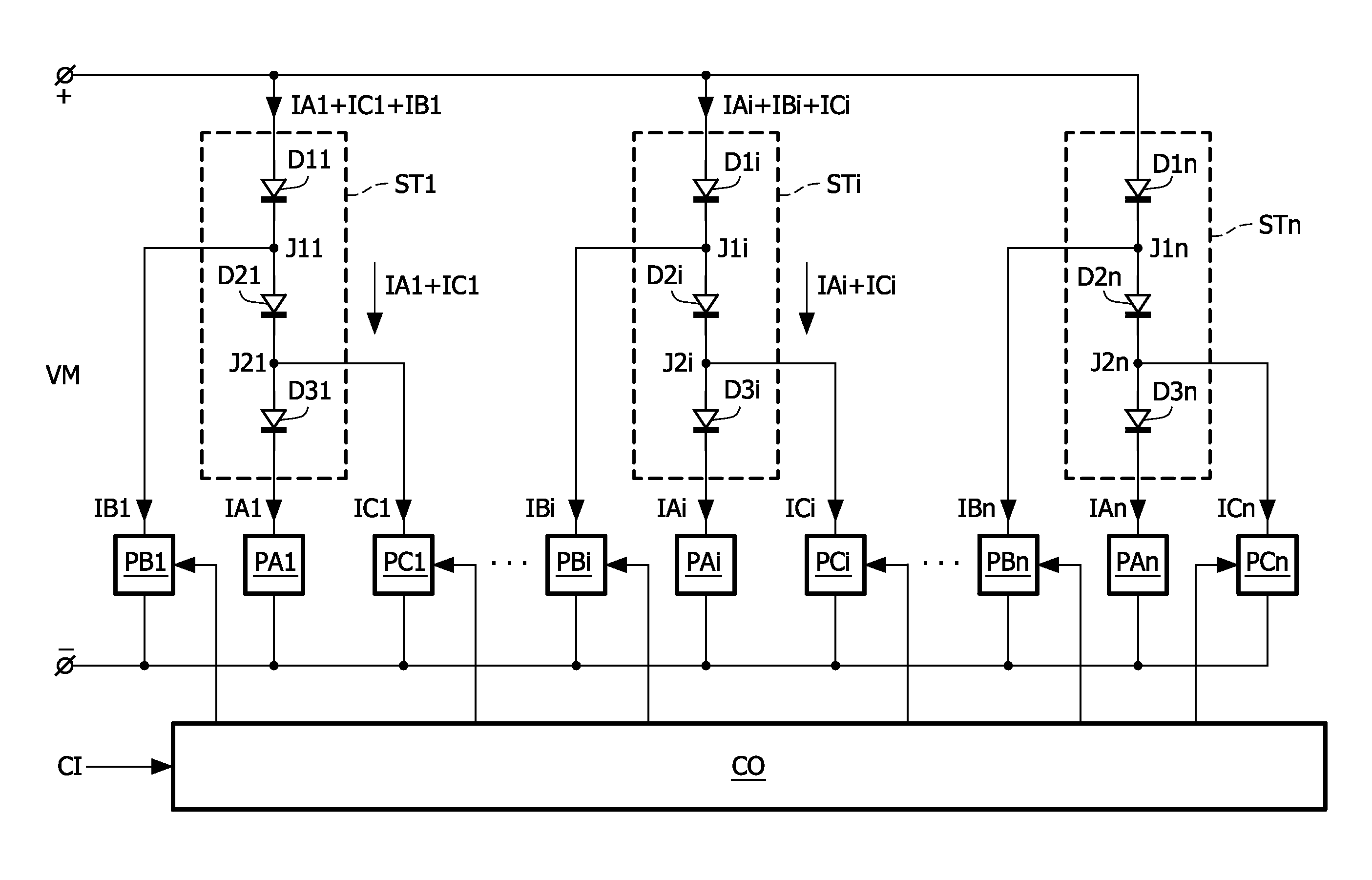

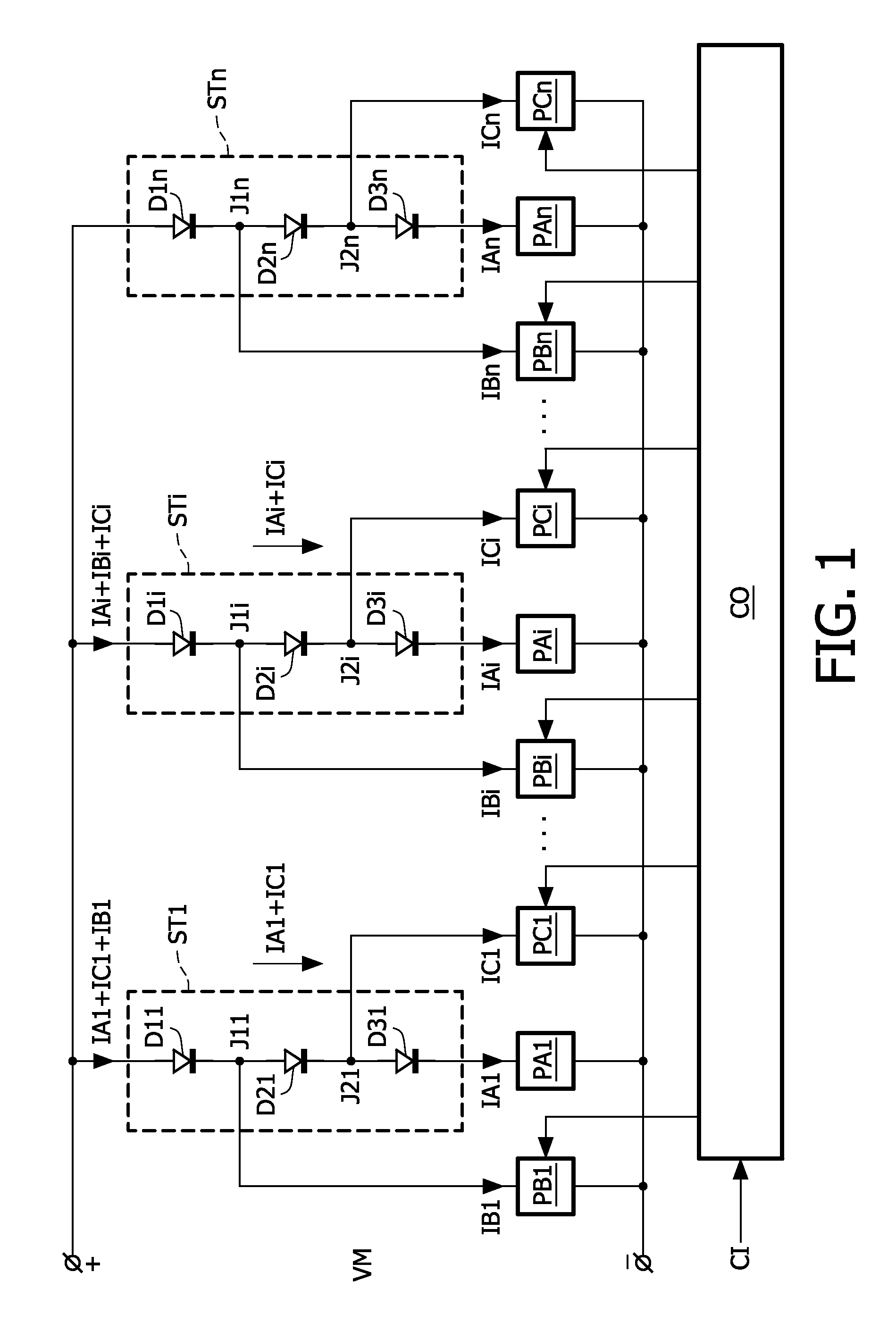

Driving light emitting diodes

ActiveUS20100102732A1Minimize the numberLittle powerElectrical apparatusElectroluminescent light sourcesEngineeringLight-emitting diode

The present invention relates to a driver for a string (STi) of series arranged light emitting diodes (D1i, D2i, D3i) of which at least two emit light having different spectra. The driver comprises a main power supply (PAi) which has outputs coupled across the string (STi) to supply a main current (IAi) to the string (STi). A secondary power supply (PBi) is coupled to at least one of junctions (J1i) between successive light emitting diodes (D1i, D2i) in the string (STi) to supply or withdraw a delta current (IBi) from the junction (J1i). The delta current (IBi) is at least a factor 5 smaller than the main current (IAi). A controller (CO) controls the secondary power supply (PBi) to generate the delta current (IBi) to obtain a desired spectral composition of the mixed light emitted by the string (STi).

Owner:SIGNIFY HLDG BV

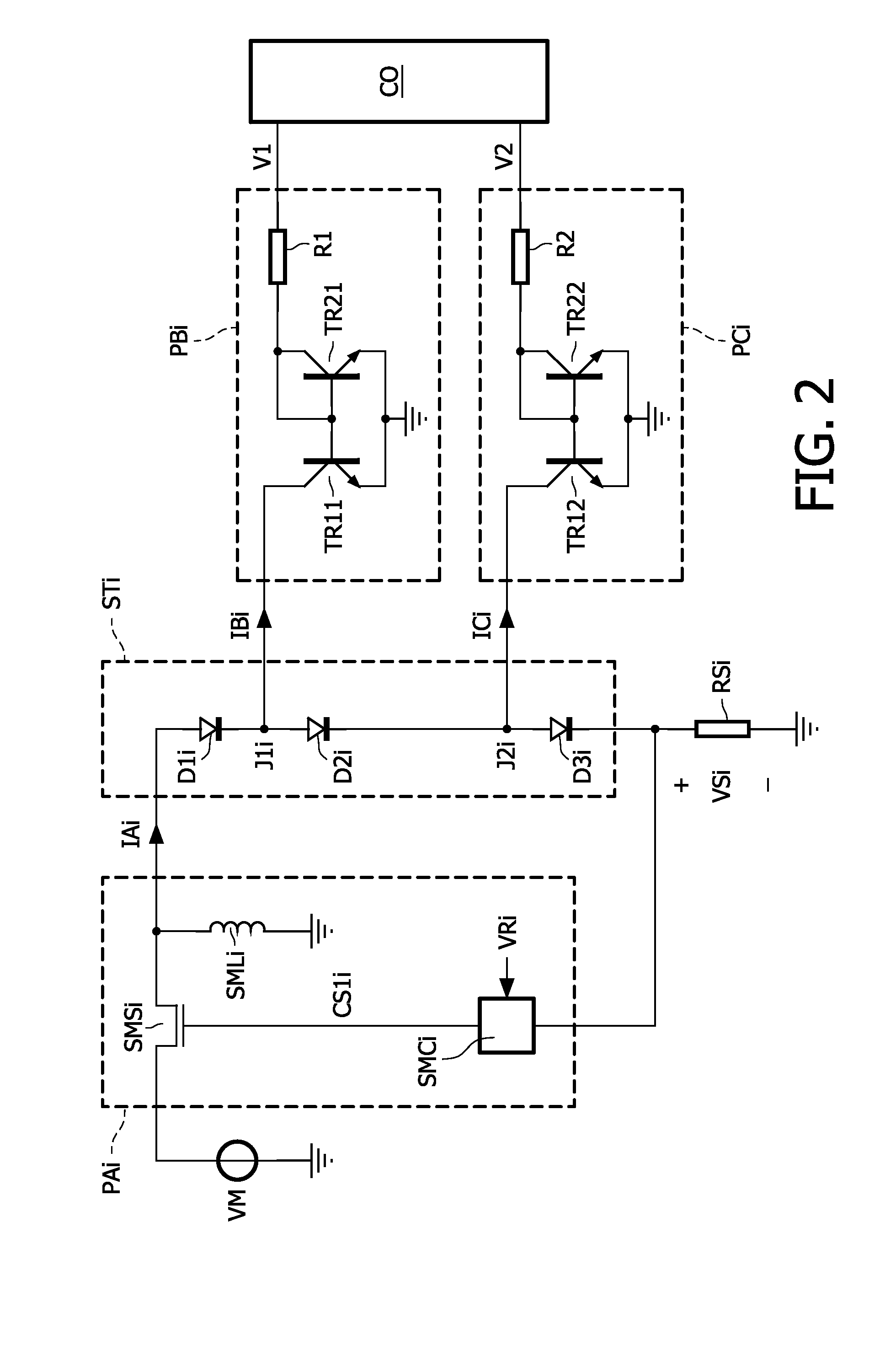

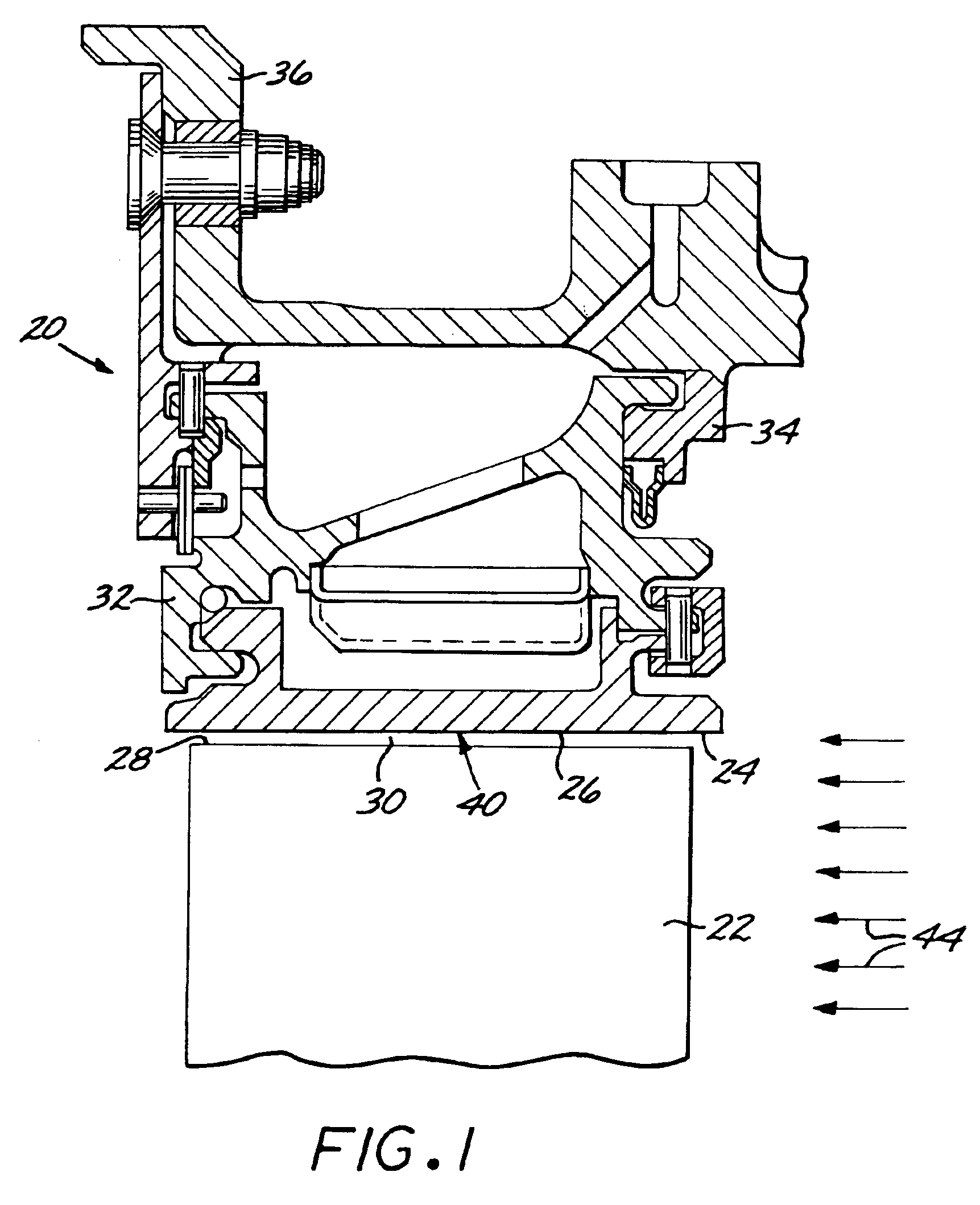

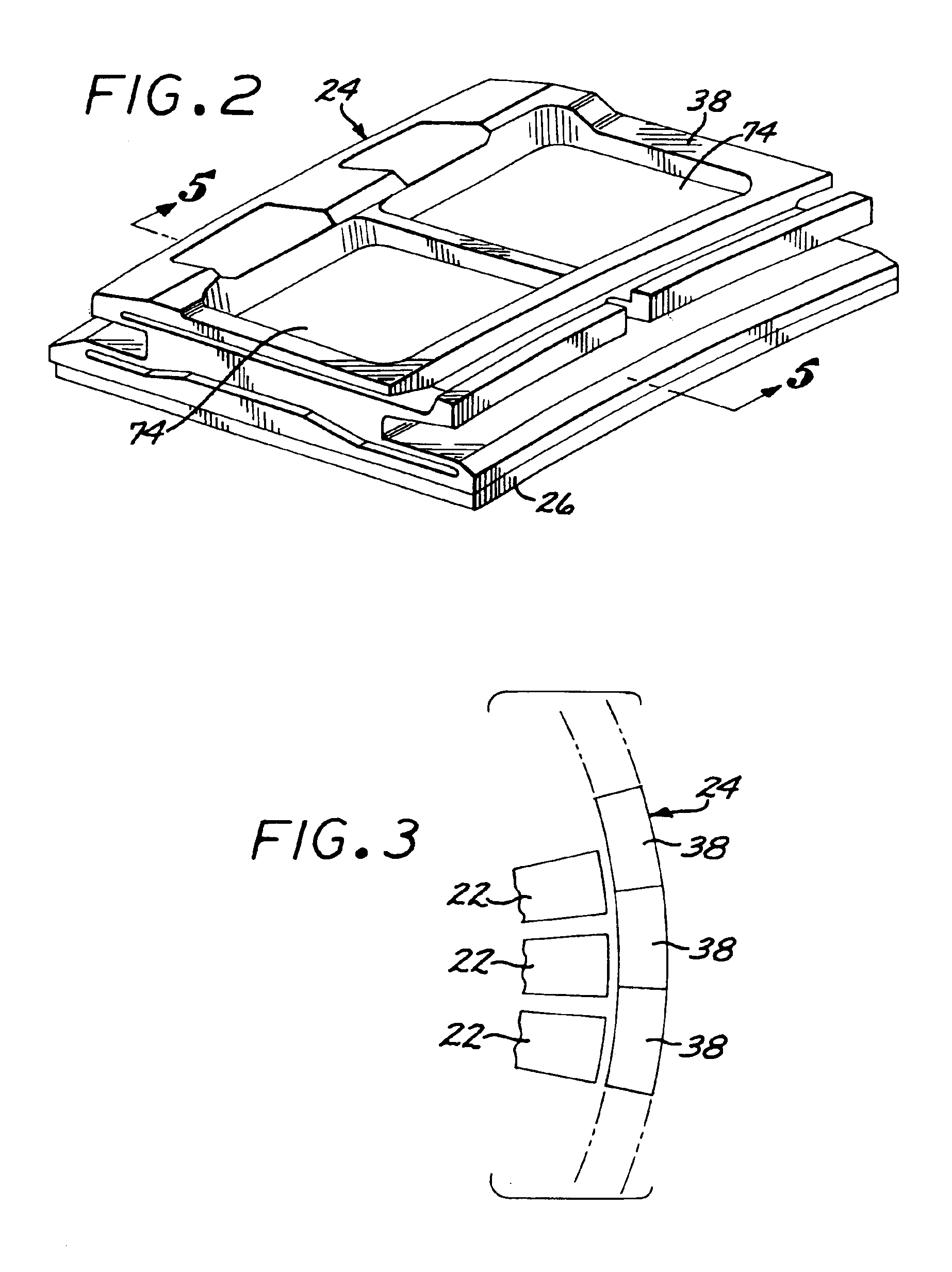

Method of repairing a stationary shroud of a gas turbine engine using plasma transferred arc welding

InactiveUS6914210B2Less process variationFaster and cheapTurbinesMolten spray coatingEngineeringGas turbines

A stationary shroud of a gas turbine engine made of a base metal is repaired by removing any damaged material from a flow-path region of the stationary shroud to leave an initially exposed base-metal flow-path surface; and applying a base-metal restoration overlying the initially exposed flow-path surface. The base-metal restoration is applied by furnishing a source of a structural material that is compatible with the base metal, and depositing the source of the structural material overlying the initially exposed base-metal flow-path surface of the stationary shroud by plasma transferred arc welding to form a repaired base-metal flow-path surface. An environmentally resistant rub coating may be applied overlying the base-metal restoration.

Owner:GENERAL ELECTRIC CO

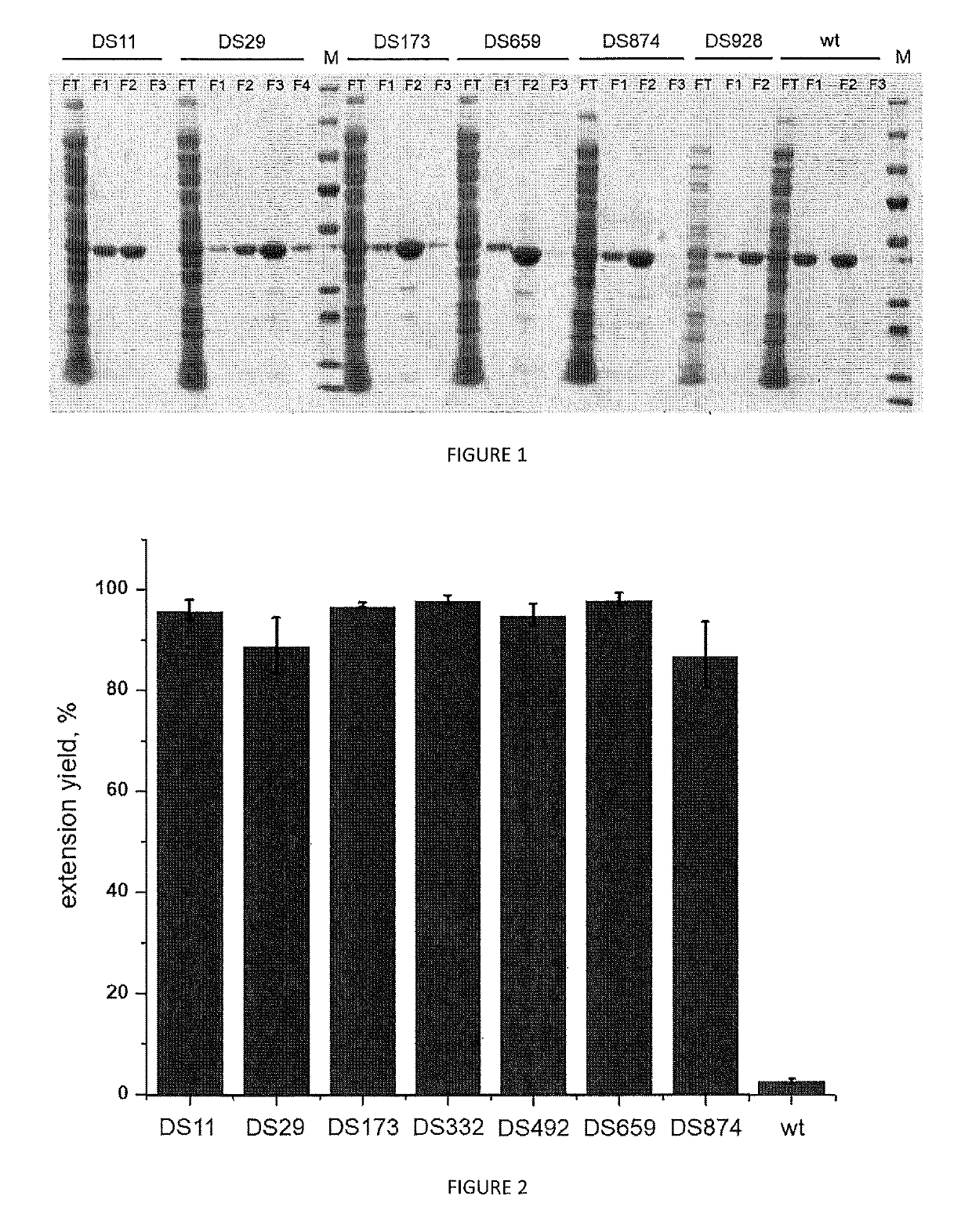

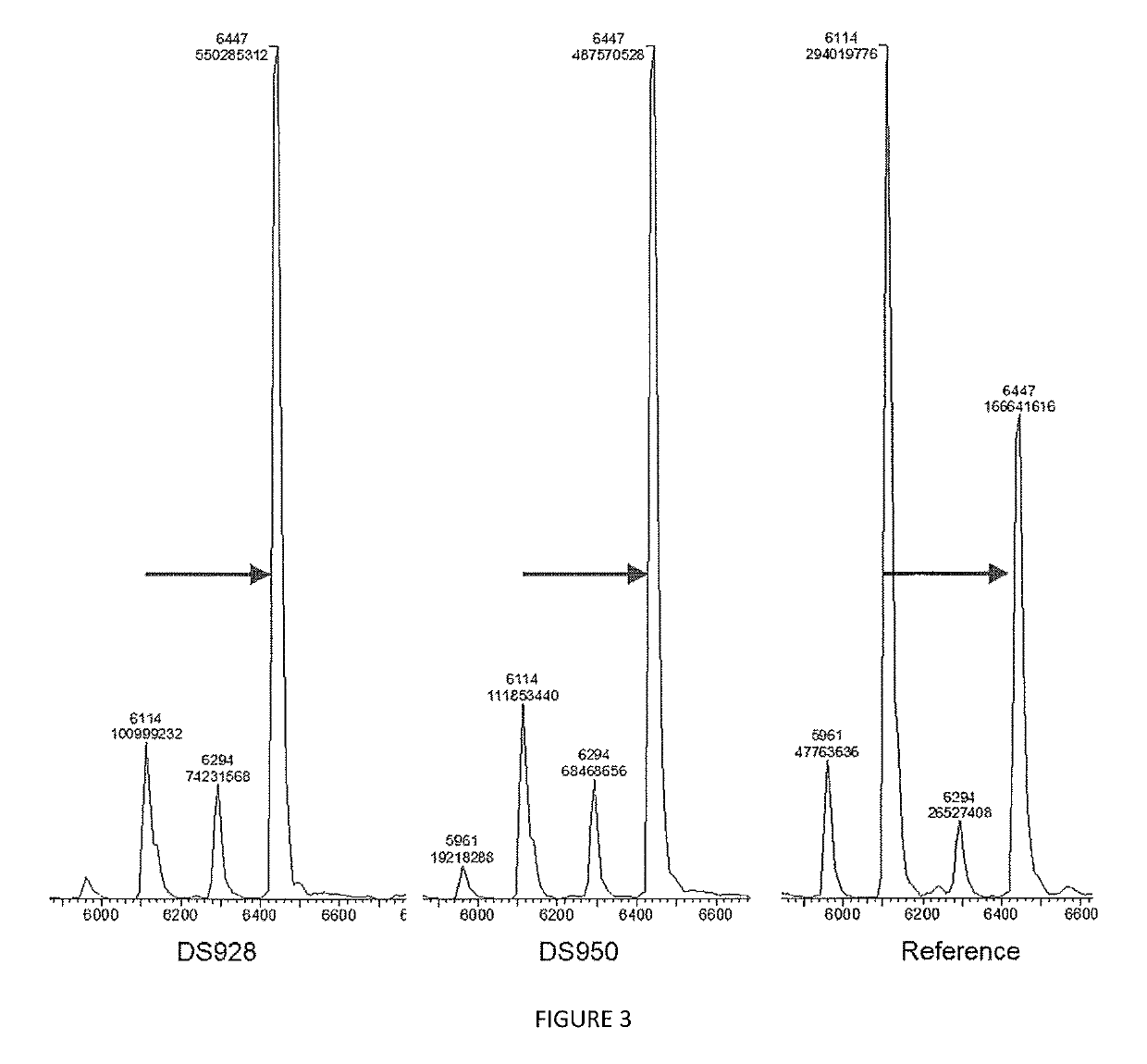

Variants of terminal deoxynucleotidyl transferase and uses thereof

ActiveUS10435676B2Improve abilitiesLow costImmobilised enzymesTransferasesNucleotideAmino acid substitution

The present invention relates to a variant of Terminal deoxynucleotidyl Transferase (TdT) which (i) comprises the amino acid sequence as set forth in SEQ ID Nº 2 or a functionally equivalent sequence, with at least an amino acid substitution at position corresponding to residue C302 or functionally equivalent residue, wherein the position is numbered by reference to the amino acid sequence set forth in SEQ ID Nº 1, (ii) is able to synthesize a nucleic acid fragment without template and (iii) is able to incorporate a modified nucleotide into the nucleic fragment.

Owner:DNA SCRIPT SAS +2

Transferring task completion to another device

ActiveUS8583090B2Useful and flexible mobile browsing experienceFaster and cheapMultiple digital computer combinationsRadio transmission for post communicationTask completionCommunication link

