Patents

Literature

40results about How to "Minimal vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

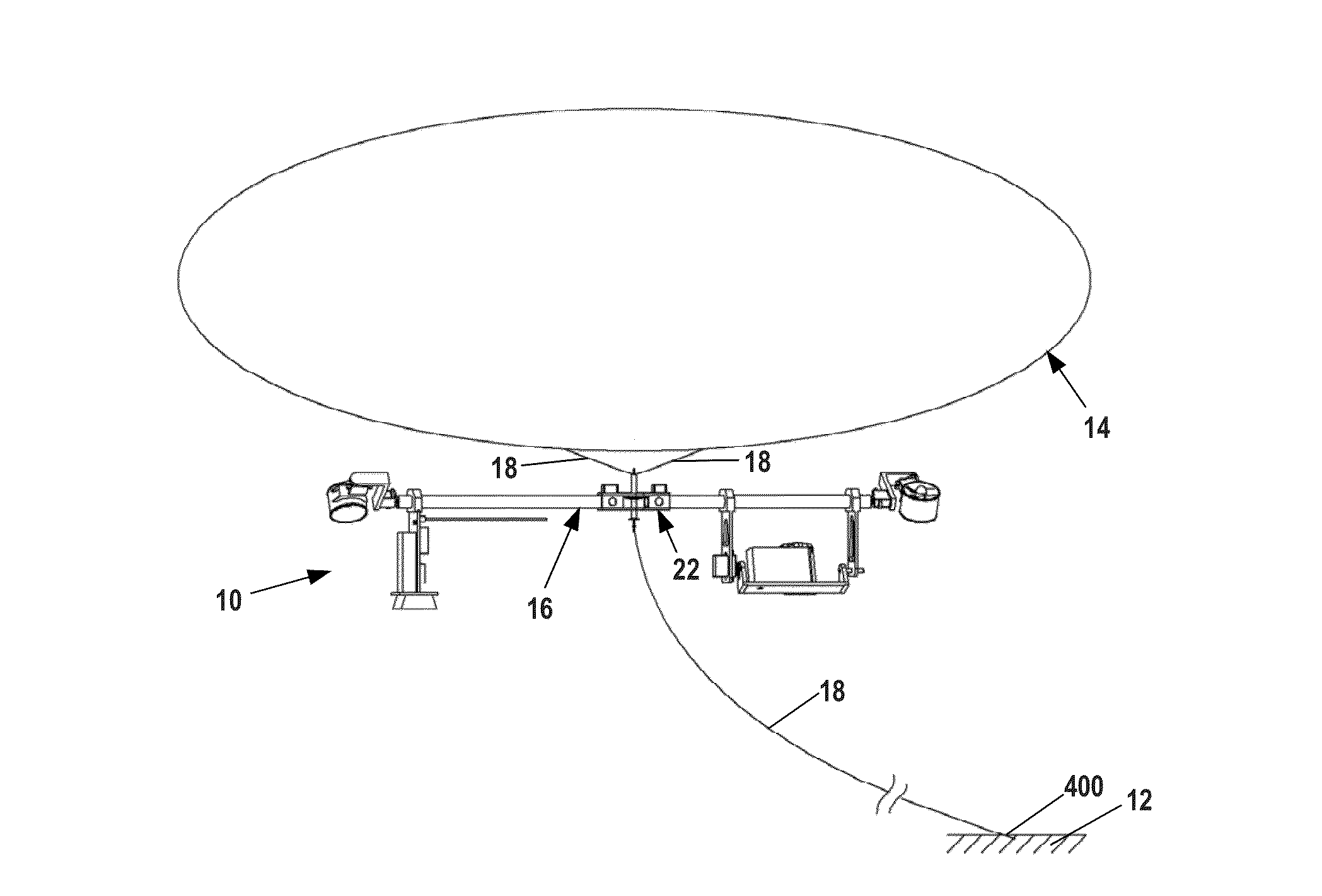

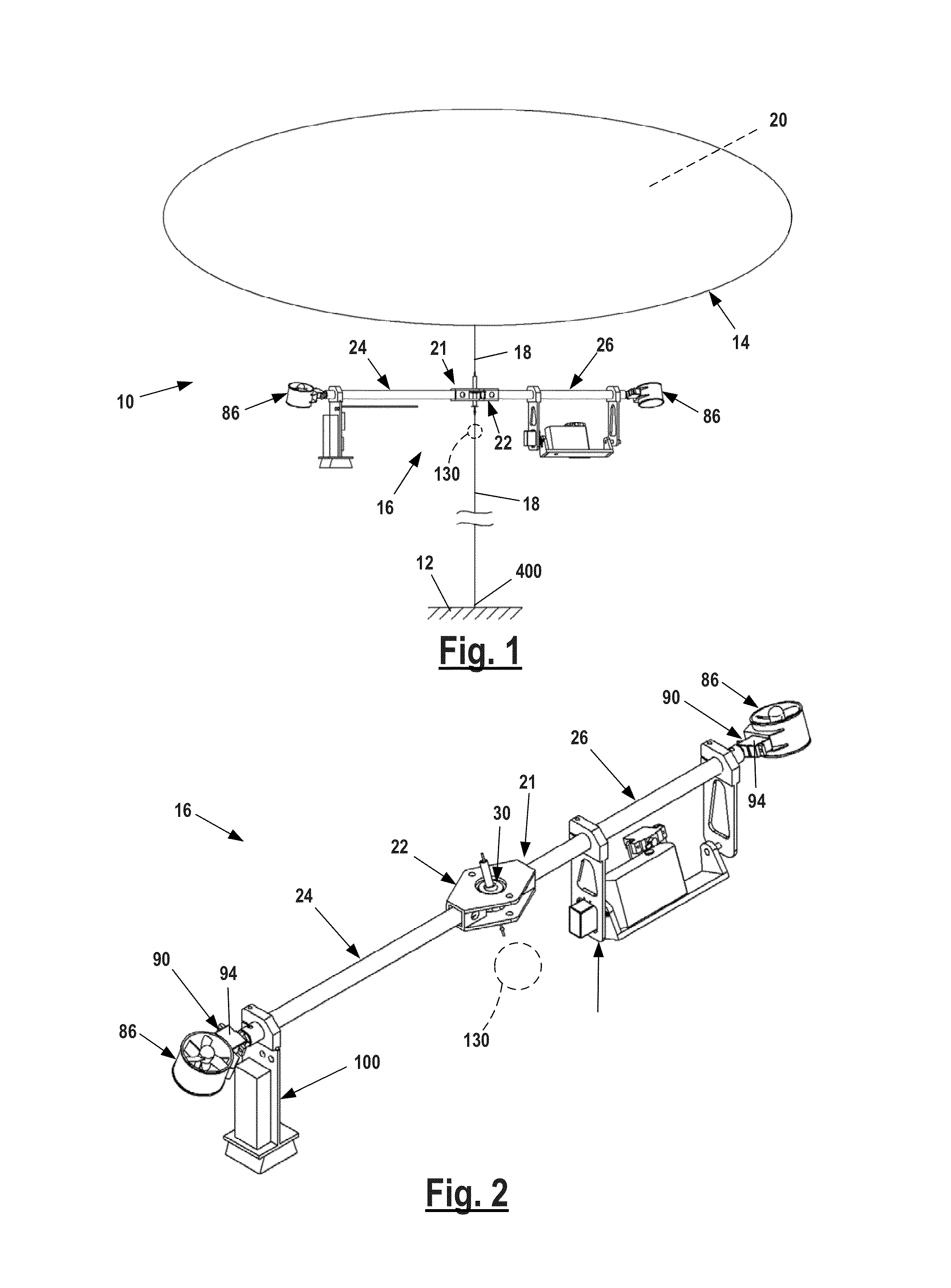

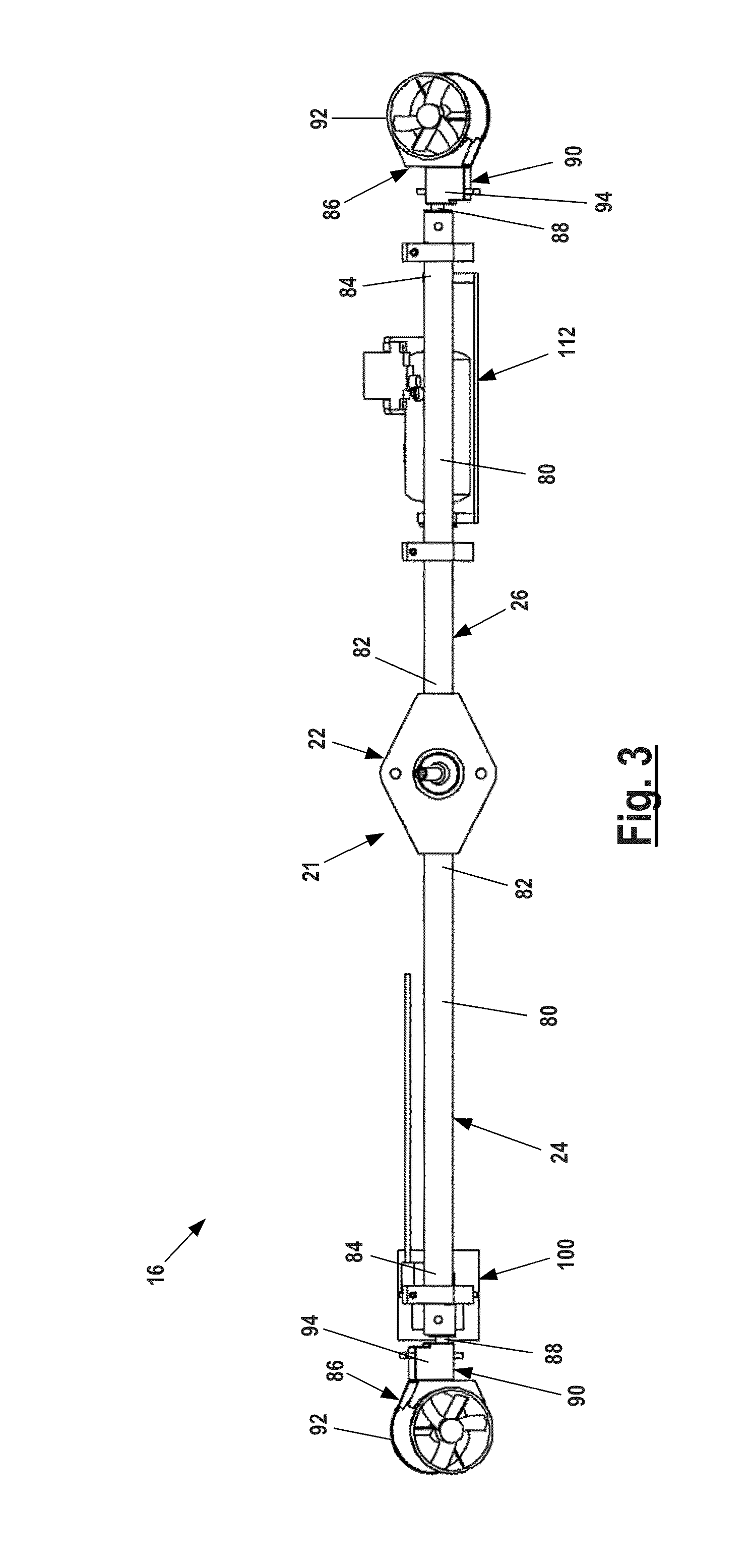

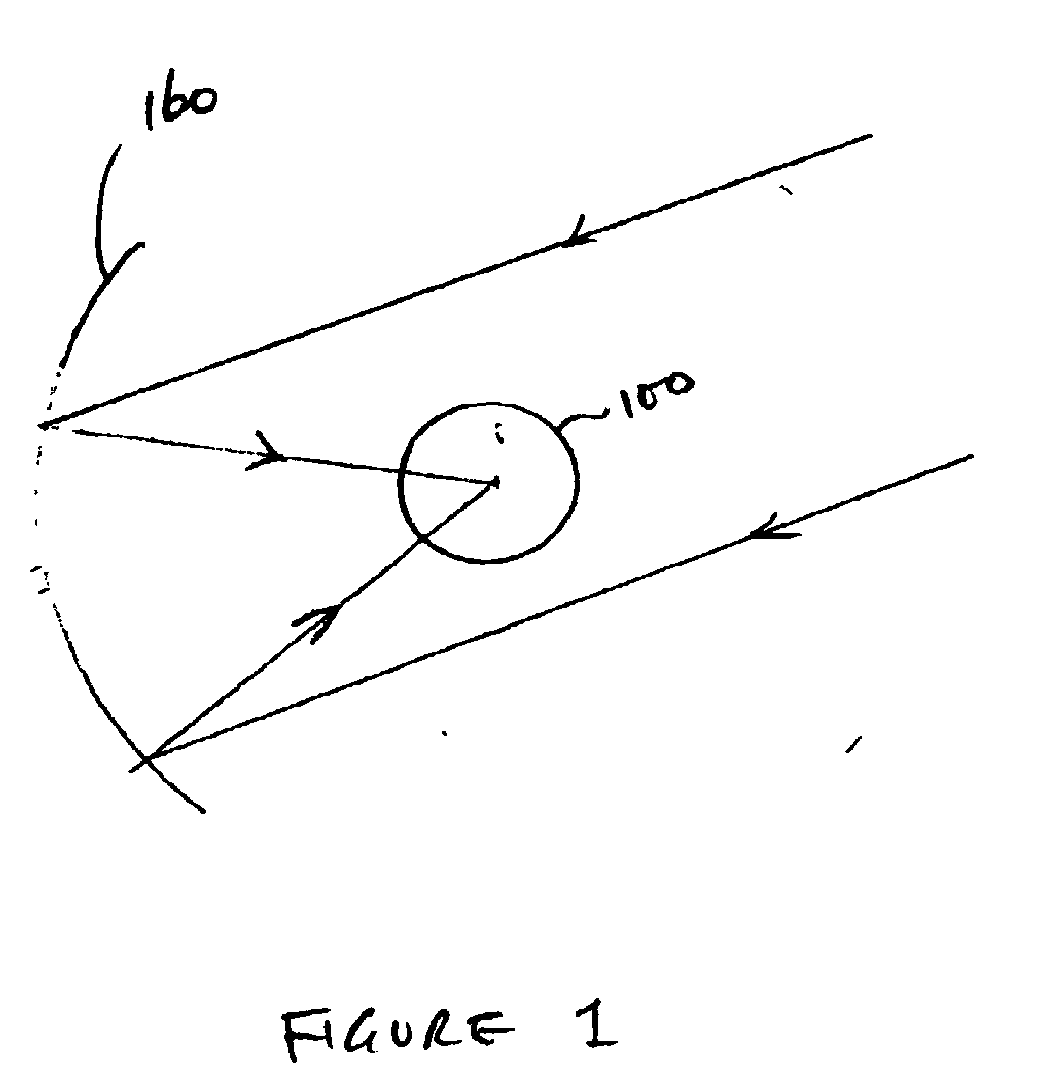

Aerostat assembly

InactiveUS8544788B1Easy to transportMinimal vibrationUnmanned aerial vehiclesRemote controlled aircraftEngineeringAerial photography

An aerostat assembly, specifically an aerostat assembly including one or more cameras for aerial photography and surveillance. The aerostat assembly includes a frame assembly having a pivot assembly joined to a balloon tether line. Thrusters on the frame allow an operator to maneuver the assembly to desired positions as well as rotate the frame assembly about the pivot assembly.

Owner:CAPTURES

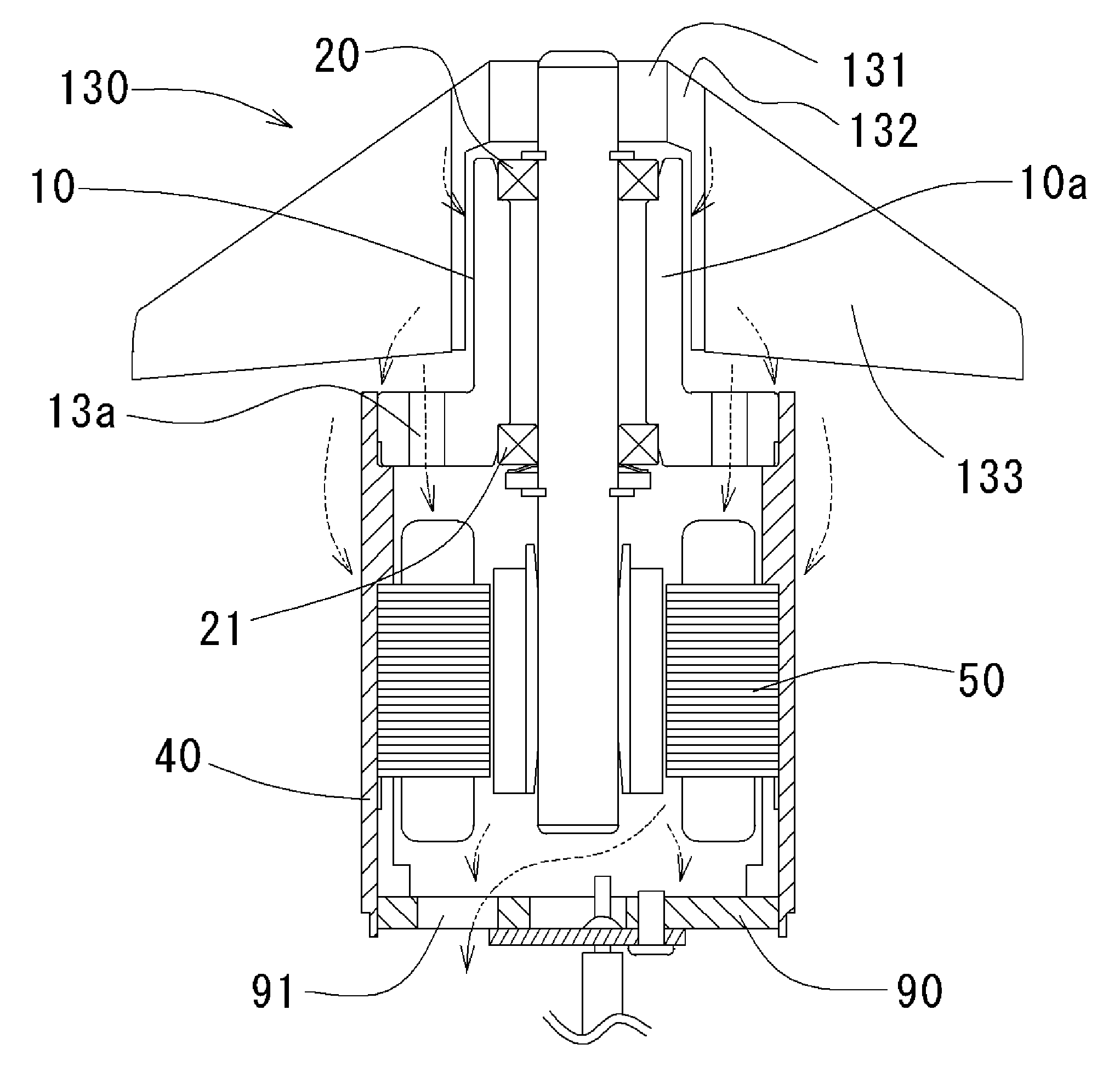

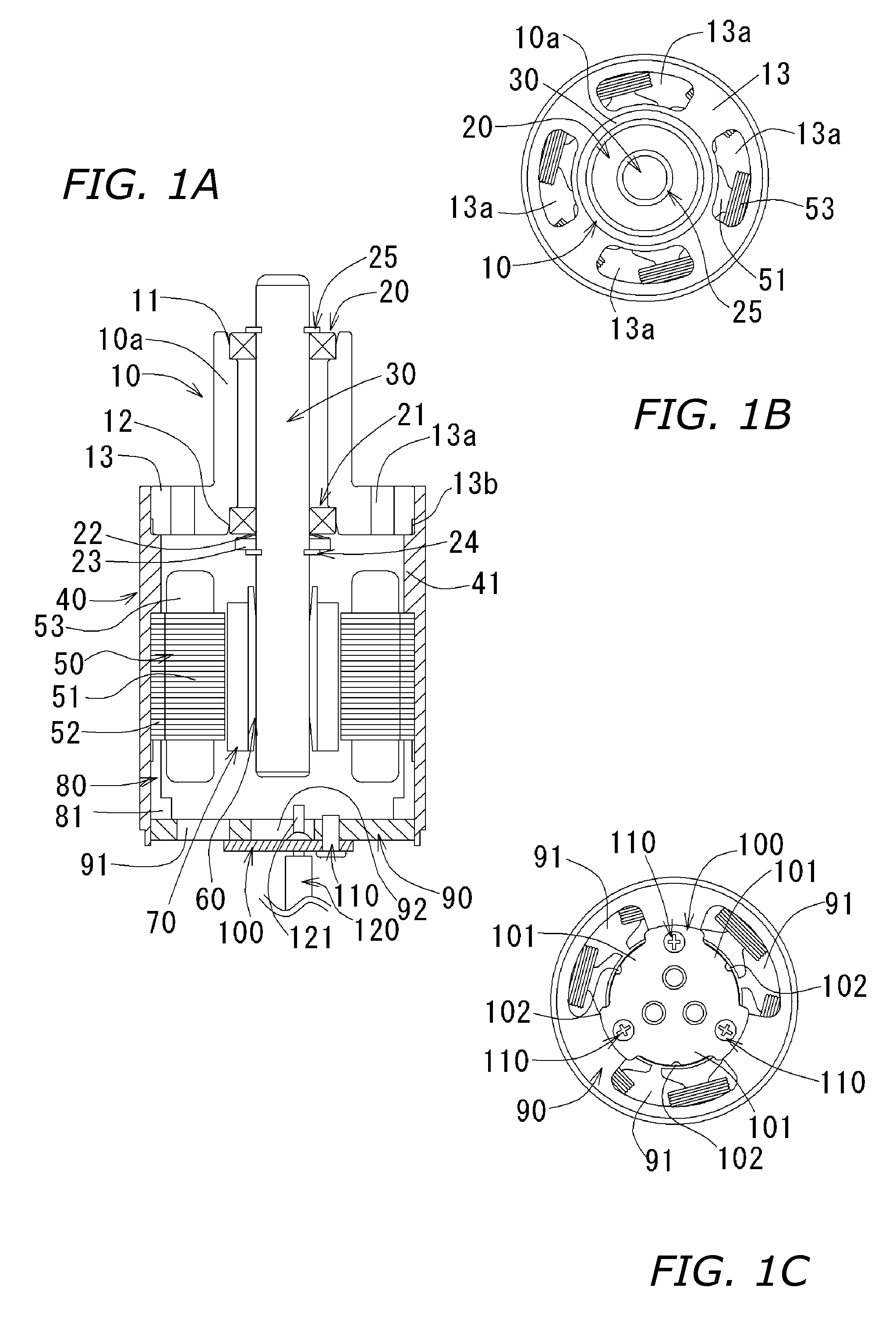

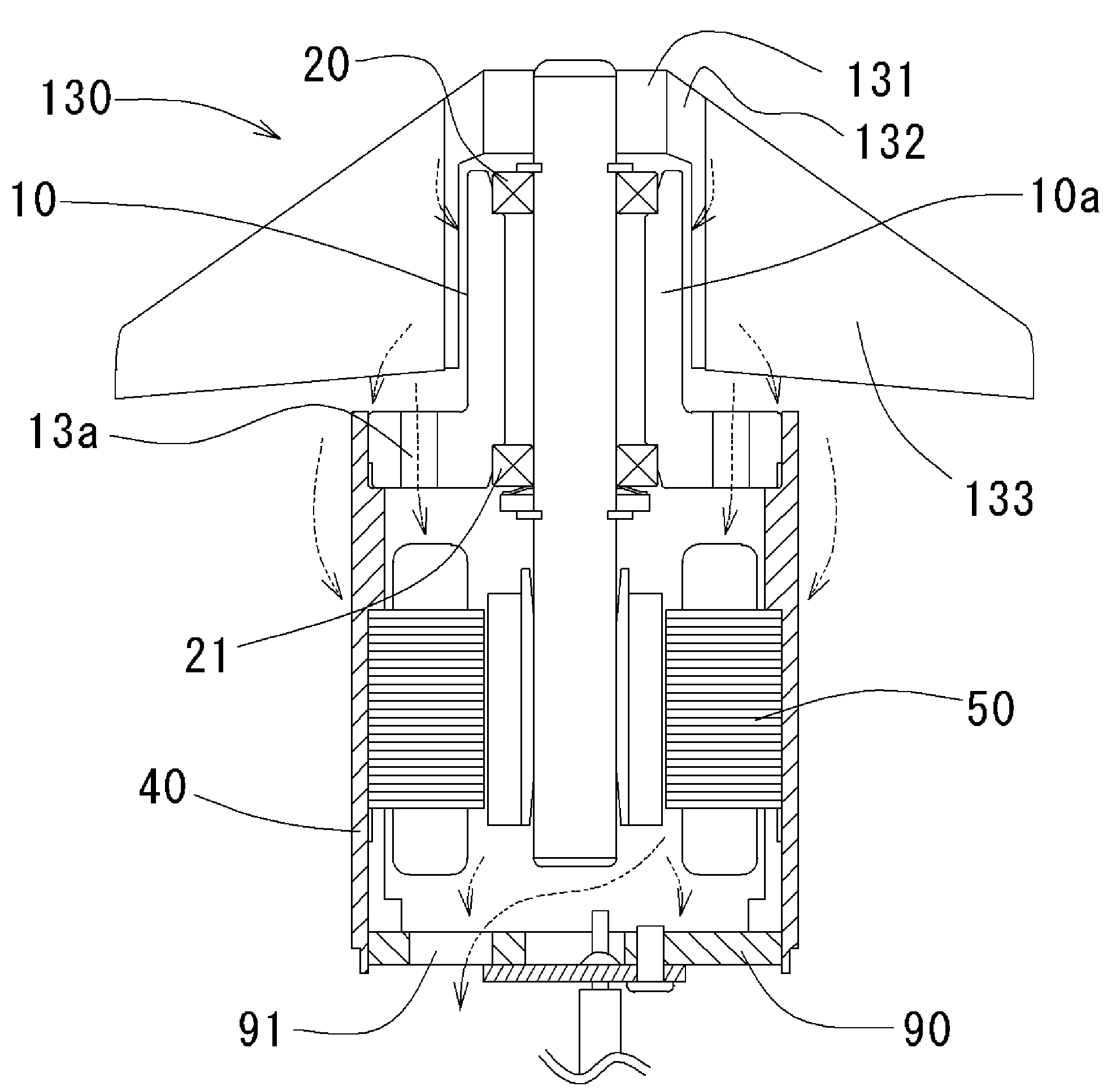

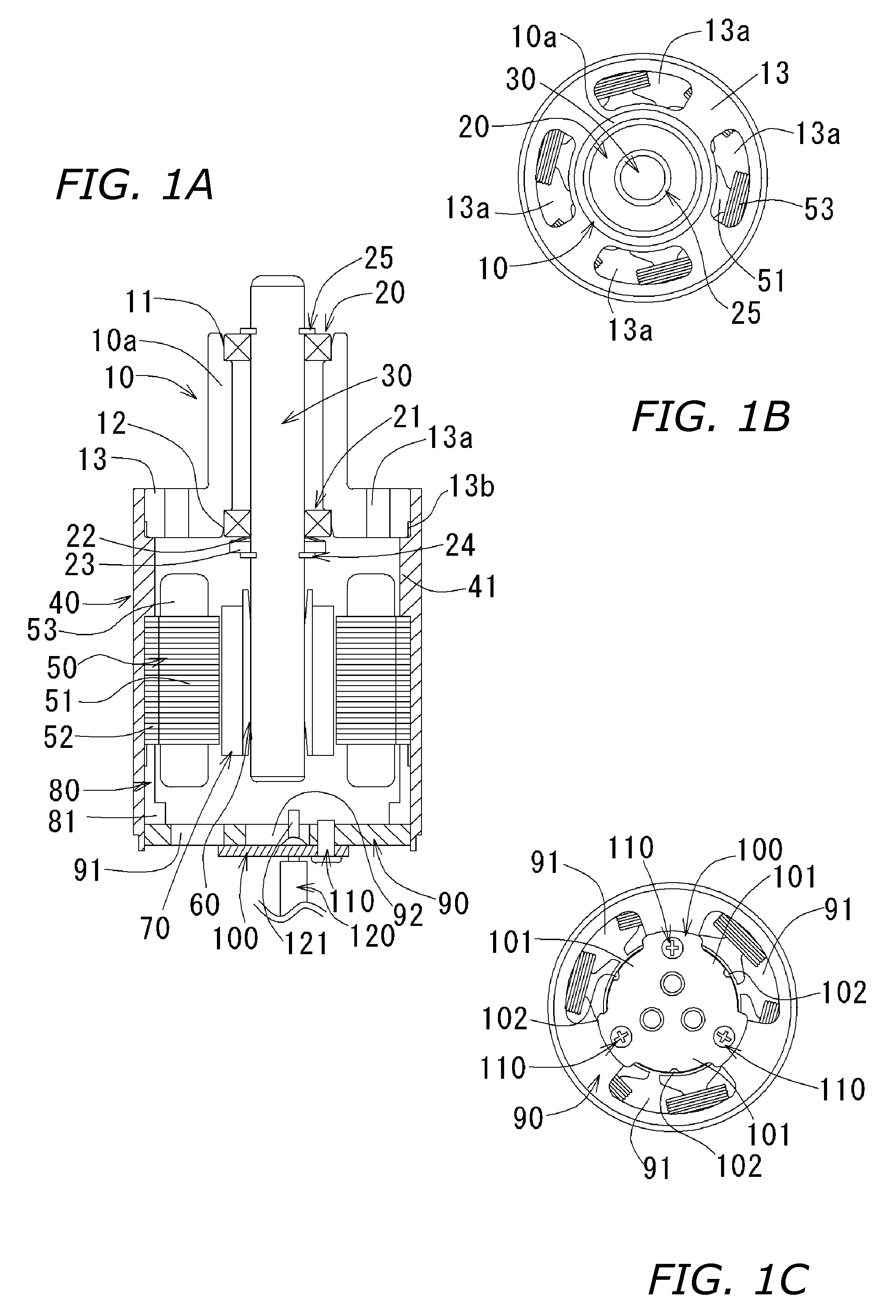

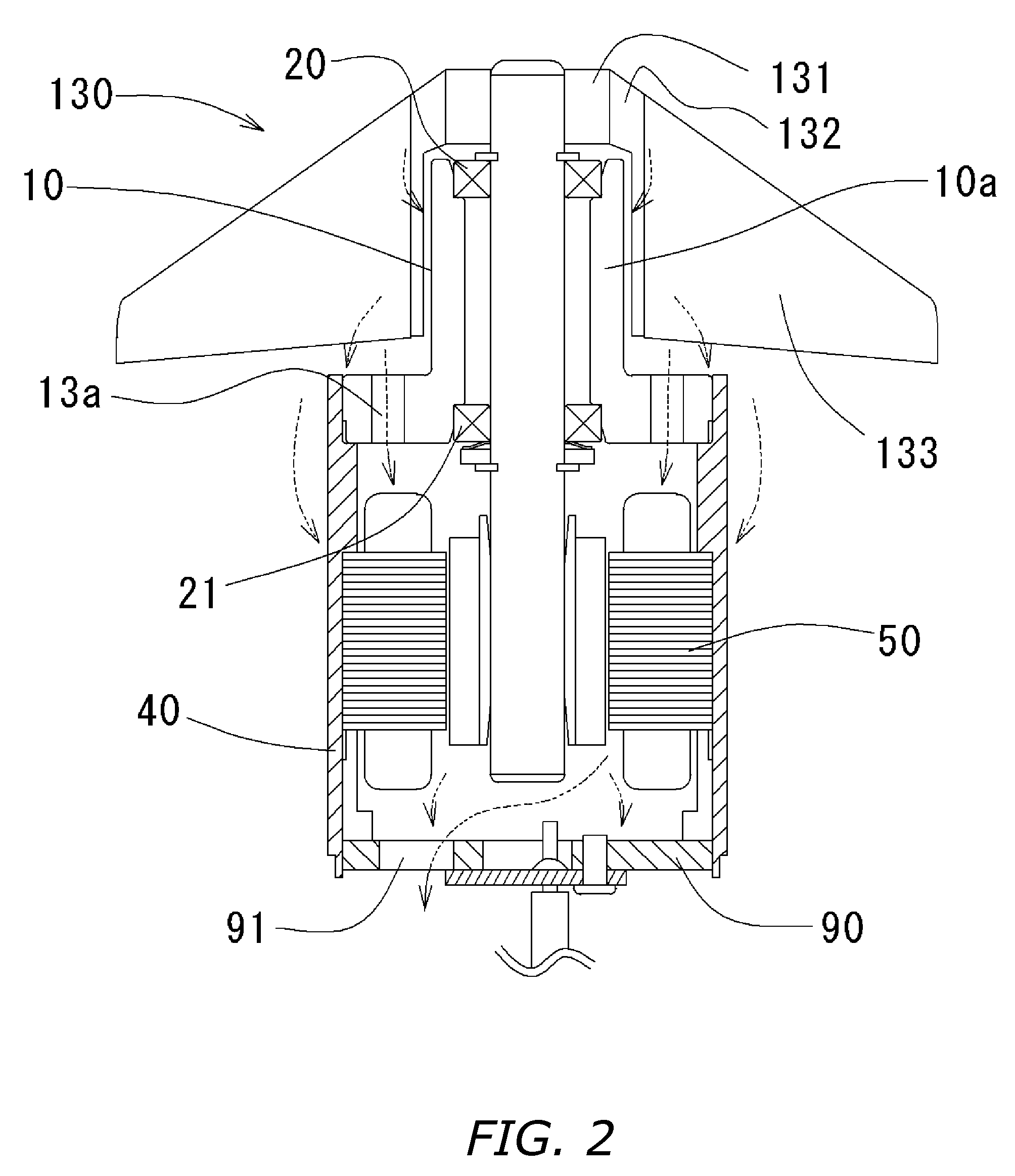

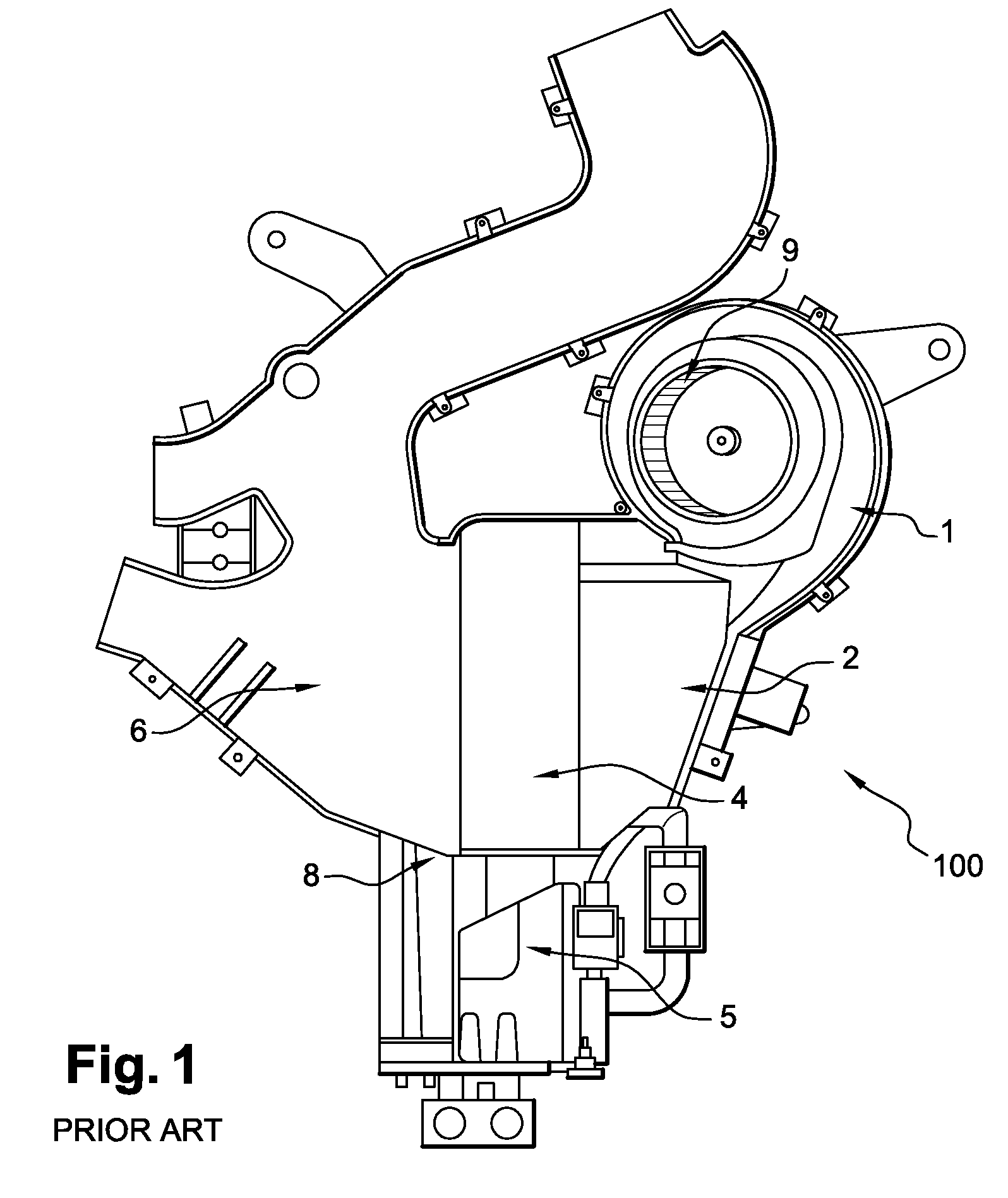

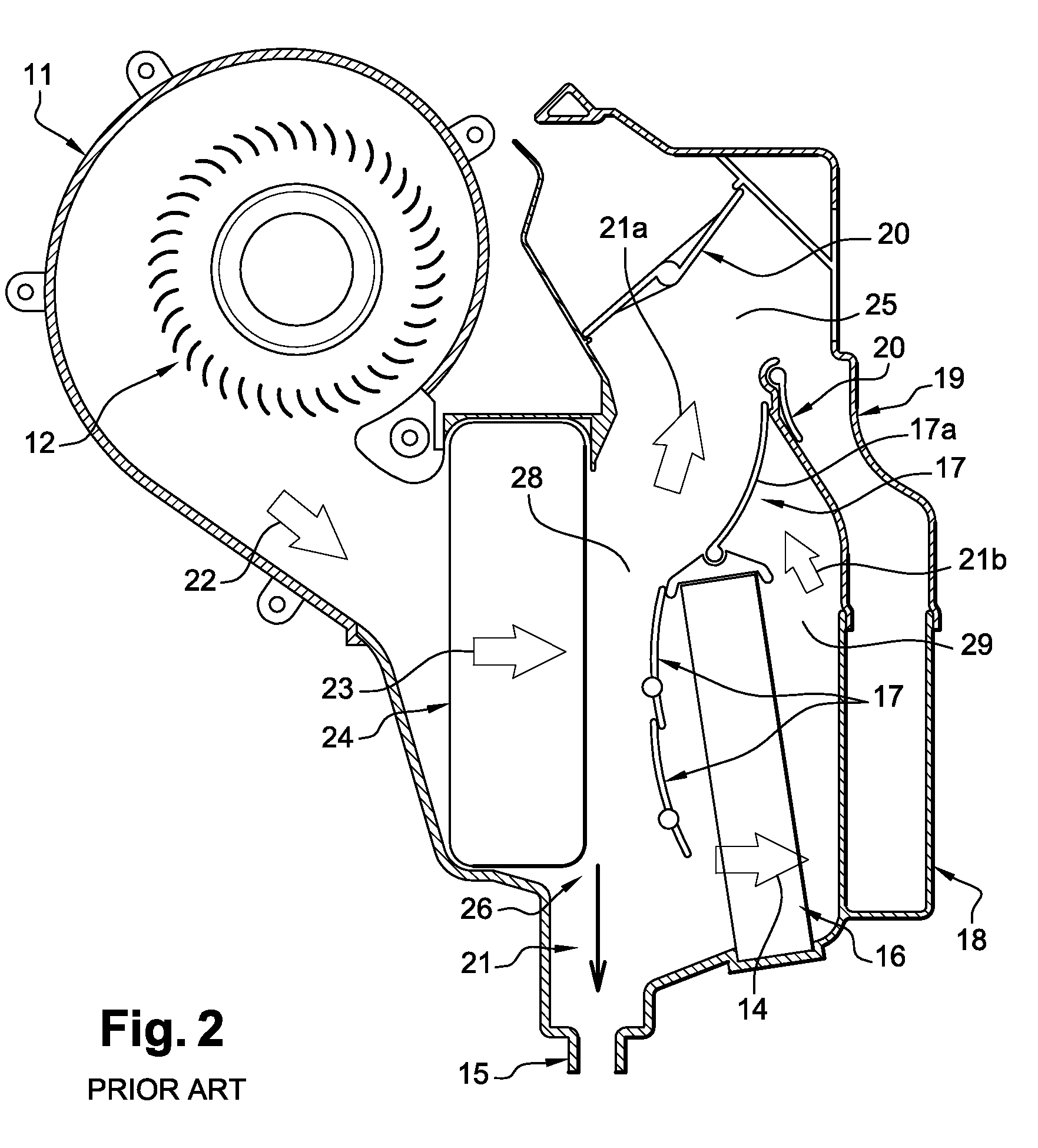

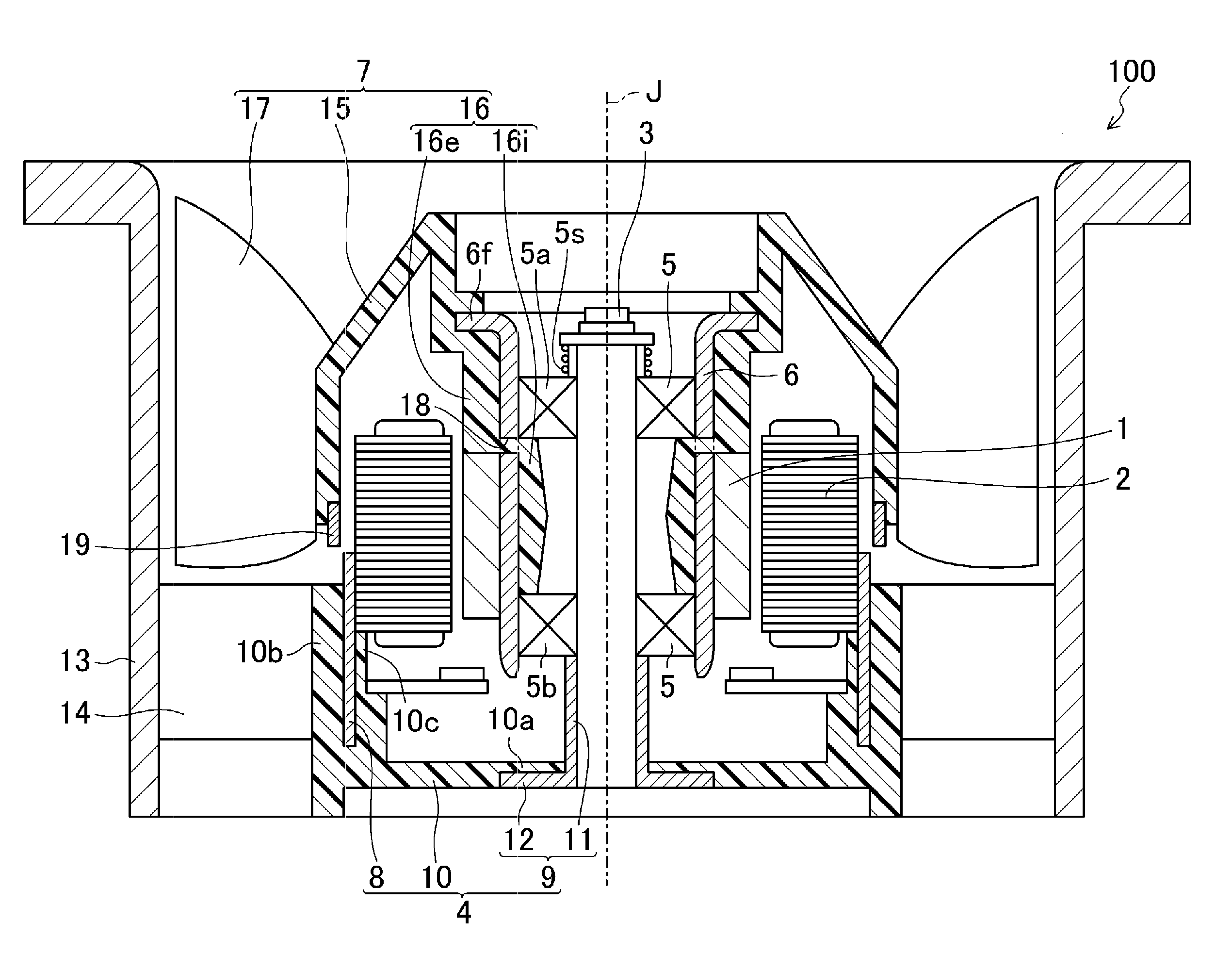

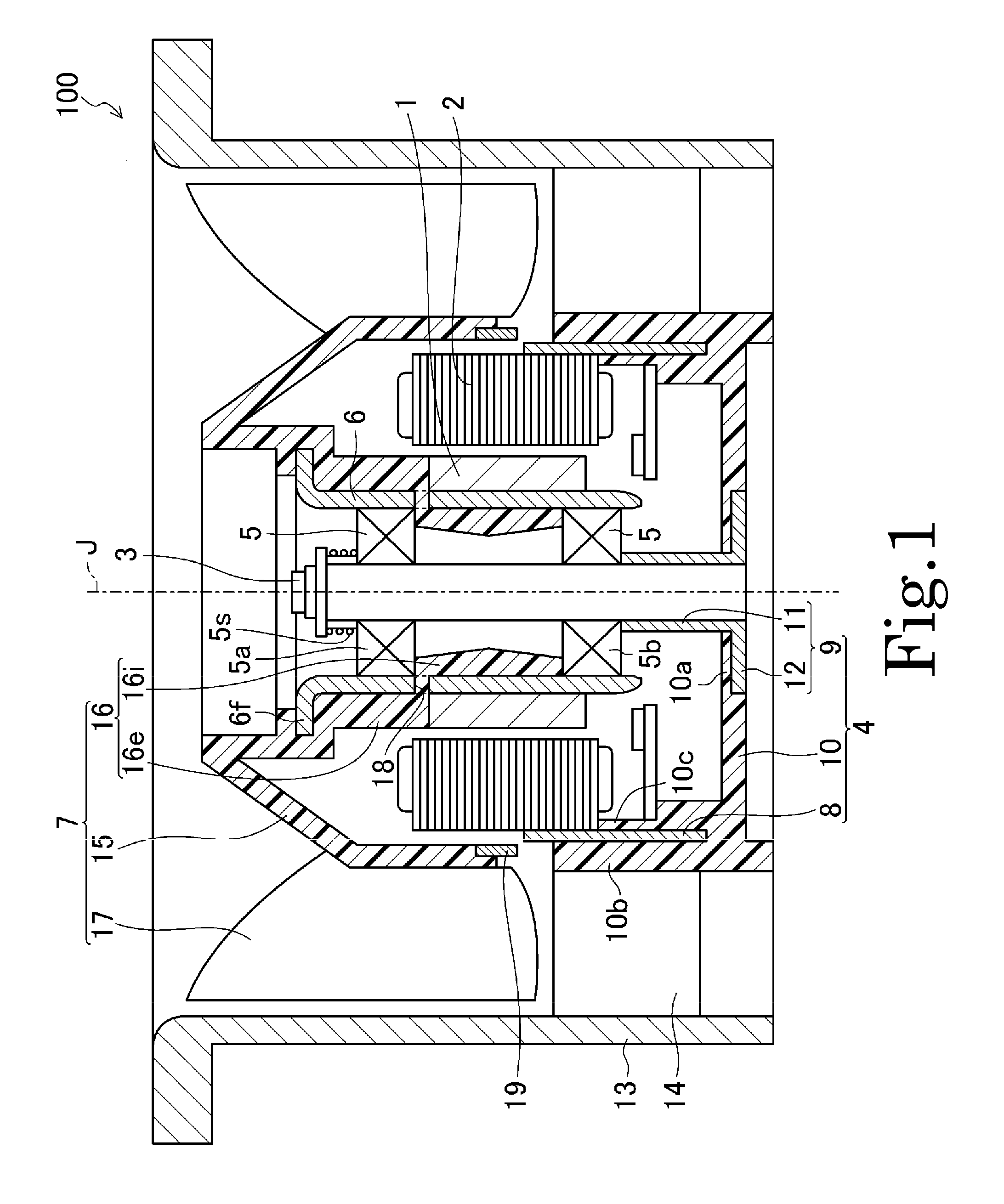

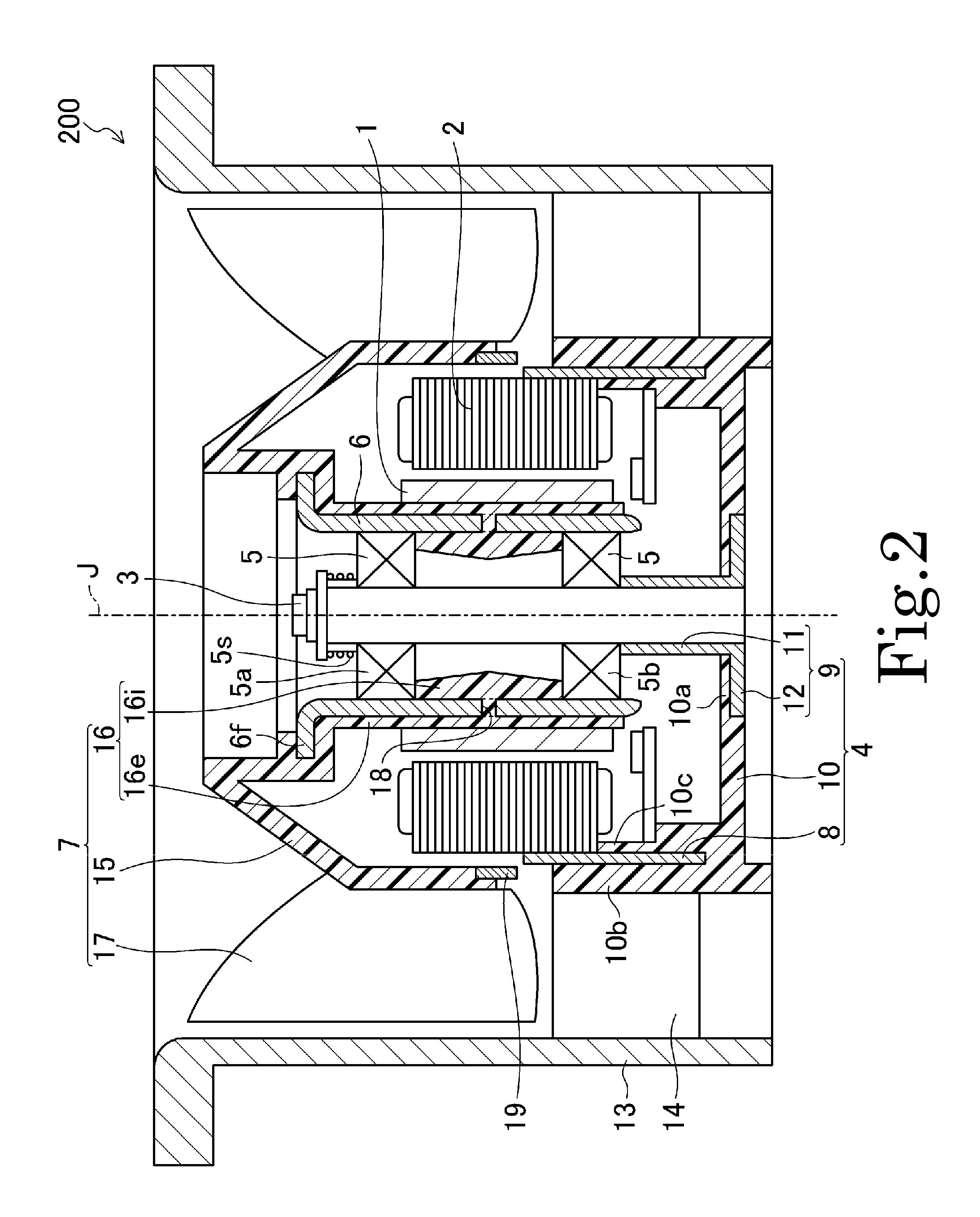

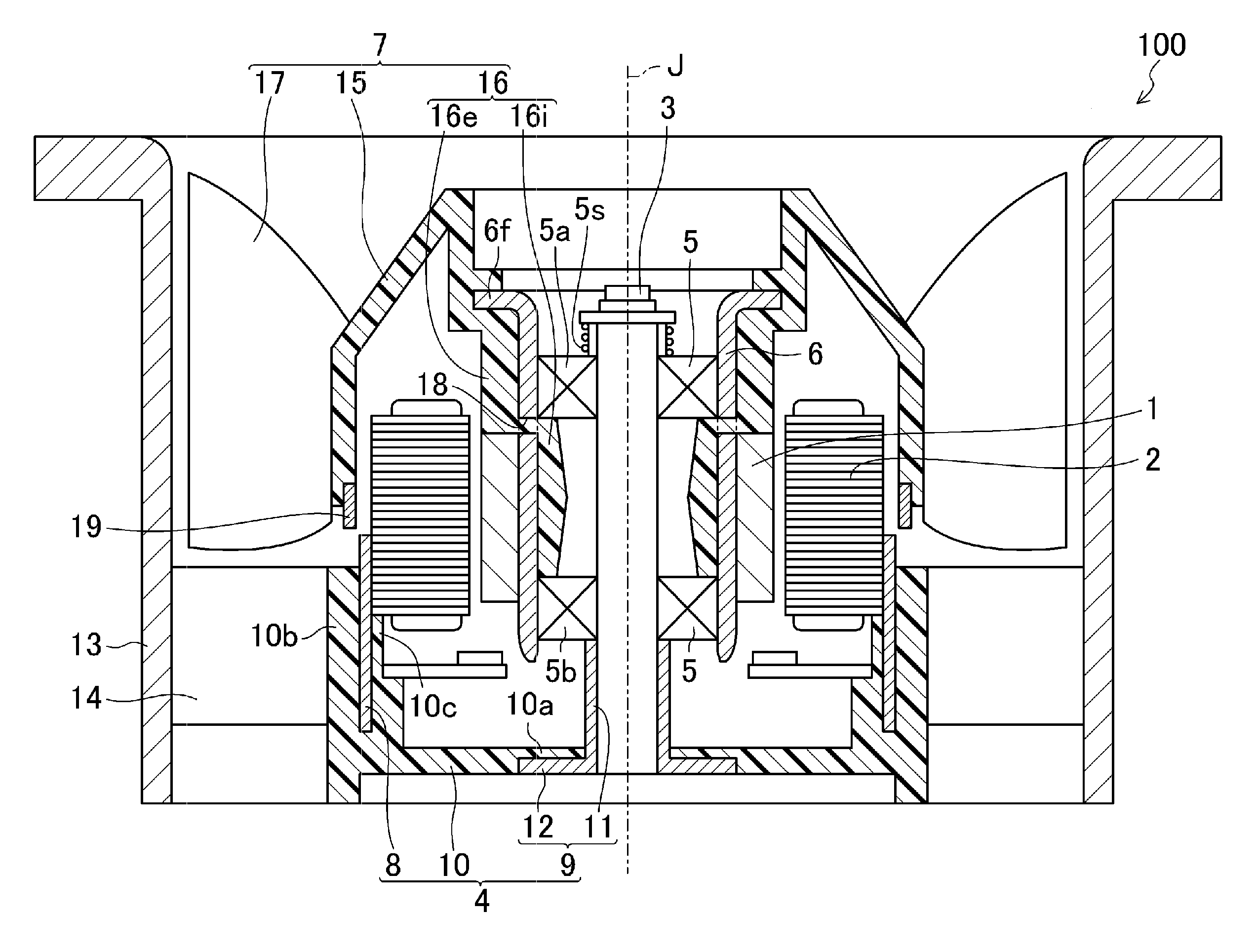

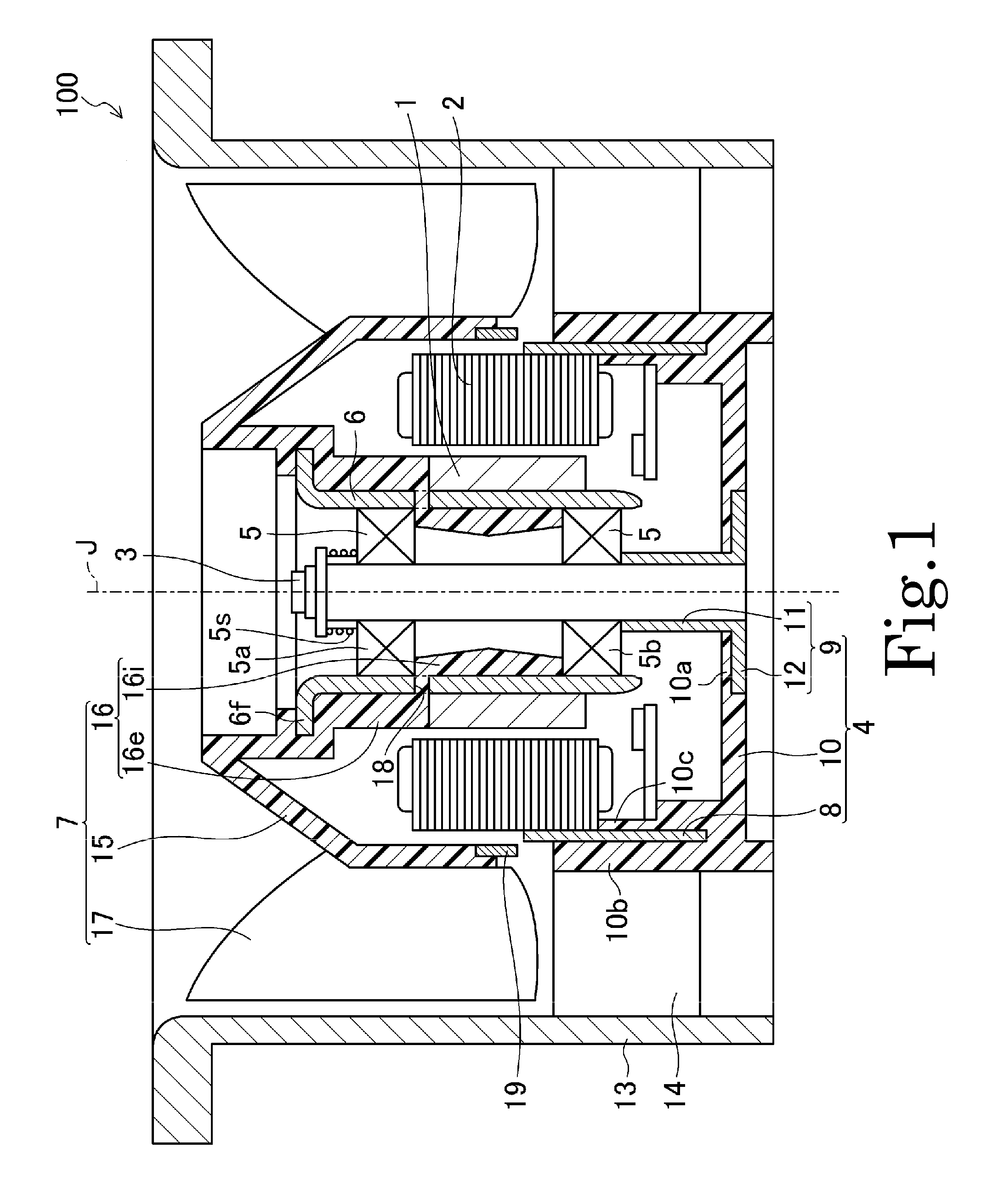

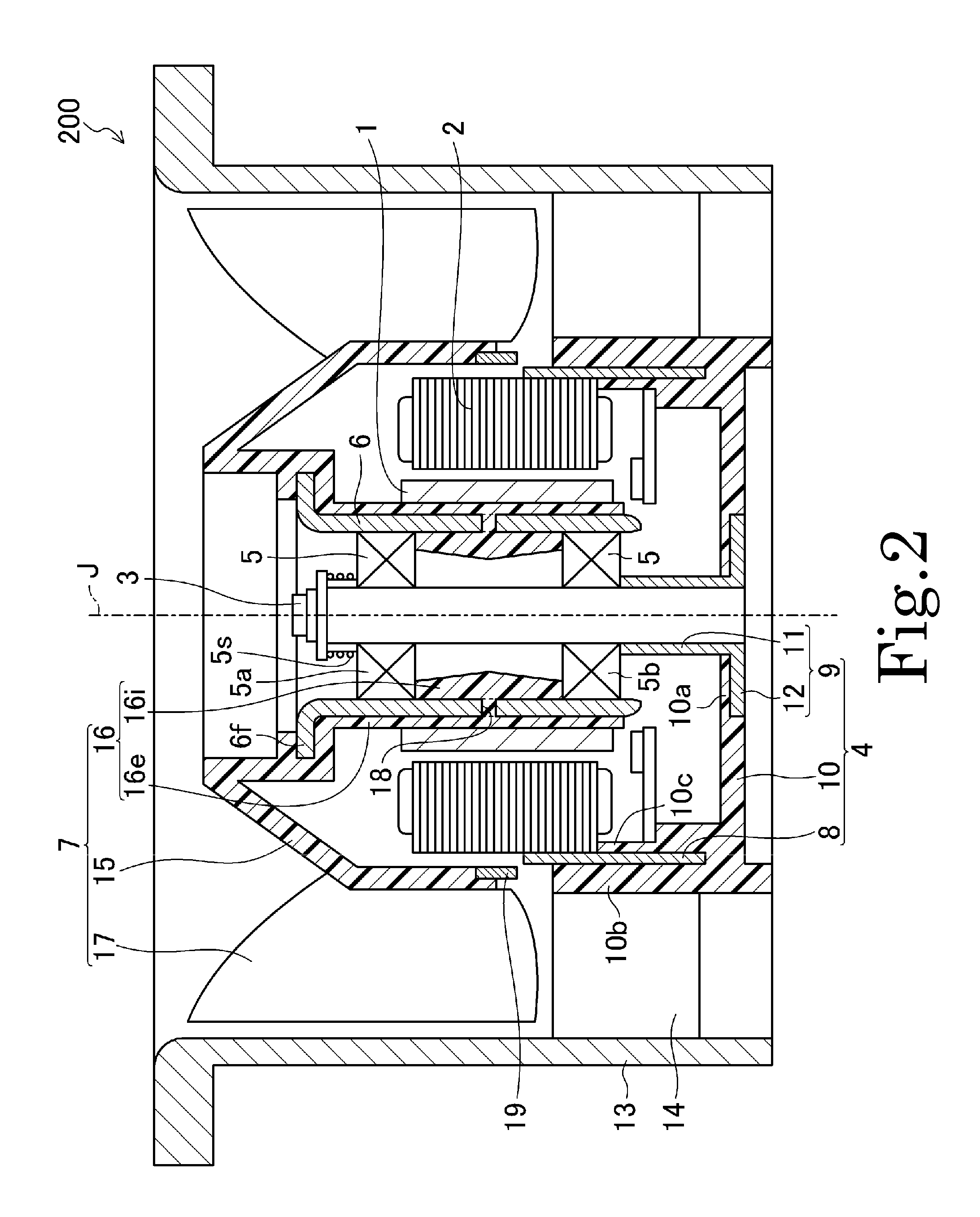

Axial Fan

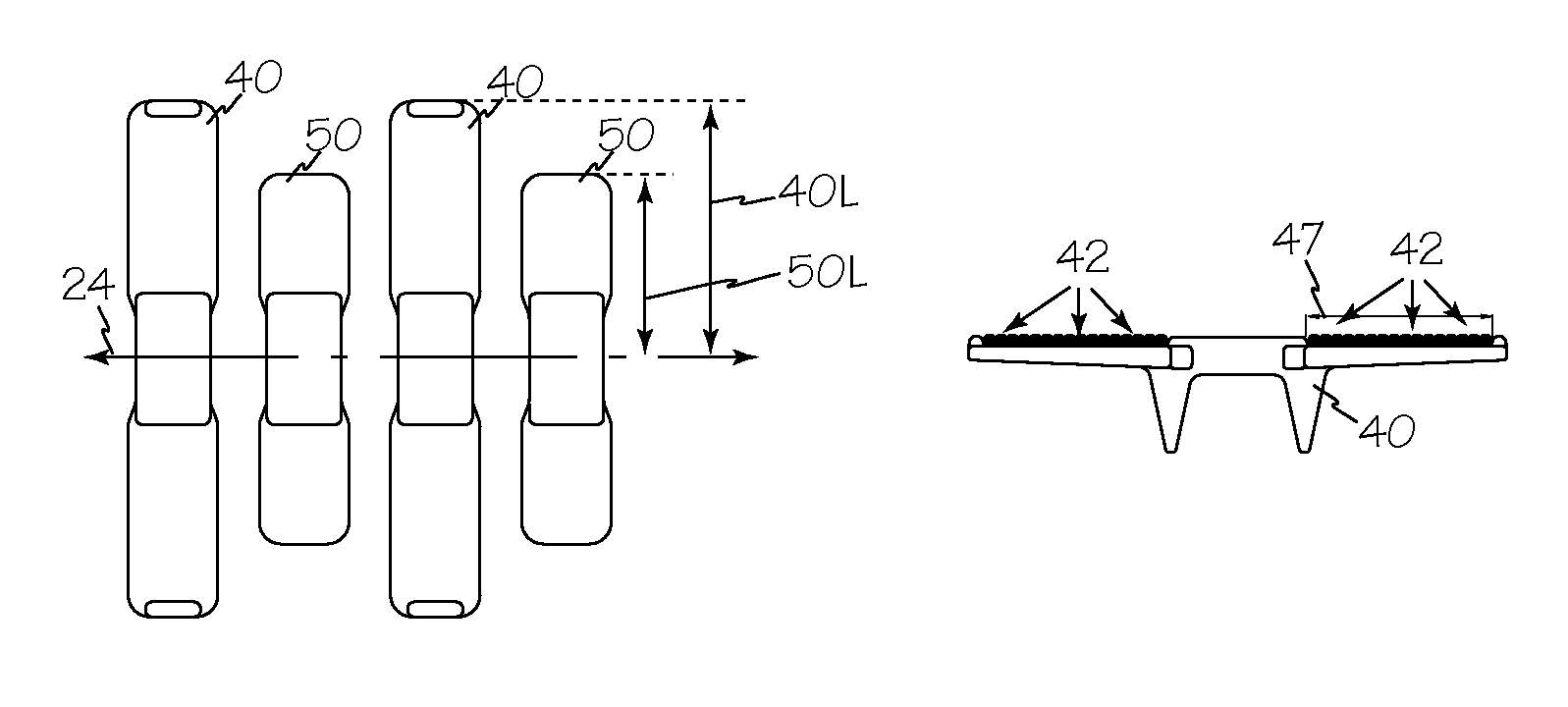

ActiveUS20060250039A1Increase air volumeImprove bearing lifeMagnetic circuit rotating partsPump componentsBall bearingElectrical and Electronics engineering

In an axial fan, a case (40) accommodating the fan motor stator (50) is anchored into a bearing retainer (10), in which ball bearings (20, 21) as a bearing unit are accommodated, along a bulge part (13) formed on the lower end portion thereof. The case (40) extends heading axially downward, wherein there is no diametrical overlap between the ball bearings (20, 21) and the stator (50). Since only the bulge part (13) of the bearing retainer (10) is fixed to the case (40), heat arising from the stator (50) is thermally conveyed via the case (40) only to the bulge part (13). The fact that the thermal conveyance zone is minimal enables unrestrained curtailment of heat transmitted to the ball bearings (20, 21). As a result the axial fan can be designed for prolonged bearing lifespan.