Owner:WSOU INVESTMENTS LLC

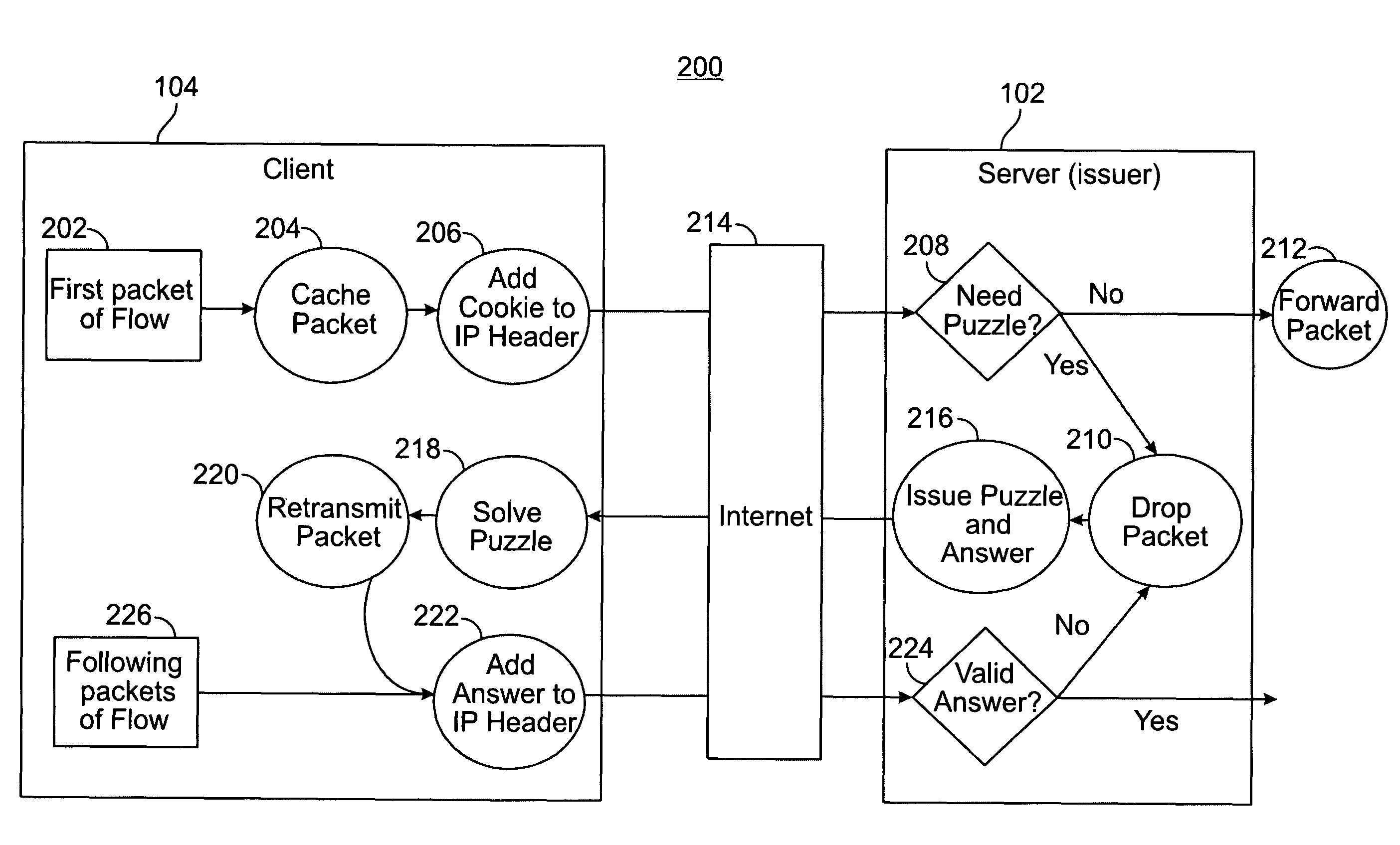

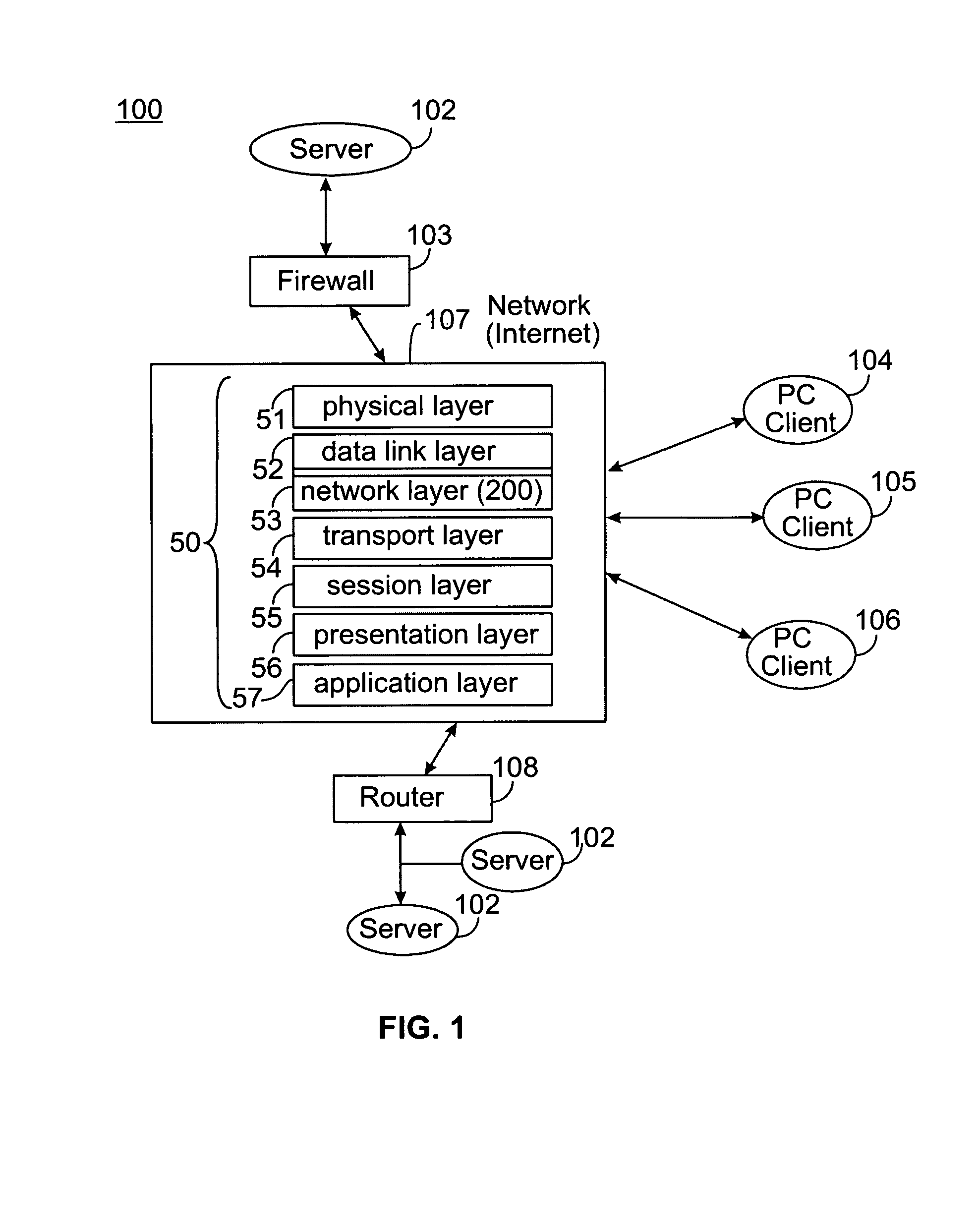

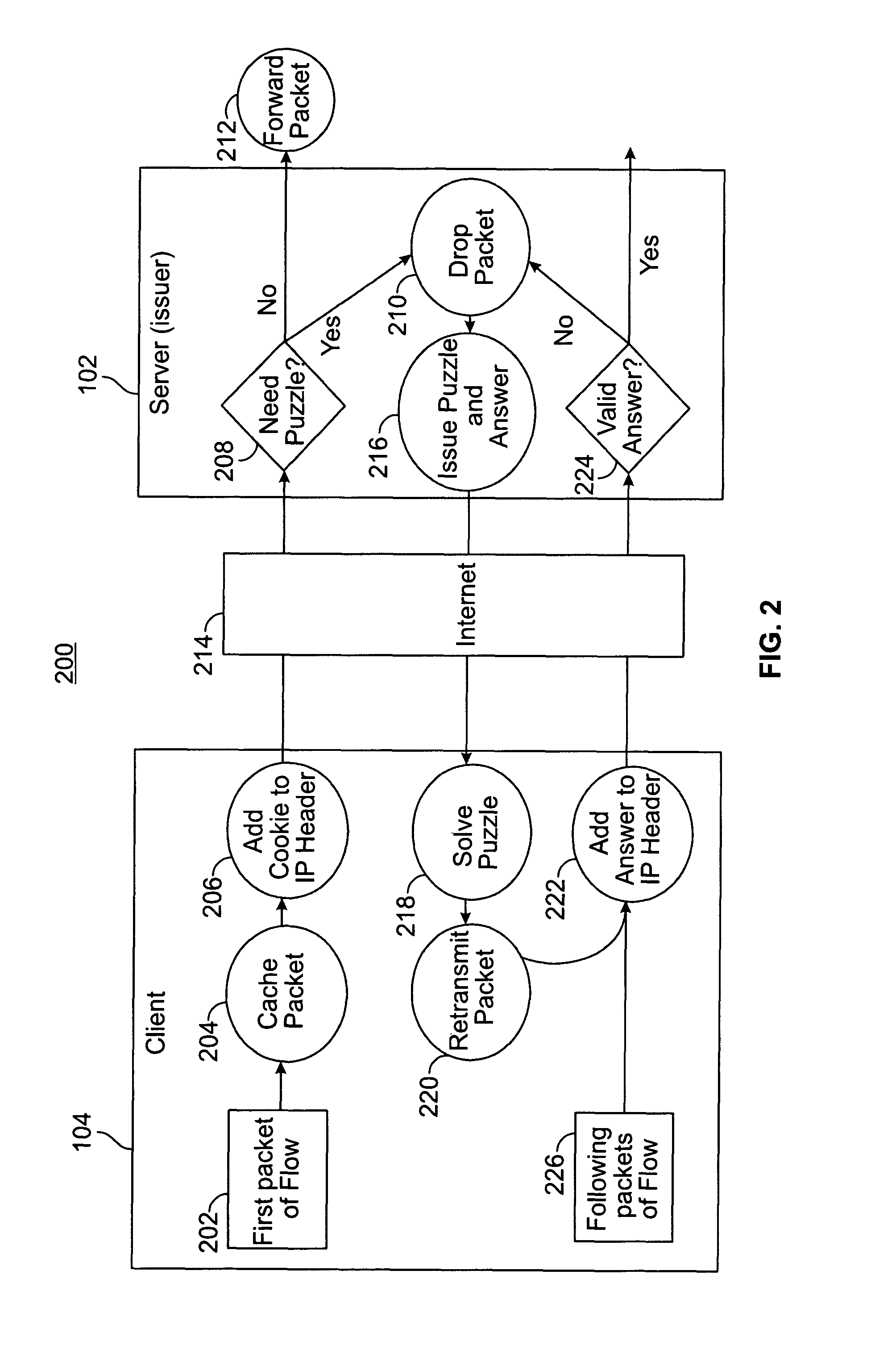

Systems and methods for protecting against denial of service attacks

InactiveUS8321955B2Faster and cheapDigital data processing detailsUser identity/authority verificationProtocol ApplicationComputer science

Systems and methods utilizing the network layer and / or application layer to provide security in distributed computing systems in order to thwart denial of service attacks. The systems and methods of the present invention utilize puzzles placed at the network layer level and / or application layer level to protect against denial of service attacks. Further, the systems and methods of the present invention advantageously provide a robust and flexible solution to support puzzle issuance at arbitrary points in the network, including end hosts, firewalls, and routers and thereby a defense against denial of service attacks.

Owner:THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF PORTLAND STATE UNIV +1

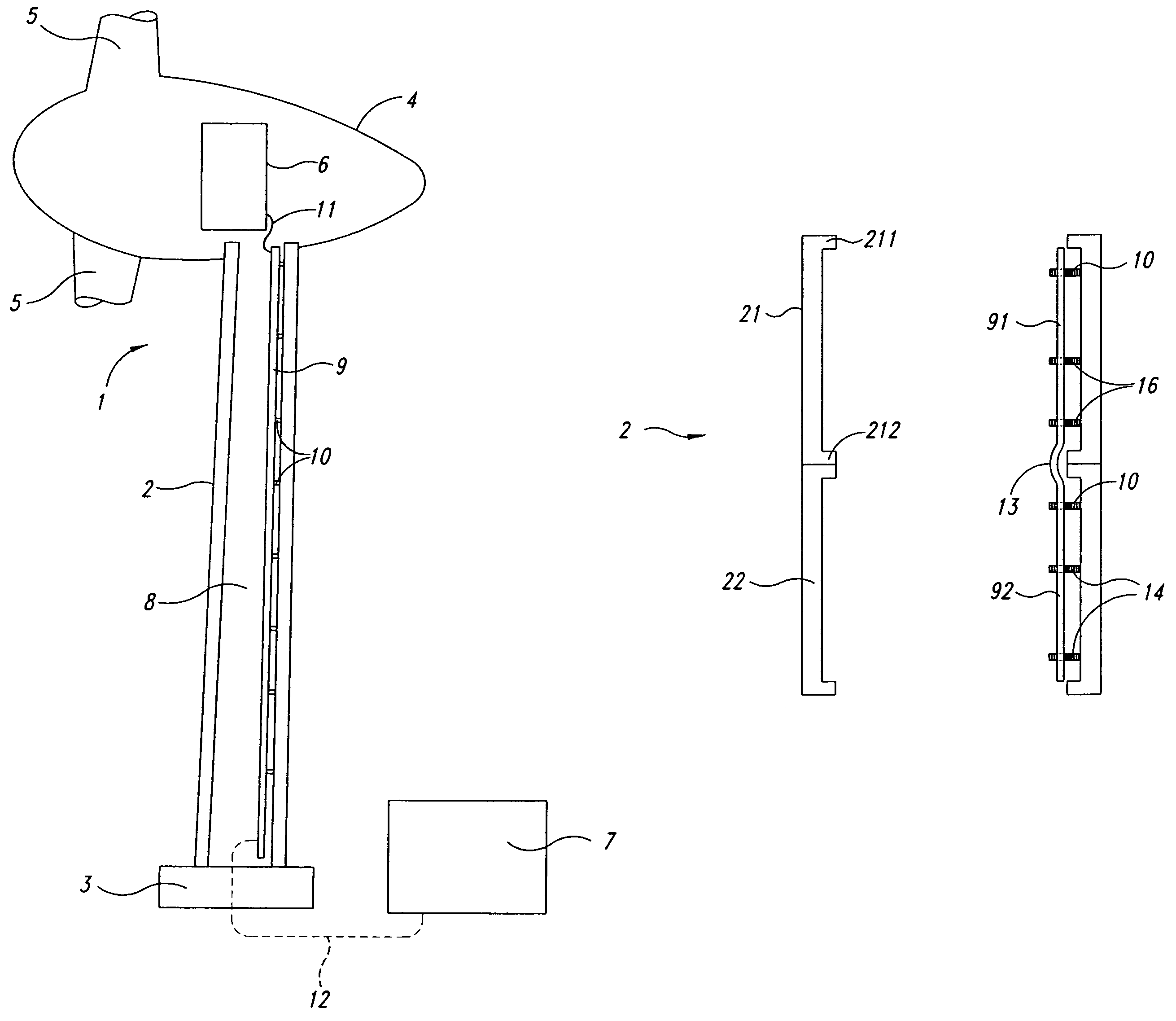

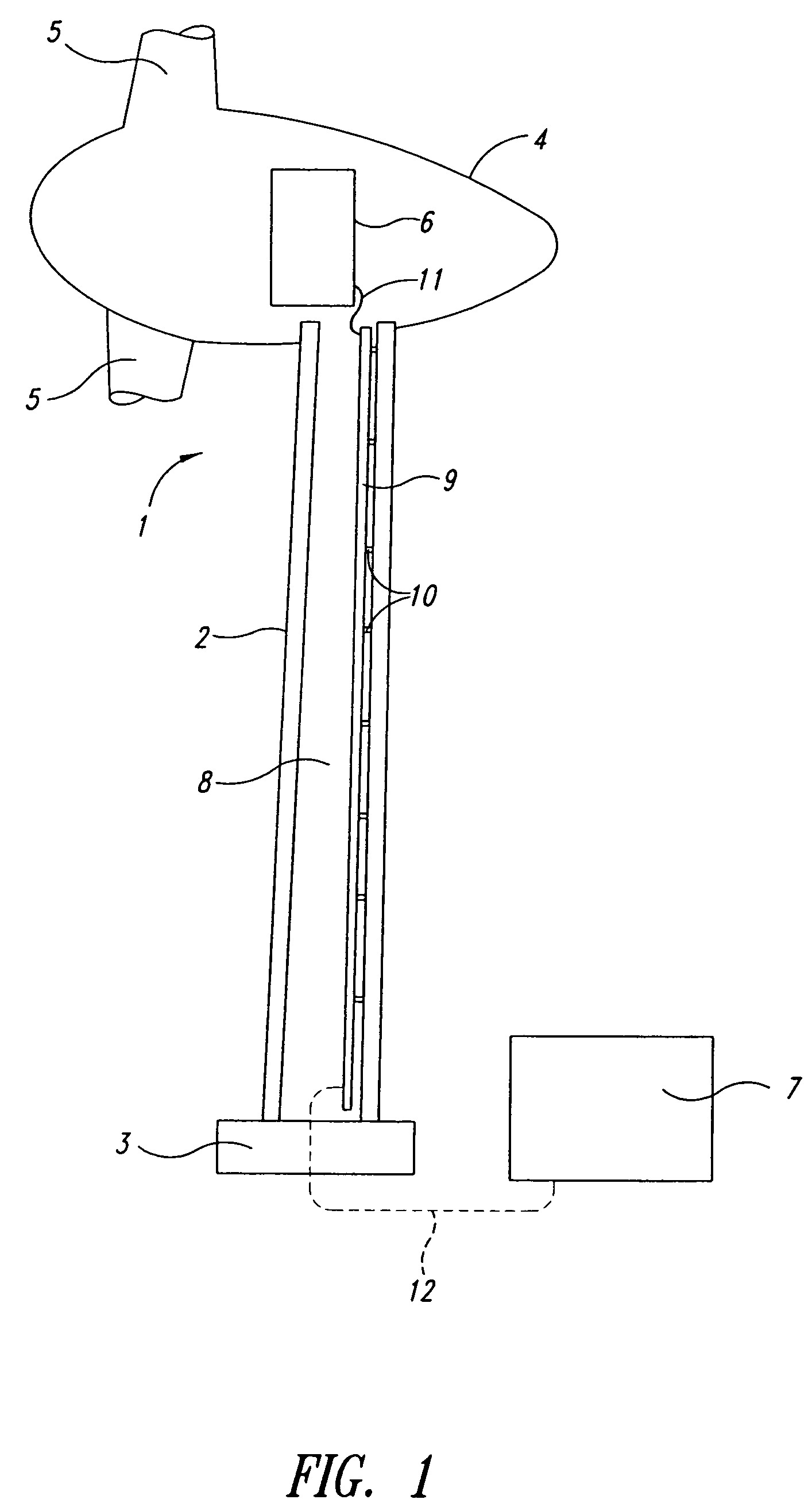

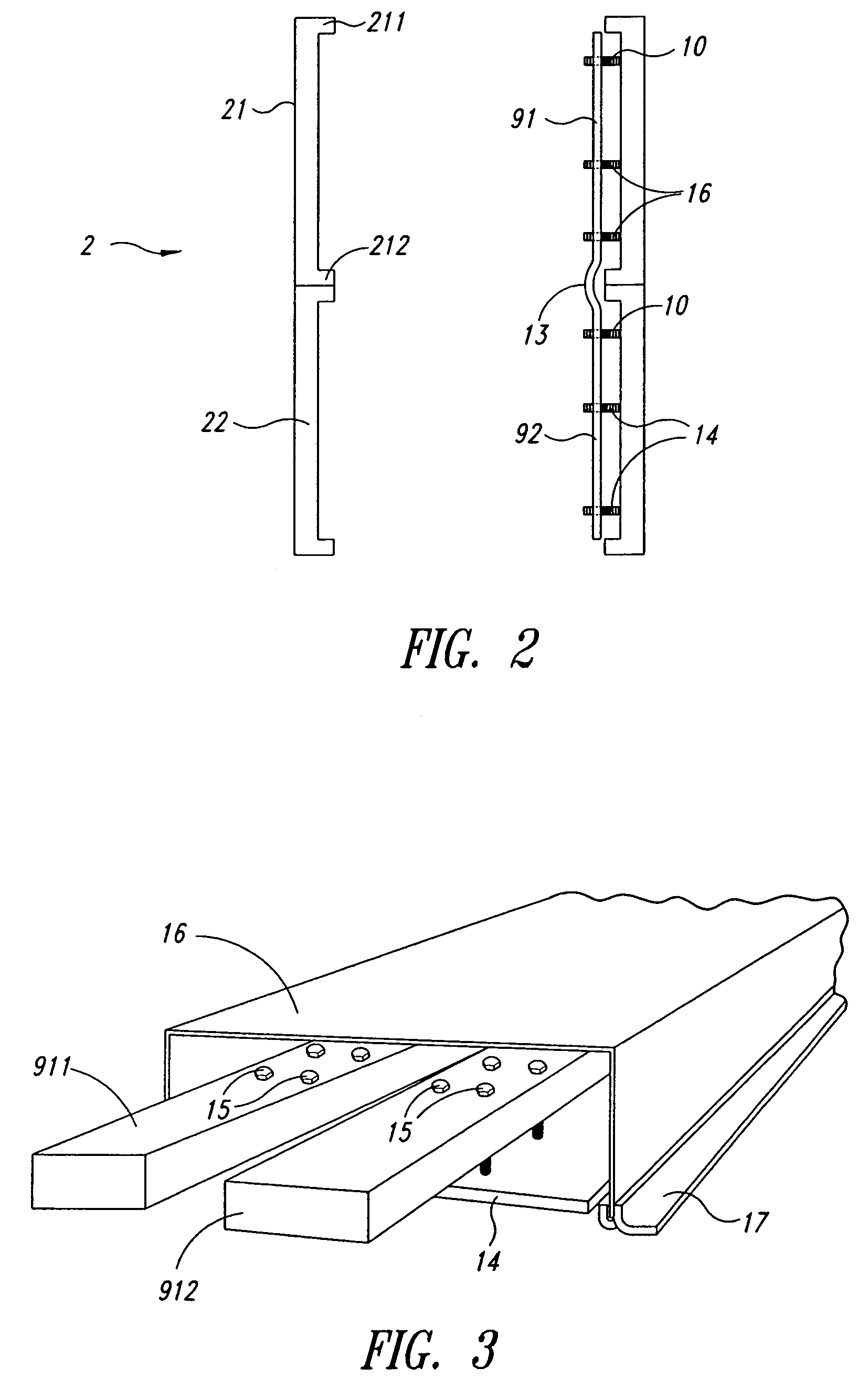

Wind turbine with current conducting means, which are pre-assembled in the tower

InactiveUS7199485B2Faster and cheapEasy erectionWind motor assemblyBus-bar installationPower flowEngineering

The present invention concerns a wind energy plant for generation of alternating current with a tower constructed of several tower segments, a generator arranged in the region of the top of the tower, a power module arranged in the region of the base of the tower, and current carrying means for transferred current from the generator to the power module. In order to enable faster, easier and thereby cheaper erection of the wind energy plant, it is provided in accordance with the present invention that the current carrying means be premounted in the tower segments in segmented form.

Owner:WOBBEN ALOYS

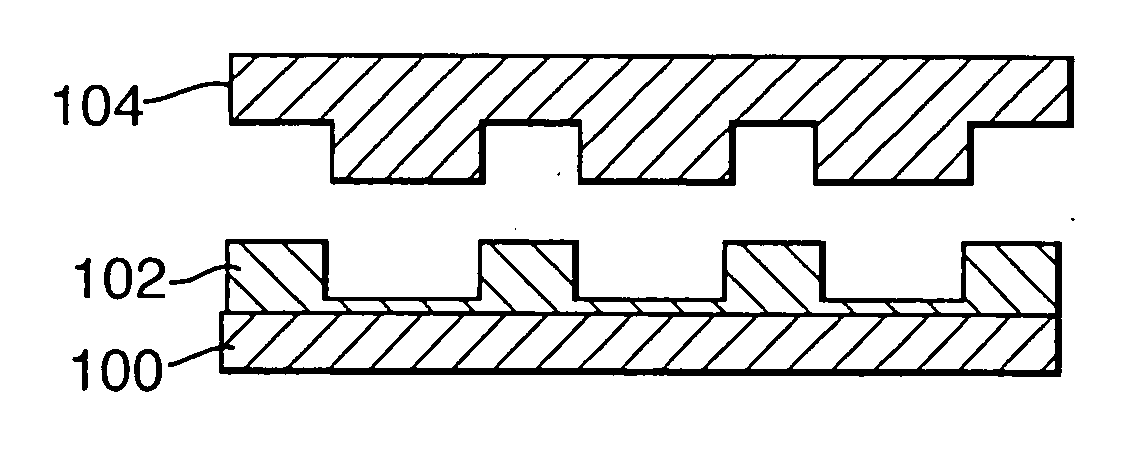

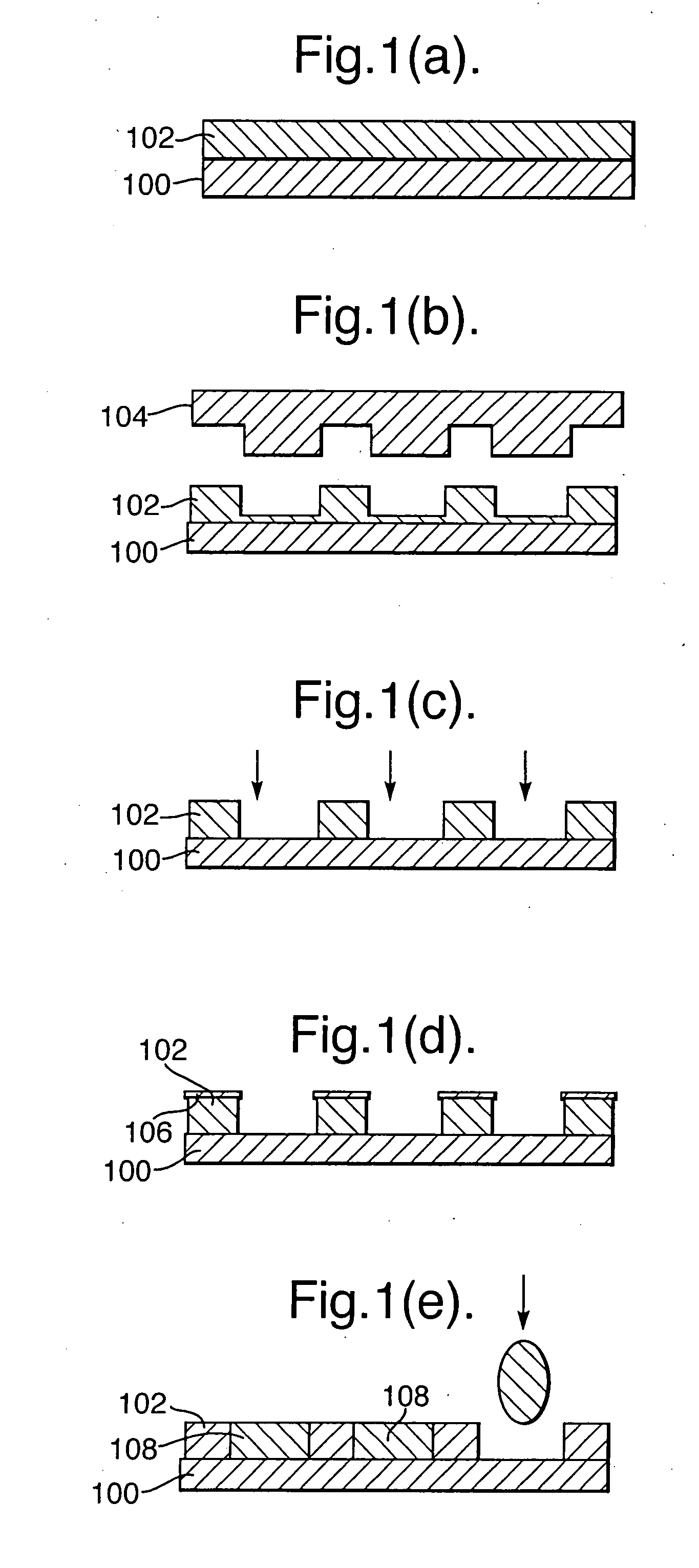

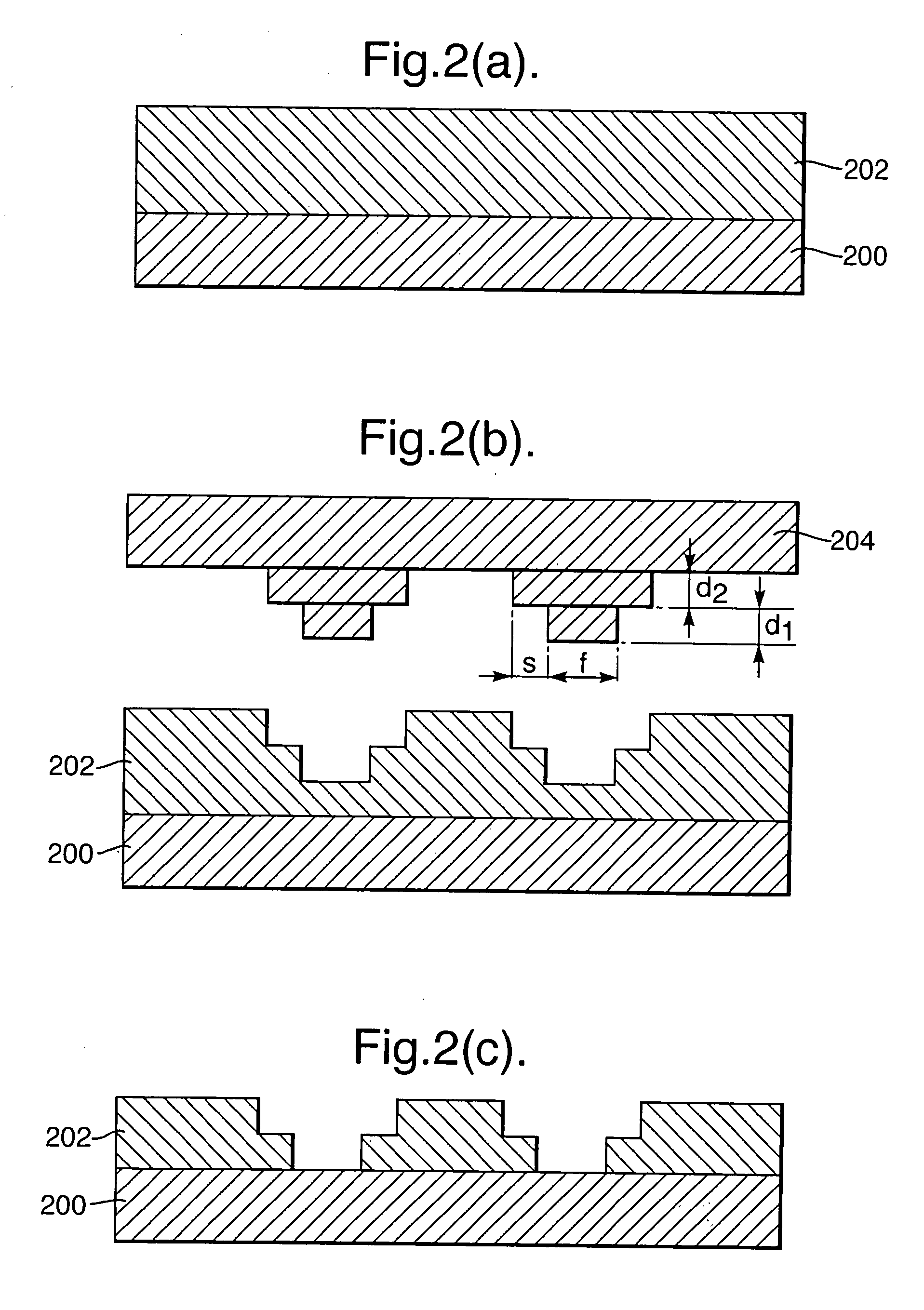

Device fabrication by ink-jet printing materials into bank structures, and embossing tool

InactiveUS20070287270A1Faster and cheapAvoids defectDecorative surface effectsOrnamental structuresPhysicsMicrostructure

The invention disclosed relates to the fabrication of electronic devices. A method for fabricating an electronic device is disclosed, comprising embossing a surface of a work-piece 200, 202 using an embossing tool 204, so as to form a microstructure having at least two levels of thickness contrast on the work-piece surface, and depositing fluid 208 containing a functional material onto the microstructure. In a preferred embodiment, the step of depositing fluid 208 comprises ink-jet printing. An embossing tool 204 for creating a microstructure on a work-piece 200, 202 is also disclosed, the embossing tool 204 comprising a first surface and steps of at least two different heights relative to the first surface.

Owner:SEIKO EPSON CORP

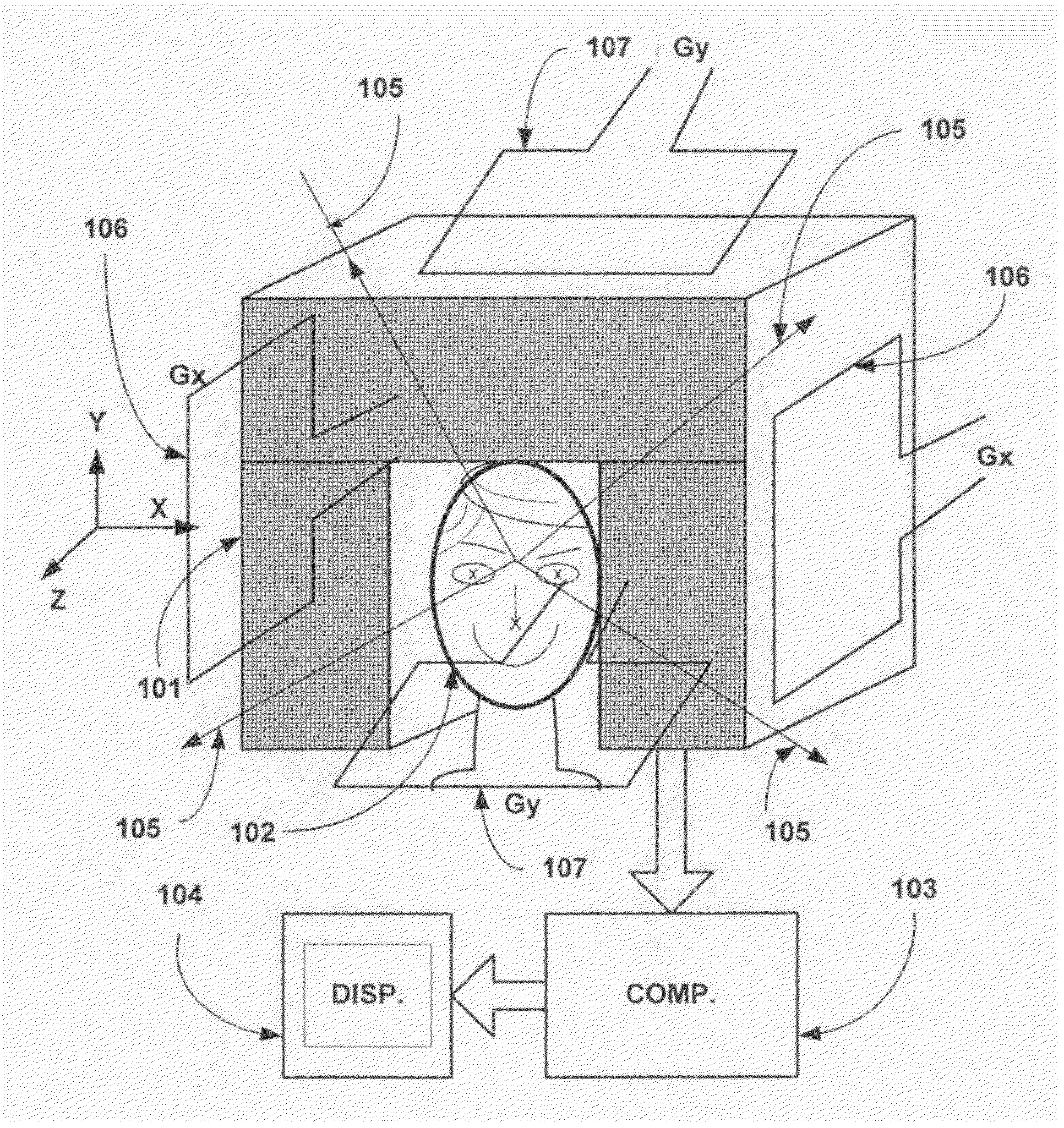

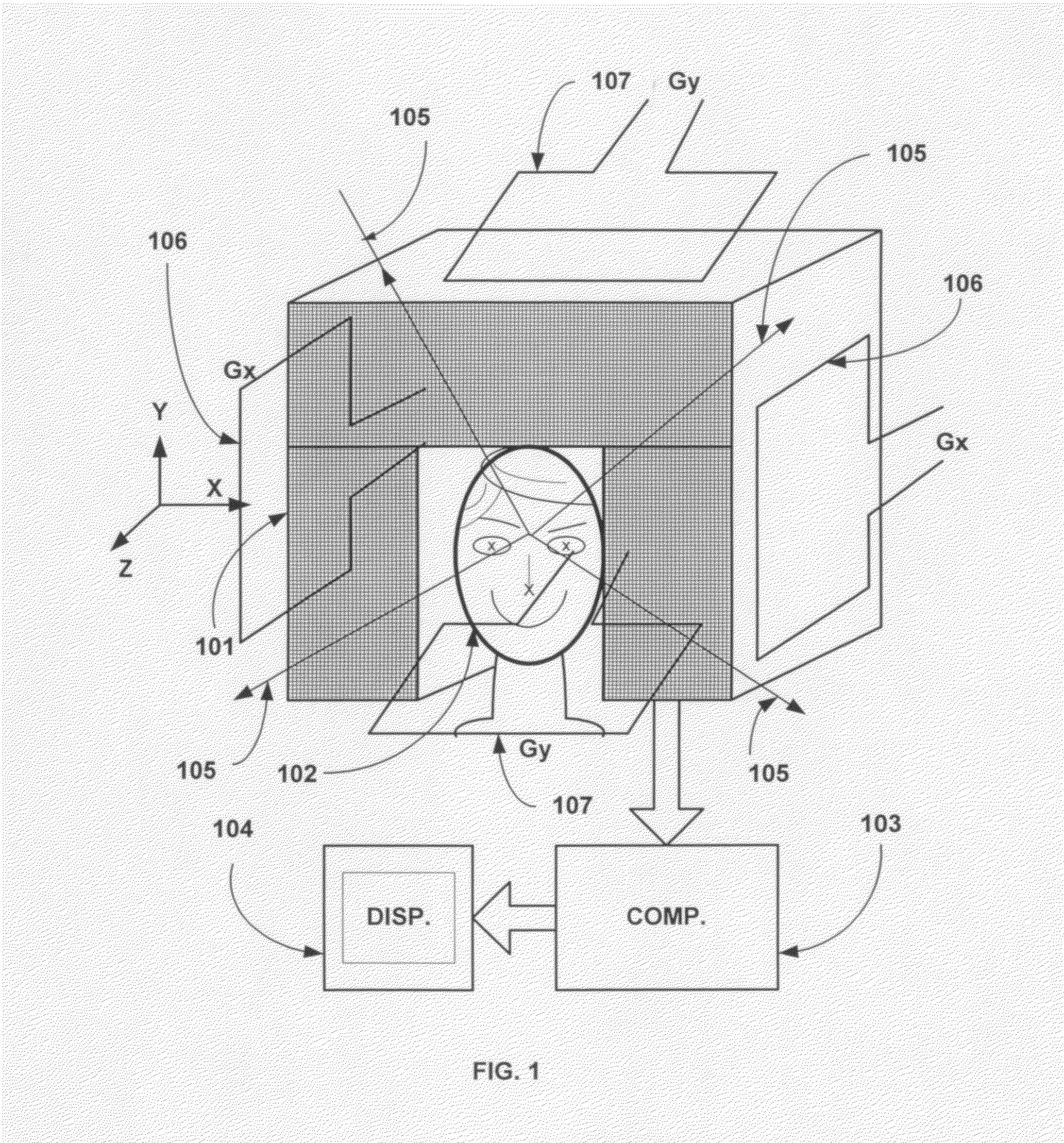

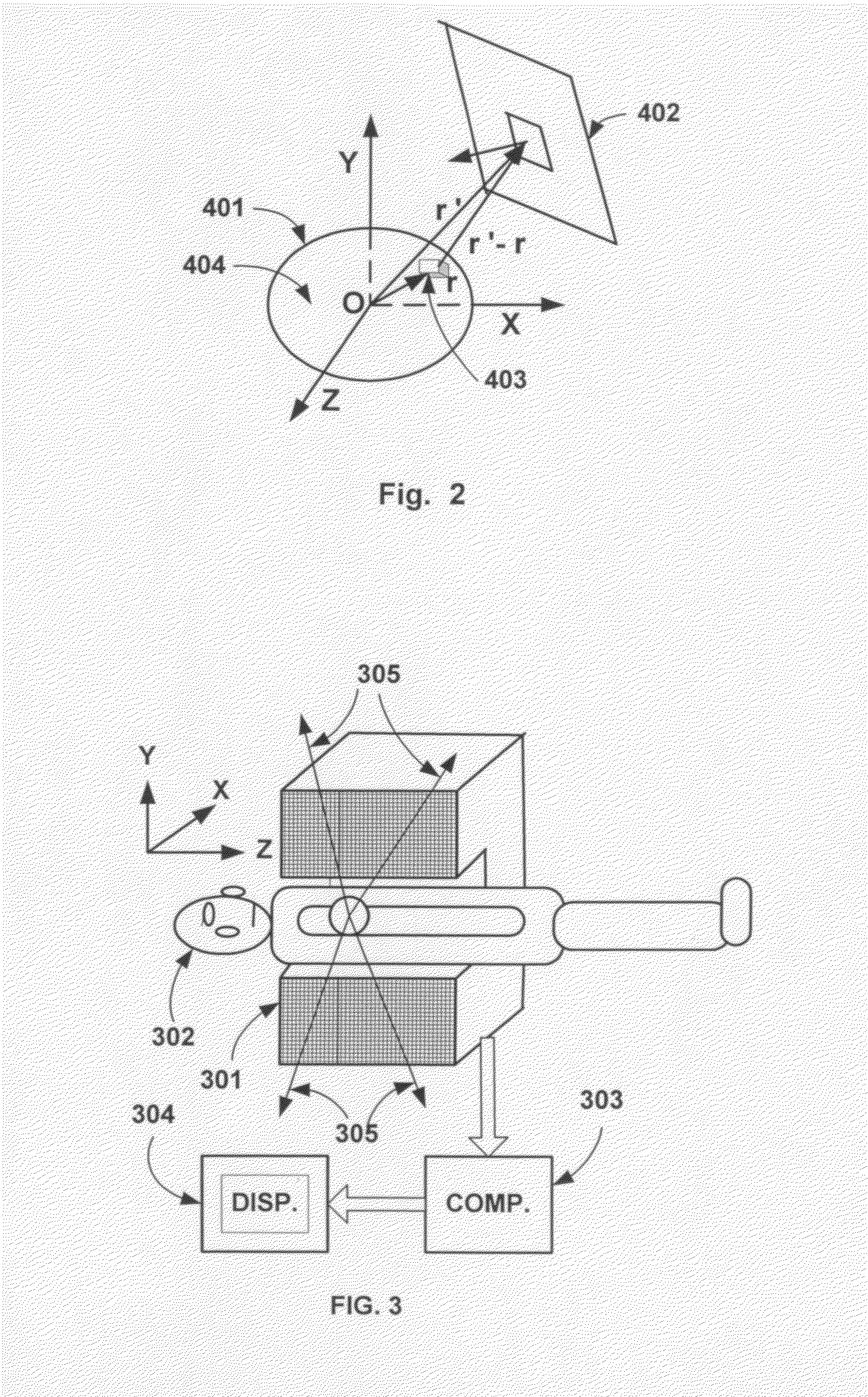

Three-dimensional magnetic density imaging and magnetic resonance imaging

InactiveUS20140354278A1Faster and cheapAvoid frequencyMeasurements using NMR imaging systemsElectric/magnetic detectionTomographic imageMR - Magnetic resonance

Apparatus for measuring magnetic field intensity characteristics around a target object enclosed in a 3D volume space is disclosed. It comprises (a) a means for magnetically polarizing the target object with a known polarizing magnetic field to introduce a magnetic density distribution (MDI) f(r1), (b) a means for measuring magnetic field characteristics g(r2) around the target object at a set of points r2 in a 3D volume space that in particular extends substantially along a radial direction pointing away from the approximate center of the object, (c) a means for setting up a vector-matrix equation; and (d) a means for solving this vector-matrix equation and obtaining a solution for f(r1) that provides a 3D tomographic image of the target object. This novel apparatus is integrated with frequency and phase encoding methods of Magnetic Resonance Imaging (MRI) technique in prior art to achieve different trade-offs.