Owner:NIPPON DENSAN CORP

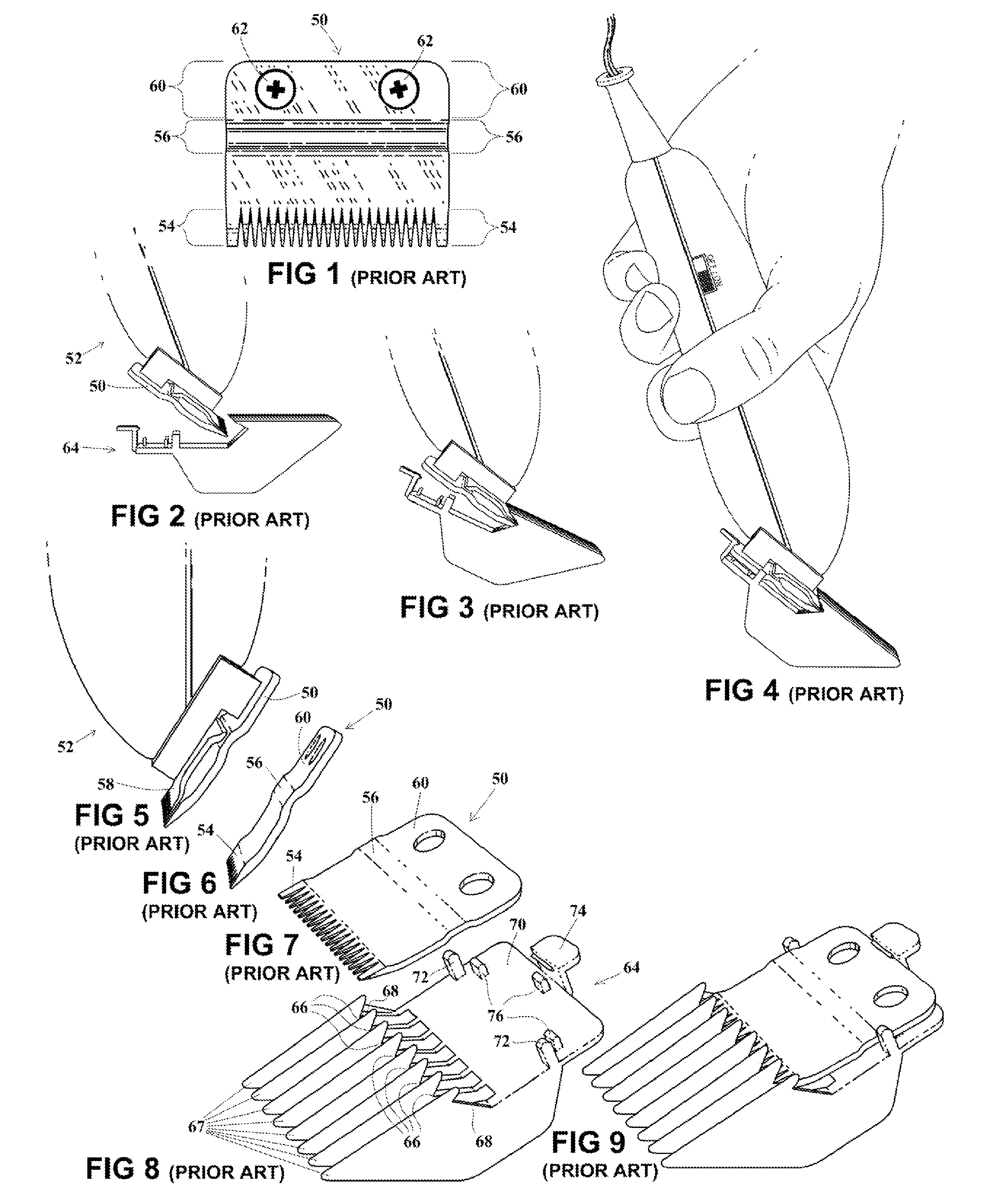

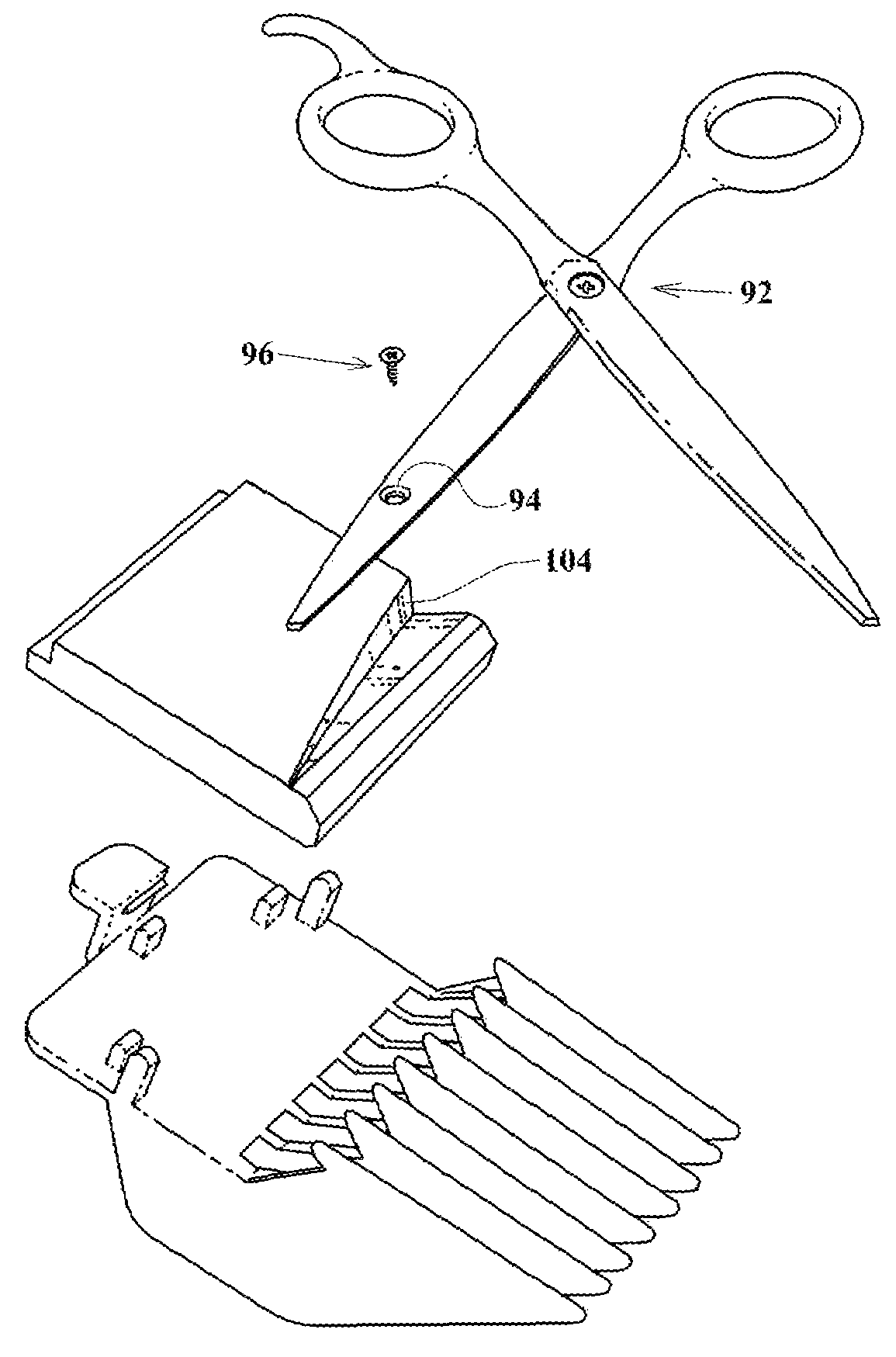

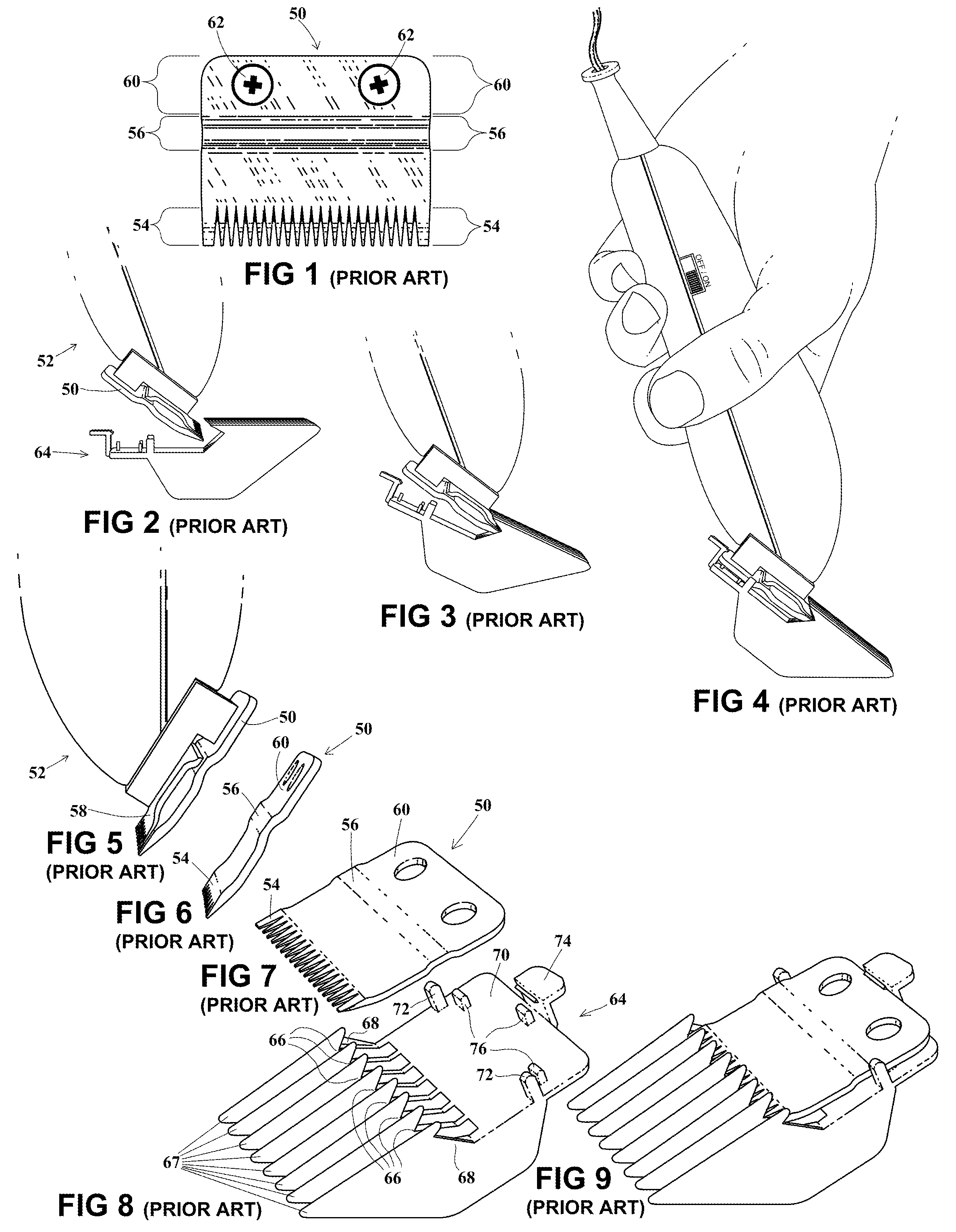

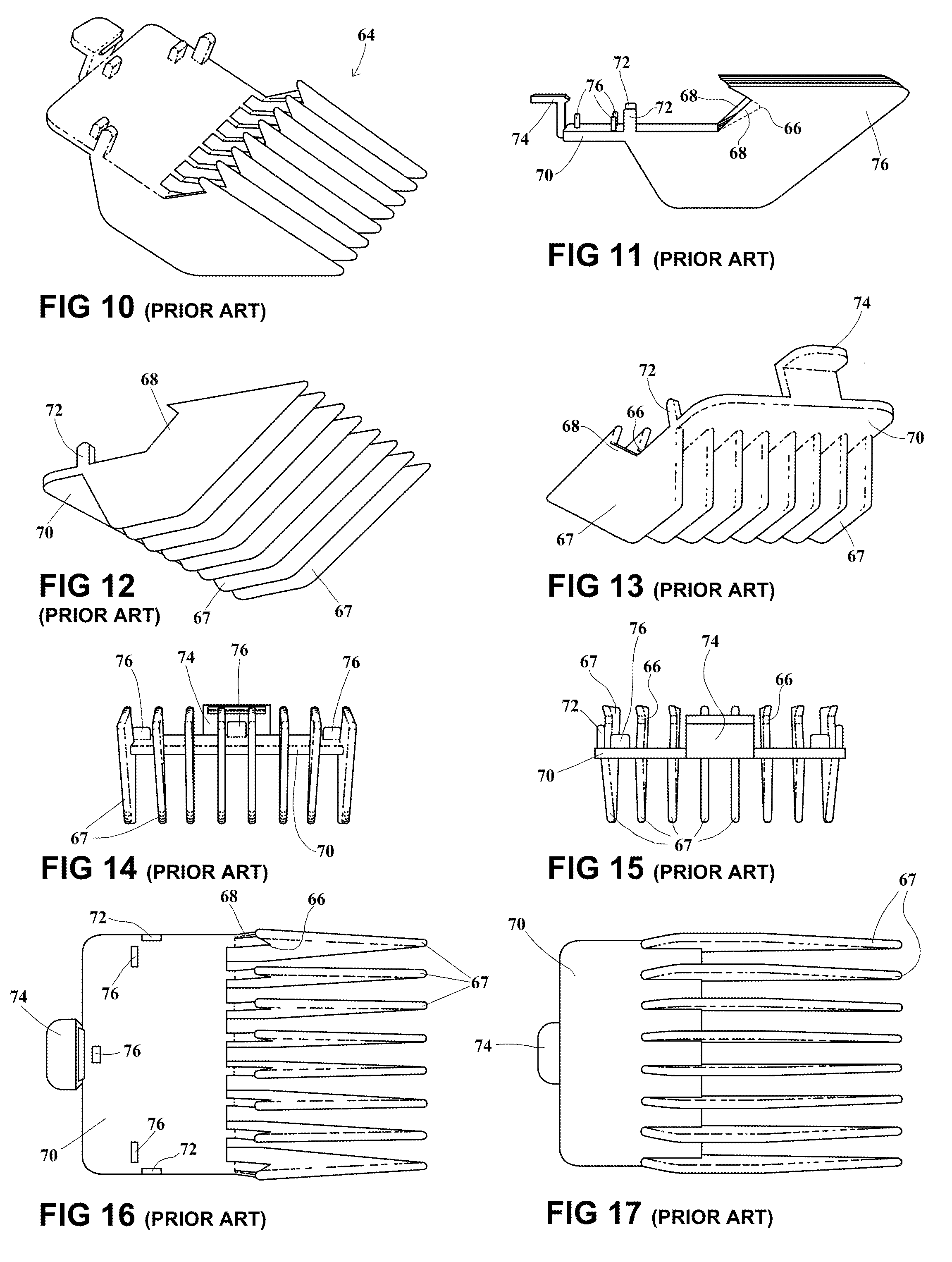

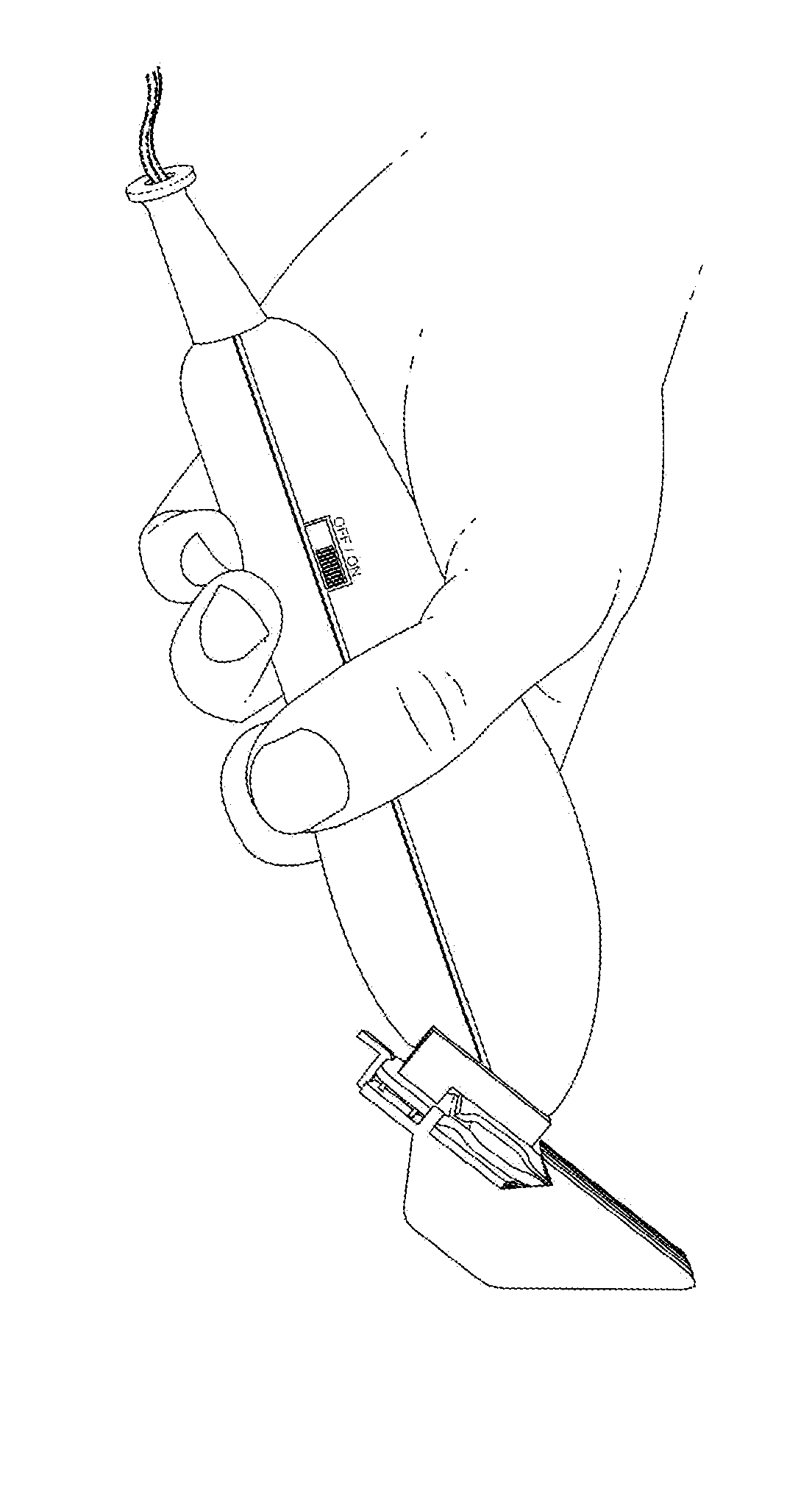

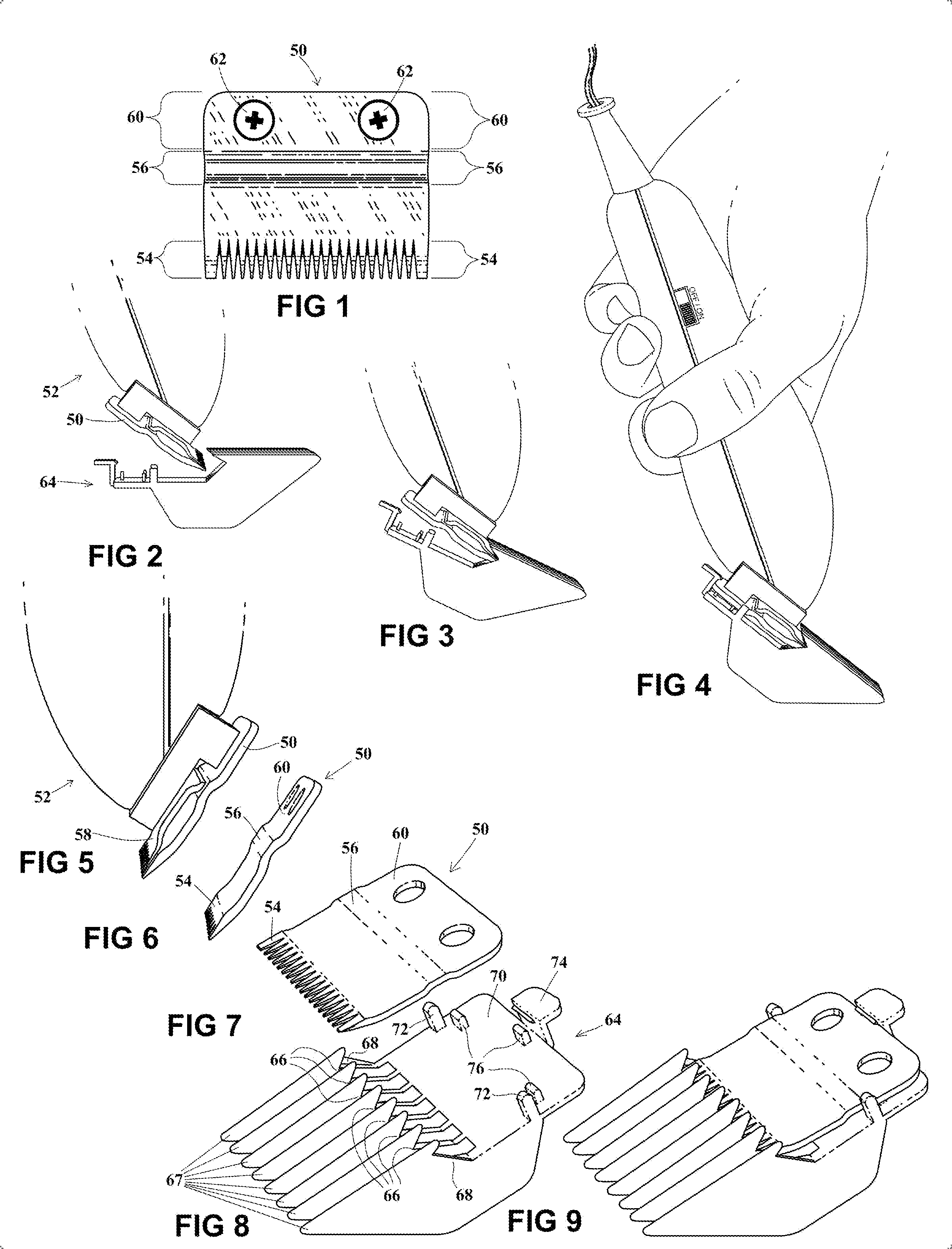

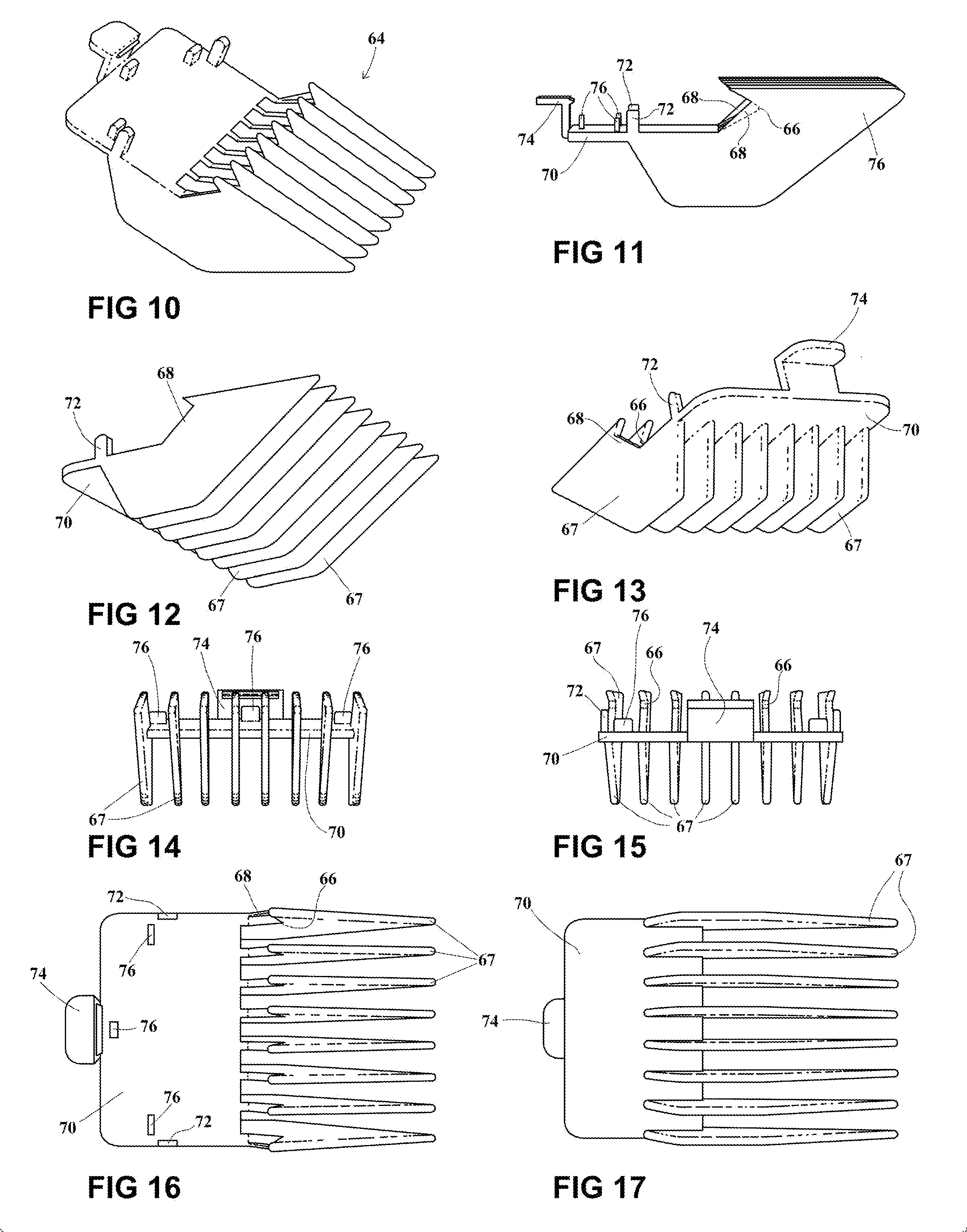

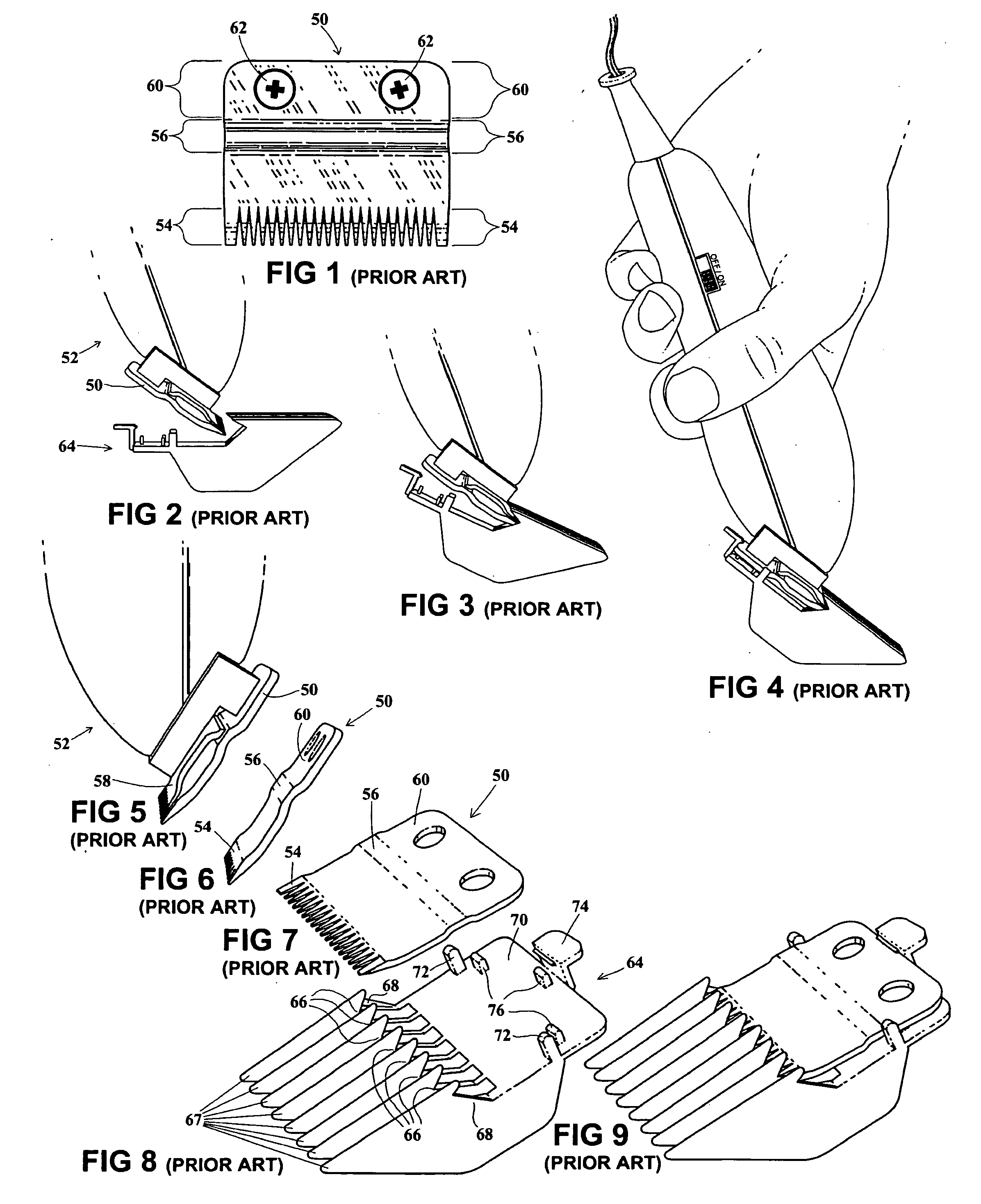

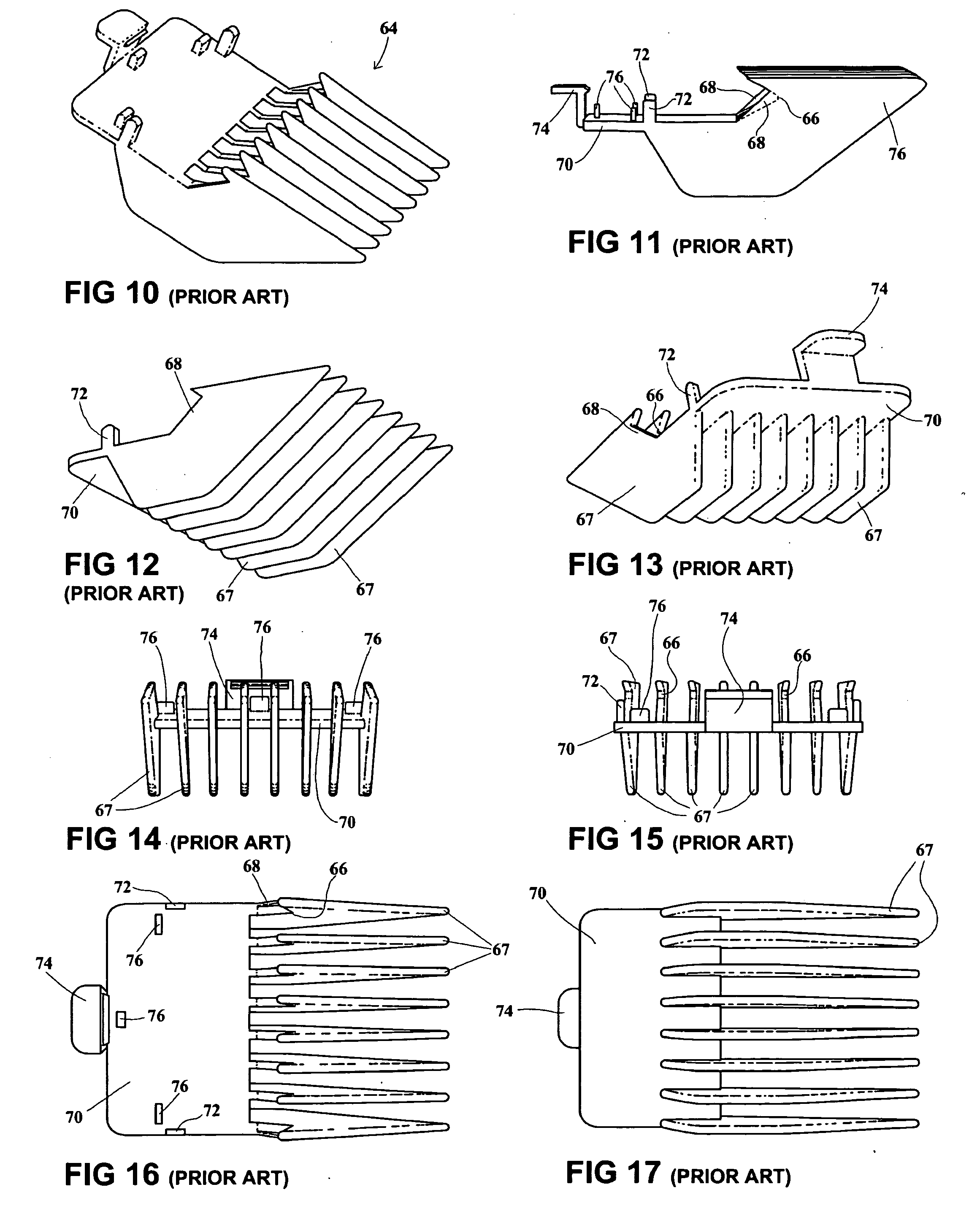

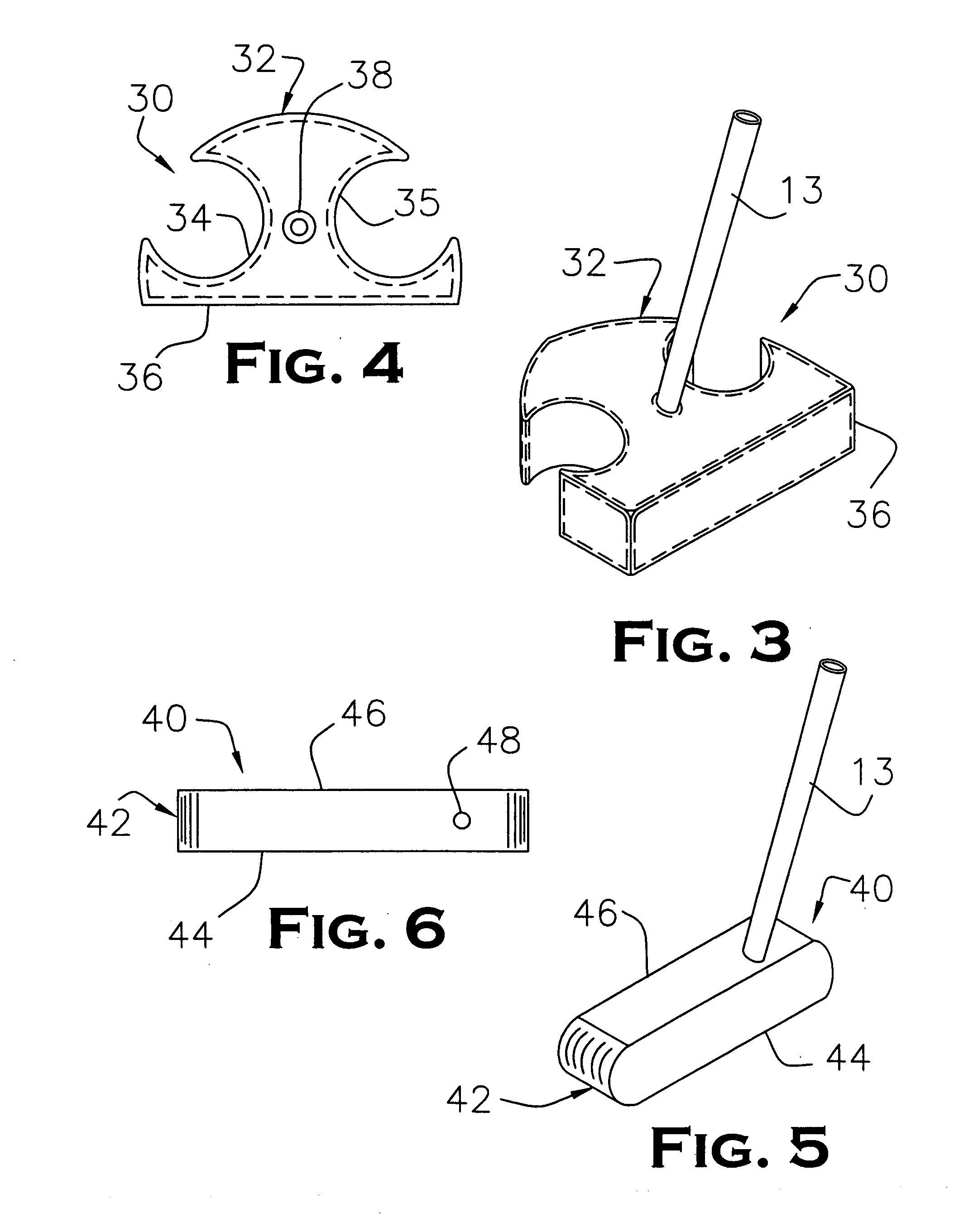

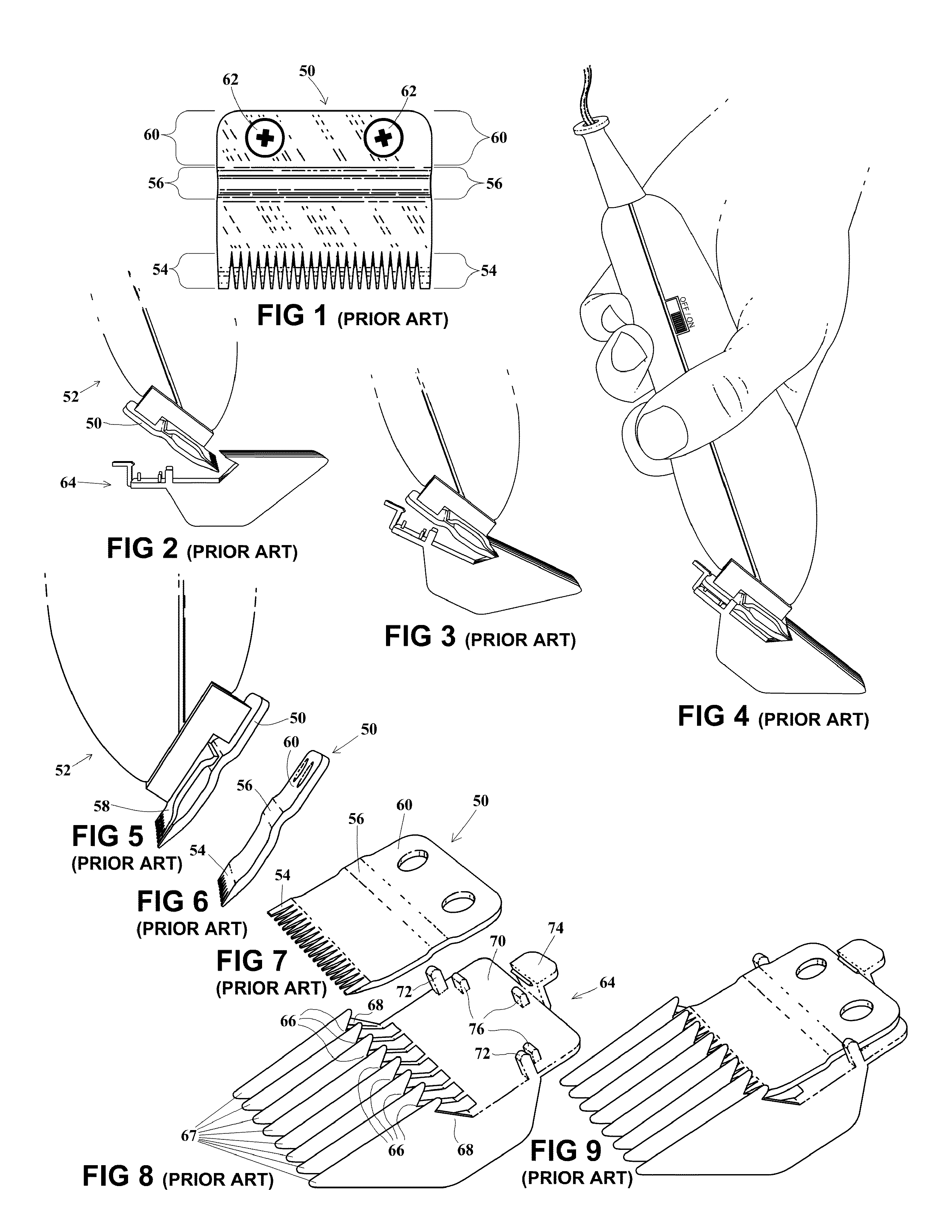