Owner:SUBBARAO MURALIDHARA

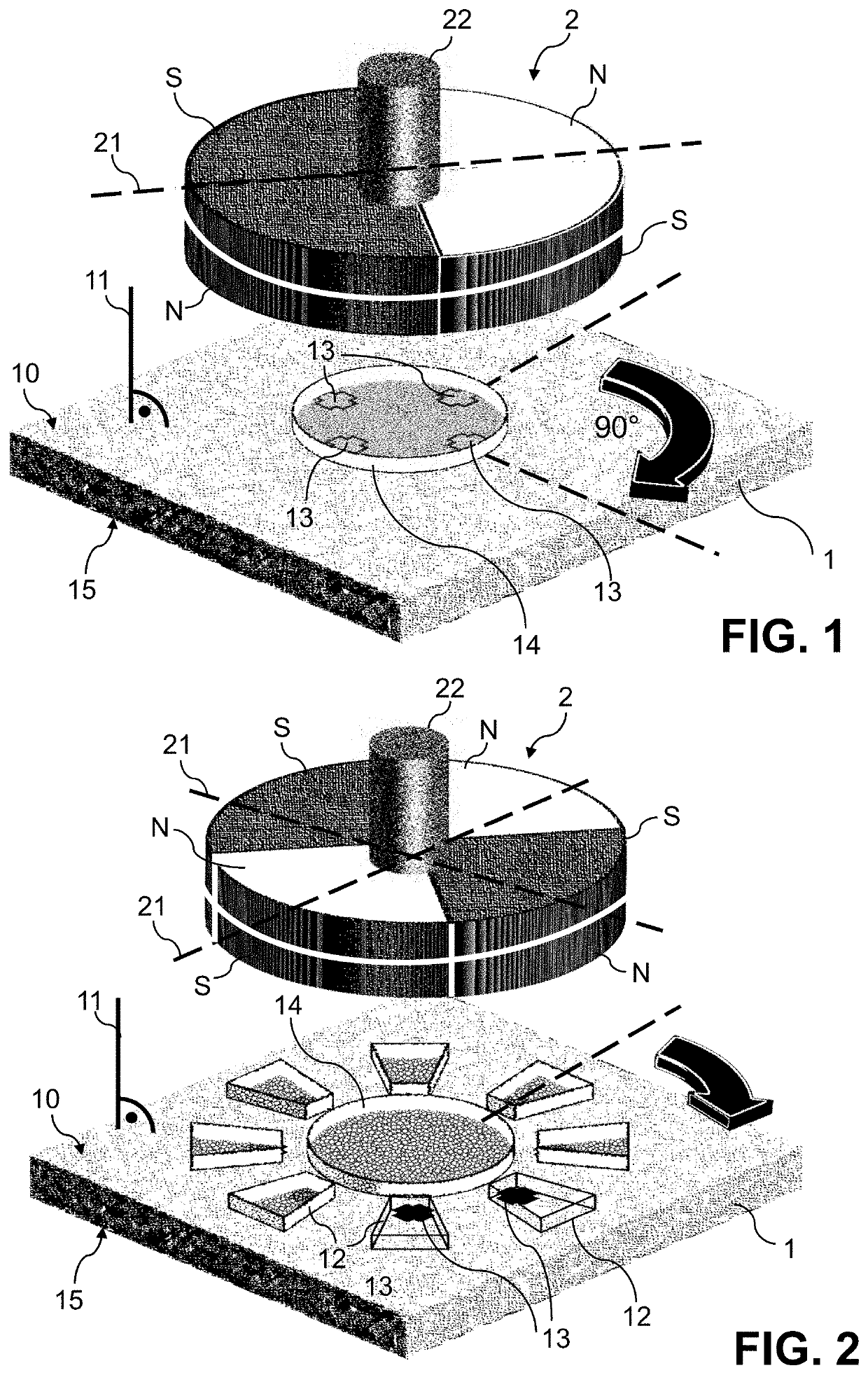

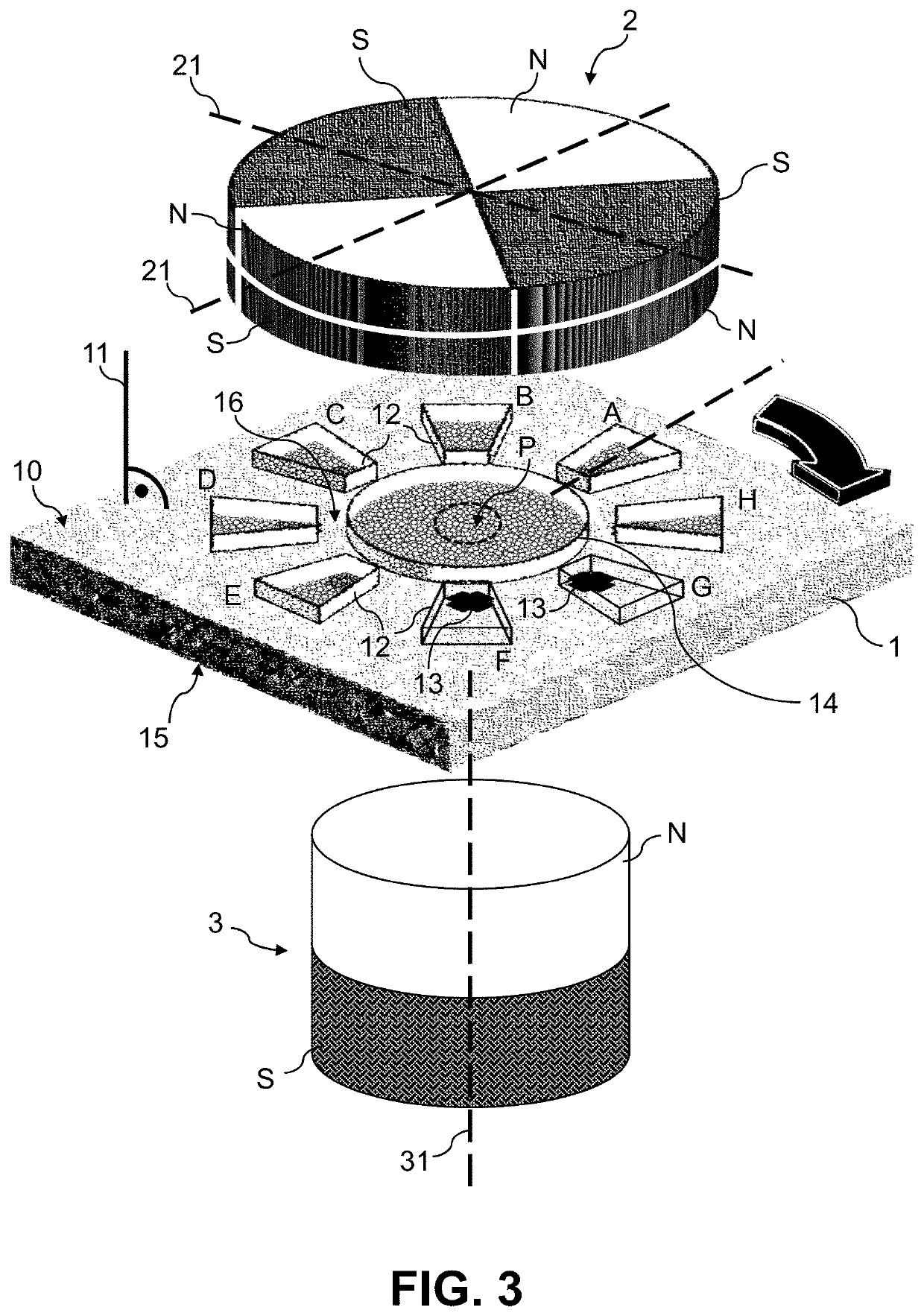

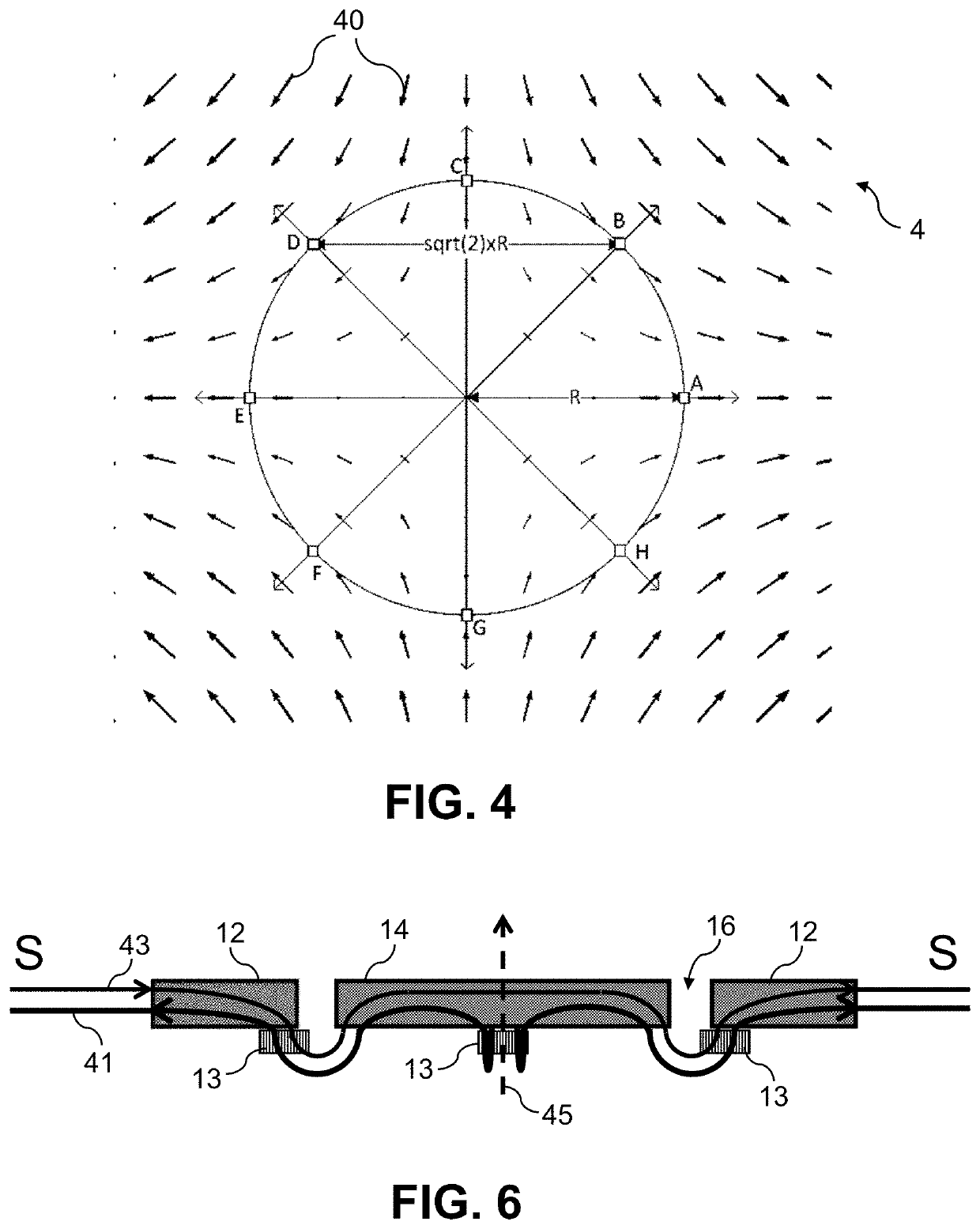

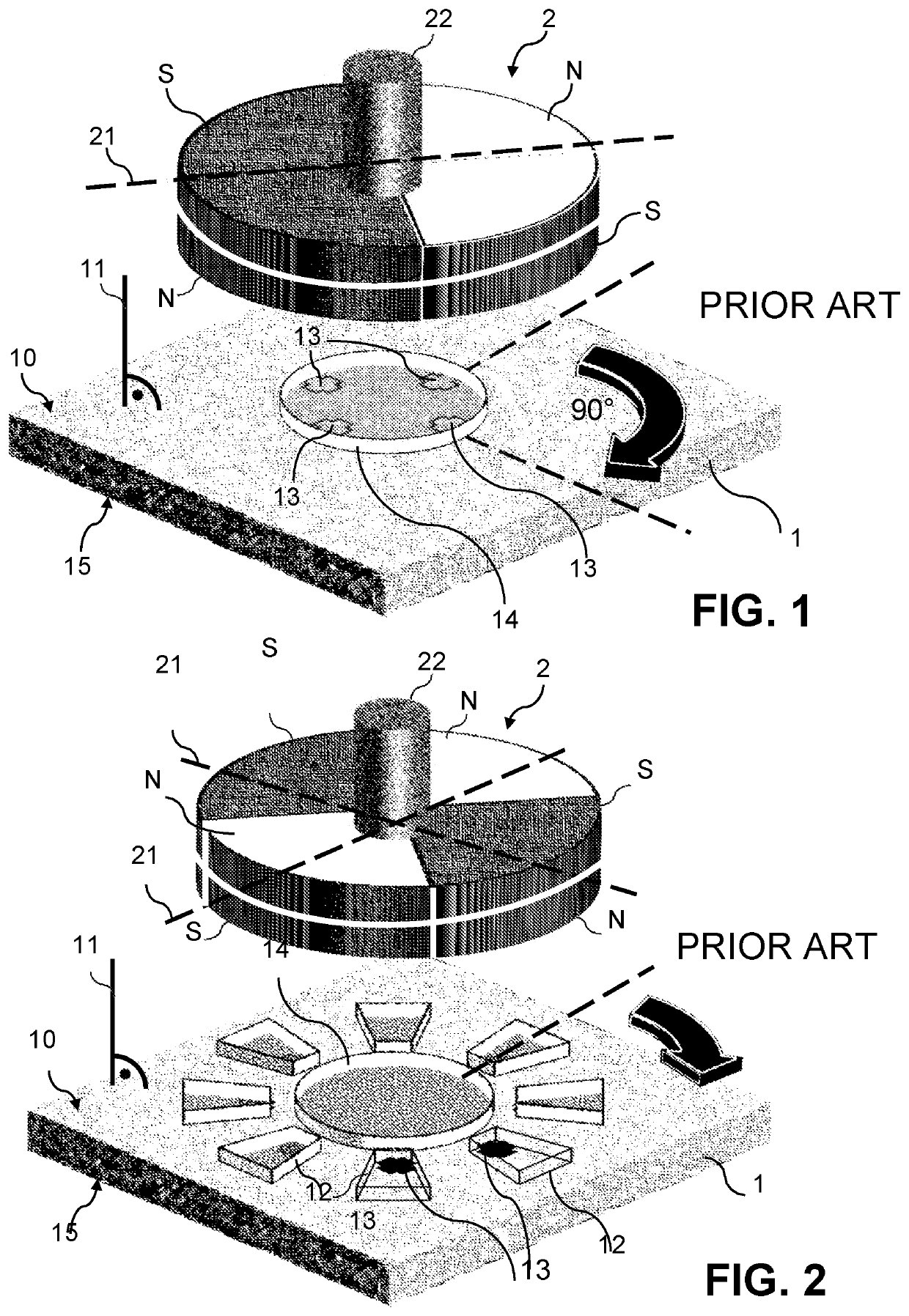

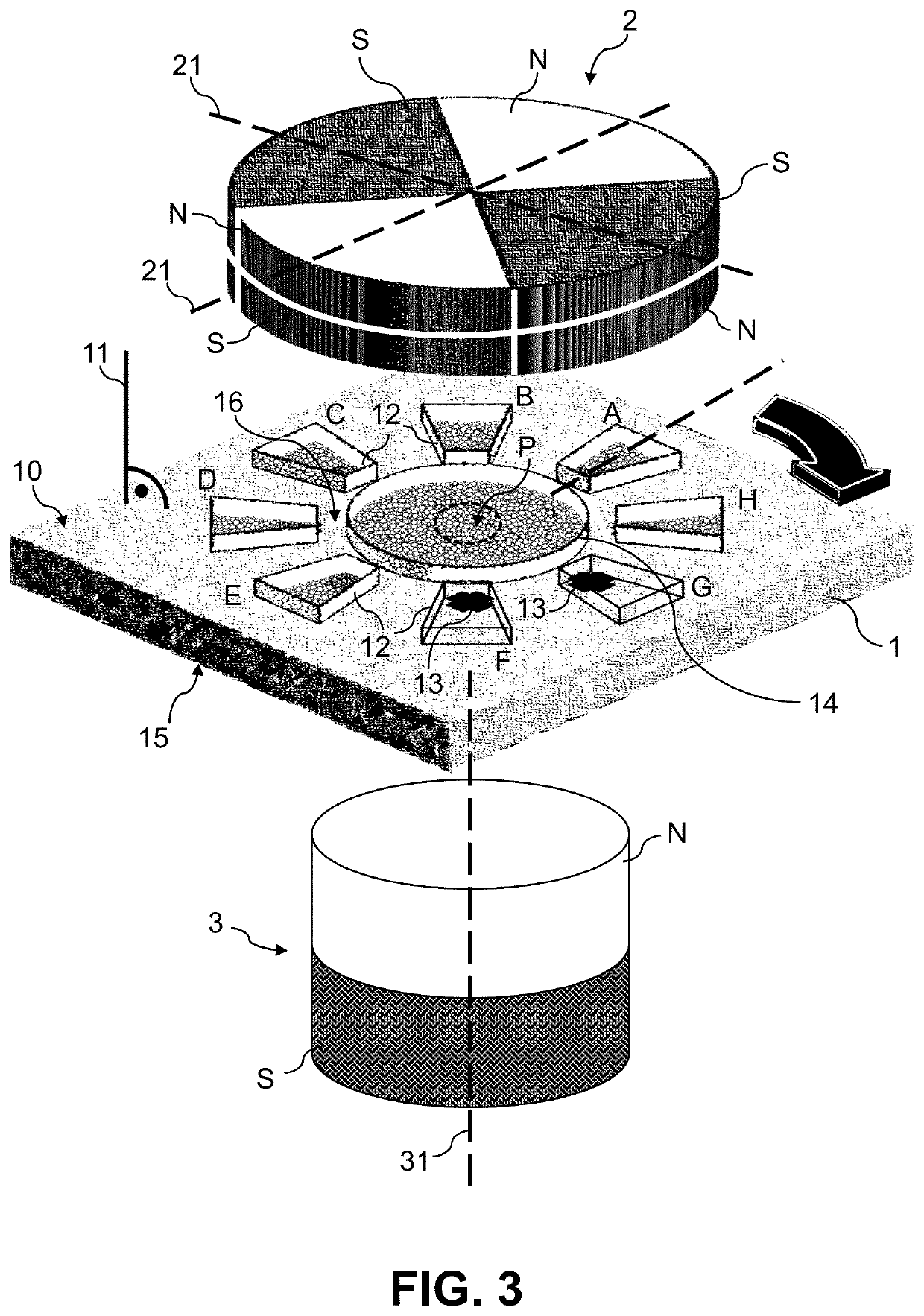

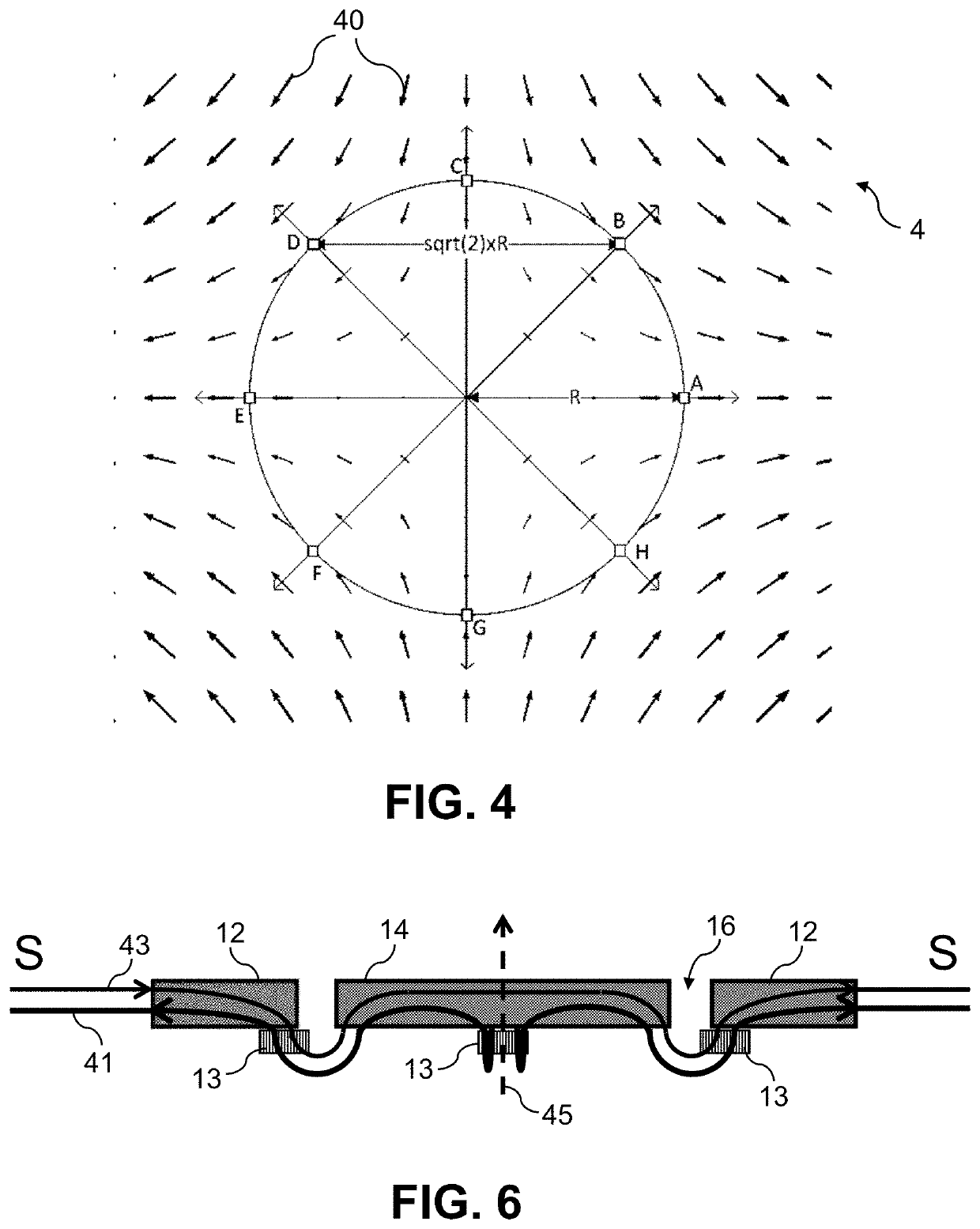

Sensor system for rotation angular detection and 3D joystick function

ActiveUS20200271479A1More robust sensor systemWithout compromising sensor system overall accuracyManual control with multiple controlled membersAircraft controlMagnetic sourceJoystick

A sensor system and a joystick including the sensor system. The sensor system comprises a magnetic field sensor, and first and second magnetic sources. The first magnetic source is rotatable relative to a sensitive surface of the sensor and generates a first magnetic field contribution of at least quadrupolar order. The second magnetic source is pivotable with respect to the sensitive surface and generates a second magnetic field contribution. The sensor is configured for detecting at least an in-plane component of a superimposition field of the first and second magnetic contributions at a plurality of lateral measurement locations on the sensitive surface, obtaining measurements, and determining a rotation angle for the first source from the field gradient measurements and two angular directions for the second source from the field mean measurements. Lateral measurement locations are arranged into two pairs of diametrically opposite measurement locations with respect to the sensitive surface.

Owner:MELEXIS TECH NV

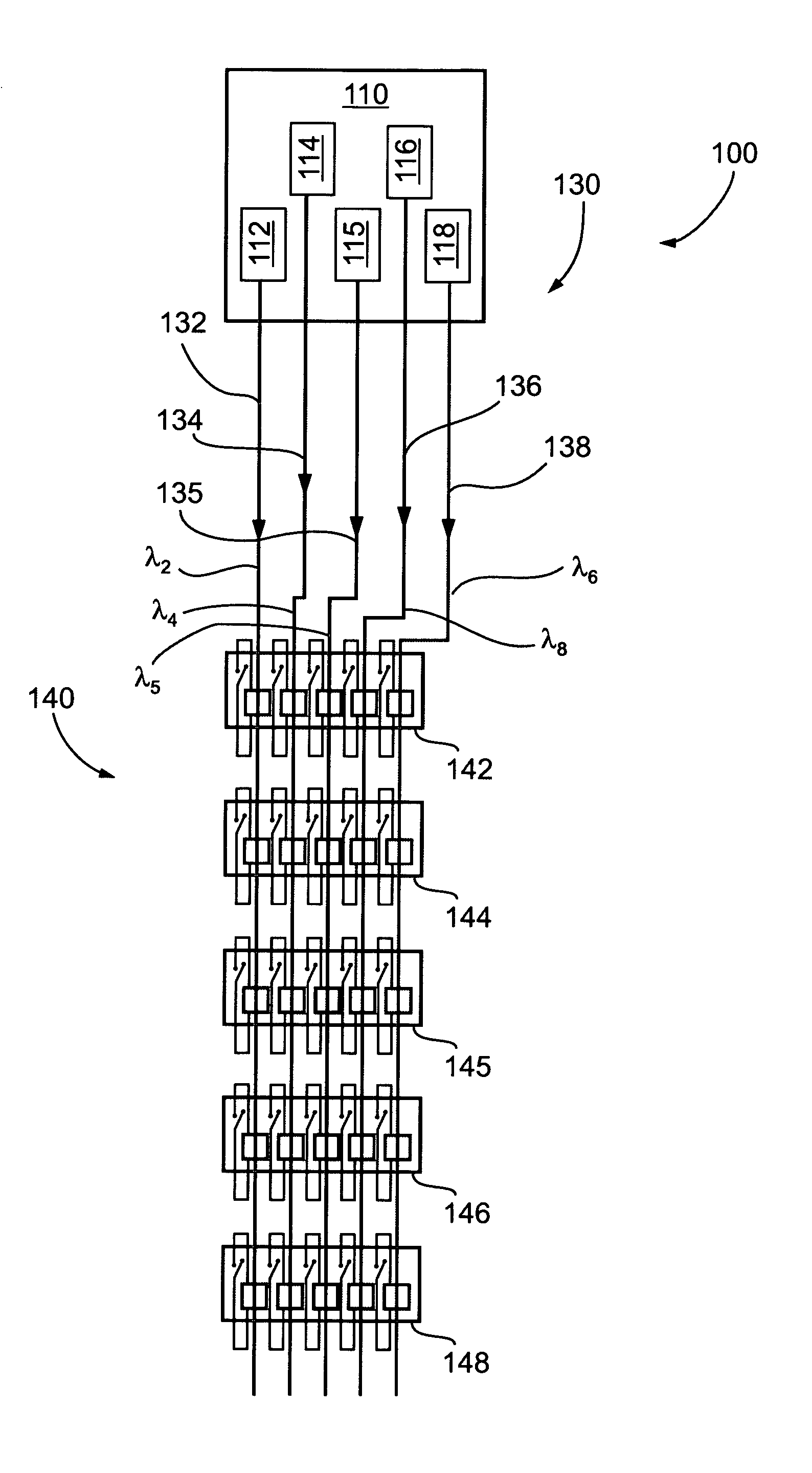

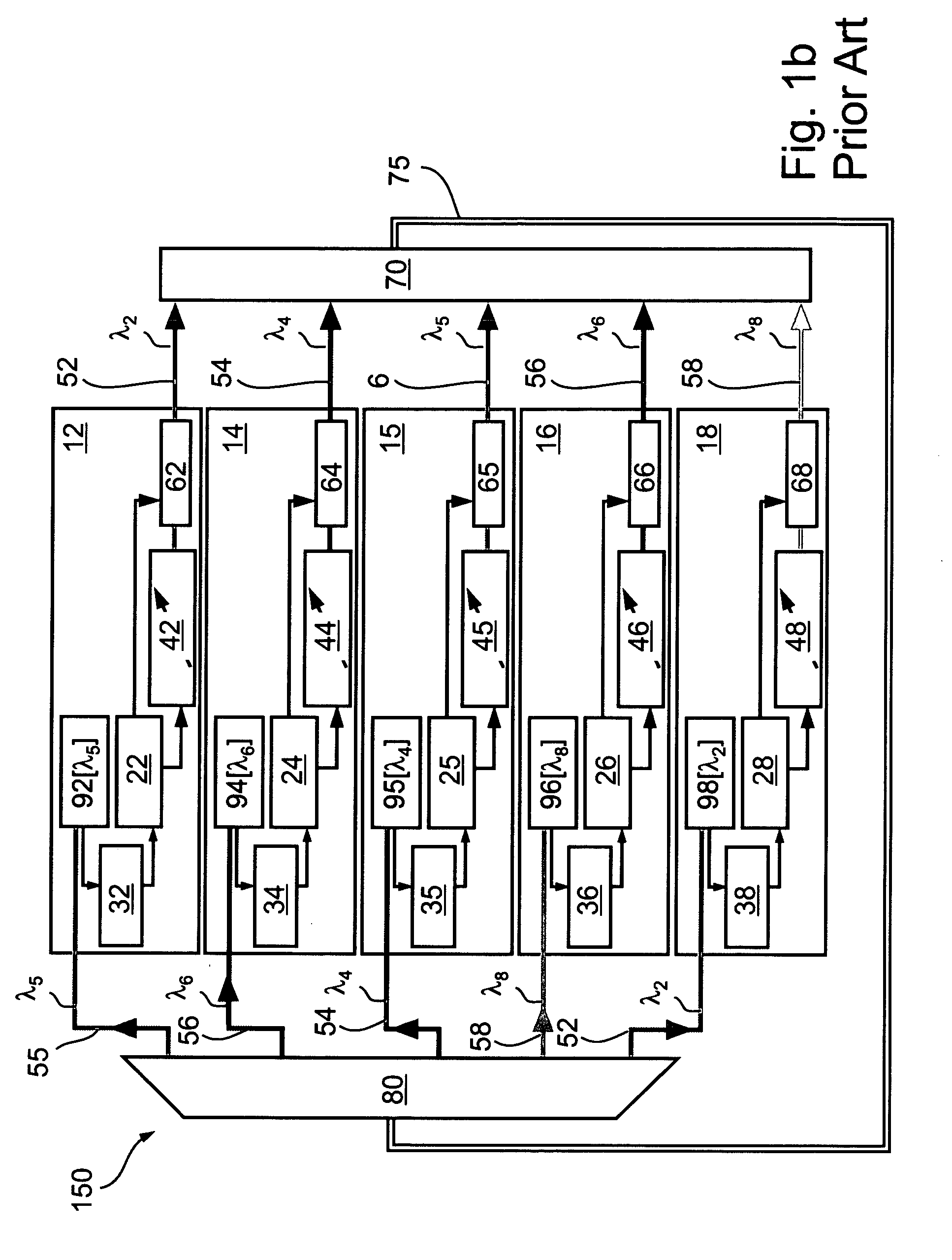

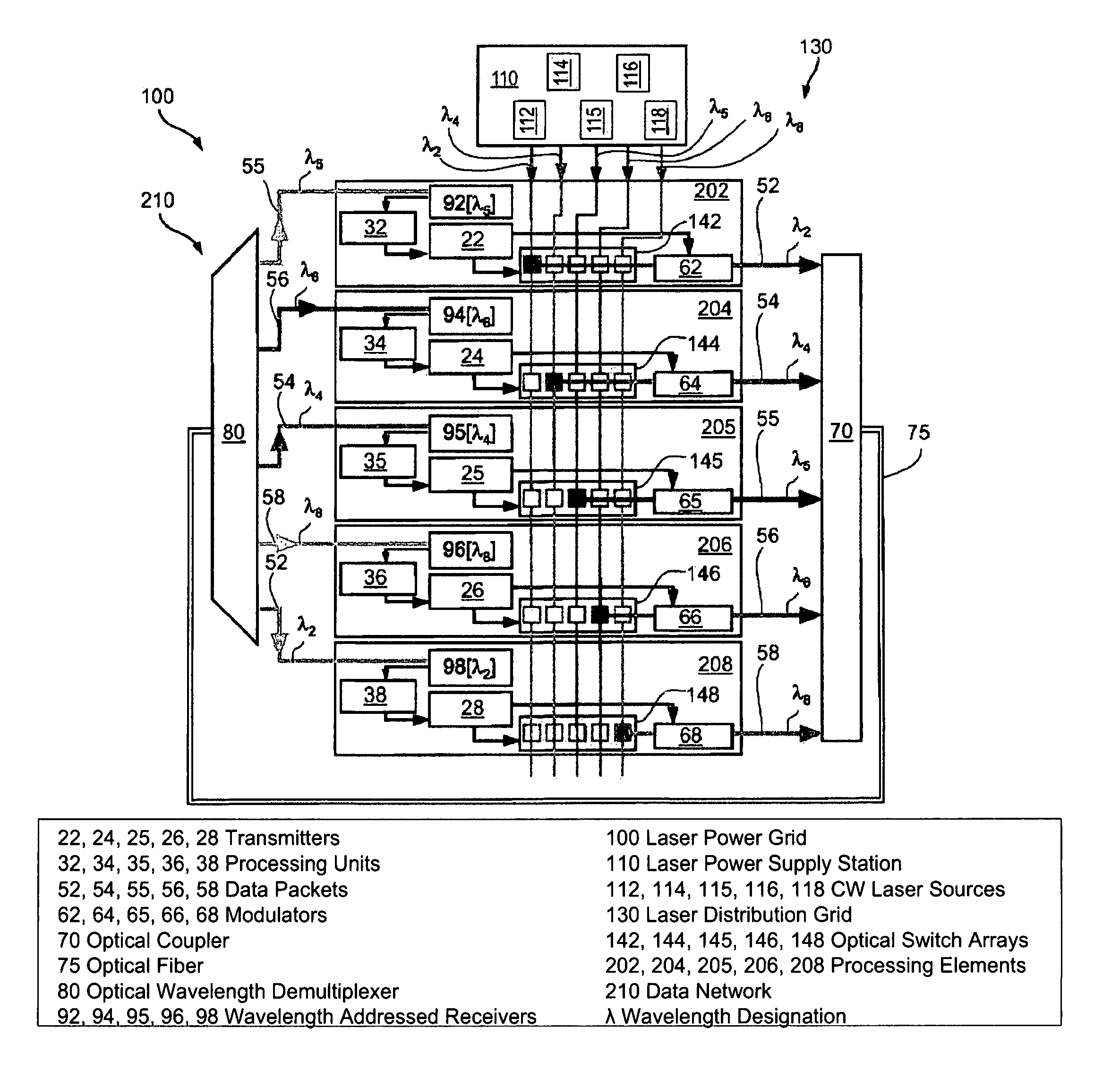

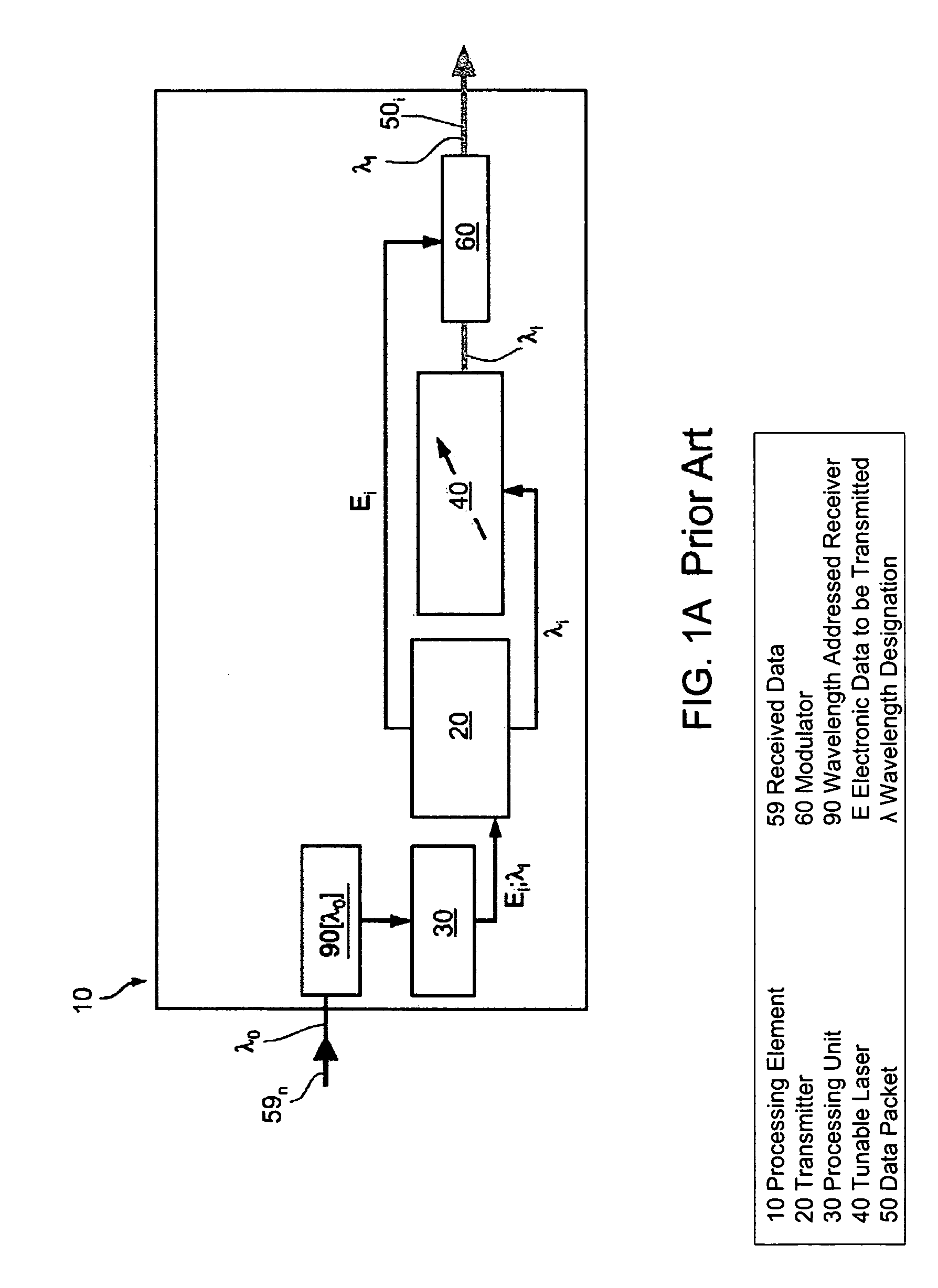

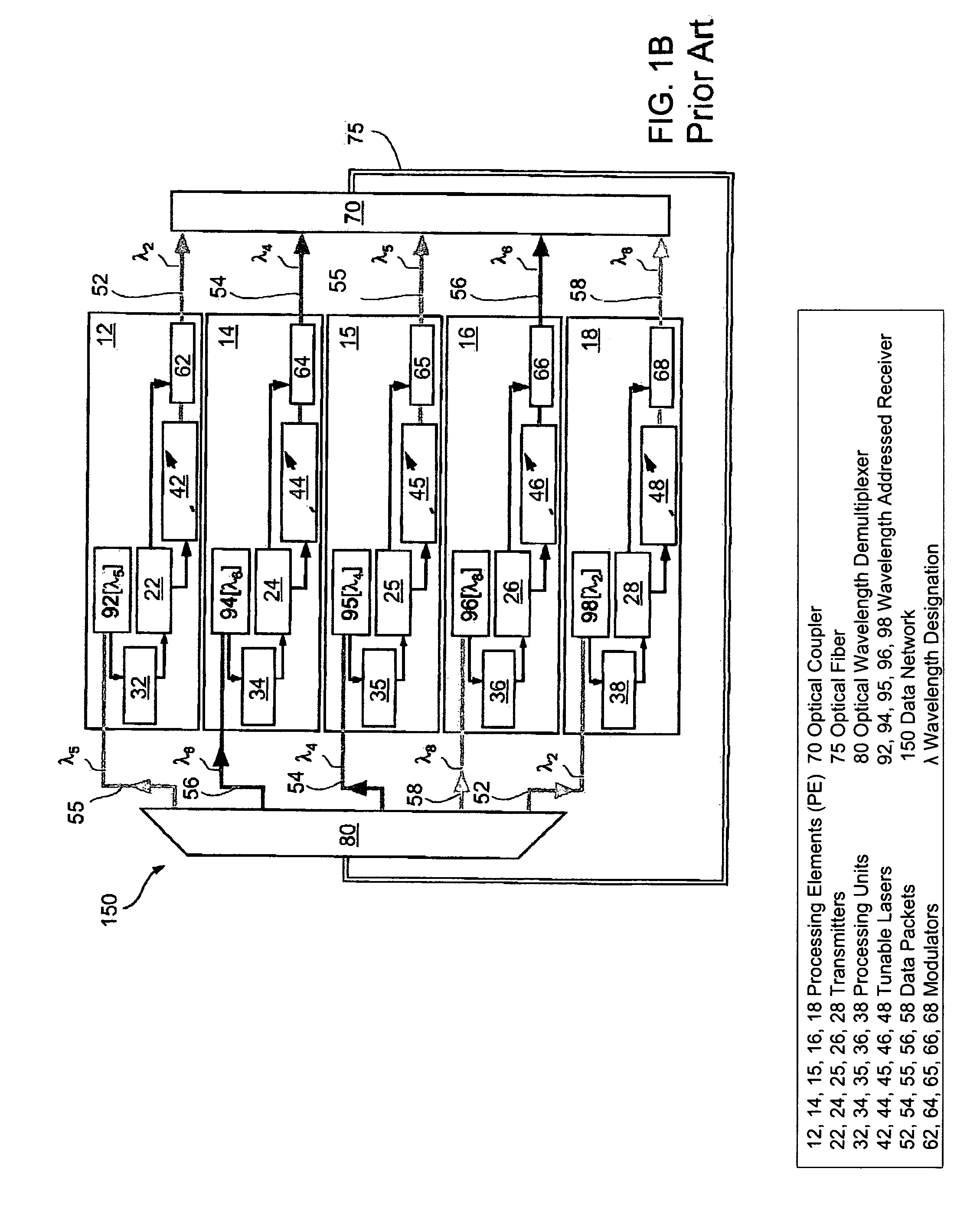

Laser power grid

InactiveUS20060062514A1Produce heatFaster and cheapWavelength-division multiplex systemsCoupling light guidesExchange networkPower grid

A laser power grid for operation with data networks employs WDM and incorporates wavelength addressing. The laser power grid (100) includes a laser power supply station (110) comprising a plurality of continuous-work laser sources (112, 114, 115, 116, 118), a laser distribution grid (130) for distributing light propagations of different wavelengths throughout a data network and an optical switching network (142, 144, 145, 146, 148) coupled to the laser distribution grid for locally turning the laser power on when it is needed. The laser power grid replaces systems of tunable lasers. It is considerably faster and cheaper than systems of tunable lasers and produces less waste heat within the data network surroundings. The laser power grid incorporates parallel fast optical communication in complex multi-node communication and computer networks and enables the implementation of burst switching and packet switching by wavelength addressing.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

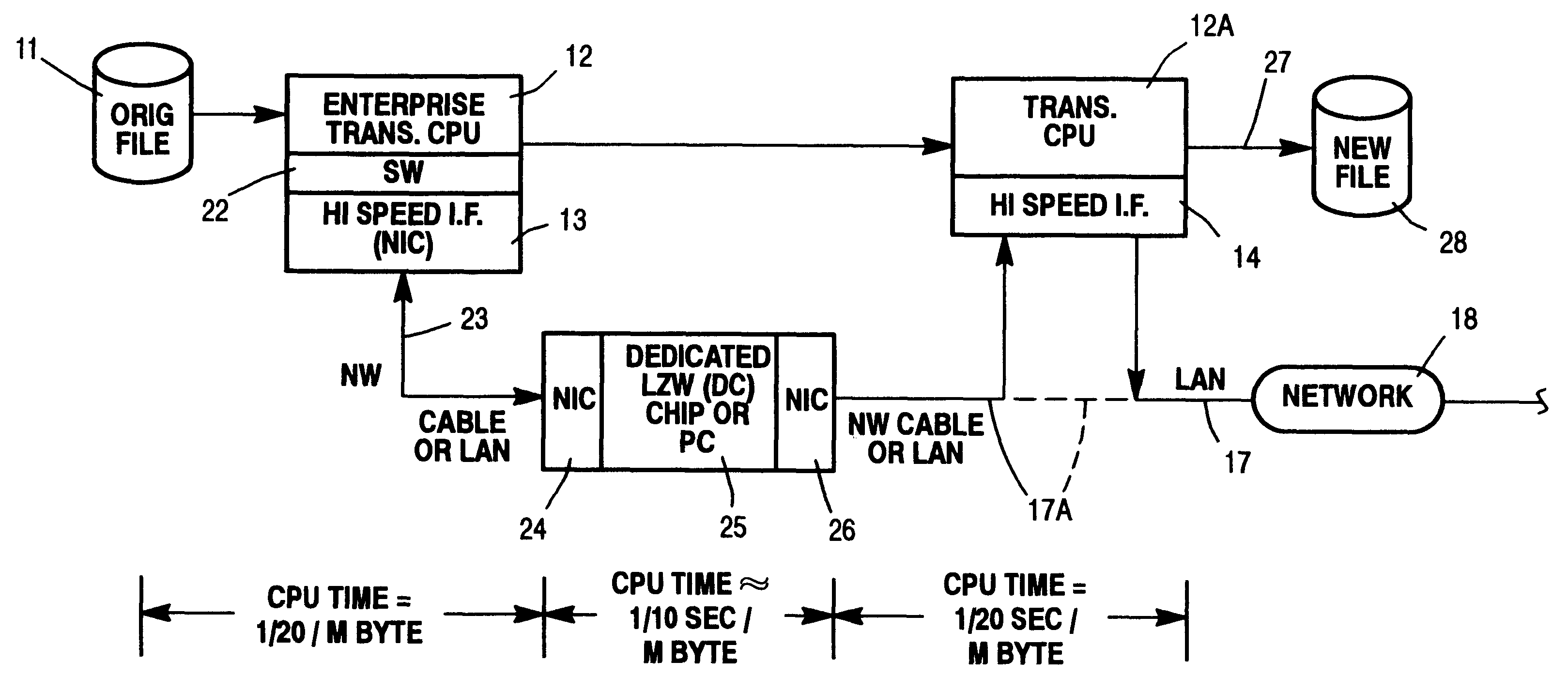

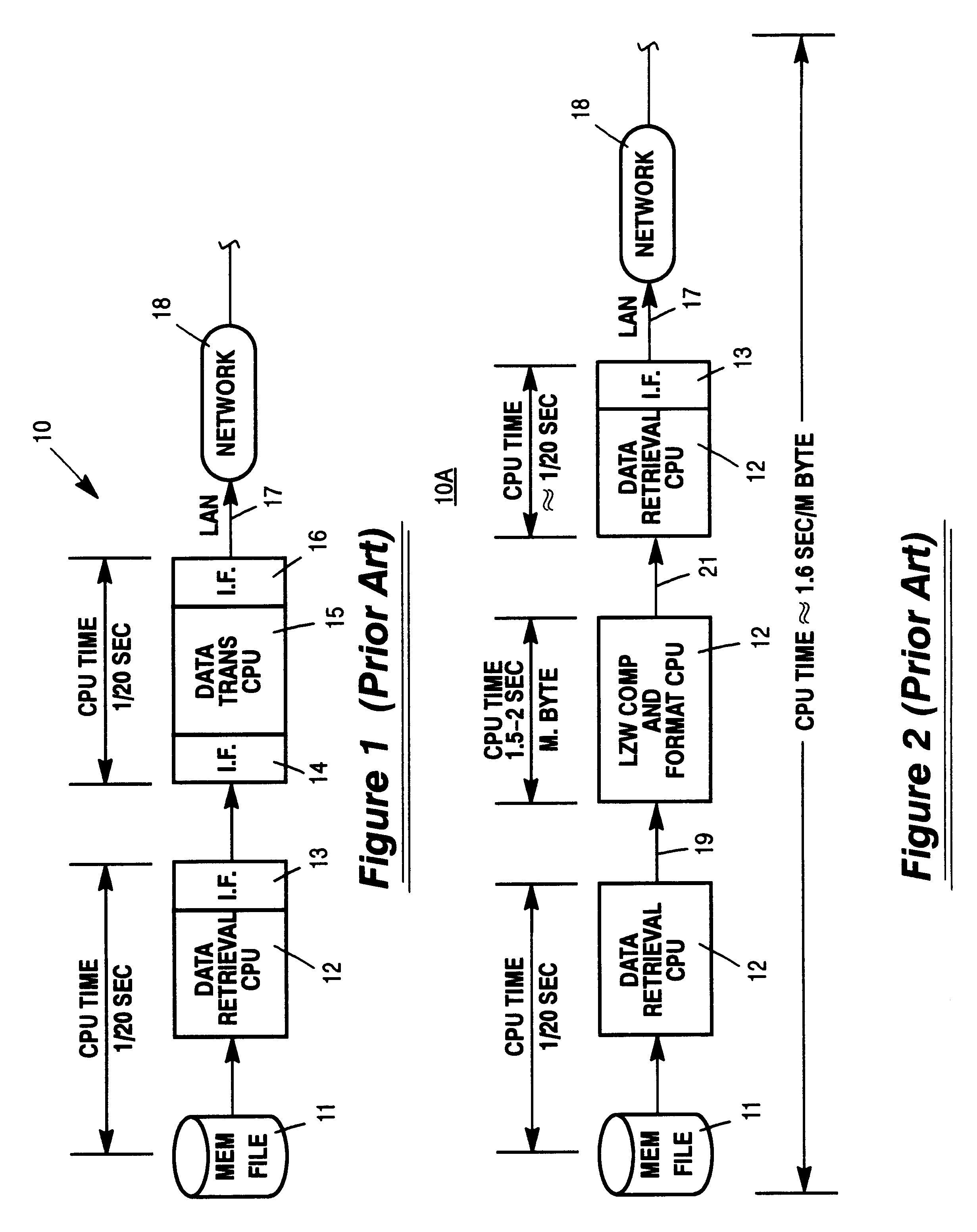

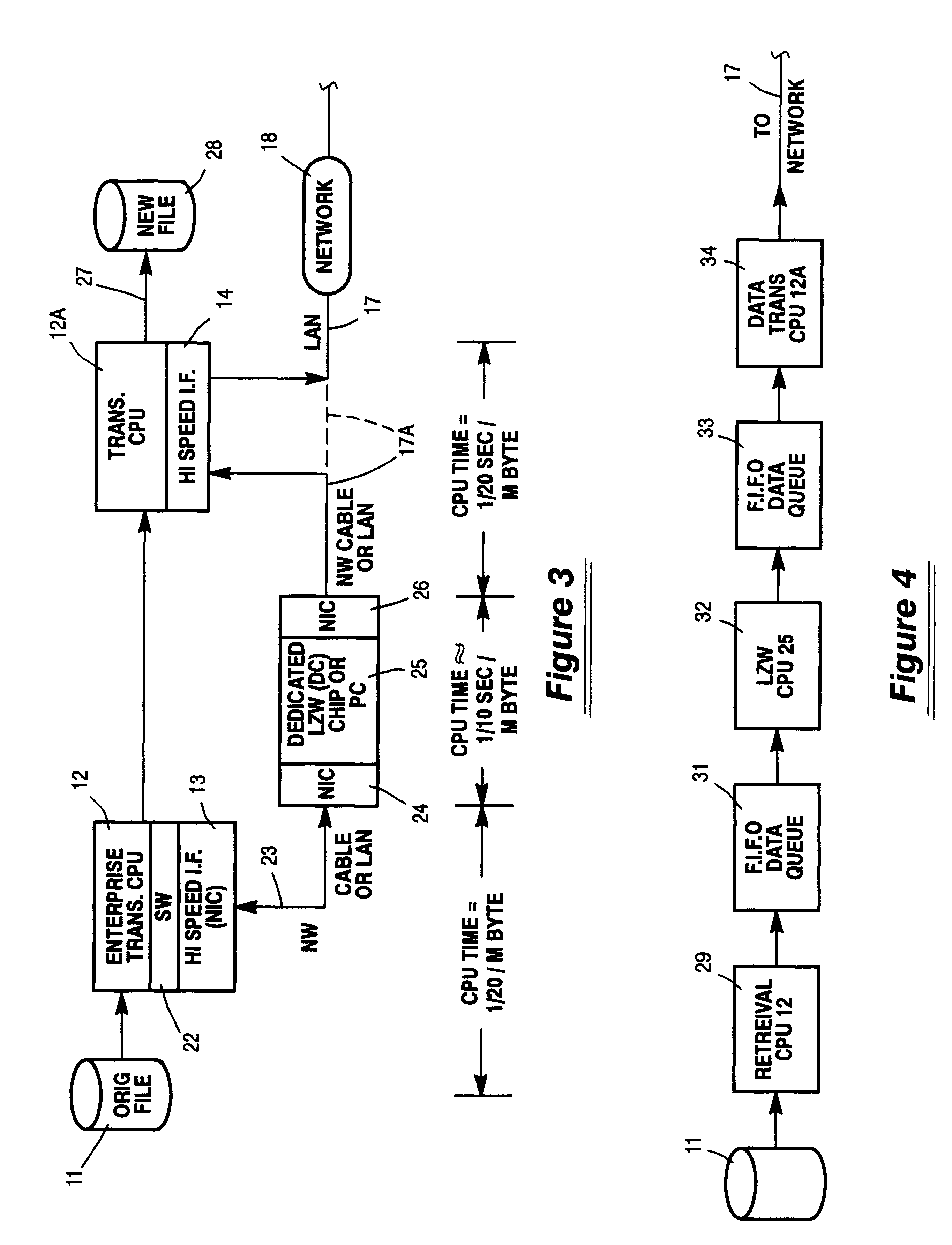

System for high speed continuous file transfer processing of data files

InactiveUS6401133B1Low costFaster and cheapResource allocationMultiple digital computer combinationsData fileComputer access

In a system for economically and continuously transmitting data files from one location to a remote location there is provided a high speed mainframe computer adapted to read a data file and to determine if the process to be performed on the data requires a large amount of mainframe processor cycle time. If so the data file is down loaded to a memory accessible by a much less expensive single chip type dedicated computer that is particularly well suited to perform the process that would require high mainframe processor time cost. The output of the dedicated computer in coupled to a communication network for transmittal to the remote location. In the preferred embodiment-of the present invention first-in-first-out (FIFO) data queues are employed to maintain optimum utilization of the dedicated computer and transfer of the data files.

Owner:UNISYS CORP

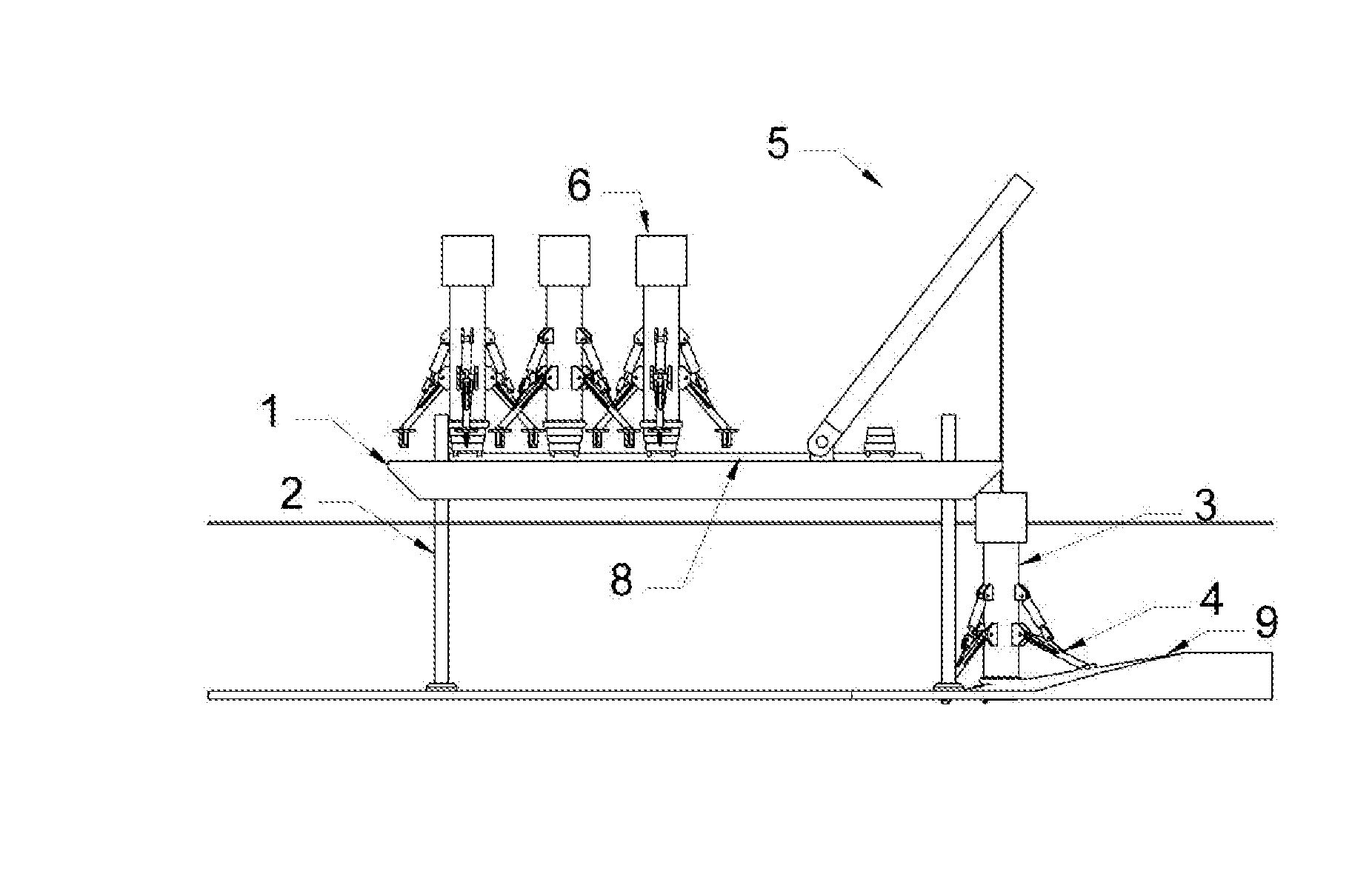

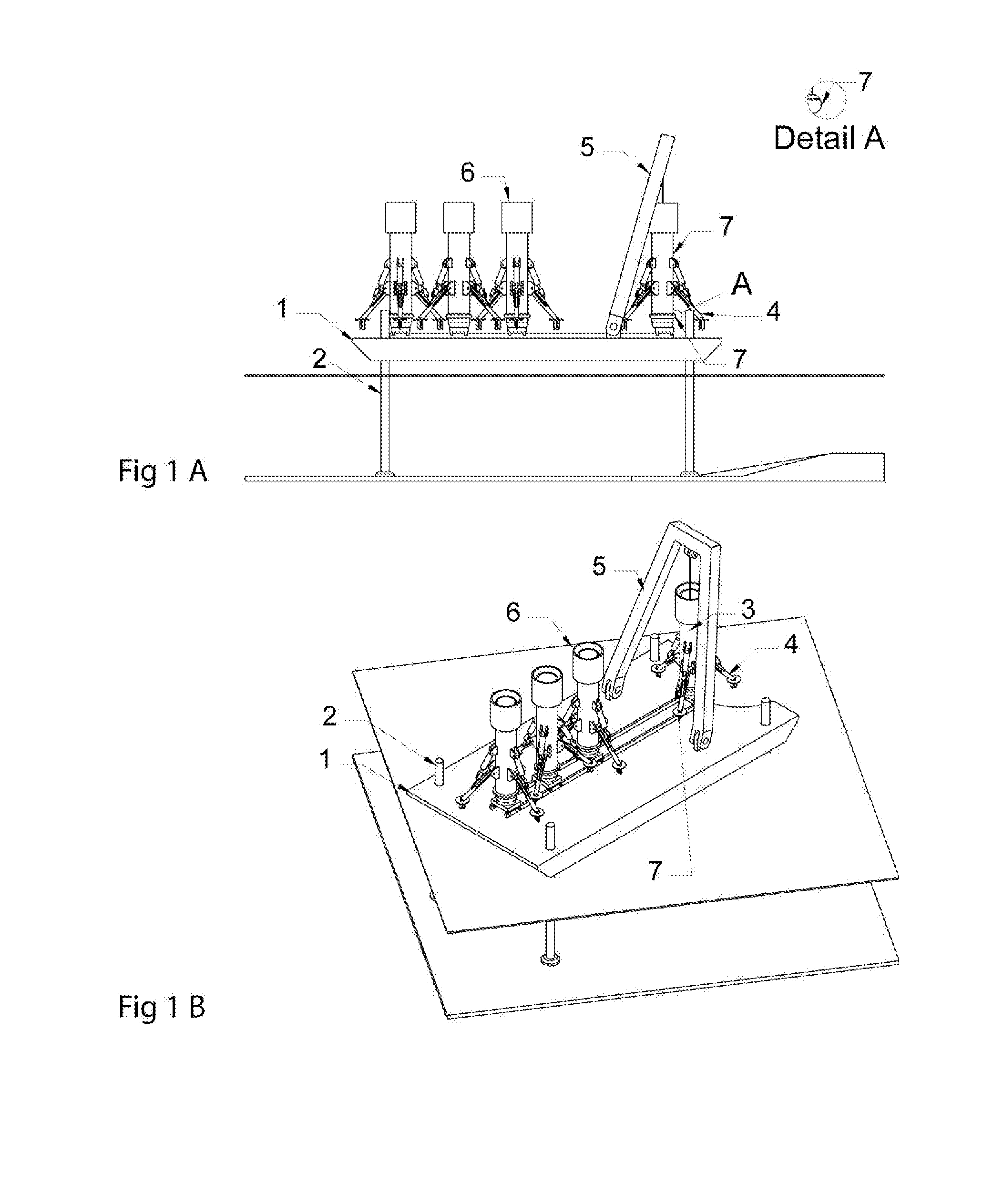

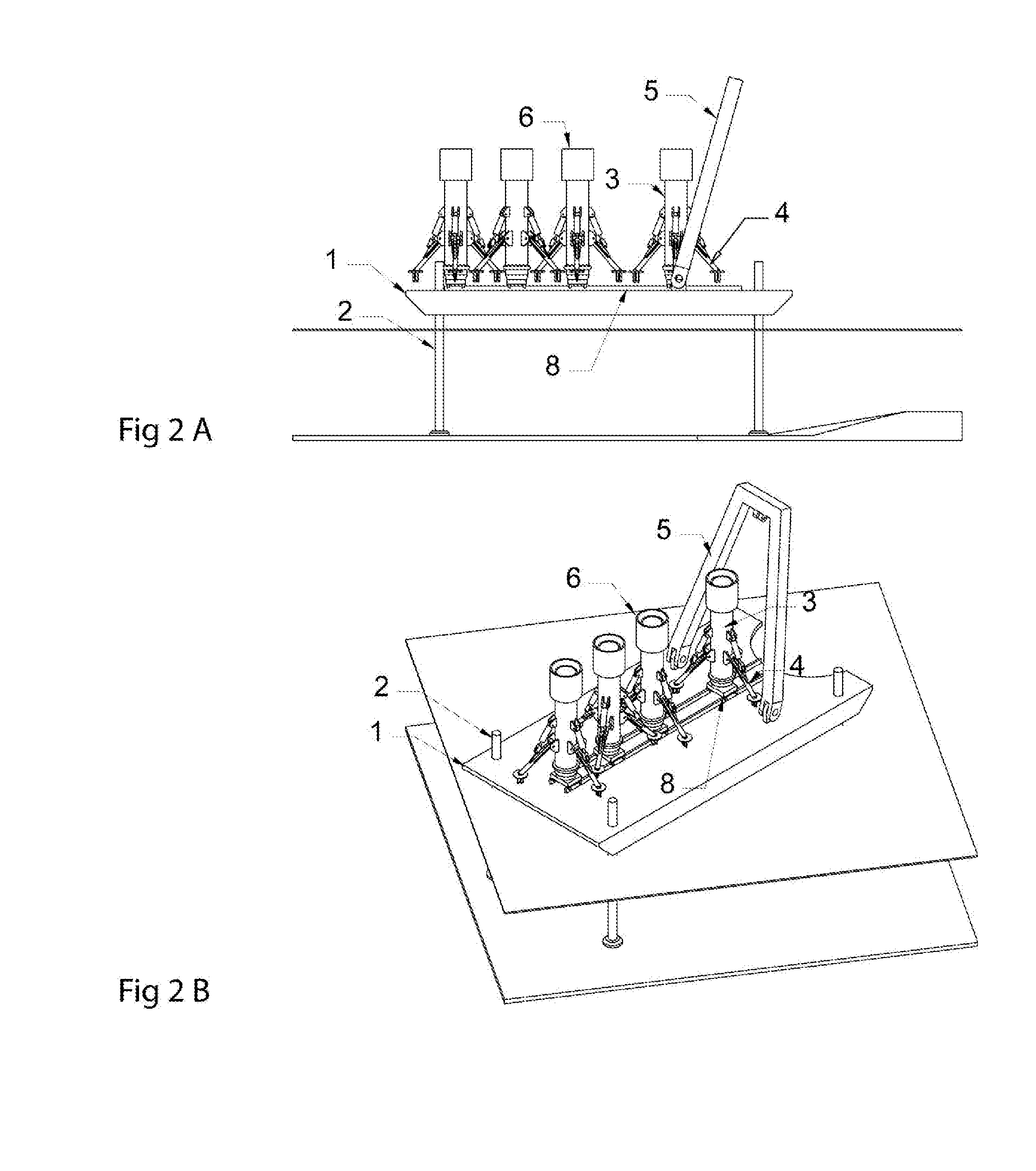

Apparatus and method for reduction of sonic vibrations in a liquid

An apparatus for reduction of sonic vibrations caused when driving a foundation member below the surface of a liquid has a tube structure which is lowered below the surface of the liquid, and which receives the foundation member. A seal is in contact with the tube structure and creates a contained volume around the foundation member, which may be pumped dry so as to minimize the communication of sonic vibrations into the liquid.