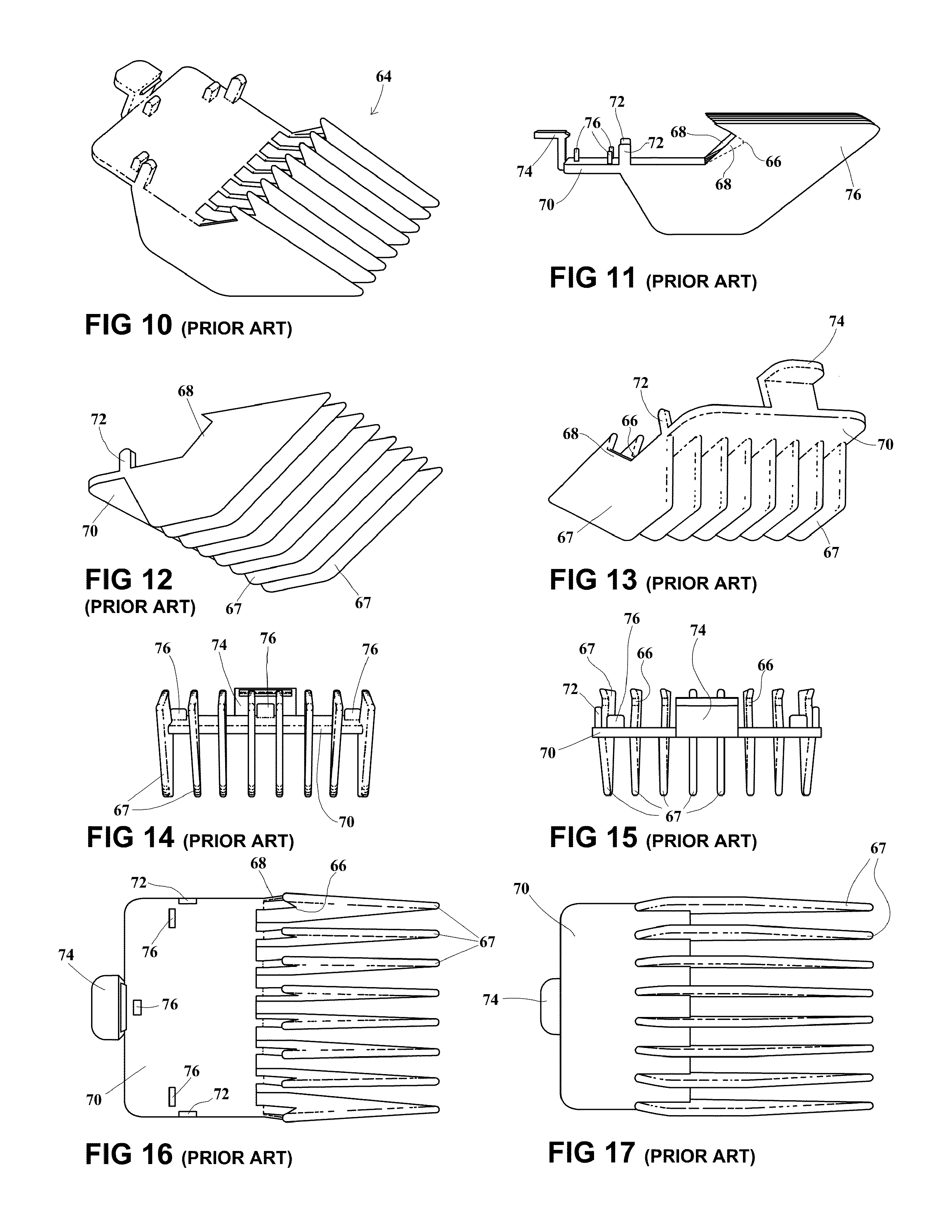

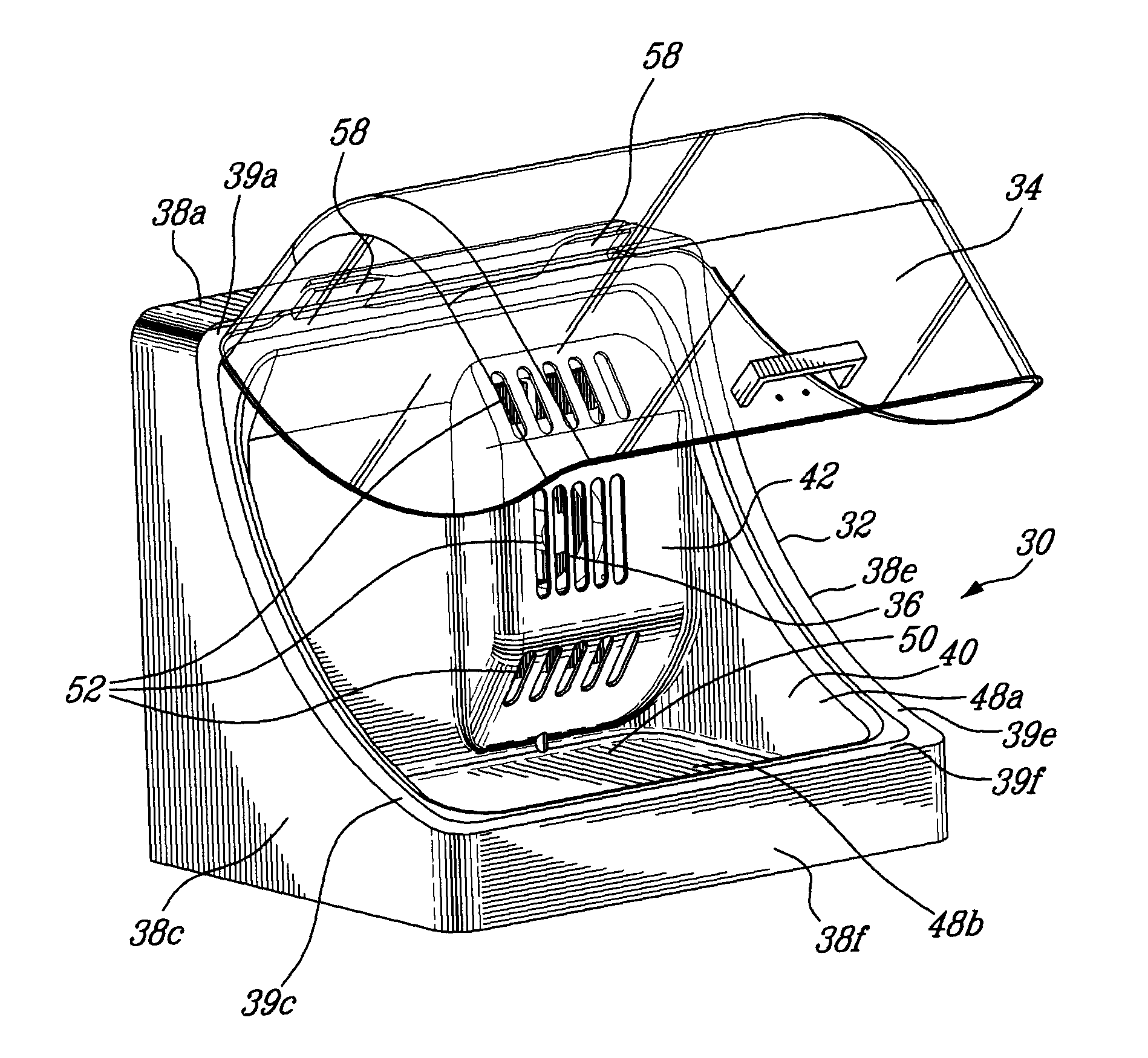

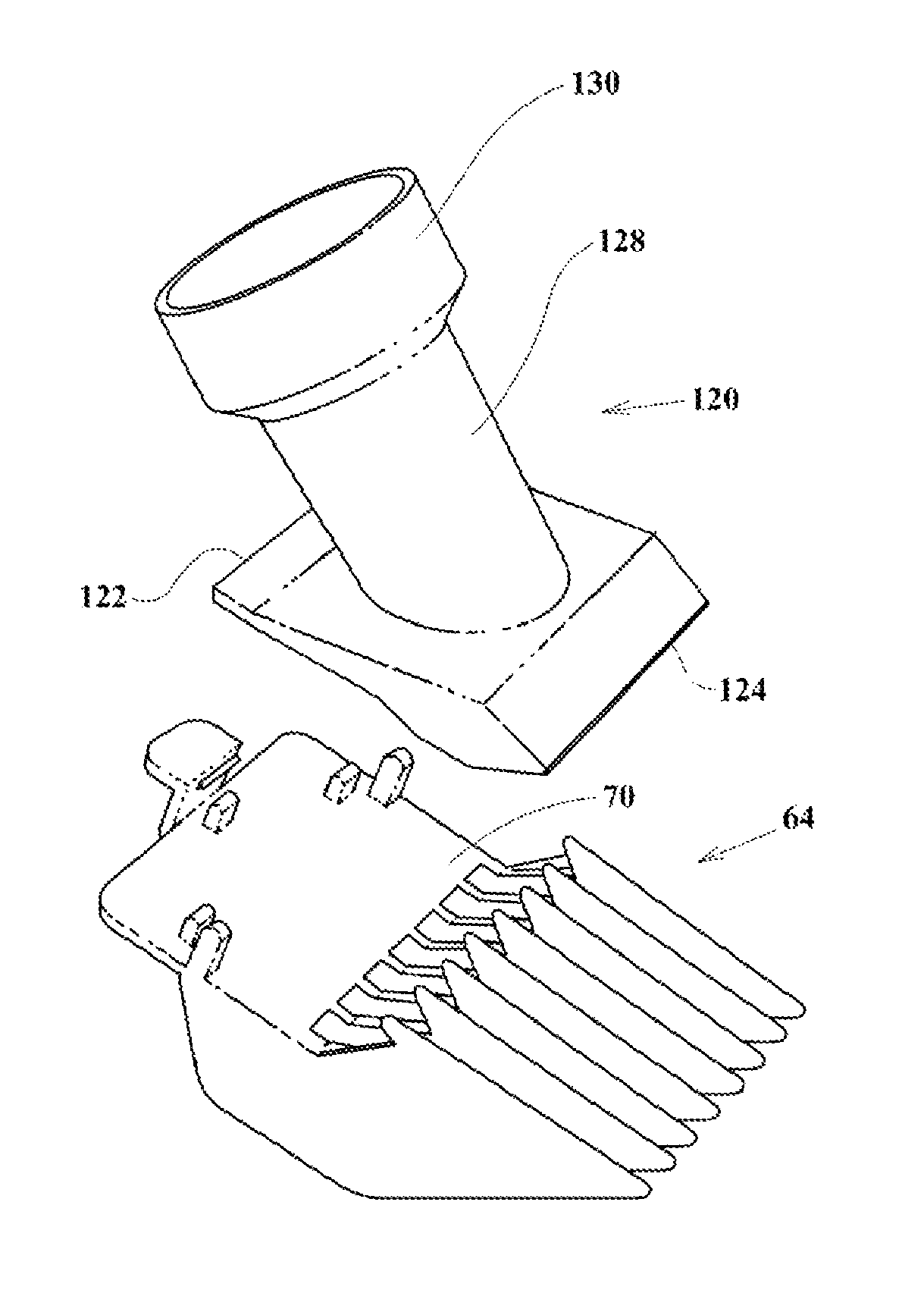

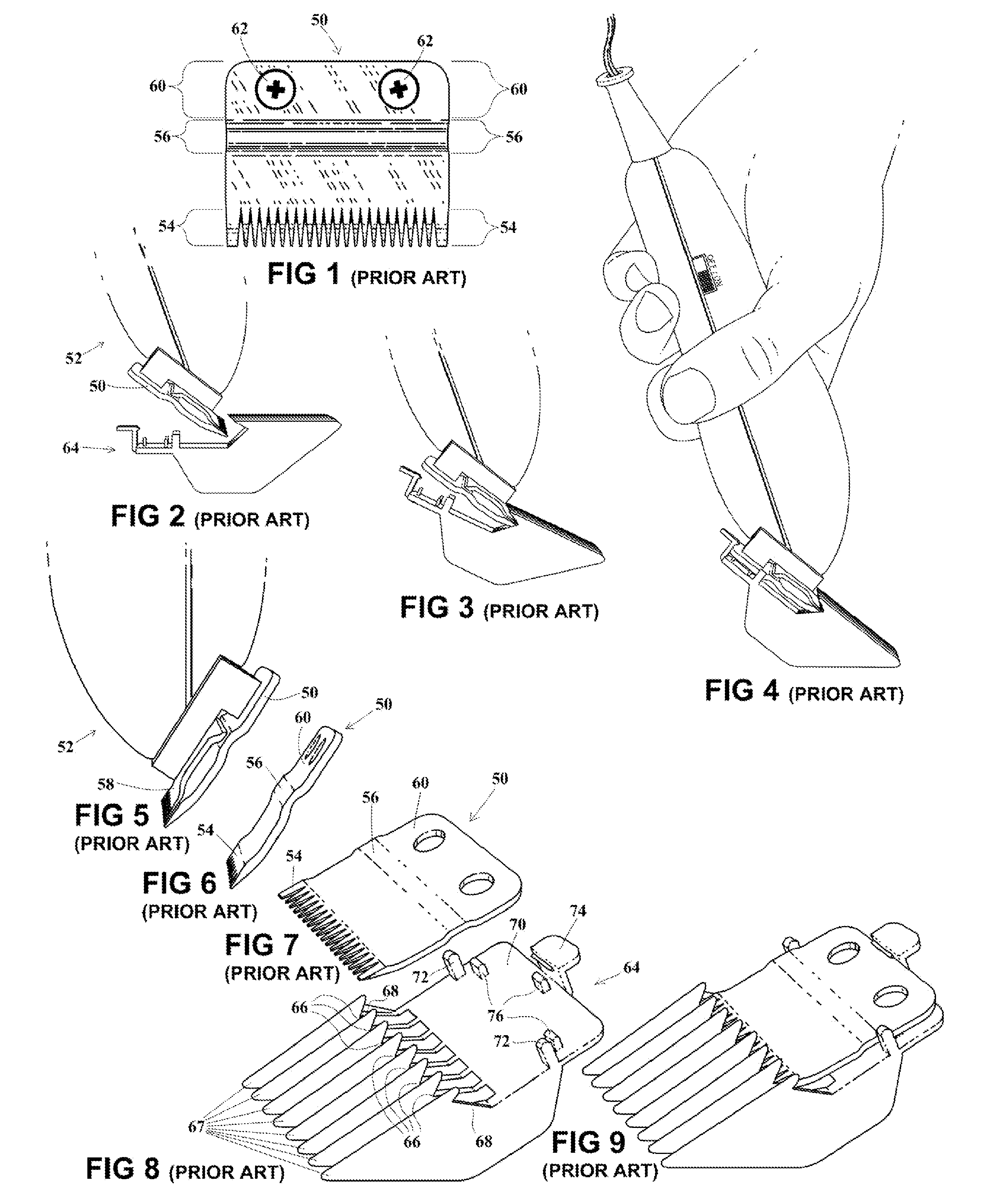

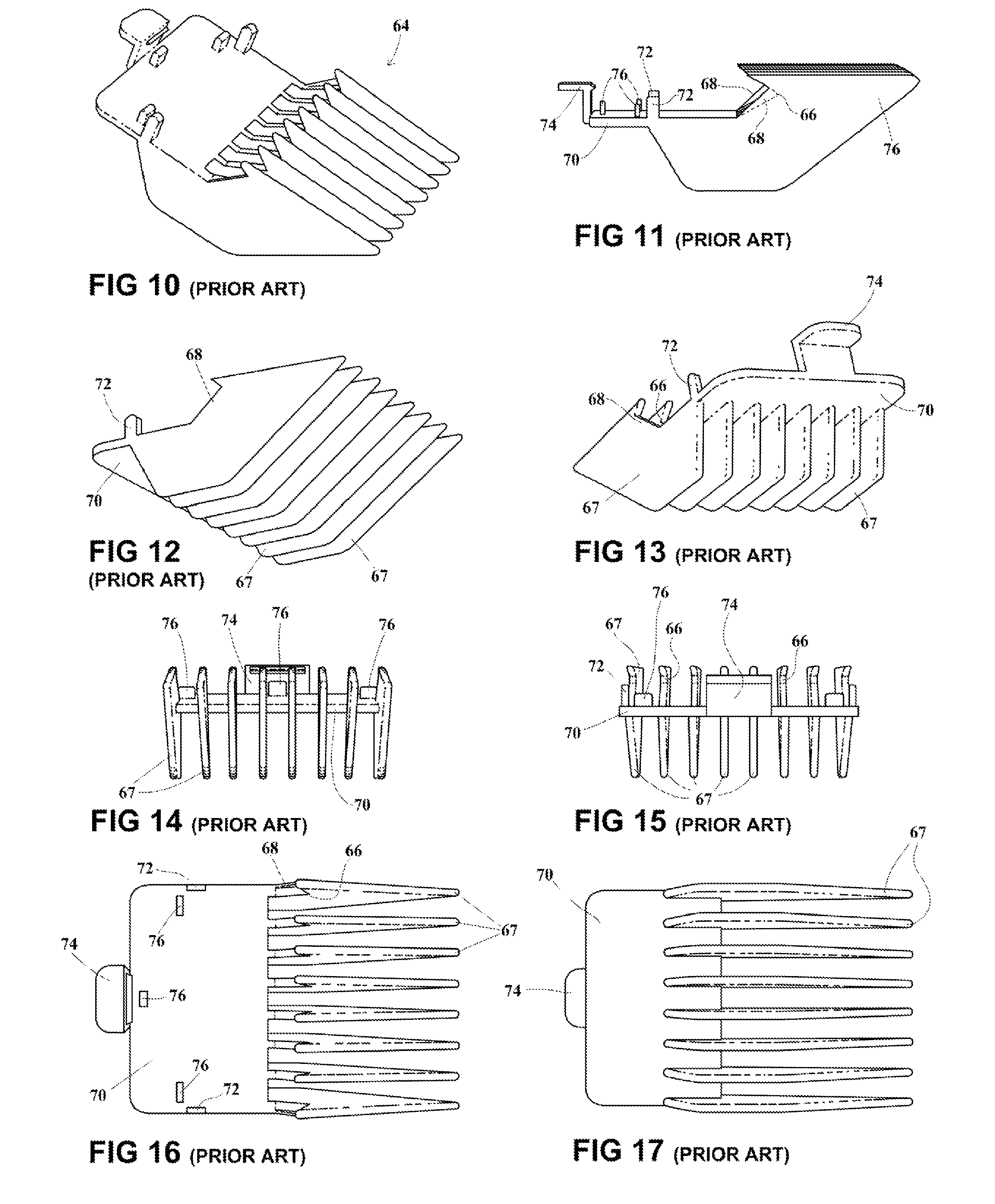

Attachment guide comb conduit

A dummy hair clipper head, or dummy blade, which is a form conforming to those dimensions of a hair clipper's stationary blade which are necessary for its compatibility with attachment guide combs, is employed in a conduit comb which comprises a form configured to allow air or liquid to pass through the form and between the teeth of the attachment guide comb, whereby an attachment guide comb can be employed in vacuuming, drying, washing and treating hair. The form can be connected in turn to a bottle, air hose, or faucet to allow for the transmission of air or liquid through the comb. The use of the form also makes possible a variety of new uses for attachment guide combs including a scissor comb, razor comb, and comb organizer.