Owner:LO NOISE APS

Laser power grid

InactiveUS7715714B2Produce heatFaster and cheapWavelength-division multiplex systemsCoupling light guidesExchange networkPower grid

A laser power grid for operation with data networks employs WDM and incorporates wavelength addressing. The laser power grid (100) includes a laser power supply station (110) comprising a plurality of continuous-work laser sources (112, 114, 115, 116, 118), a laser distribution grid (130) for distributing light propagations of different wavelengths throughout a data network and an optical switching network (142, 144, 145, 146, 148) coupled to the laser distribution grid for locally turning the laser power on when it is needed. The laser power grid replaces systems of tunable lasers. It is considerably faster and cheaper than systems of tunable lasers and produces less waste heat within the data network surroundings. The laser power grid incorporates parallel fast optical communication in complex multi-node communication and computer networks and enables the implementation of burst switching and packet switching by wavelength addressing.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

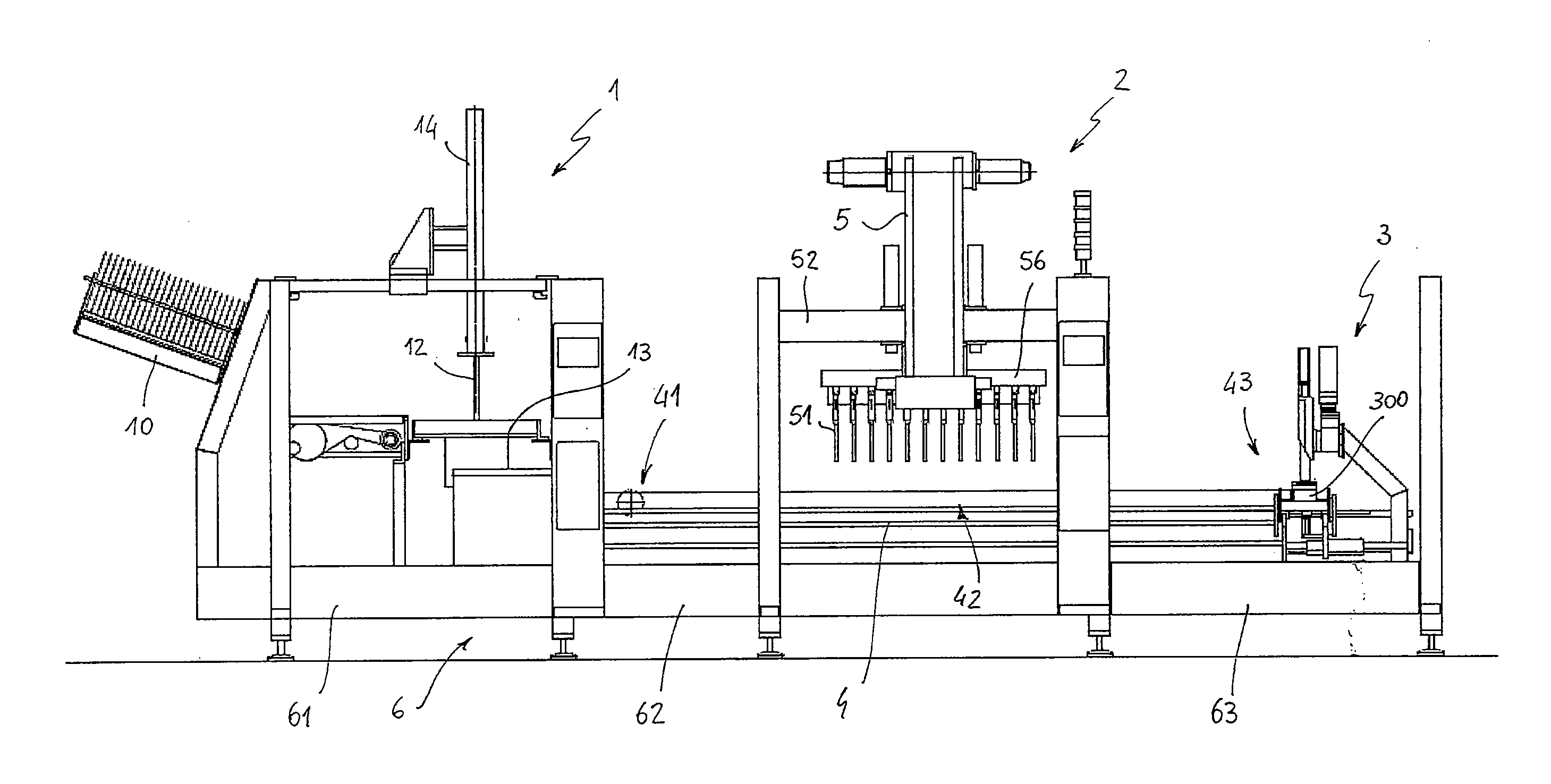

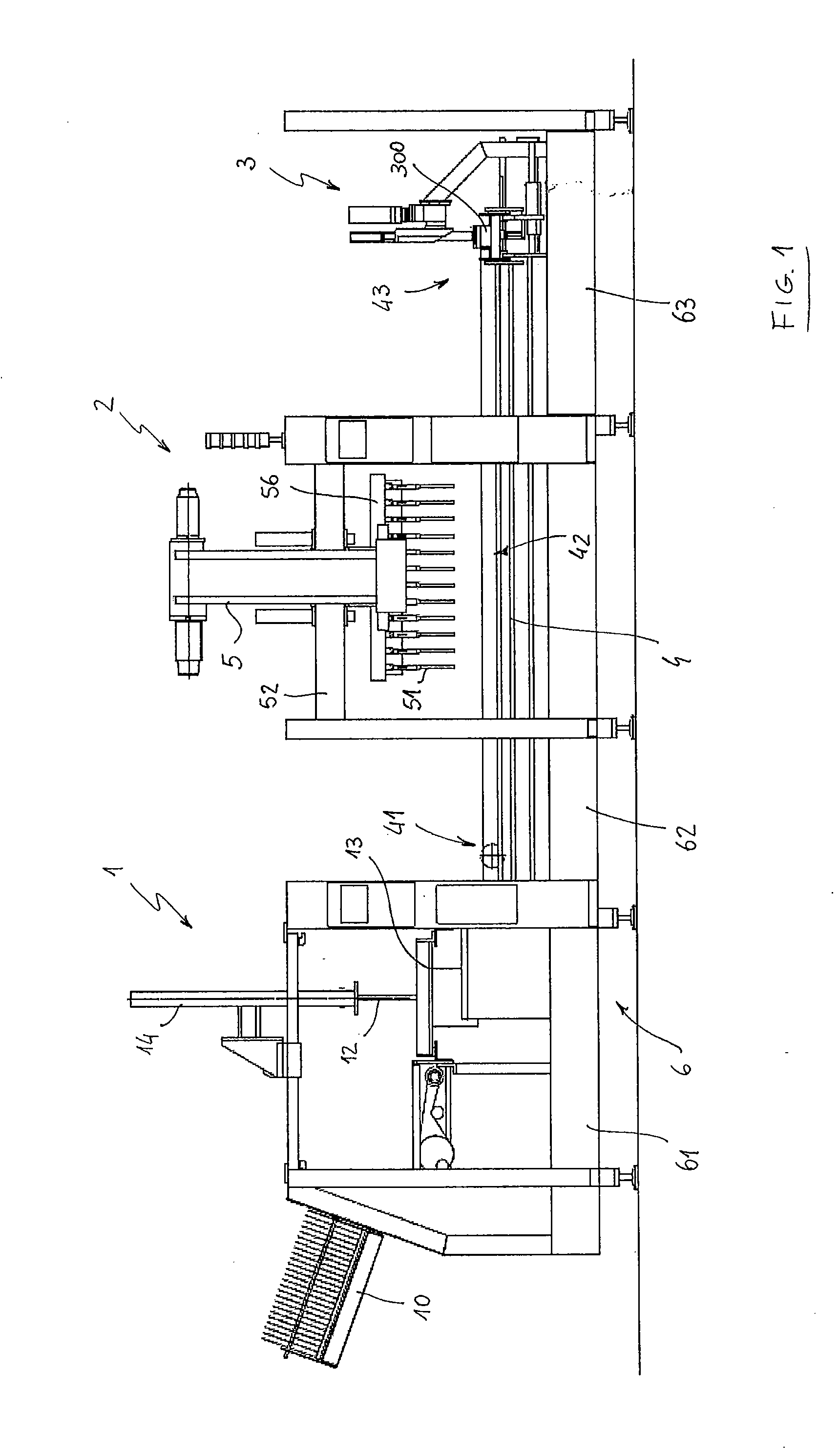

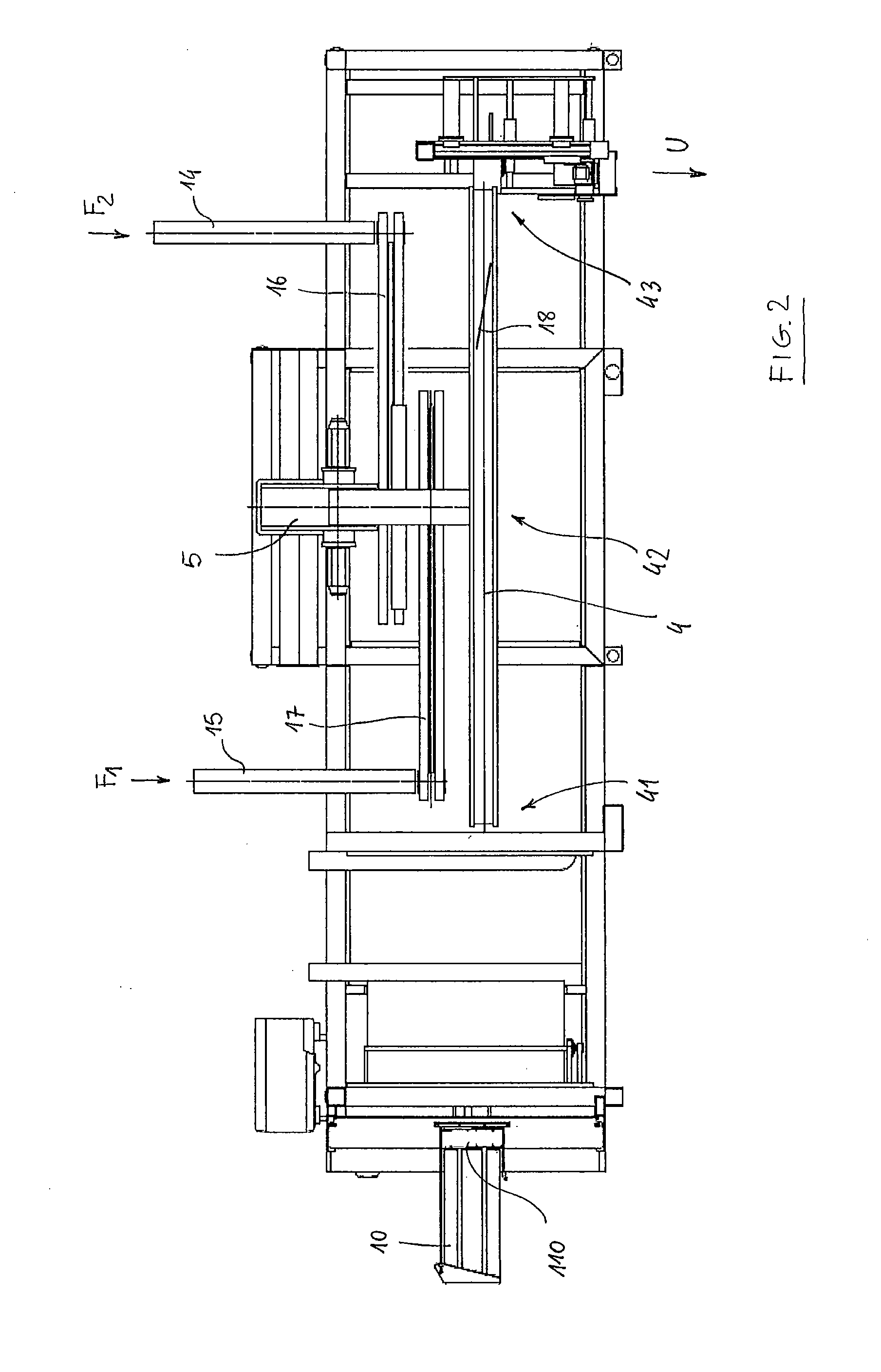

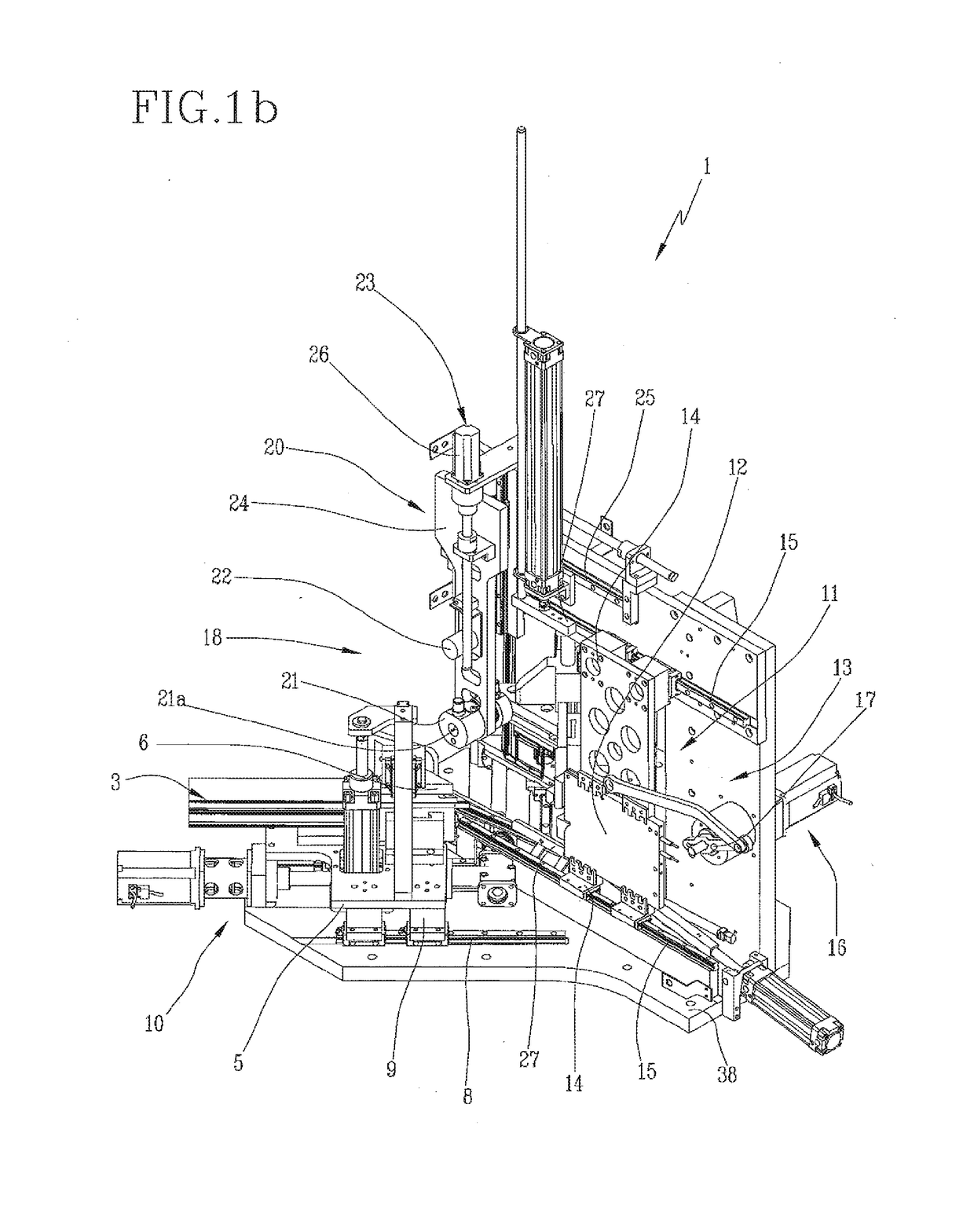

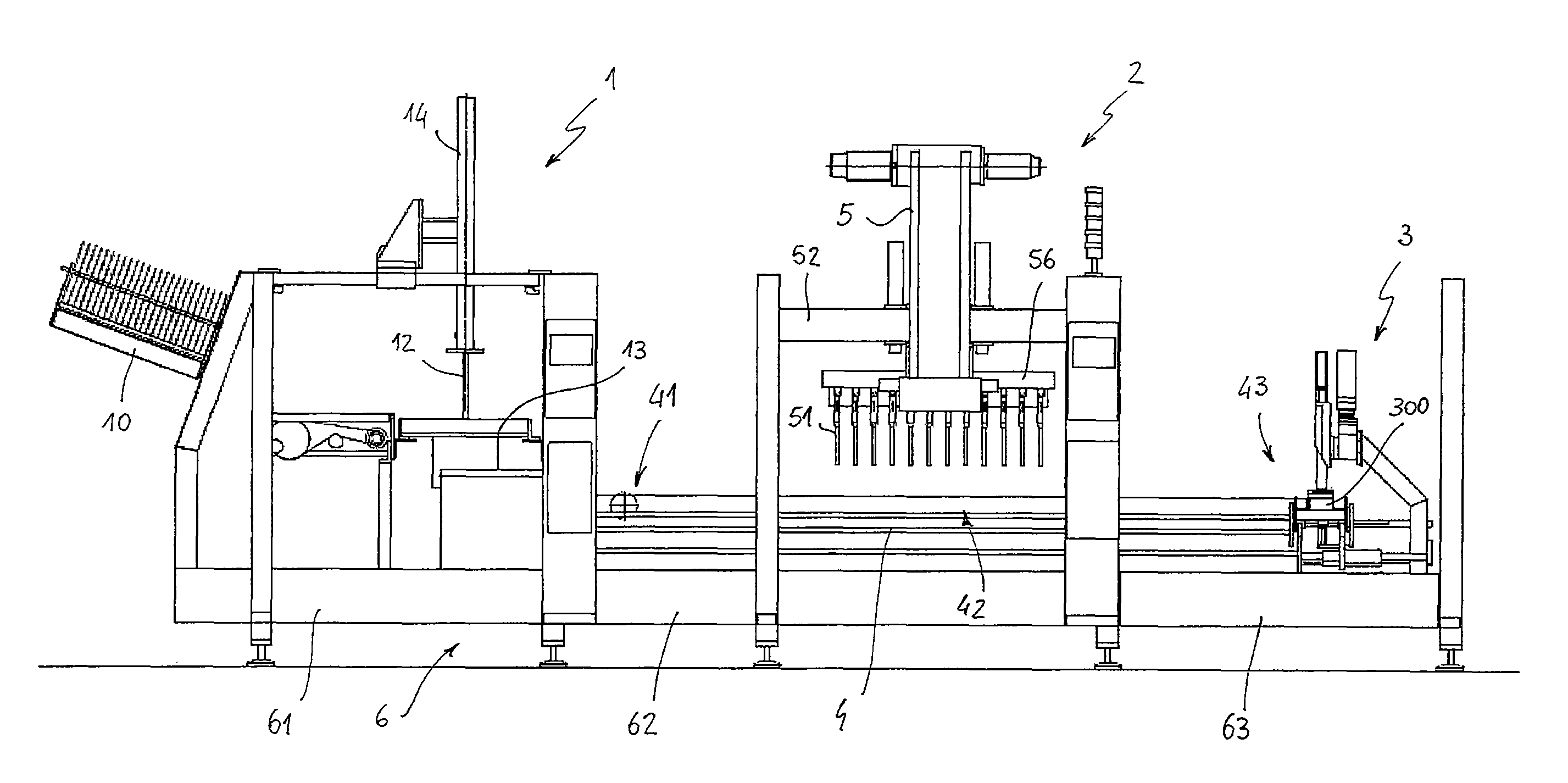

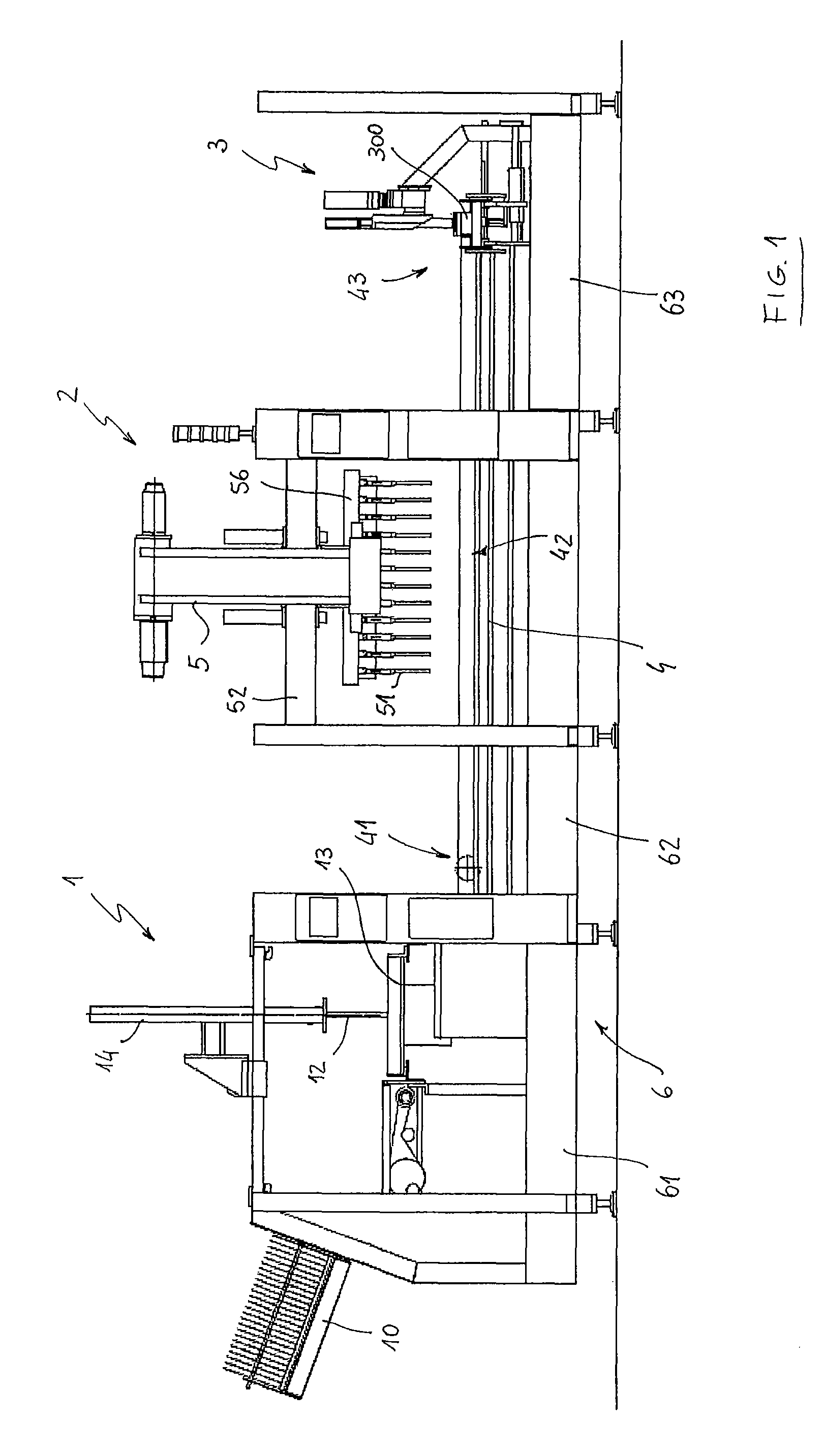

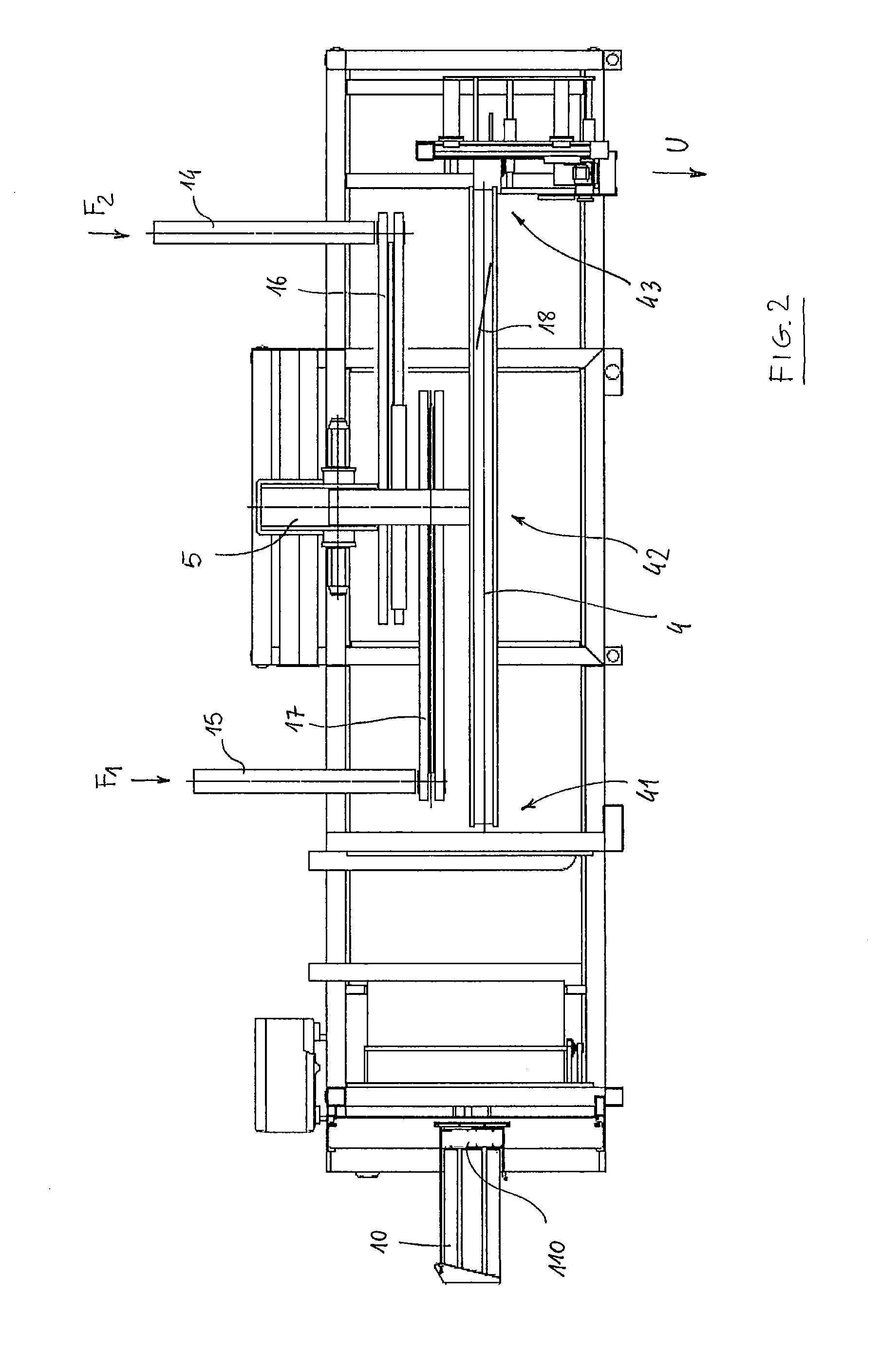

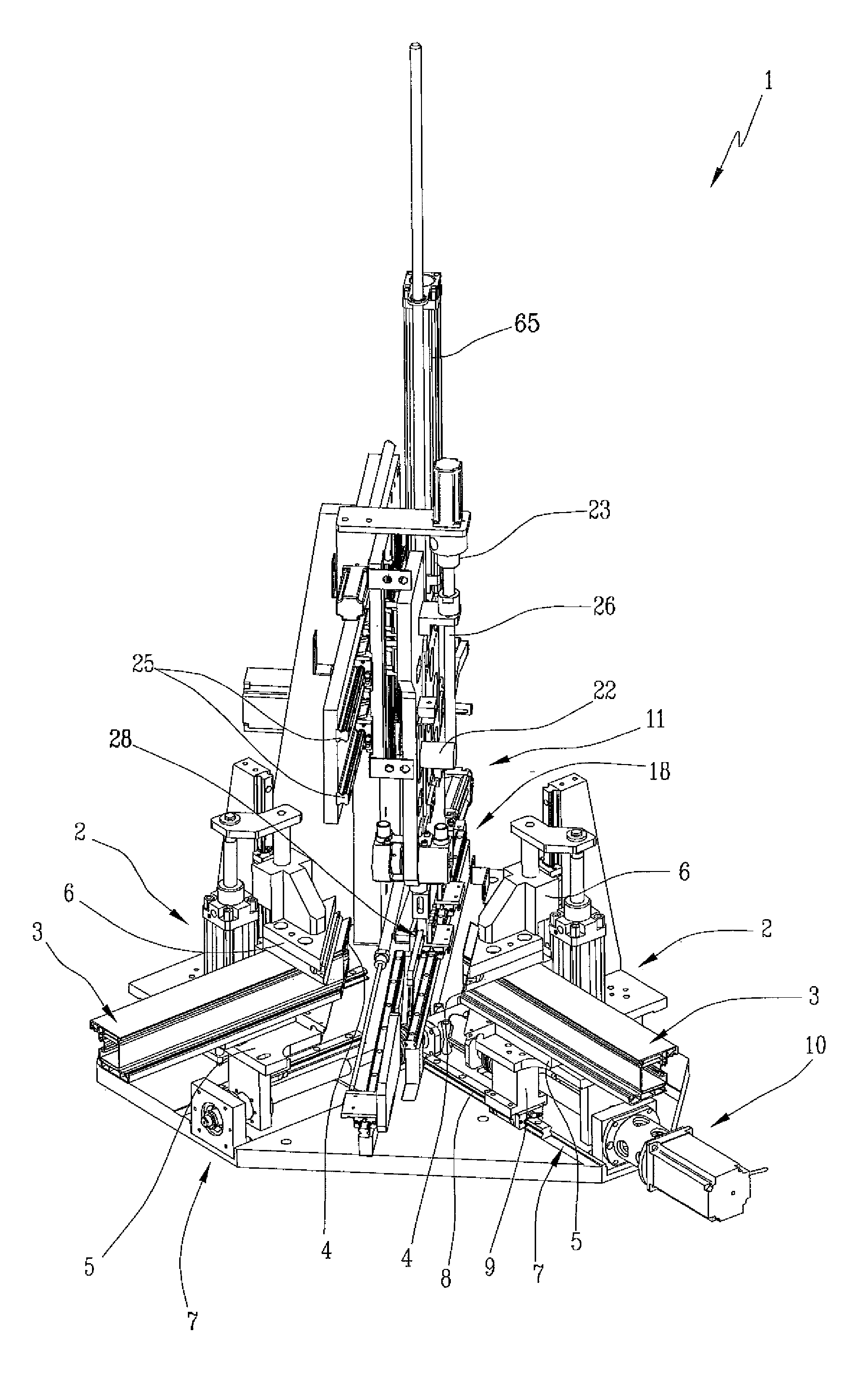

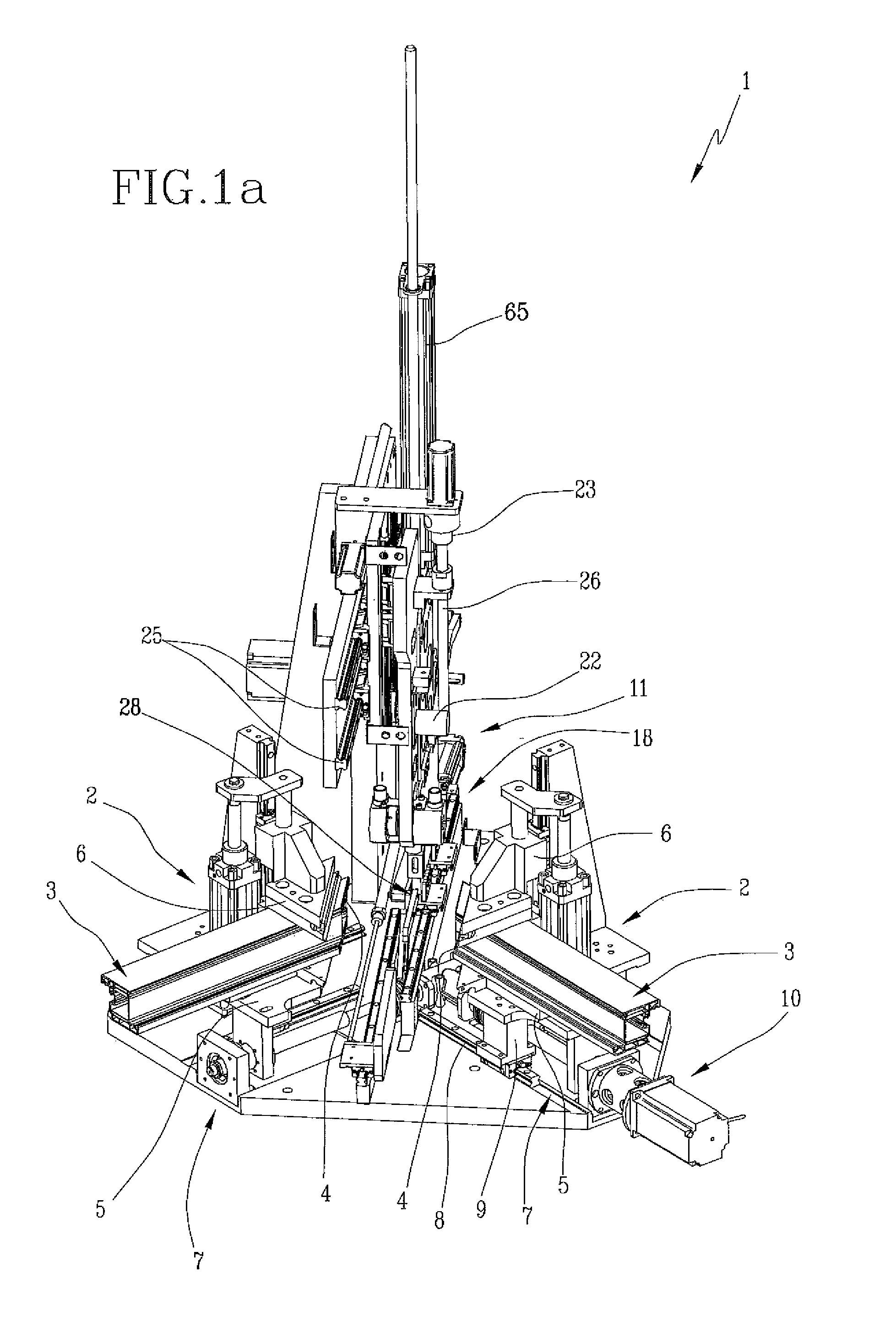

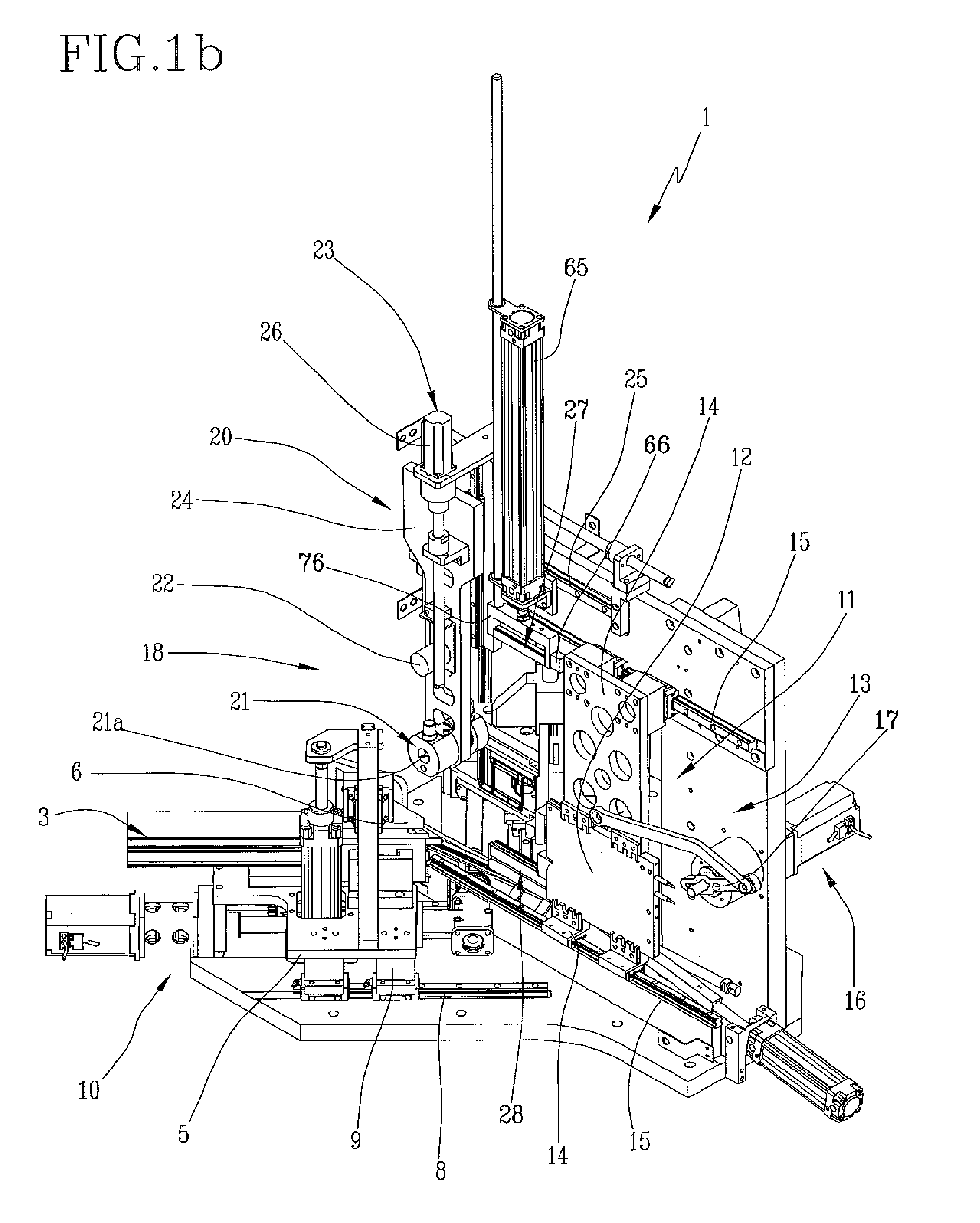

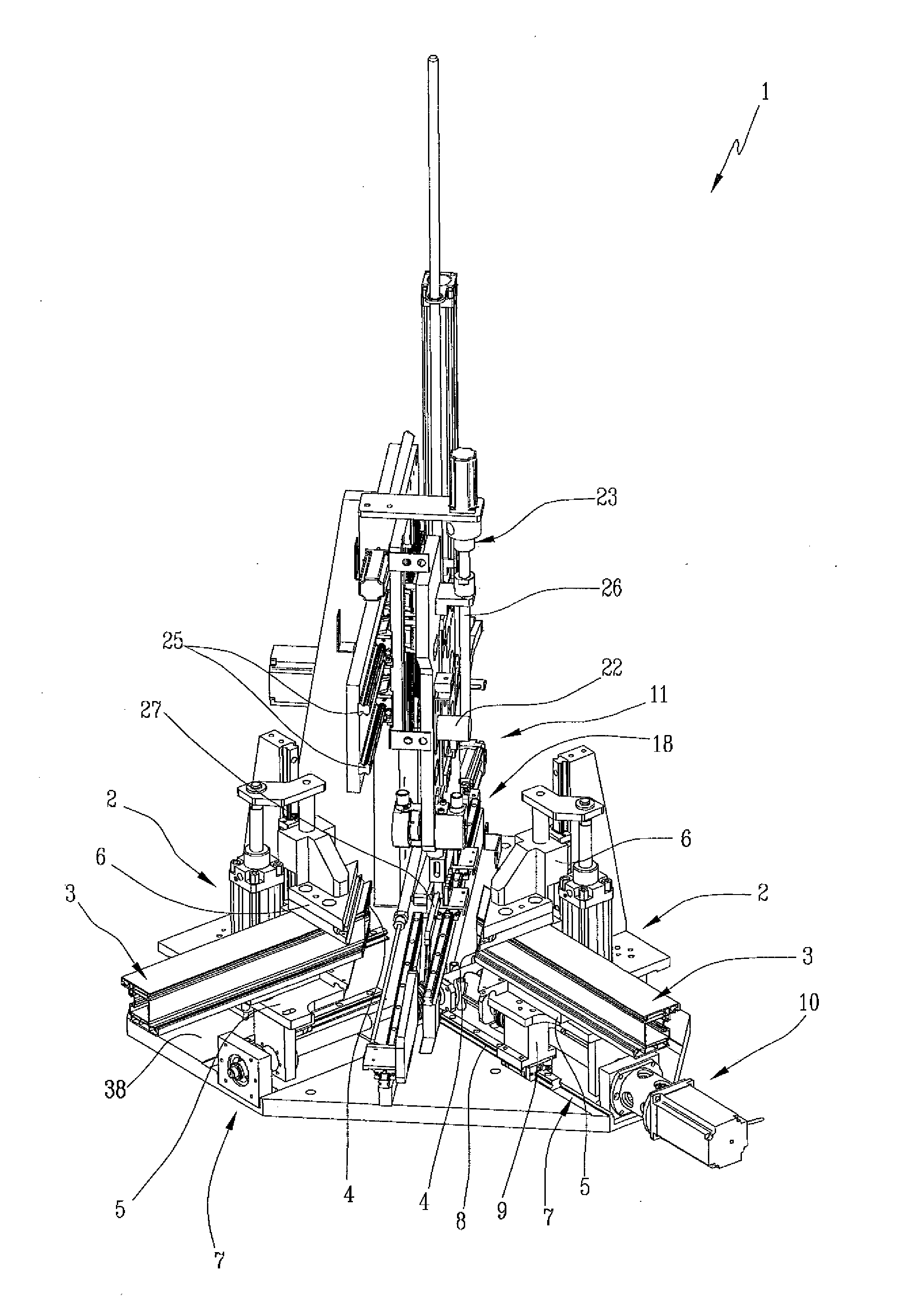

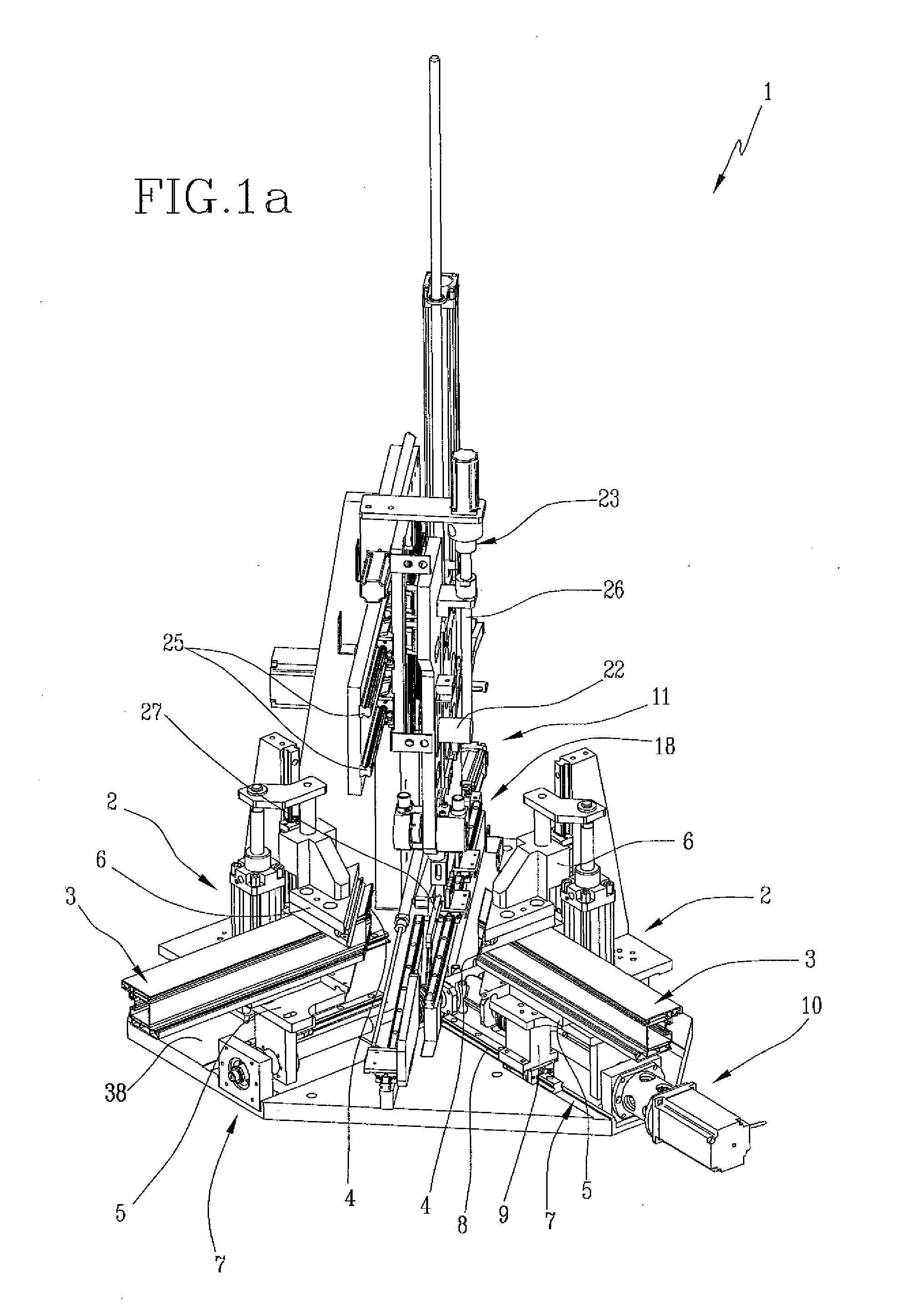

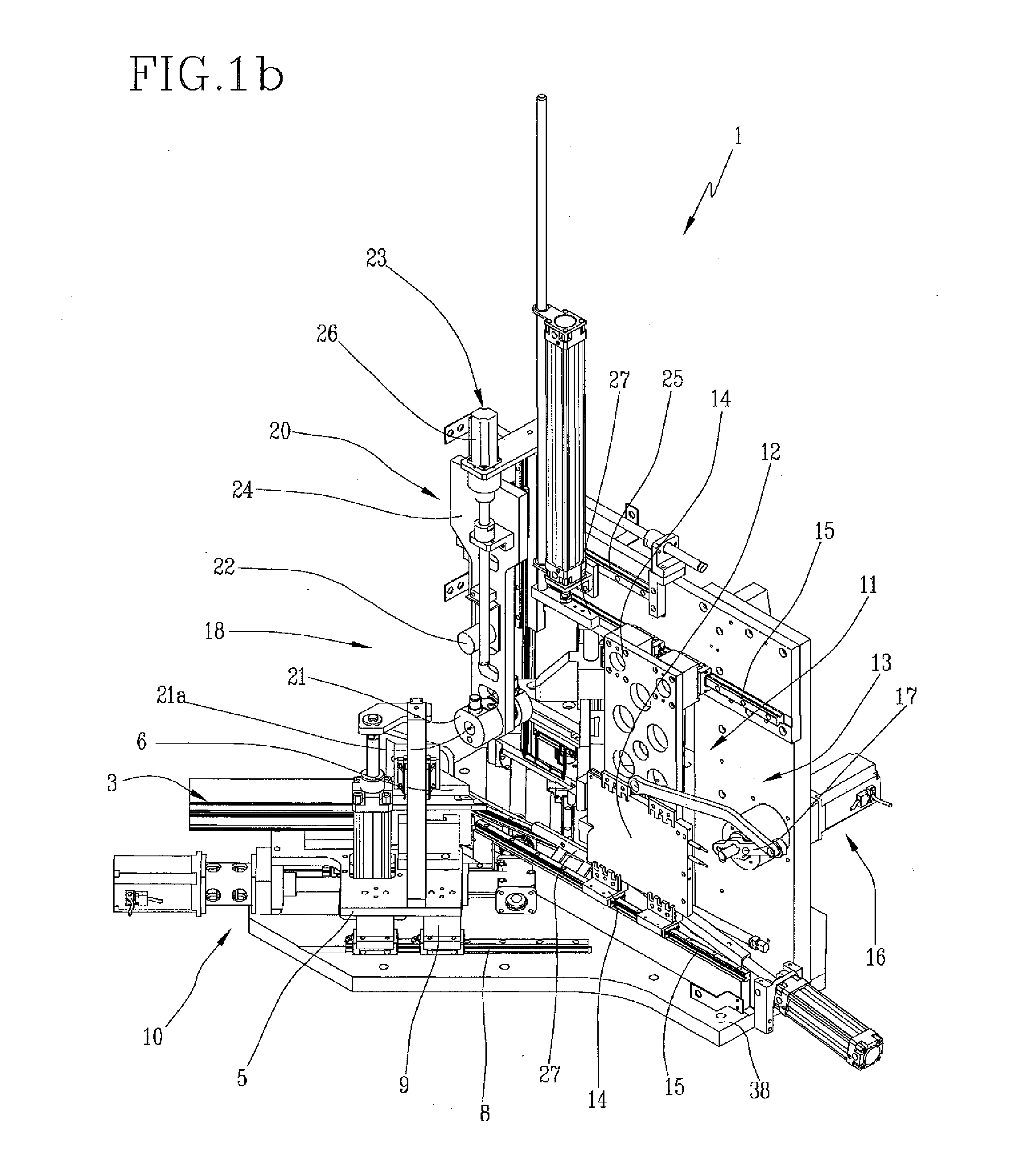

Machine for cartoning products

InactiveUS20110283668A1Increase speedRemove complicationsWrapper twisting/gatheringSolid materialWork cycleEngineering

A machine for cartoning products, comprising a cardboard box forming section, at least one conveyor of said boxes and one robotic loading section; the machine comprises a section for closing boxes for example by folding and gluing the respective flaps; said closing section is fed directly by said box conveyor; during the closing operation a servo-train of said conveyor is operated with a forward motion synchronized with the work cycle of a closing device of said closing section.