Owner:MICHEL MATTHEW JUSTIN

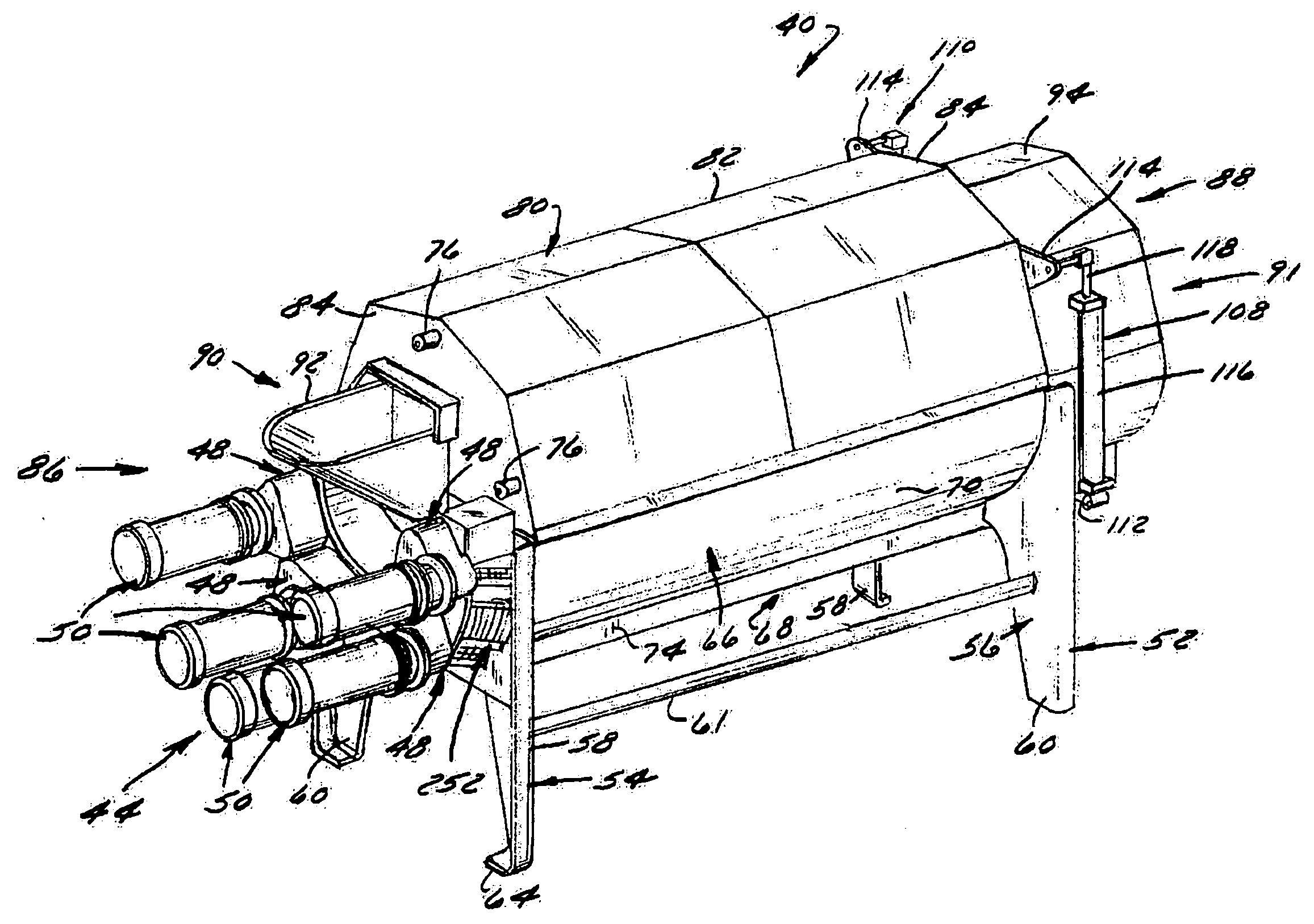

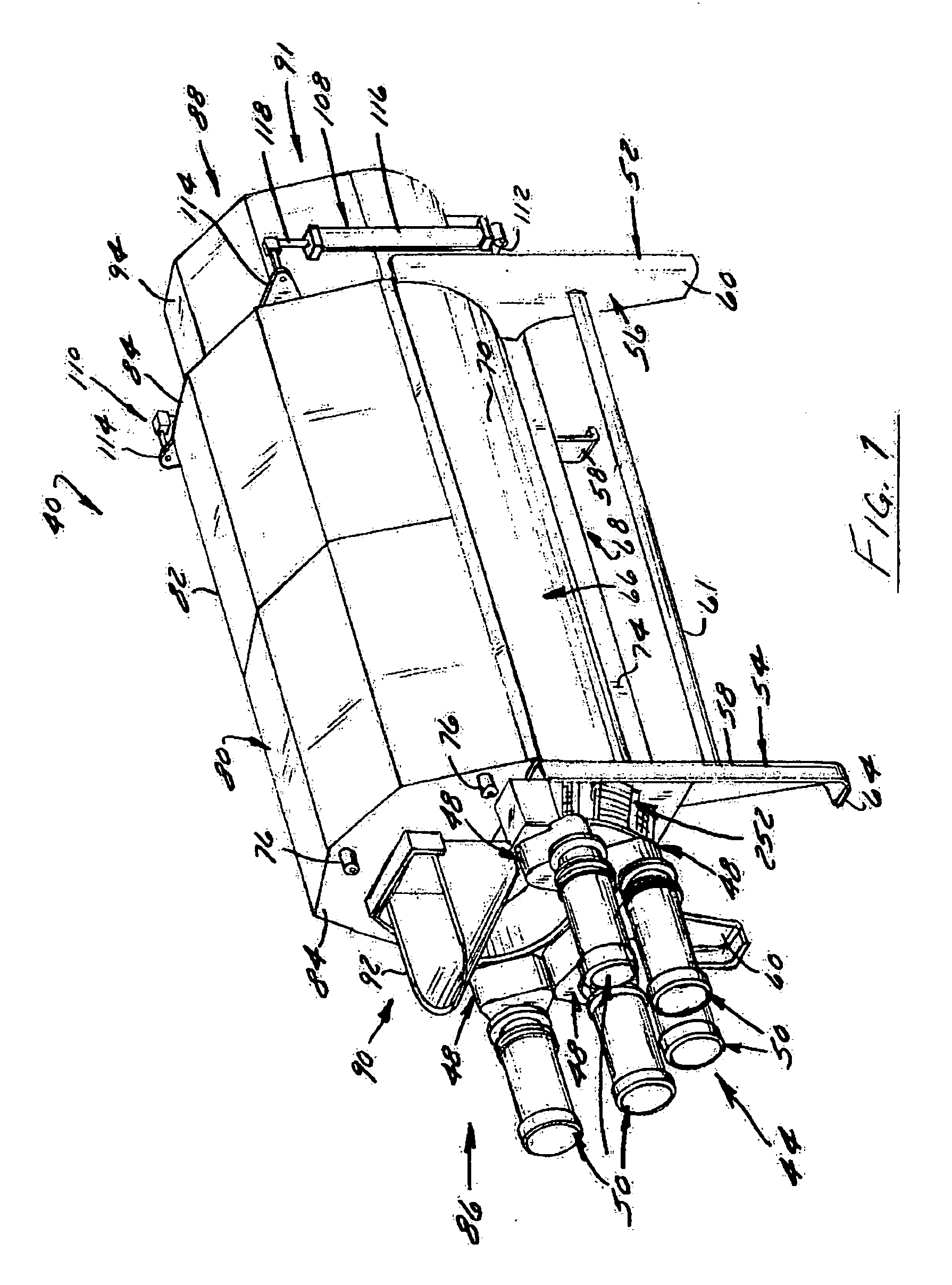

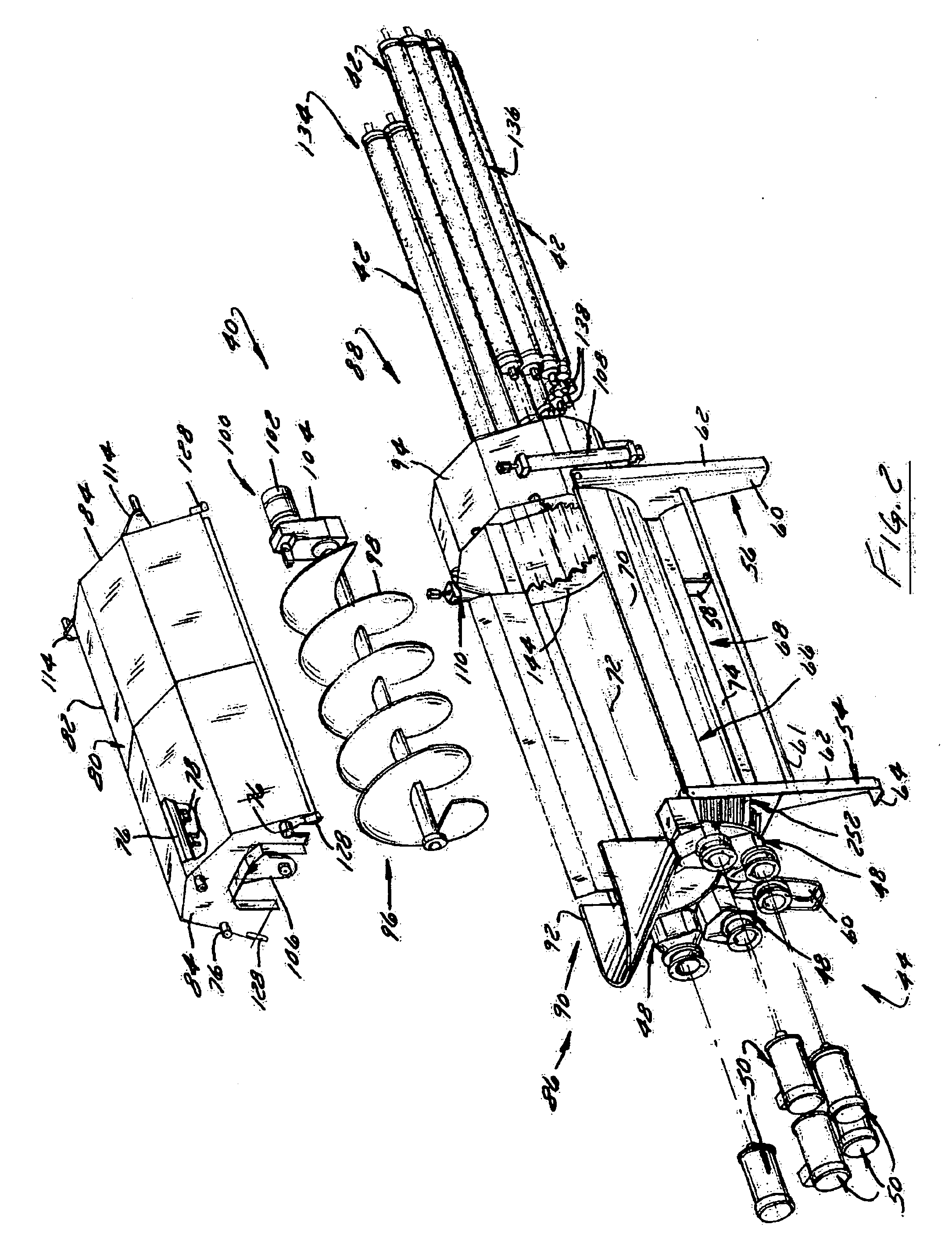

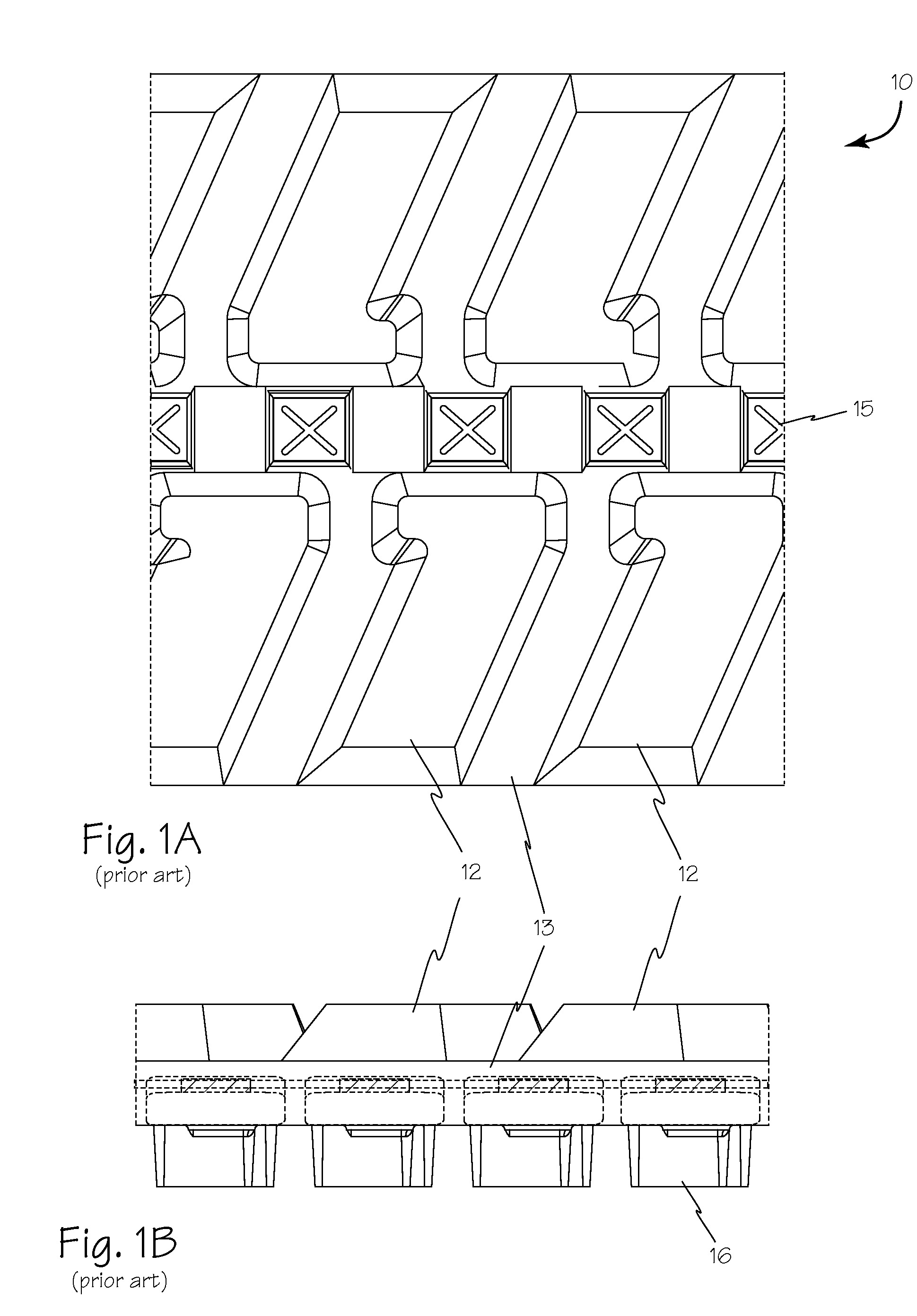

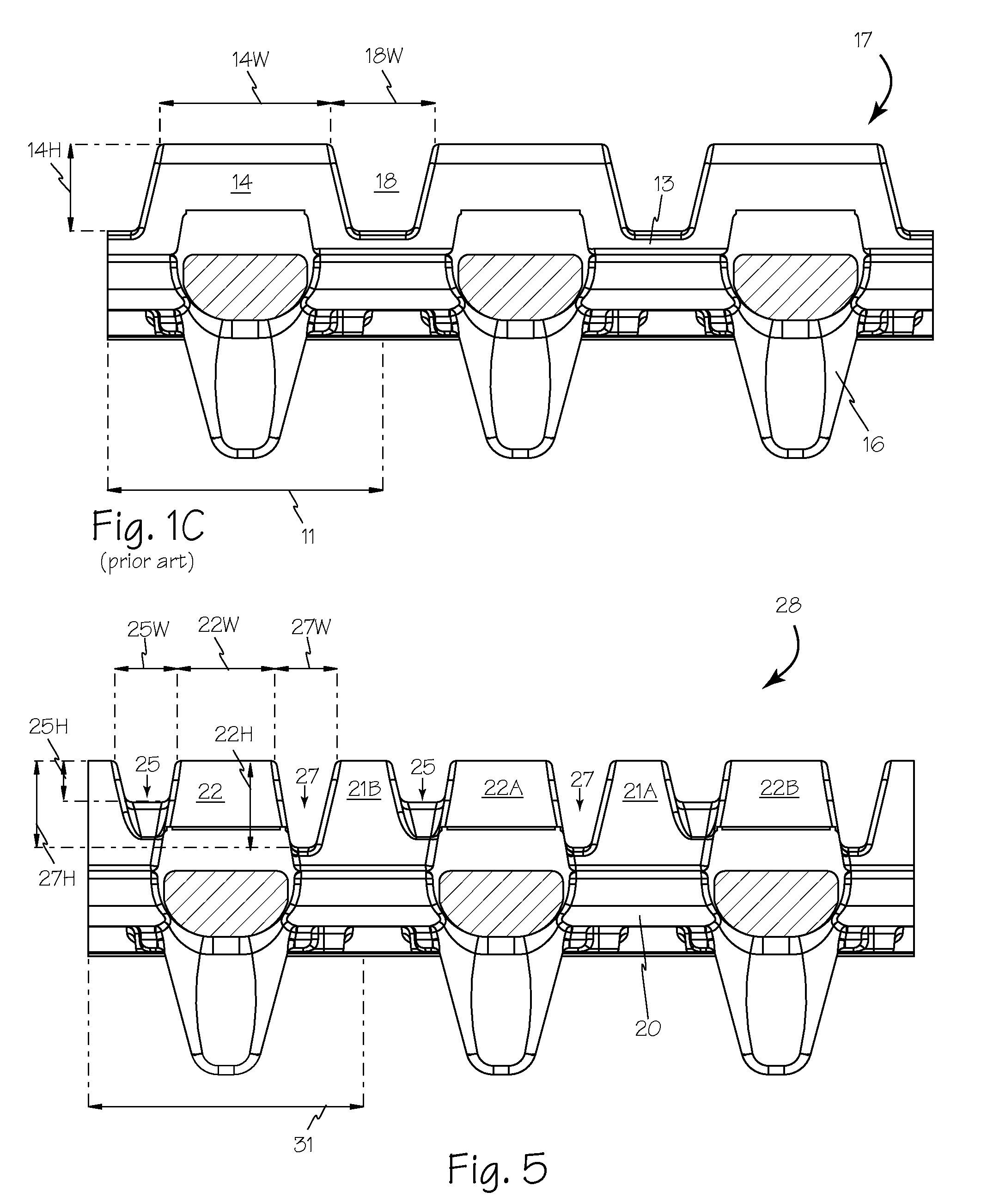

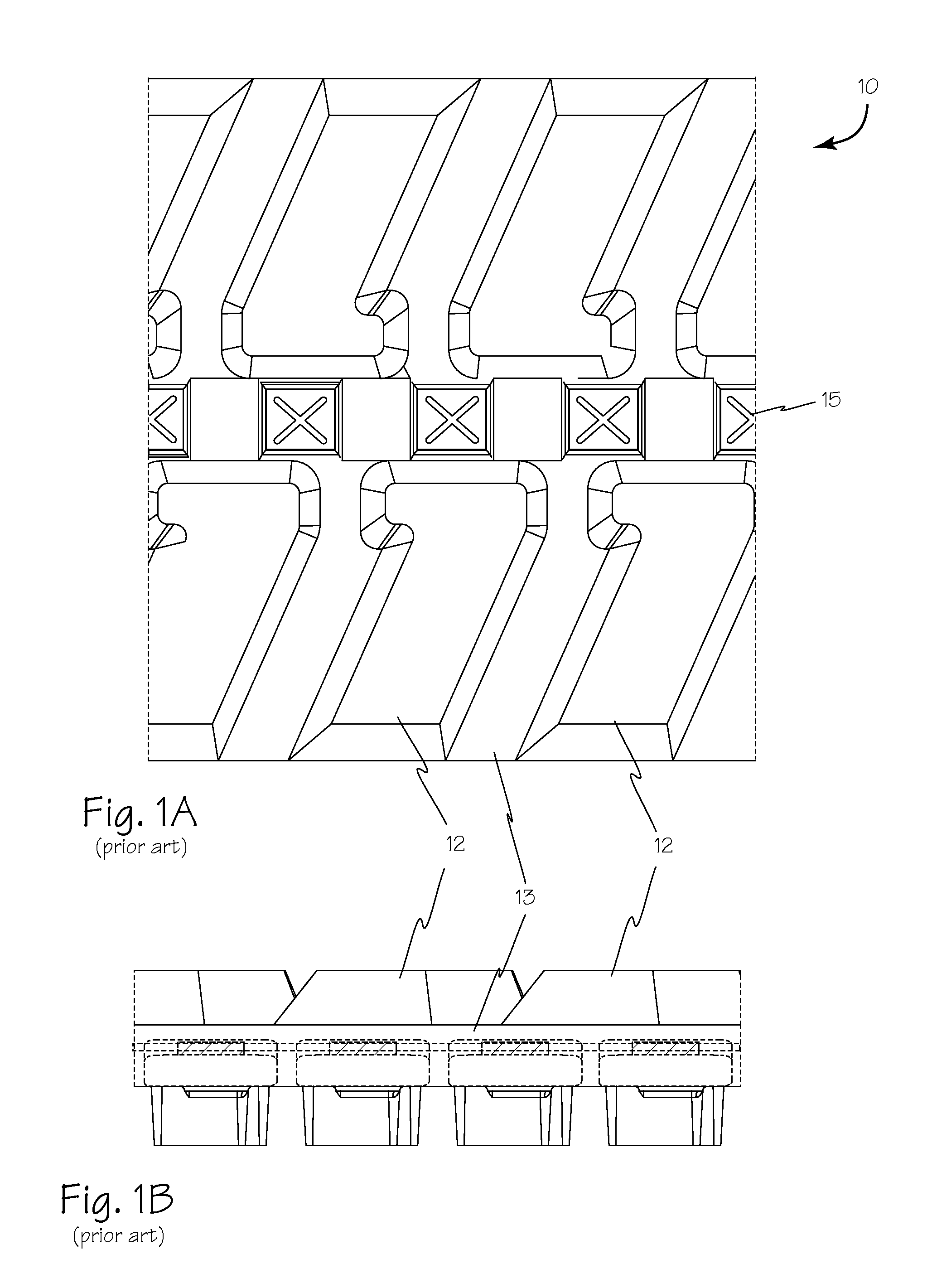

High speed food product peeling or cleaning machine and method

InactiveUS20050082144A1Increase speedReduce maintenancePackagingVegetable peelingCouplingEngineering

An apparatus for peeling or cleaning food product that includes a plurality of rollers each coupled to a drive box, preferably a gear box, by a vibration dampening coupling that preferably is disposed exteriorly of one end of the roller and part of the frame of the machine that supports the roller. A drive that preferably is an electric motor is attached to the drive box such that a plurality of rollers is driven thereby. Such an arrangement enables rollers to be driven at speeds of 600 RPM and preferably 750 RPM or faster, which decreases processing time and increases capacity and throughput. In a method of operation, each roller is driven at a speed of 750 RPM or greater to peel or clean food product before being discharged from the machine. In one preferred method, the rollers are driven at speeds between 900 and 1200 RPM.

Owner:LYCO MFG

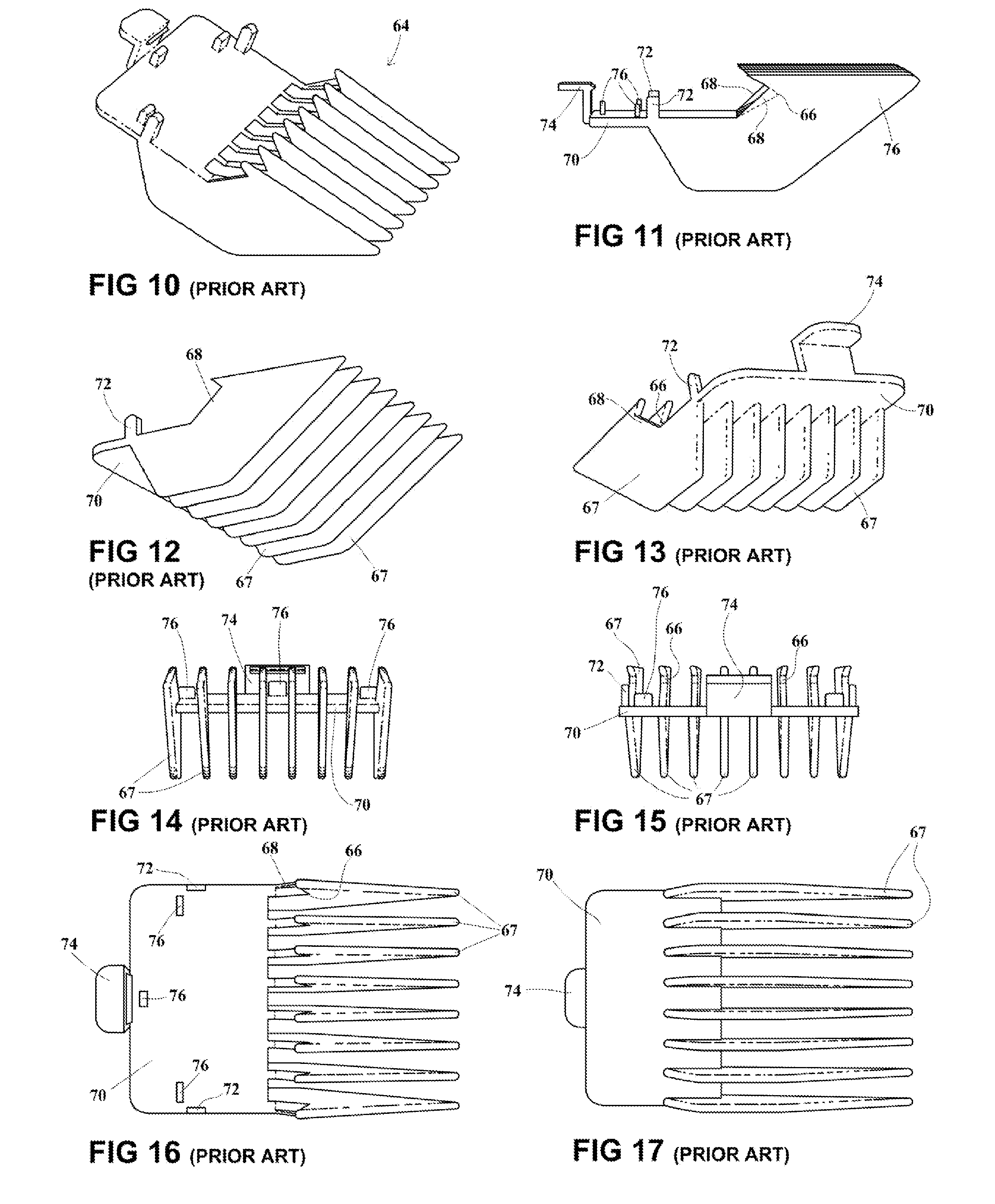

Dummy hair clipper head for the attachment of guide combs

A dummy hair clipper head which conforms to those dimensions of the head of a hair clipper (its stationary blade) which are necessary for its compatibility with attachment guide combs. This dummy hair clipper head provides a base onto which the attachment guide combs can be attached, and by which they can be held, allowing them to be organized within a kit among other uses. The dummy hair clipper head can be connected to a tool to allow the combs to be used with that tool, such as a pair of scissors to create a scissor comb, or including a conduit through the dummy hair clipper head to be used as a vacuum comb, a dryer comb, and a liquid dispensing comb.

Owner:MICHEL MATTHEW JUSTIN

Axial fan

ActiveUS7259486B2Reduce tiltLifespan can be assuredMagnetic circuit rotating partsPump componentsBall bearingEngineering

In an axial fan, a case (40) accommodating the fan motor stator (50) is anchored into a bearing retainer (10), in which ball bearings (20, 21) as a bearing unit are accommodated, along a bulge part (13) formed on the lower end portion thereof. The case (40) extends heading axially downward, wherein there is no diametrical overlap between the ball bearings (20, 21) and the stator (50). Since only the bulge part (13) of the bearing retainer (10) is fixed to the case (40), heat arising from the stator (50) is thermally conveyed via the case (40) only to the bulge part (13). The fact that the thermal conveyance zone is minimal enables unrestrained curtailment of heat transmitted to the ball bearings (20, 21). As a result the axial fan can be designed for prolonged bearing lifespan.

Owner:NIDEC CORP

Dummy hair clipper head incorporated for the attachment of guide combs

ActiveUS20080072437A1Lack complexitySimple and inexpensive to manufactureHair combsMetal working apparatusEngineeringKnife blades

Herein a dummy hair clipper head is a rigid form conforming to those dimensions of the head of a hair clipper (typically its stationary blade) which are necessary for its compatibility with attachment guide combs and optionally including a novel method of dual engagement with the V shaped groove of the guide comb. Said rigid form being incorporated into an object to allow the attachment of guide combs to that object. The diverse embodiments of this device include a comb organizer, a scissor comb, a razor comb, a vacuum comb, a dryer comb, and a liquid dispensing comb.