Owner:CAMA 1 SPA

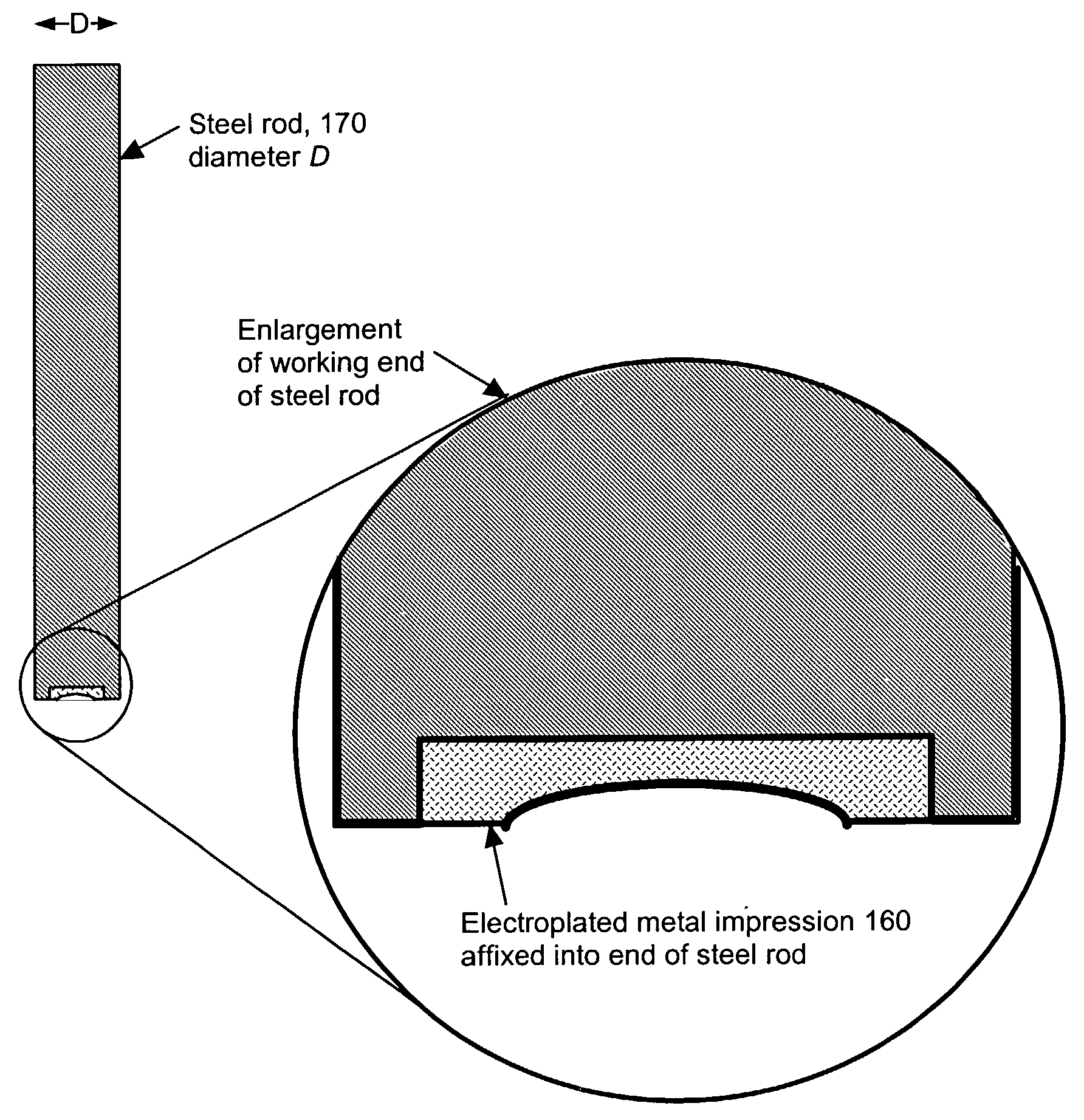

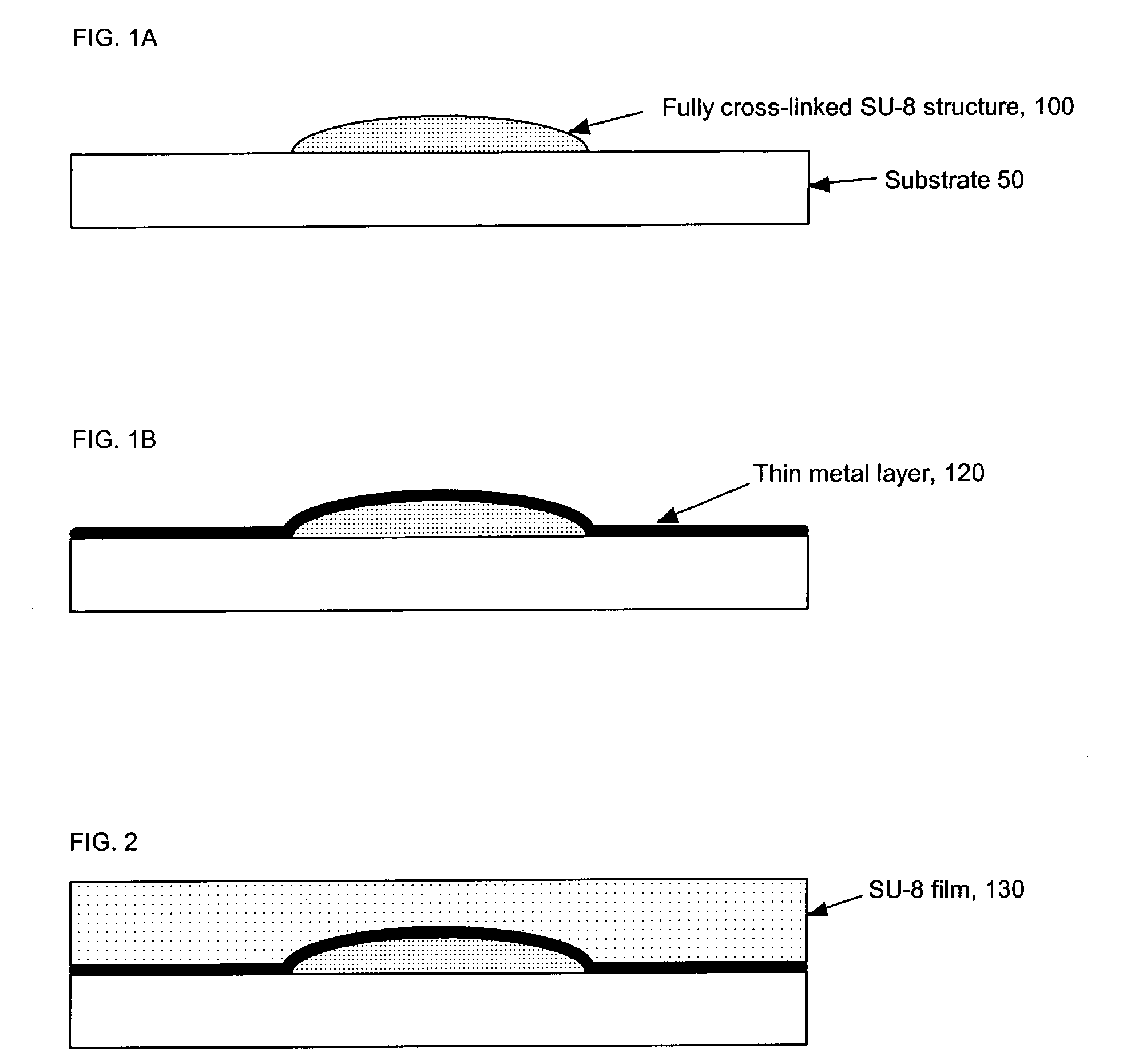

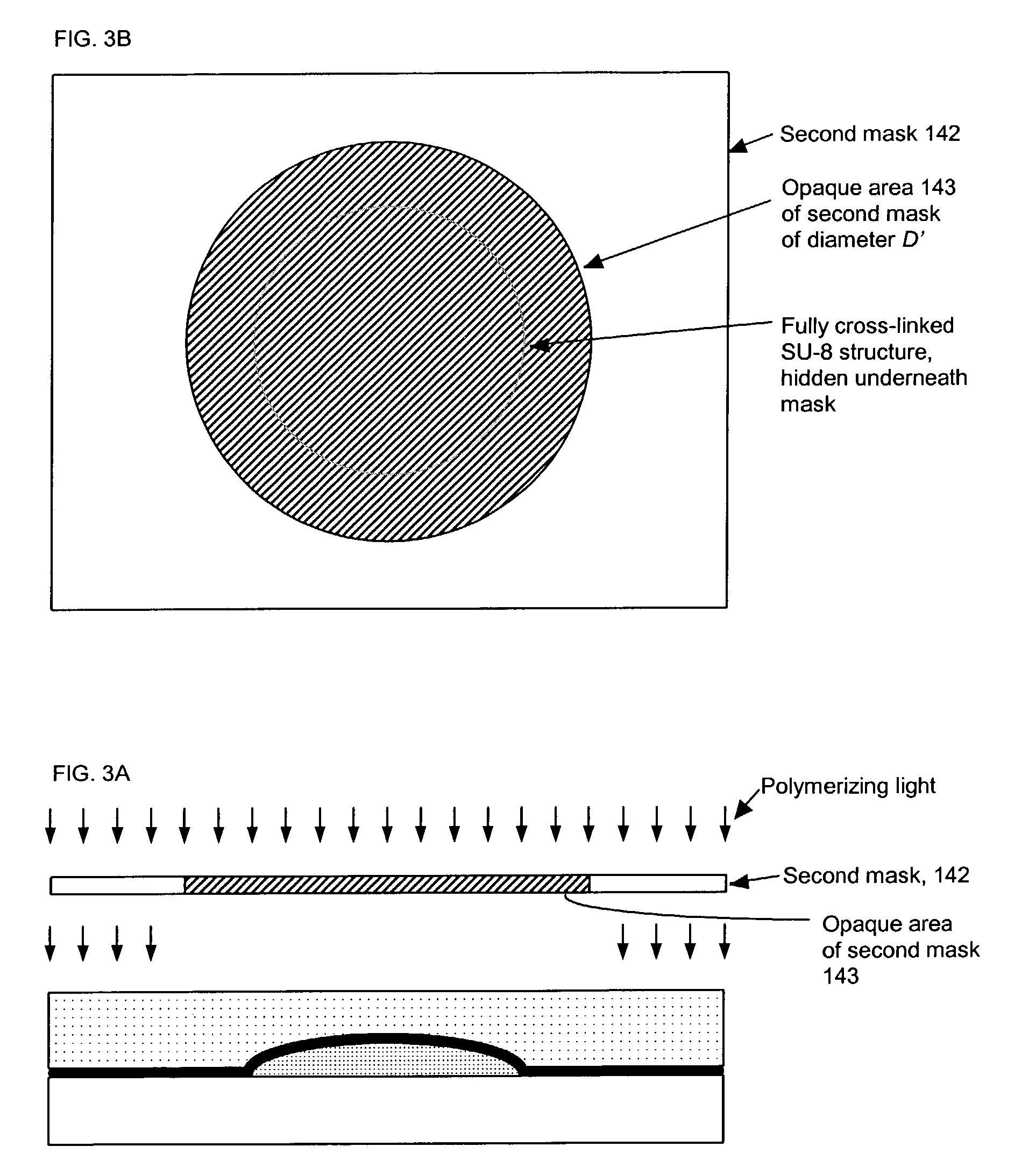

Fabrication of molds and mold components using a photolithographic technique and structures made therefrom

The method includes the step of forming a solid epoxy member on a substrate, the epoxy member having an upper surface of desired configuration. A first metal layer is deposited on the epoxy member with the upper surface thereof conforming to the desired configuration. A layer of epoxy is deposited on the first metal layer and epoxy material from the epoxy layer is removed to create a well, exposing the metal layer on the epoxy member. A metal impression layer is then deposited in the well. The metal impression layer is then removed from the well and affixed to a mounting member as a mold component for injection molding of small structures.

Owner:AFROMOWITZ MARTIN A

Driving light emitting diodes

ActiveUS8203284B2Minimize the numberLittle powerElectrical apparatusElectroluminescent light sourcesPower flowEngineering

Disclosed is a driver that includes a main power supply that has outputs coupled across a string of light emitting diodes to supply a main current. A secondary power supply is coupled to a junction between successive light emitting diodes in the string to supply or withdraw a delta current from the junction. The delta current is at least five times smaller than the main current. A controller controls the secondary power supply to generate the delta current to obtain a desired spectral composition of the mixed light emitted by the string.

Owner:SIGNIFY HLDG BV

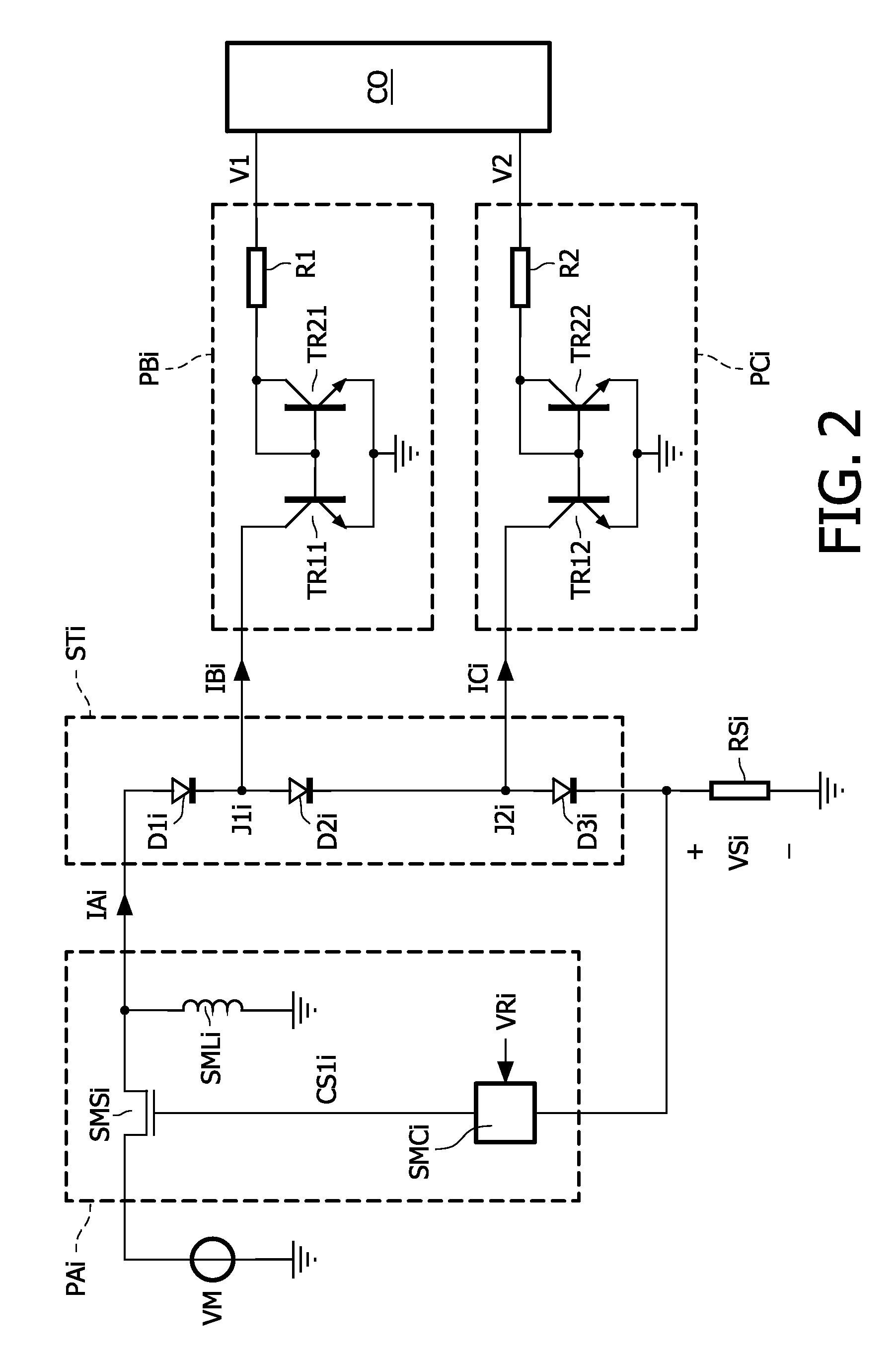

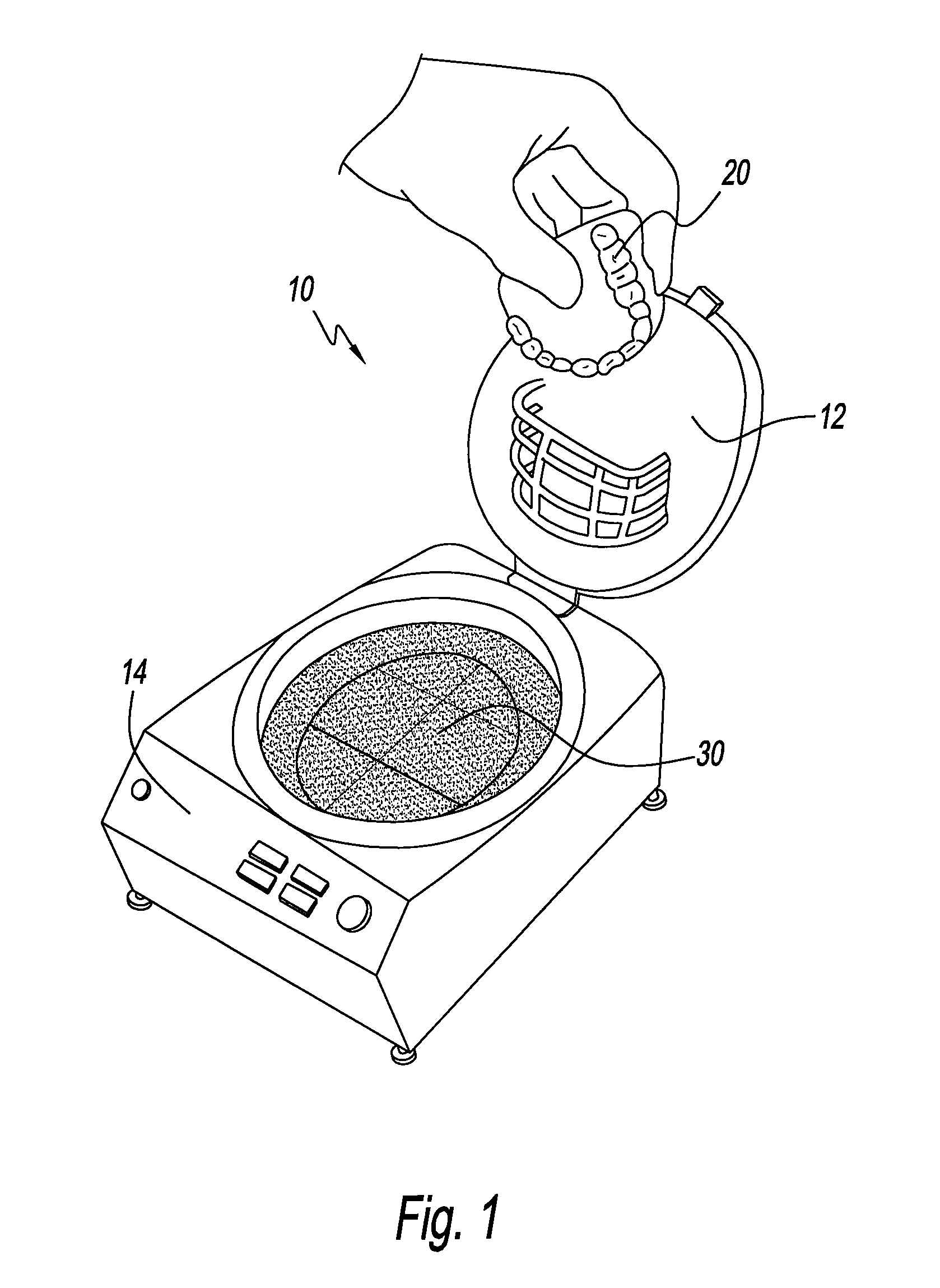

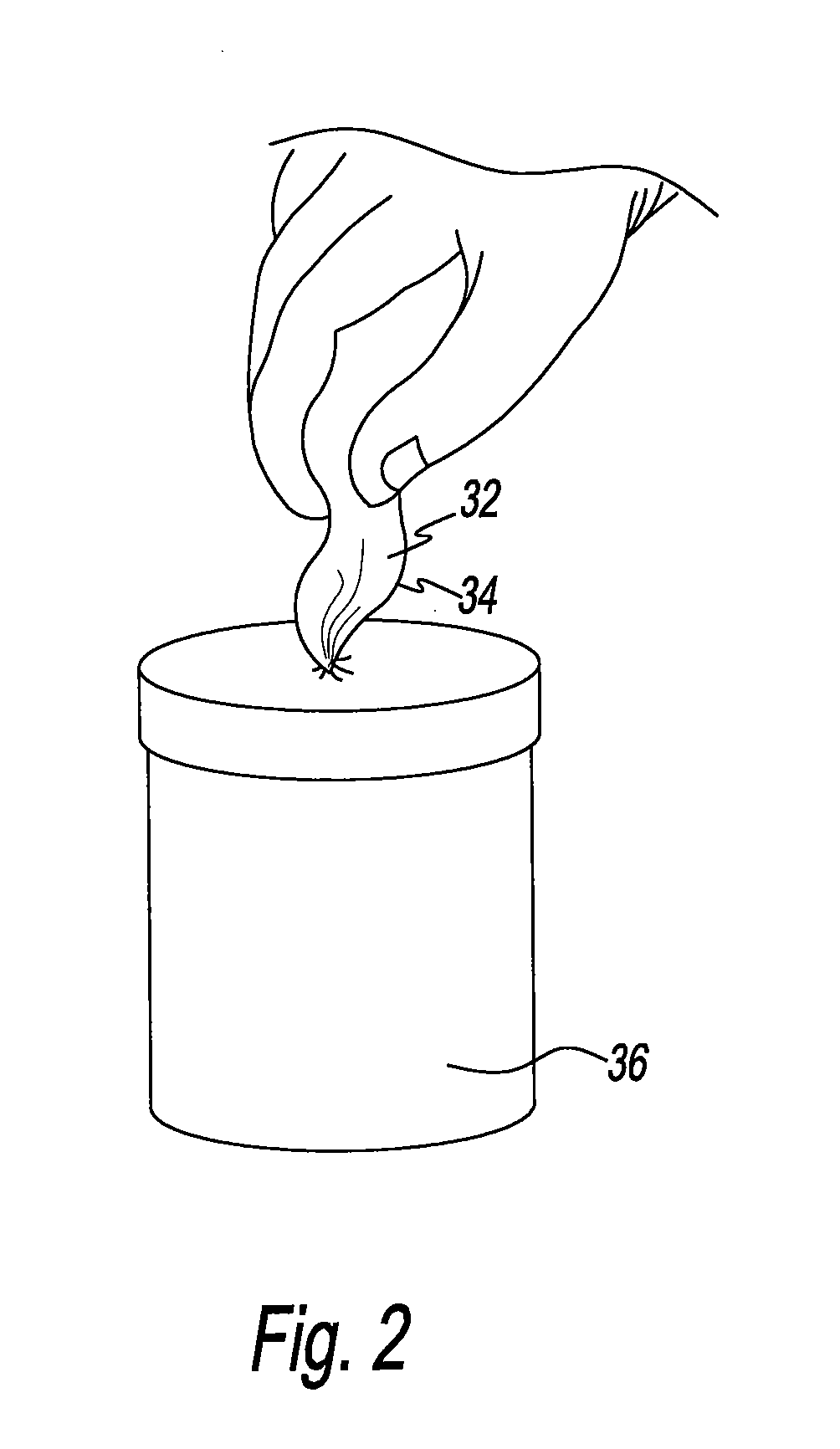

Chemo-mechanical Polishing of Dentures

InactiveUS20100330535A1Quality improvementFaster and cheapCleaning using liquidsTooth cleaningDenturesChemo mechanical

Owner:GLAXO SMITHKLINE LLC

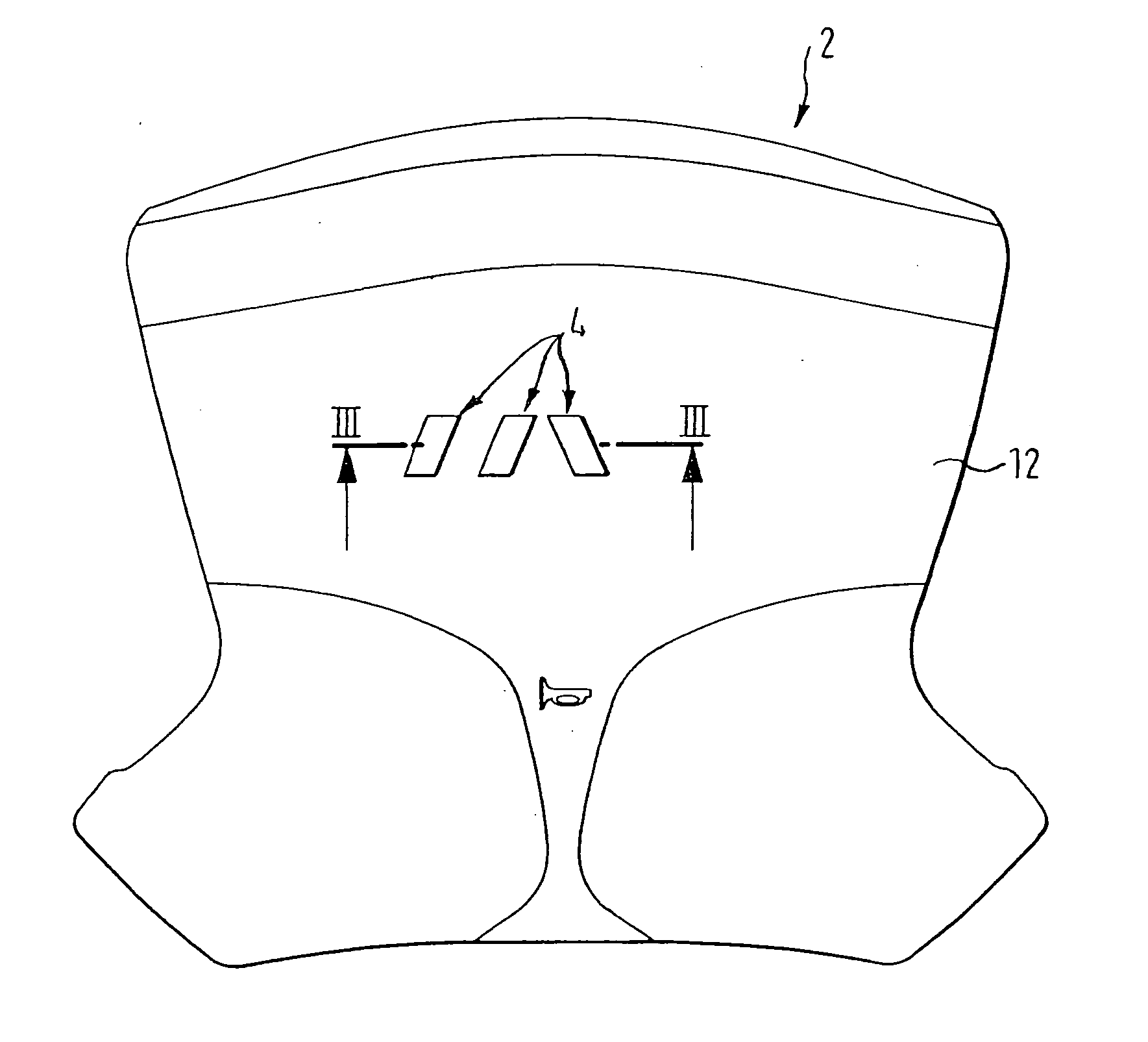

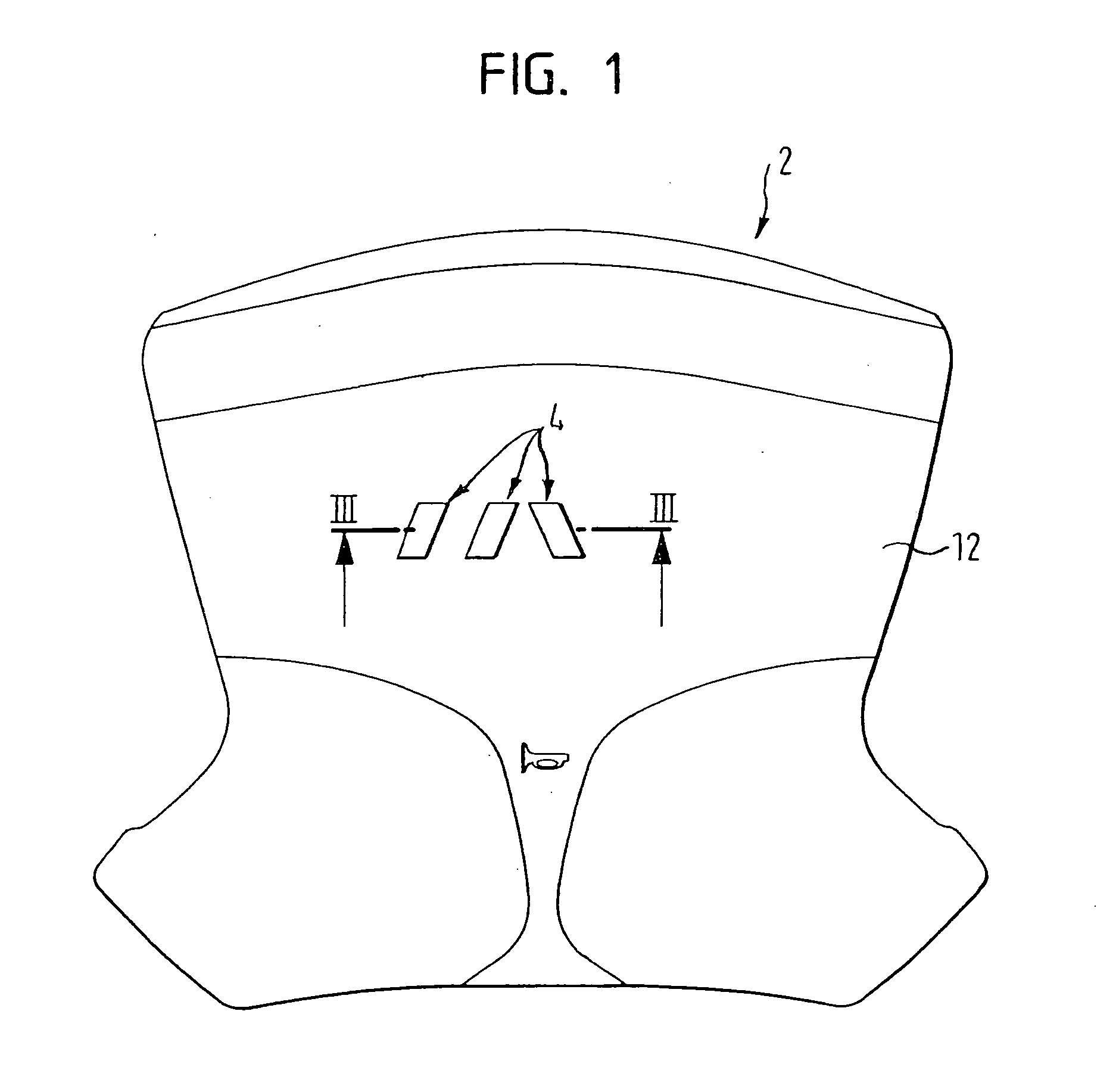

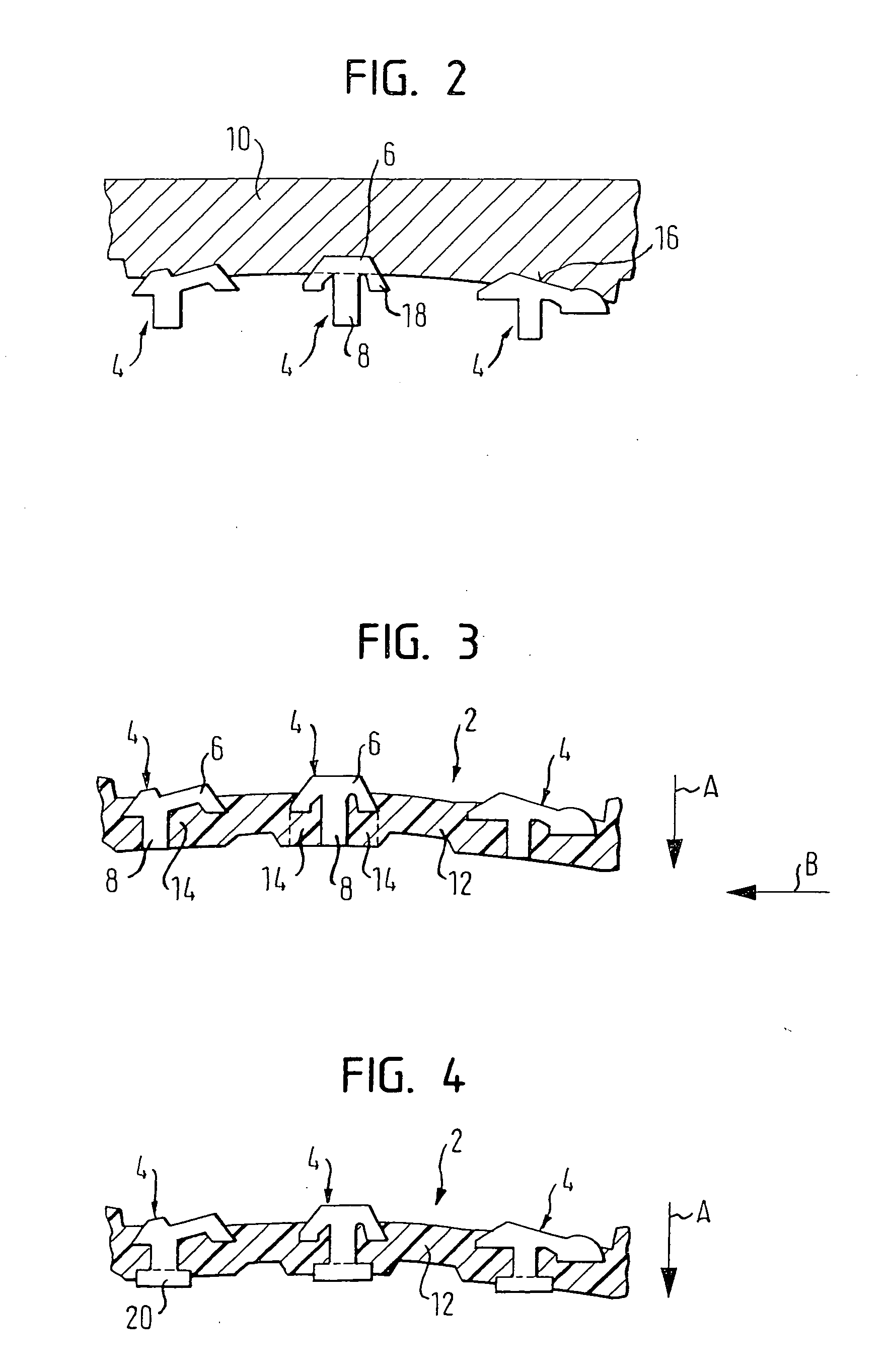

Device for welding profiled elements in plastic material, in particular PVC

ActiveUS20170203500A1Faster and cheapReduce spacingLamination ancillary operationsCorner/edge jointsBraced frameMachine tool

Owner:GRAF SYNERGY

Method for manufacturing a vehicle interior paneling part, and vehicle interior paneling part

InactiveUS20060061140A1Faster and cheapVehicle seatsPedestrian/occupant safety arrangementPanellingEngineering

Owner:TRW AUTOMOTIVE SAFETY SYST

Machine for cartoning products

InactiveUS8387349B2Increase speedRemove complicationsSolid materialLiquid materialWork cycleEngineering

A machine for cartoning products incorporates a cardboard box forming section, at least one box conveyor, and one robotic loading section. The machine includes a section for closing boxes, for example by folding and gluing the respective flaps. The closing section is fed directly by the box conveyor. During the closing operation, a servo-train of the conveyor is operated with a forward motion synchronized with the work cycle of a closing device of the closing section.

Owner:CAMA 1 SPA

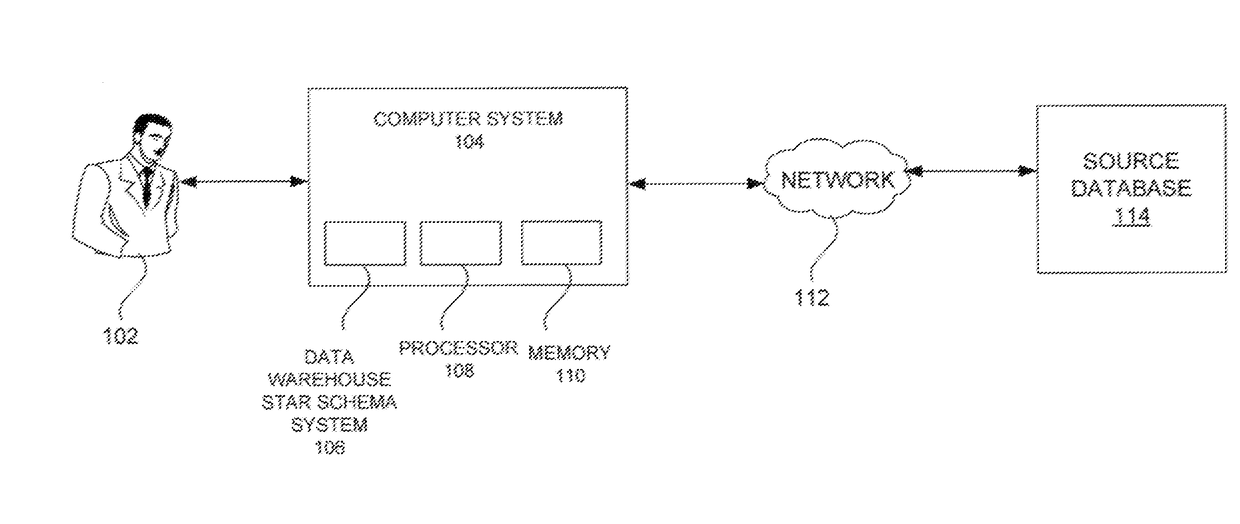

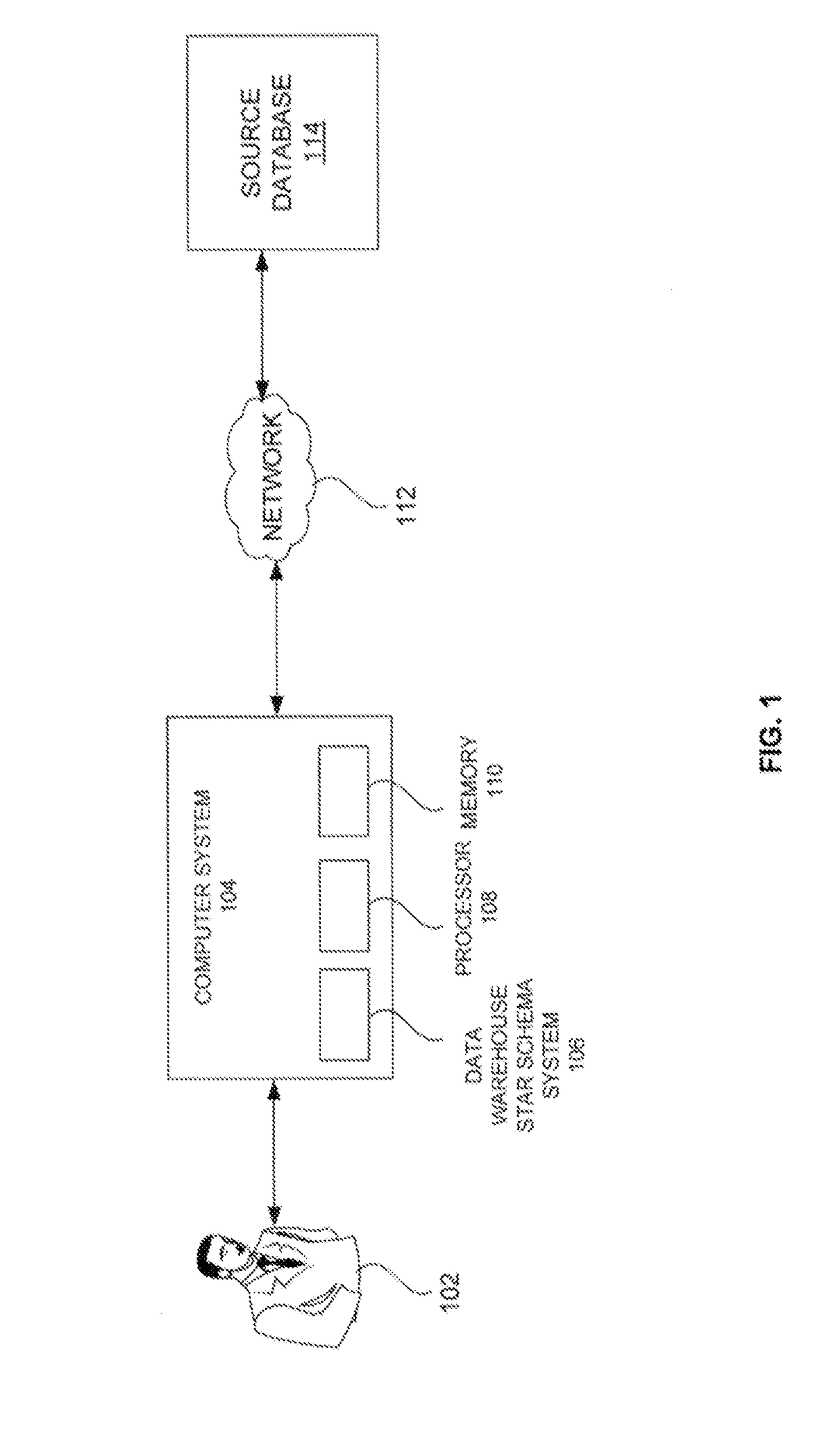

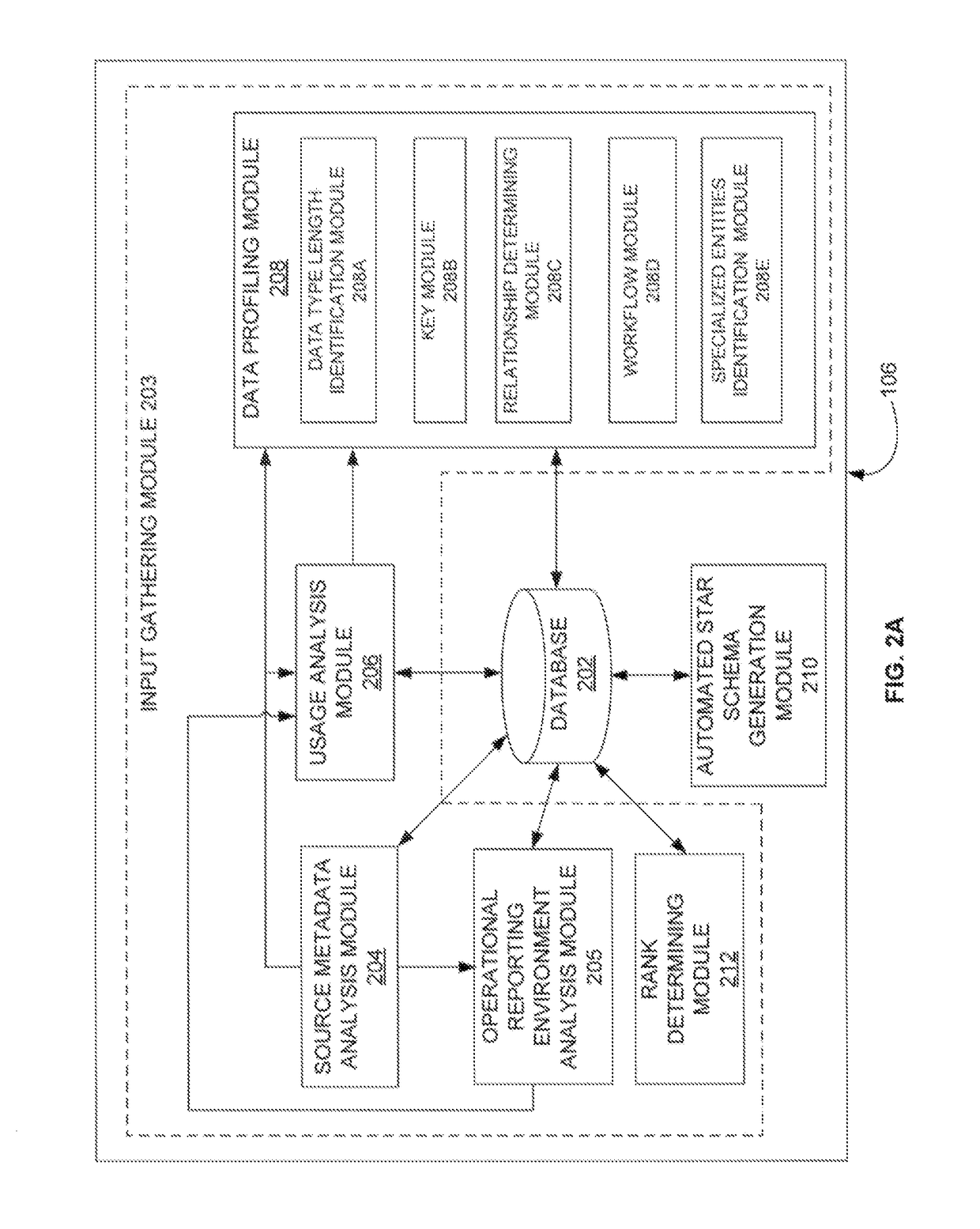

Automated Definition of Data Warehouse Star Schemas

ActiveUS20170116306A1Faster and cheapMulti-dimensional databasesHierarchical databasesStar schemaWorkflow

An automated system for defining a star schema for a data source. The system based on automatically gathered information from the data source such as entities and columns, entity column types and lengths, entity keys, relationships between and within entities, measures, workflow and correlated attributes, specialized entities, an update frequency of entities and columns, and grouping of entity and column updates associated with the source database automatically determines facts, dimensions, dimension hierarchies, measures, workflow specific measures (if data source has workflows) and workflow correlated attribute specific measures (if data source has temporal, priority, ownership and progress tracking attributes) to come up with a star schema for the data source.

Owner:DIGITAL AI SOFTWARE INC

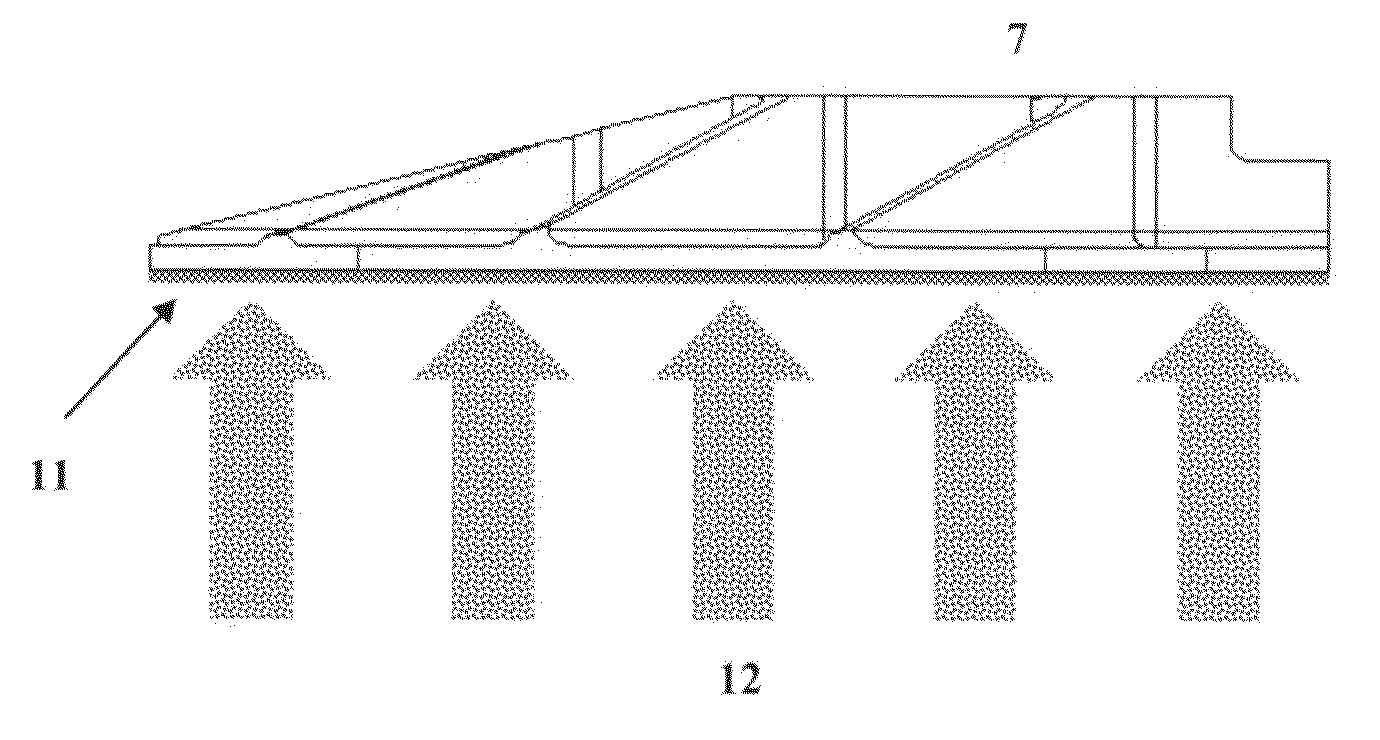

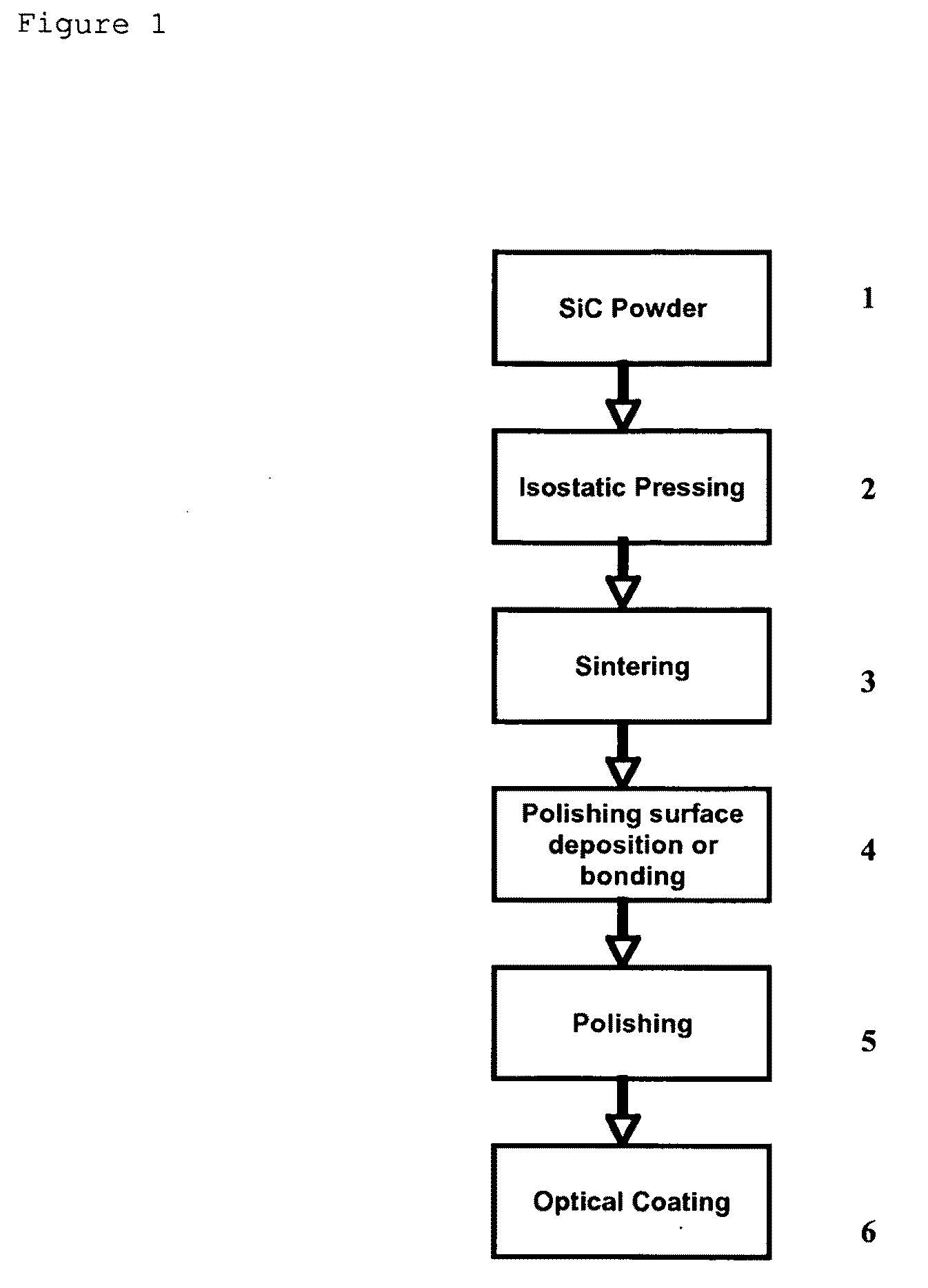

Method of manufacturing and processing silicon carbide scanning and optical mirrors

InactiveUS20100136248A1Fast and cheap to manufactureEasy to lapMolten spray coatingMirrorsOptical coatingLength wave

The invention relates to a method of Silicon Carbide scanning or optical mirror production. In order to reduce the costs for manufacturing a scanning or optical mirror, according to the present invention, Silicon Carbide powder is pressed or stamped or isostatically pressed using an engineered stamp or tool to form the shape and structure of a scanning or optical mirror which is then in this embodiment sintered to provide a surface that will become the face surface of said scanning or optical mirror that is then coated or bonded with a suitably thick layer of in this embodiment Silicon material deposited by a thermal spray process onto said face surface of said scanning or optical mirror that is then polished to achieve the desired surface quality and / or roughness and / or flatness and then optical coated using coating technologies and materials to coat said face surface that will then become the reflective surface with suitable high reflective optical coatings specific to the wavelength or wavelengths that the finished Silicon Carbide scanning or optical mirrors will be used to reflect in final application / s.

Owner:MERSEN DEUTLAND HLDG

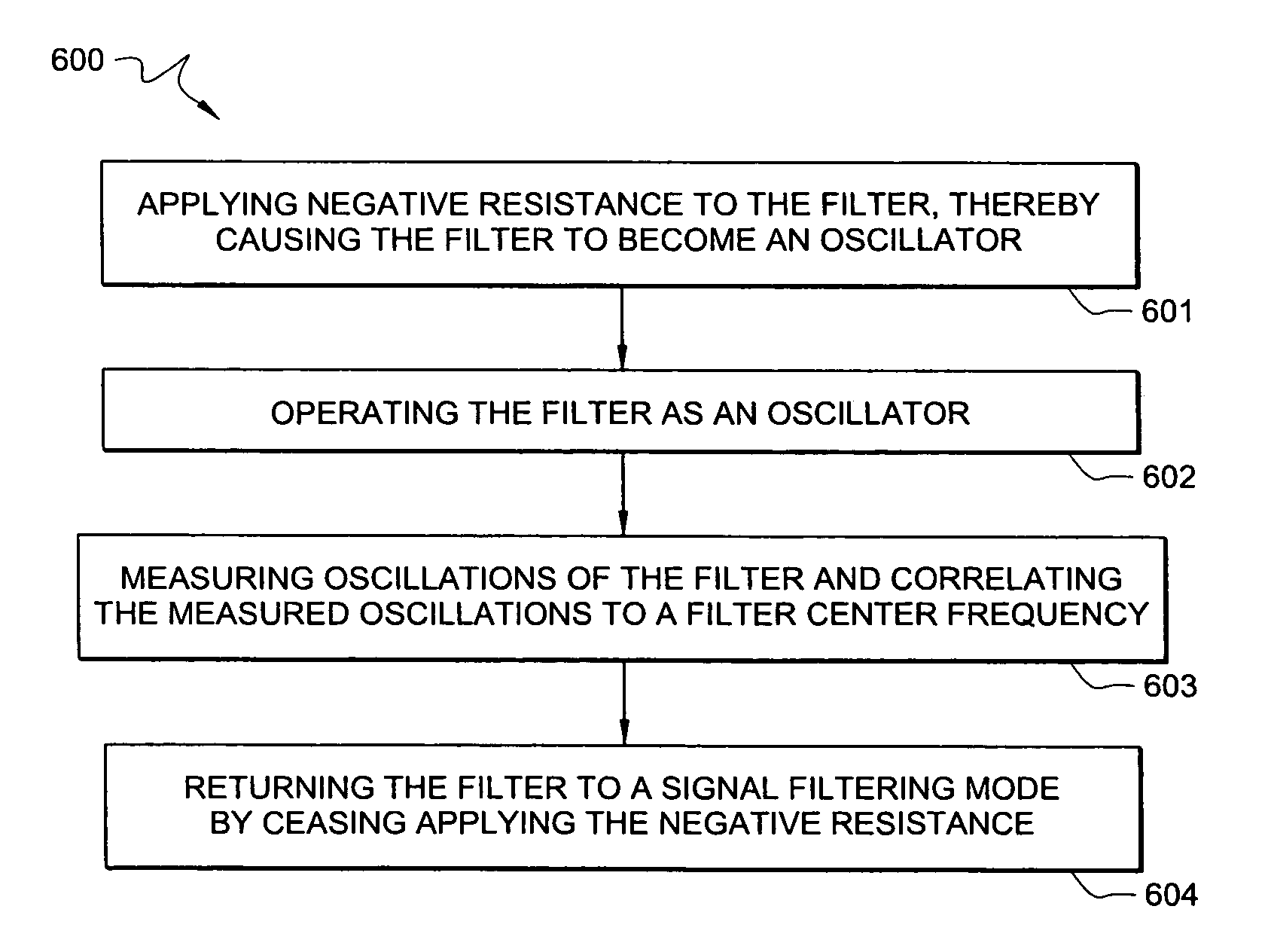

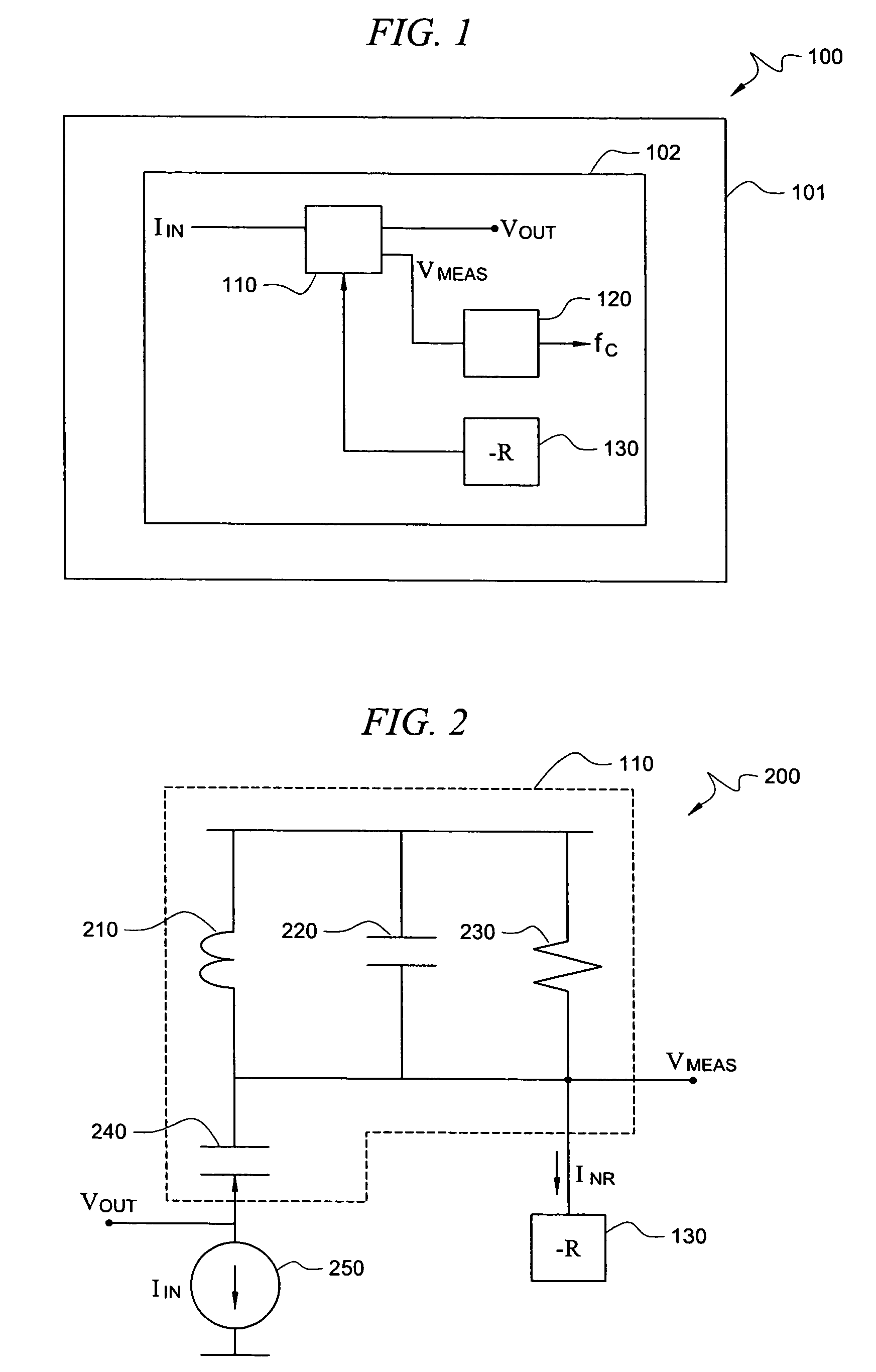

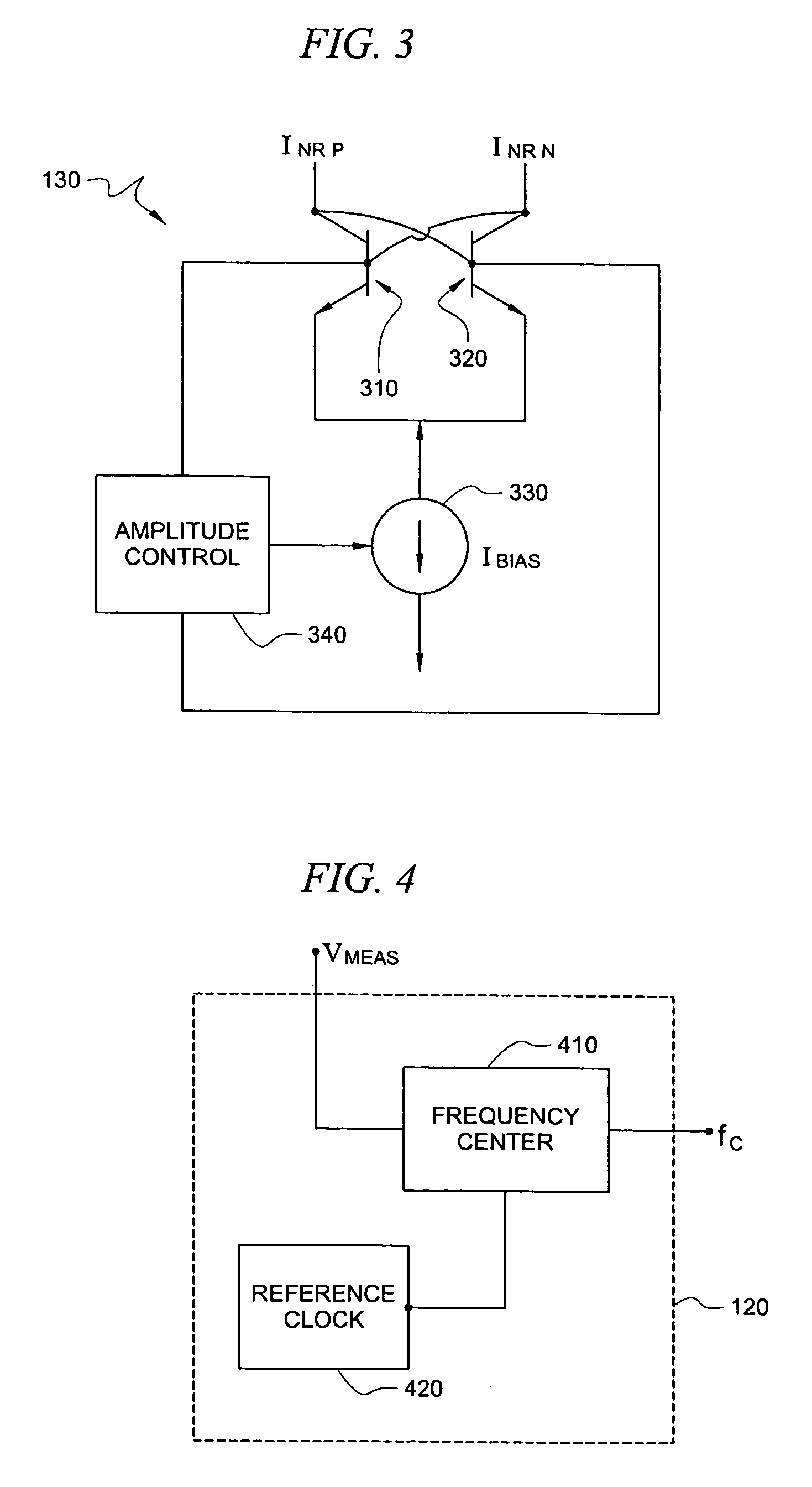

Systems and methods for filter center frequency location

InactiveUS7634242B2Faster and cheapView accuratelyMultiple-port networksActive element networkFrequency measurementsEngineering

A system for implementing a tuner comprising a Radio Frequency (RF) circuit, a filter disposed in a signal path in said RF circuit, a first negative resistance unit in communication with said filter adapted to cancel one or more resistive elements in said filter, a frequency measurement unit in communication with said filter, wherein said first negative resistance unit is adapted to cause said filter to act as an oscillator, and wherein said frequency measurement unit is adapted to measure oscillations of said filter and to calculate a center frequency of said filter therefrom.

Owner:CSR TECH INC

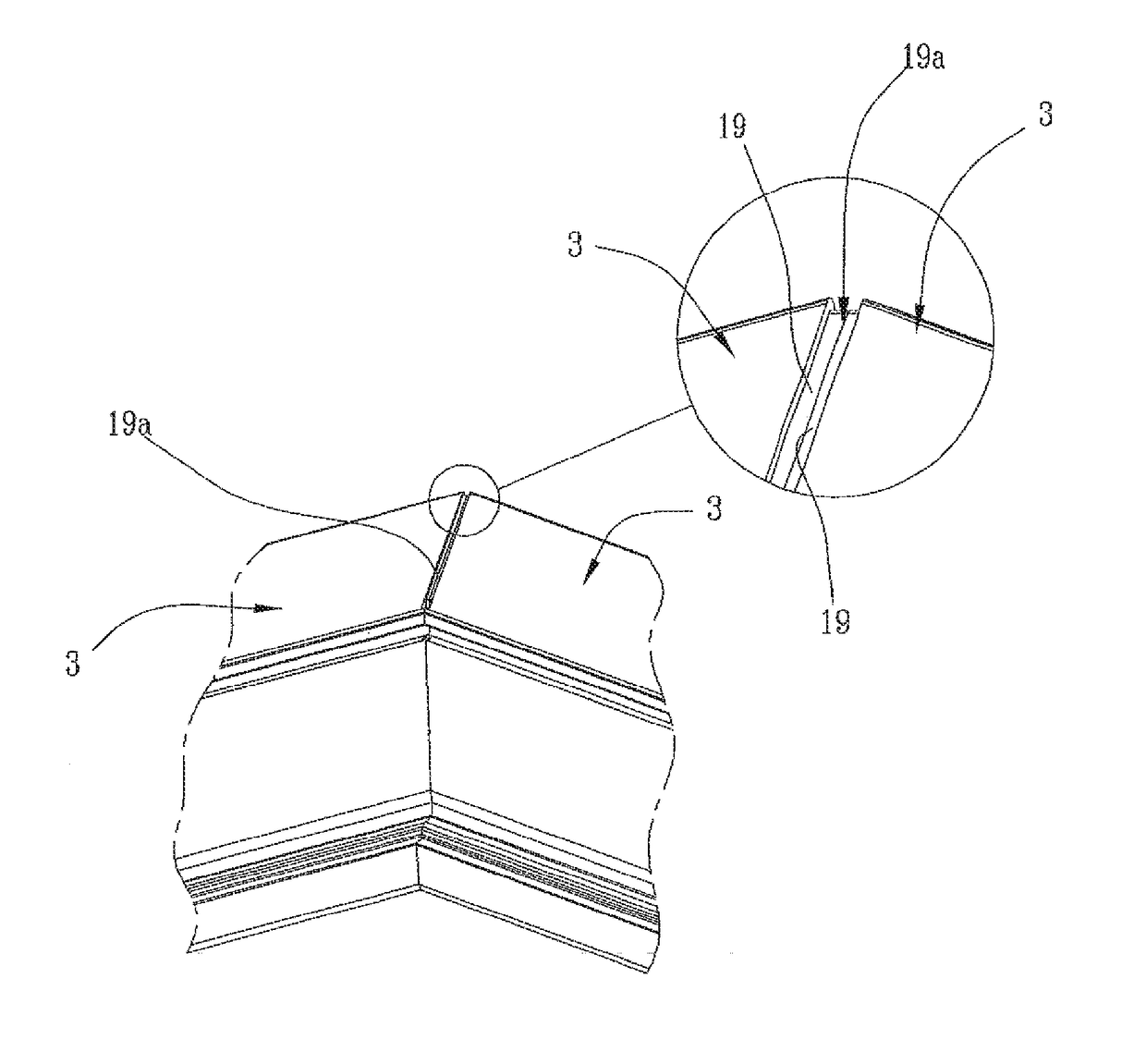

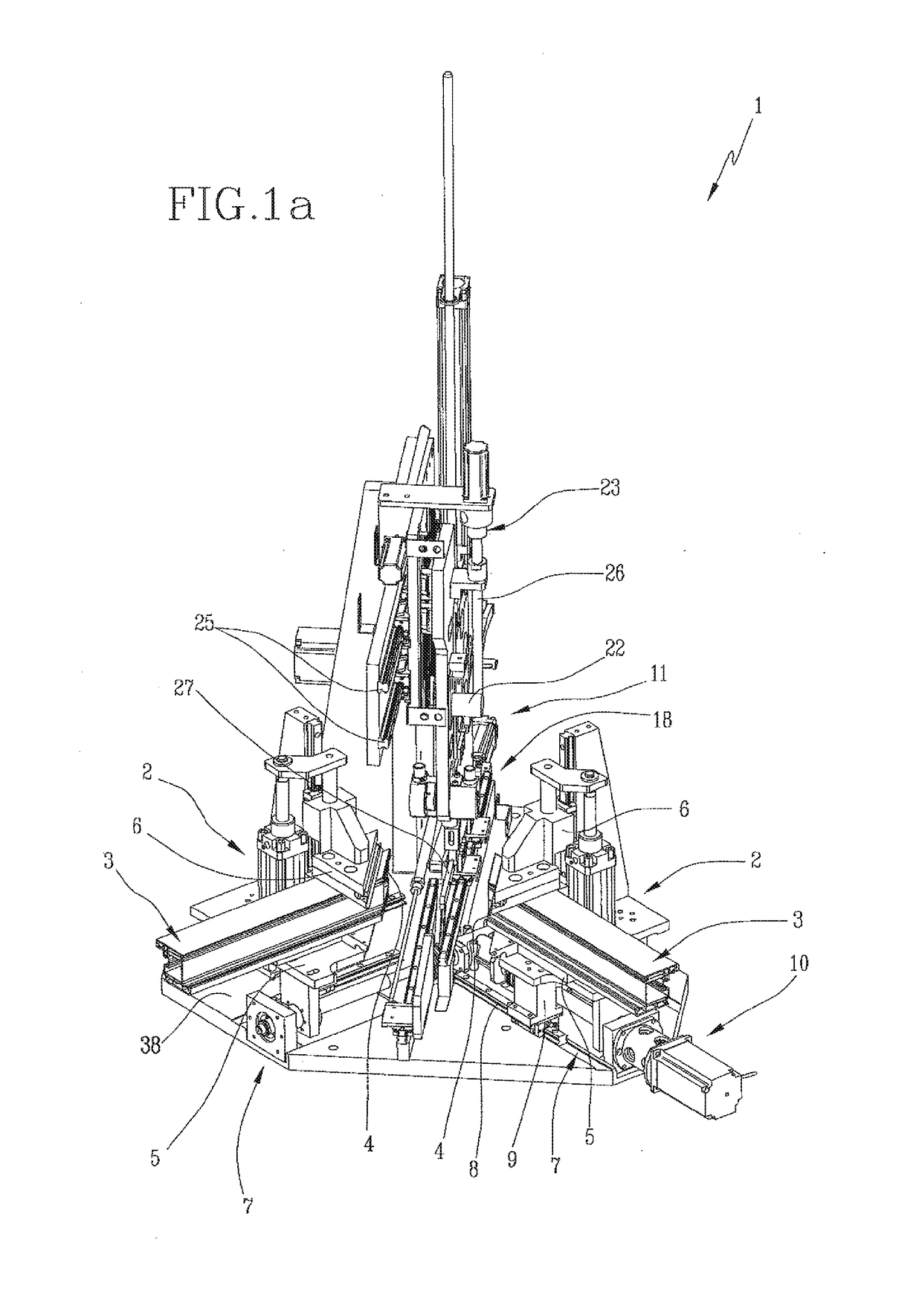

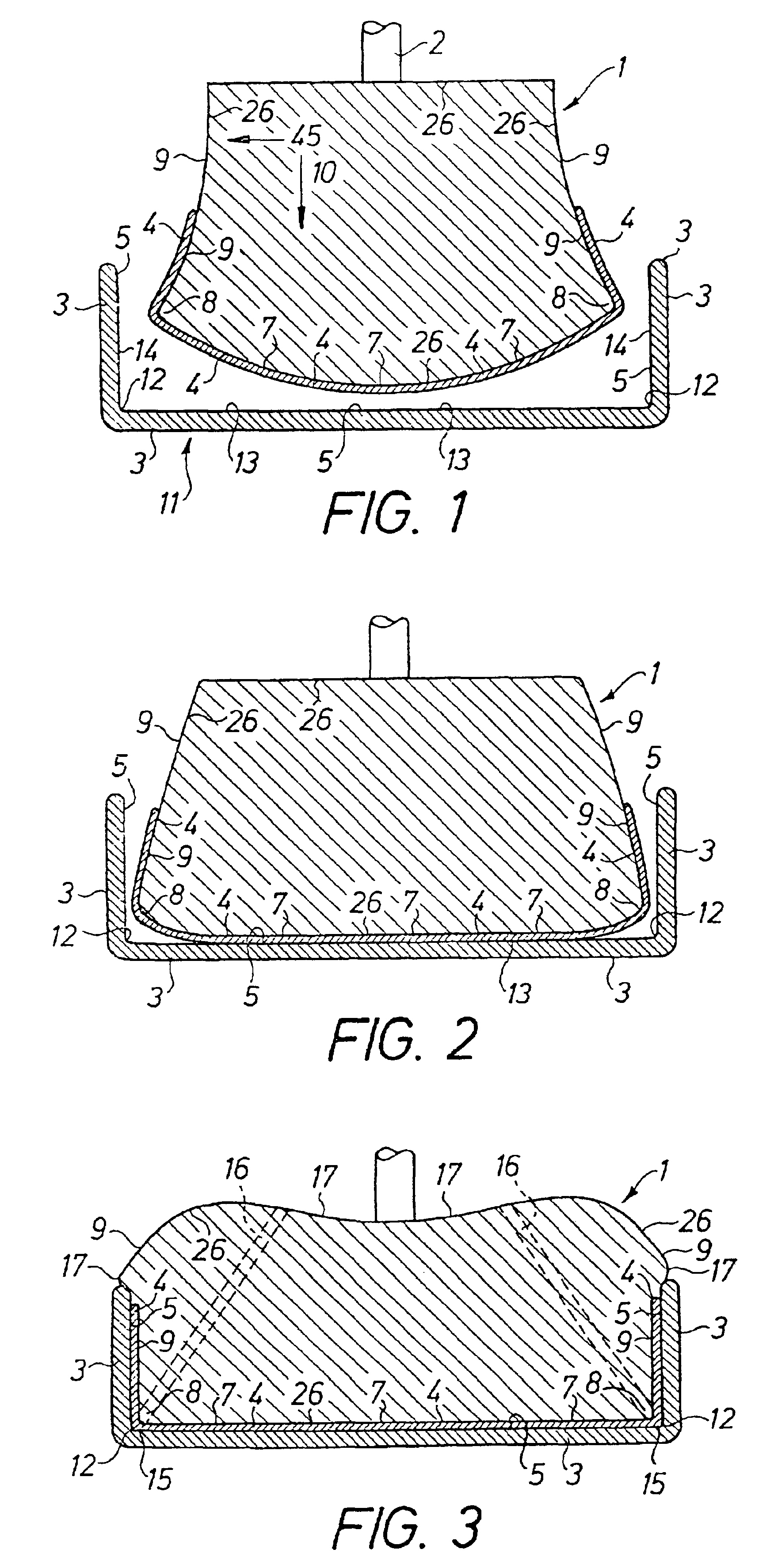

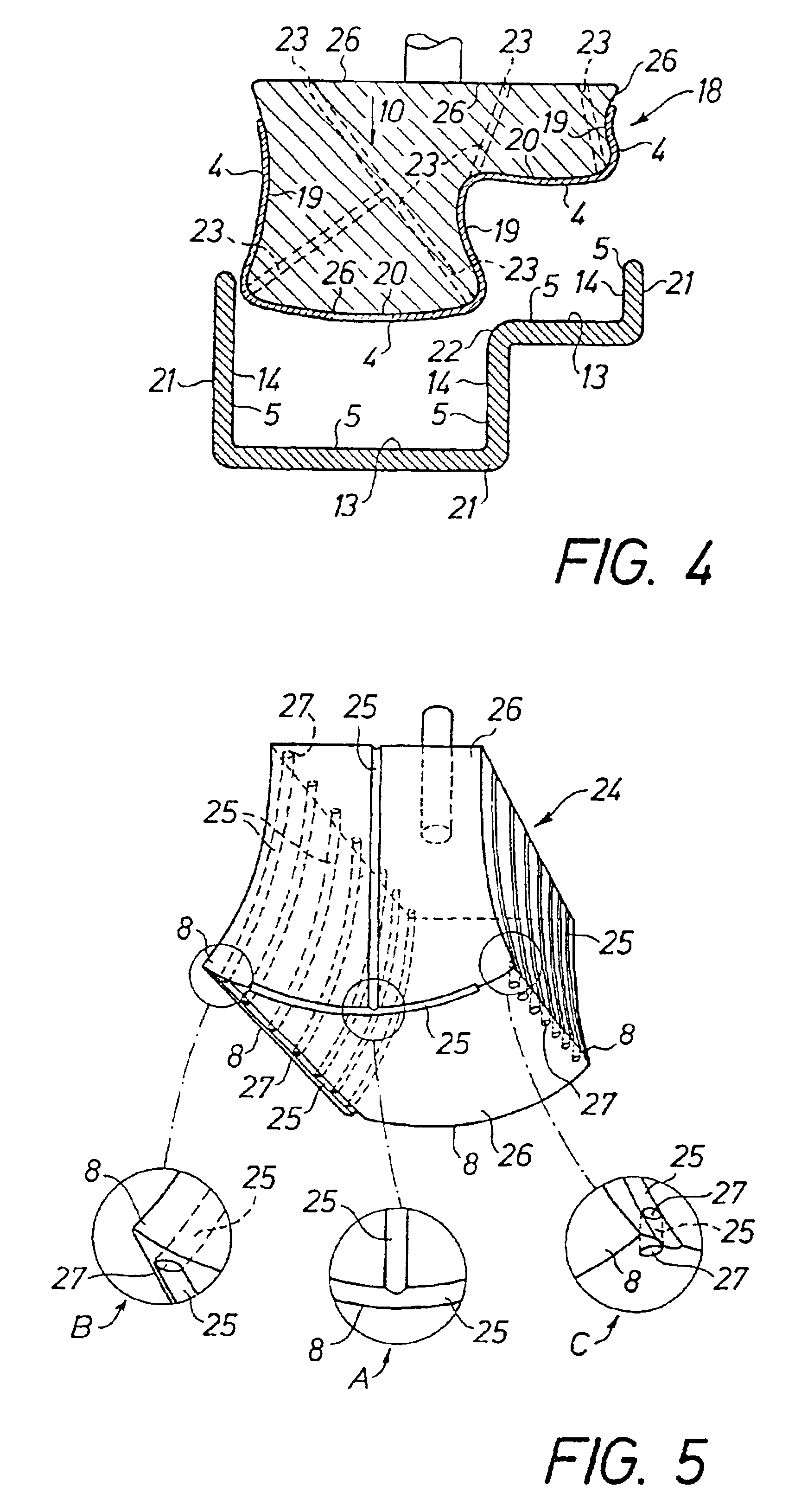

Method and device for welding profiled elements made of a plastic material, in particular PVC

The method for welding profiled elements made of a plastic material, in particular PVC, comprises the steps of:preparing two profiled elements (3) made of a plastic material, arranged with respective zones to be welded (4) facing one another;heating the zones to be welded (4);before the heating step, the step of making a groove (19) in correspondence to a peripheral edge of each of the zones to be welded (4);coupling the zones to be welded (4) to one another, by pressing the profiled elements (3) against one another to keep the zones to be welded (4) in reciprocal contact, the step of coupling the zones to be welded (4) defining a sub-step of melting the zones to be welded (4) into one another to define a welding bead and comprising the sub-steps of:arranging pressing means (27, 28) in correspondence to the grooves (19) to define, in collaboration with the grooves (19), a containing compartment (19a) of the welding bead, the pressing means (27, 28) comprising:a first work surface (62) having a protruding portion (63); anda second work surface (64) of final finishing; anddisplacing the pressing means (27, 28) alternately between:an idle position moved away from the profiled elements (3);a first work position wherein the first work surface (62) is abutted on the grooves (19) with the protruding portion (63) located inside the containing compartment (19a) to deviate the welding bead towards the side walls (61) of the containing compartment (19a); anda second work position wherein the second work surface (64) is abutted on the grooves (19) so as to obtain a finished welding bead.

Owner:GRAF SYNERGY

Tamp pad

Owner:TELEFON AB LM ERICSSON (PUBL)

Method and device for welding profiled elements in plastic material, in particular PVC

ActiveUS20150101746A1Faster and cheapReduce spacingLamination ancillary operationsCorner/edge jointsEngineeringPlastic materials

A method for welding profiled elements in plastic material, includes the steps of: preparing two profiled elements, arranged with respective zones to be facing one another; making a groove in correspondence to at least one zone, by a removal operation on a peripheral edge of at least one profiled element; heating the zones to be welded; coupling the zones to be welded to one another, pressing the profiled elements one against the other so as to keep the zones to be welded in reciprocal contact. The coupling step includes: melting the zones to be welded into one another in order to define a welding bead; making a containing compartment defined by the groove, the welding bead being made internally of the containing compartment; and arranging a containing presser in correspondence to the containing compartment for preventing exit of the welding bead from the compartment itself.

Owner:GRAF SYNERGY

Sensor system for rotation angular detection and 3D joystick function

ActiveUS11169002B2More robust sensor systemWithout compromising sensor system overall accuracyManual control with multiple controlled membersActuated personallyMagnetic sourceMagnetic effect

A sensor system and a joystick including the sensor system. The sensor system comprises a magnetic field sensor, and first and second magnetic sources. The first magnetic source is rotatable relative to a sensitive surface of the sensor and generates a first magnetic field contribution of at least quadrupolar order. The second magnetic source is pivotable with respect to the sensitive surface and generates a second magnetic field contribution. The sensor is configured for detecting at least an in-plane component of a superimposition field of the first and second magnetic contributions at a plurality of lateral measurement locations on the sensitive surface, obtaining measurements, and determining a rotation angle for the first source from the field gradient measurements and two angular directions for the second source from the field mean measurements. Lateral measurement locations are arranged into two pairs of diametrically opposite measurement locations with respect to the sensitive surface.

Owner:MELEXIS TECH NV

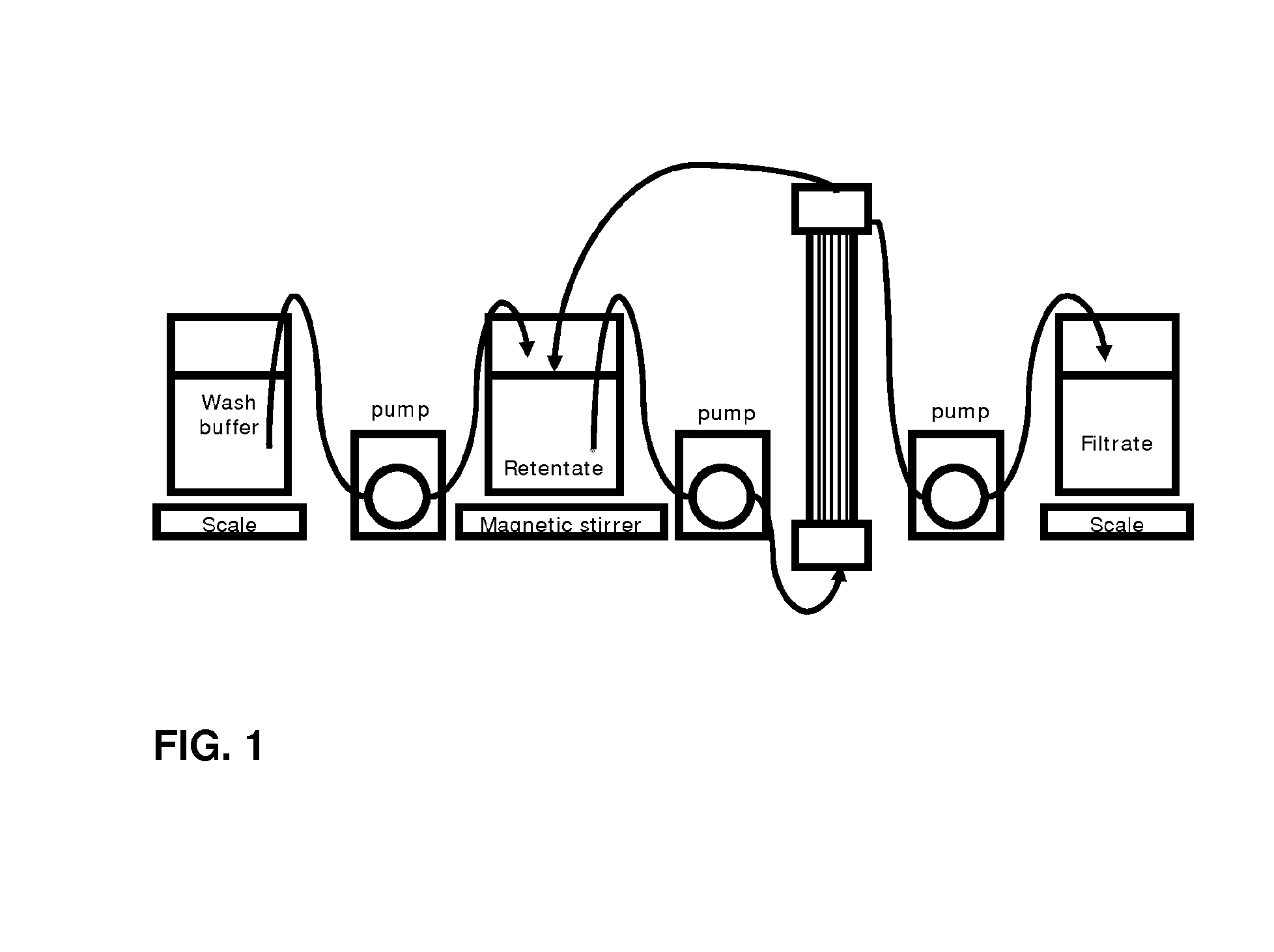

Method for the clarification of high density crude cell culture harvest

ActiveUS20160222429A1Faster and cheapImprove scalabilityMicroorganism separationImmunoglobulinsHigh cellHigh density

Owner:JANSSEN VACCINES & PREVENTION BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com