Owner:MICHEL MATTHEW JUSTIN

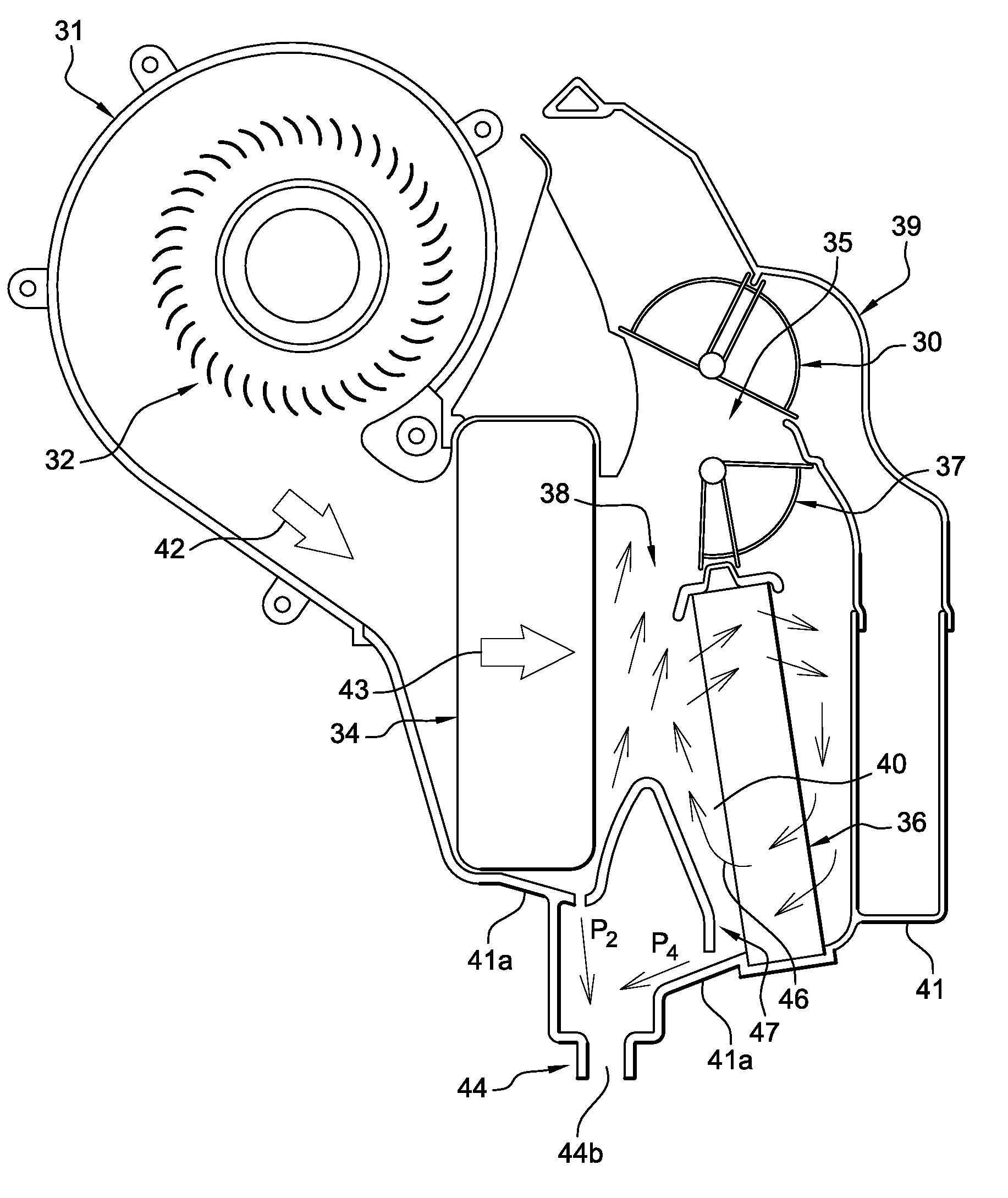

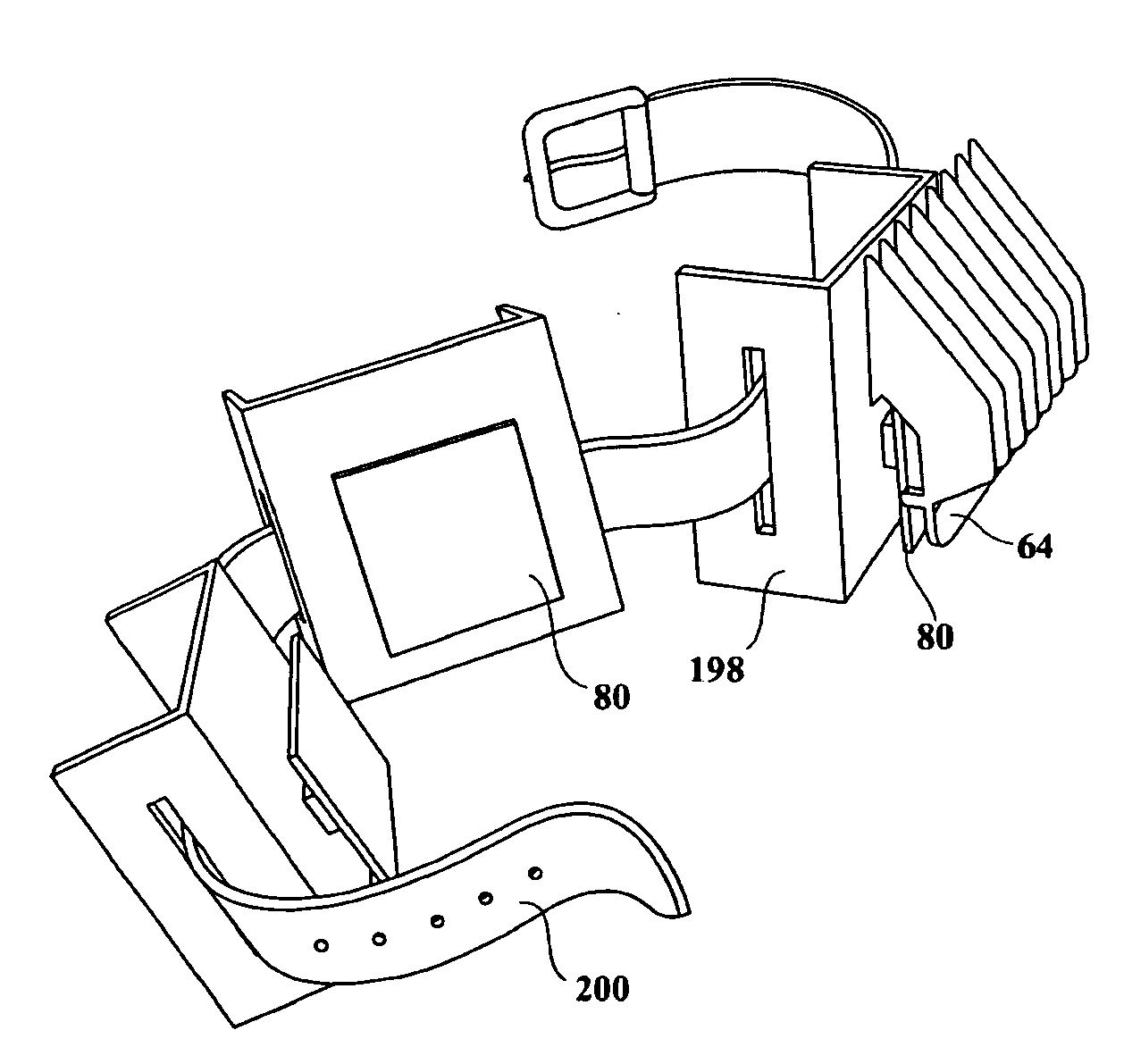

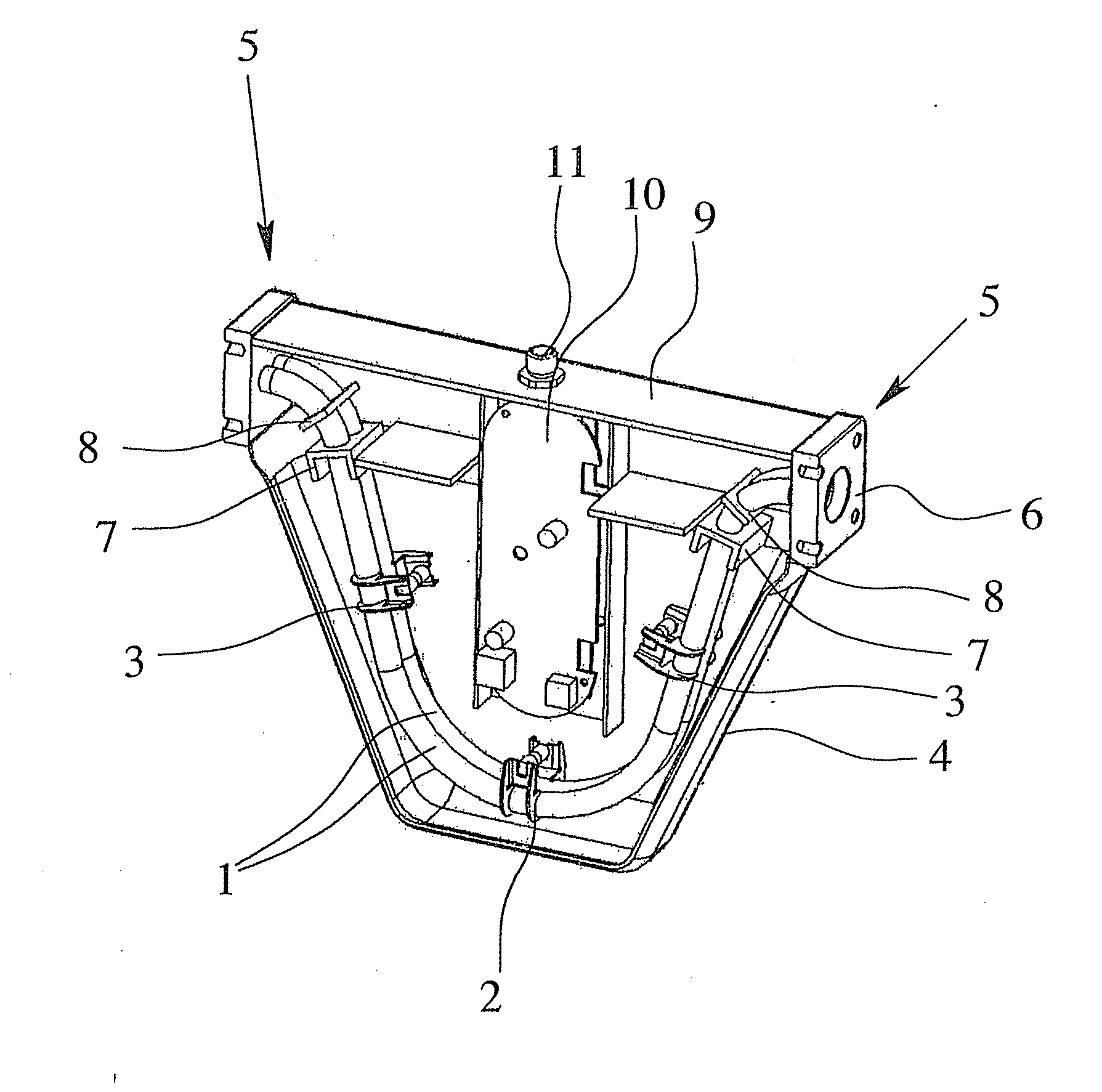

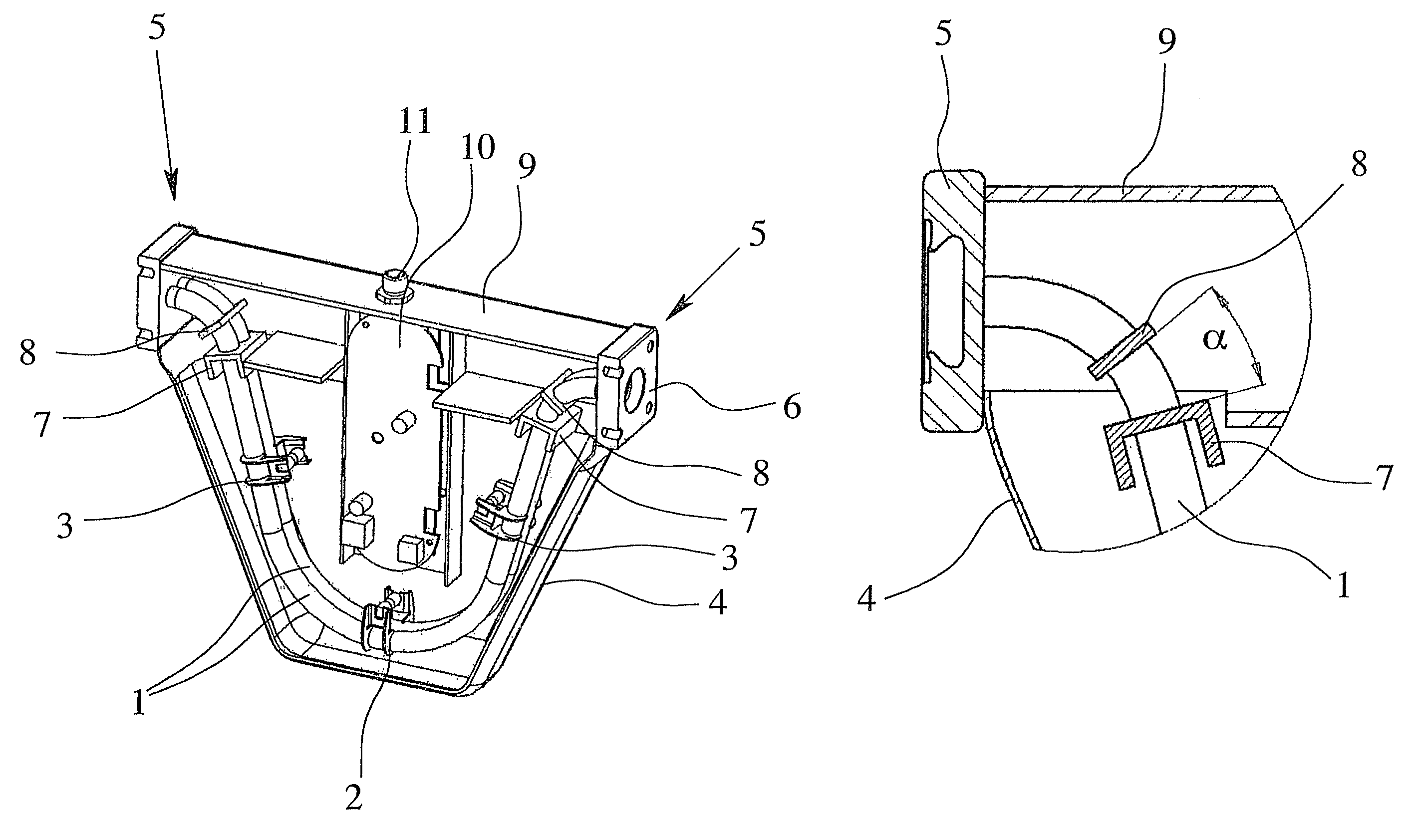

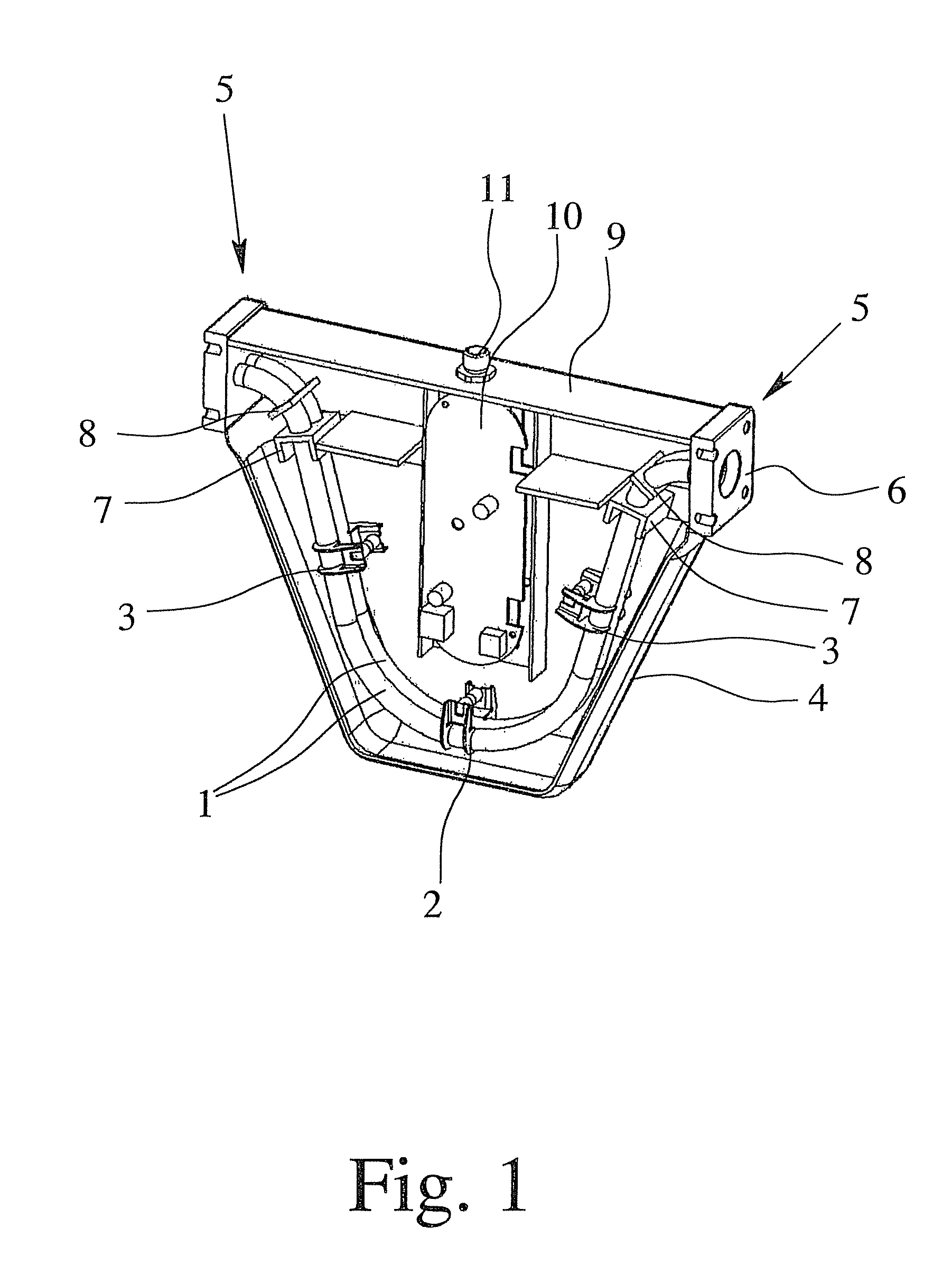

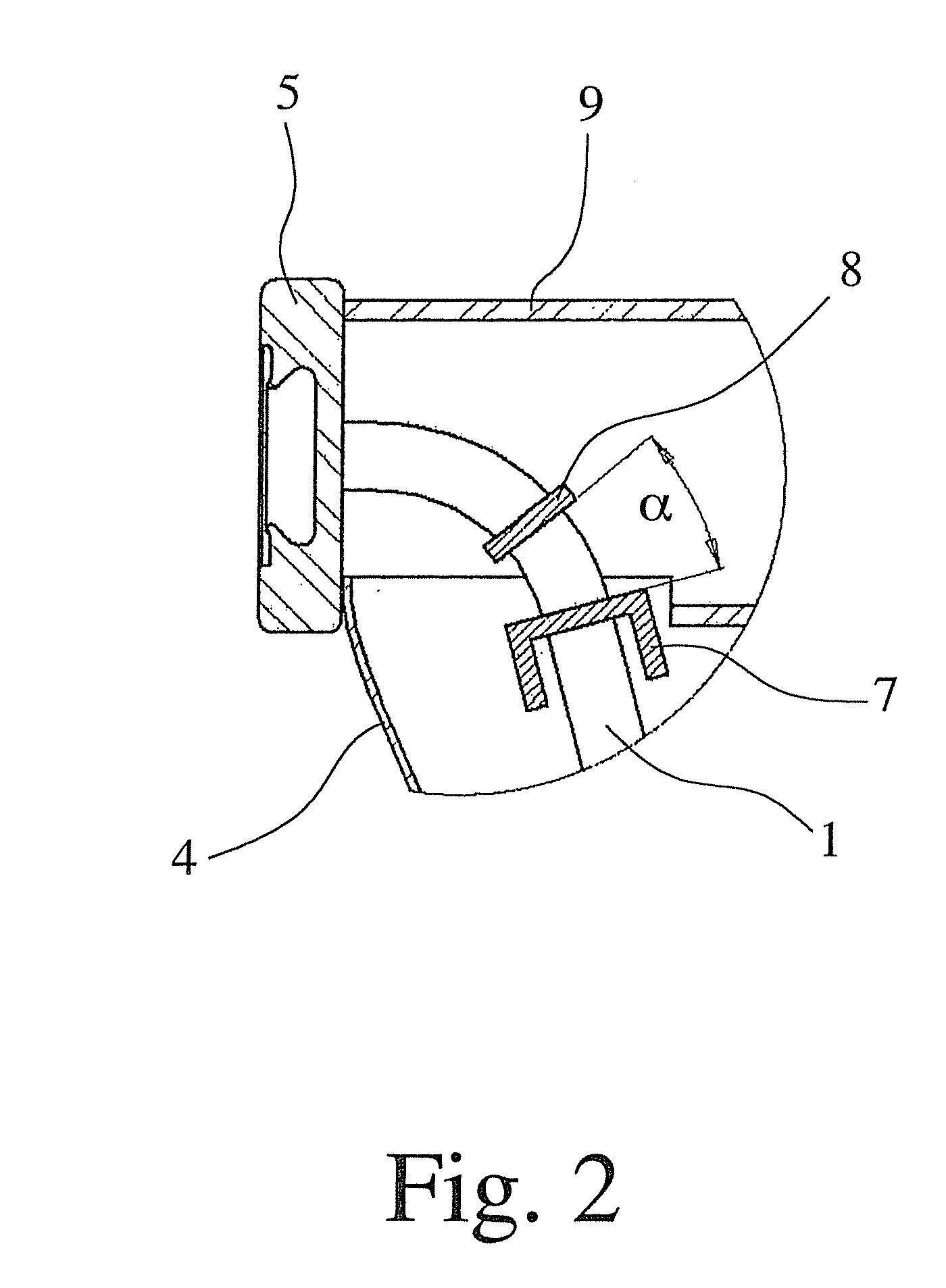

HVAC with detached deflector

ActiveUS7407001B2Reduce in quantityReduced space requirementsAir-treating devicesRailway heating/coolingWaste managementAirflow

A structure to provide air flow an mixture in an HVAC unit utilizing a separate piece air deflector located within the lower housing of the HVAC unit and ribs to direct airflow, the separate piece air deflector configured to cause air deflection and airflow towards the distribution area of the unit.

Owner:VALEO CLIMATE CONTROL

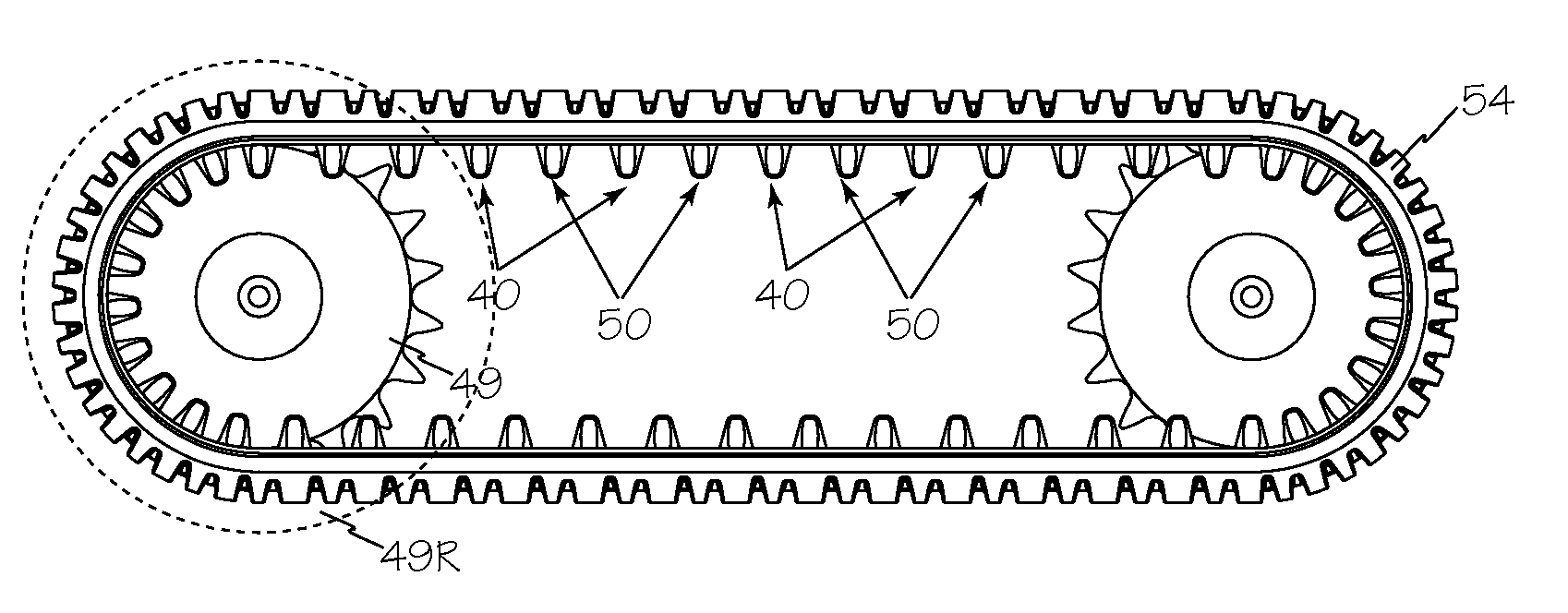

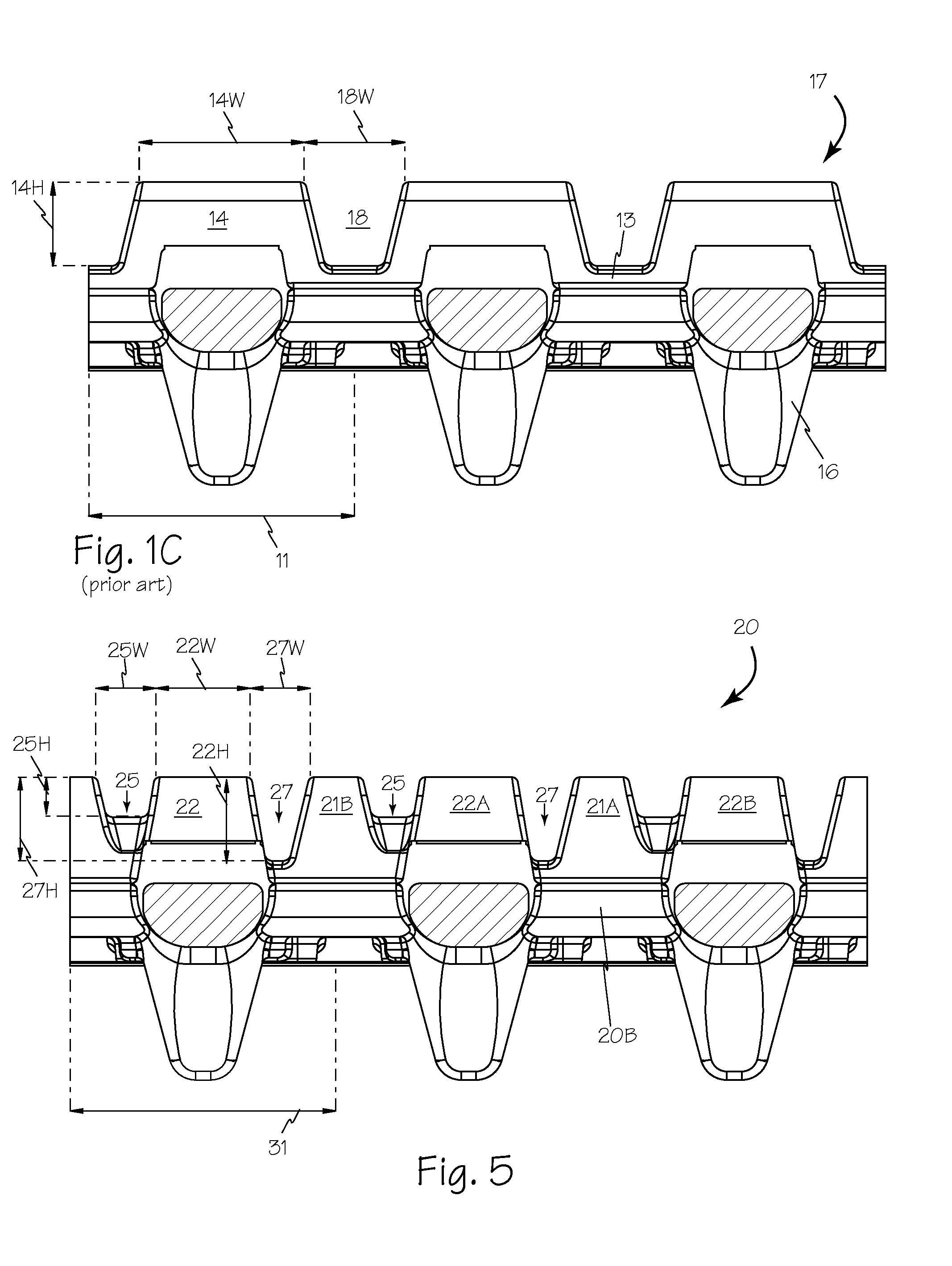

Offset Track

An offset track forms a pattern perpendicular to the centerline of the track which enables tracks to be formed with even or odd number of metal inserts and thus accommodate virtually any tracked vehicle. The offset track uses variations in body thickness and lug width to provide a high performance offset track with improved ride, minimum vibration and longer wear. Use of full size and mini-inserts in a single track minimizes the weight and further enhances the performance of an offset track.

Owner:MCLAREN GRP HLDG PTE LTD

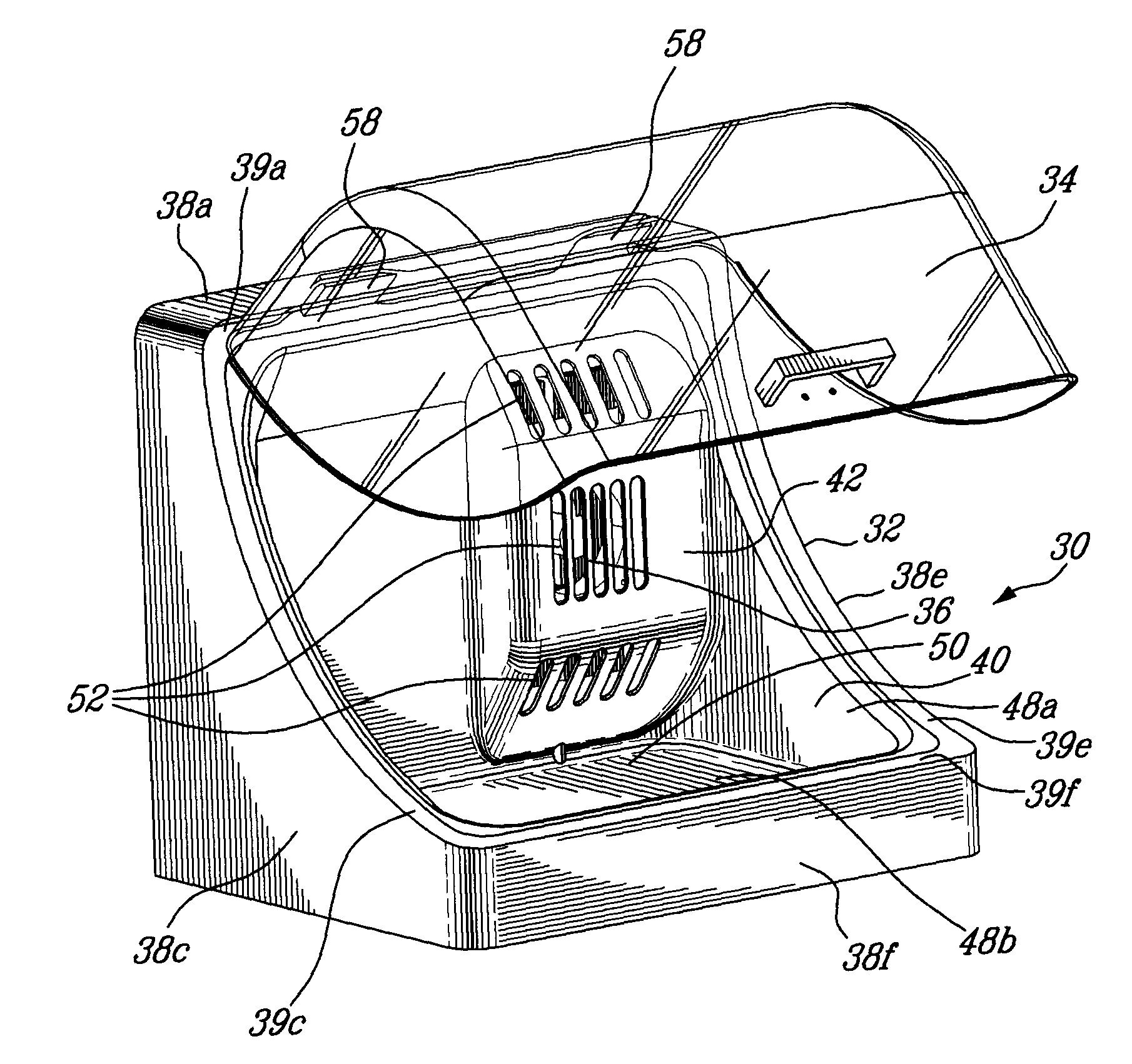

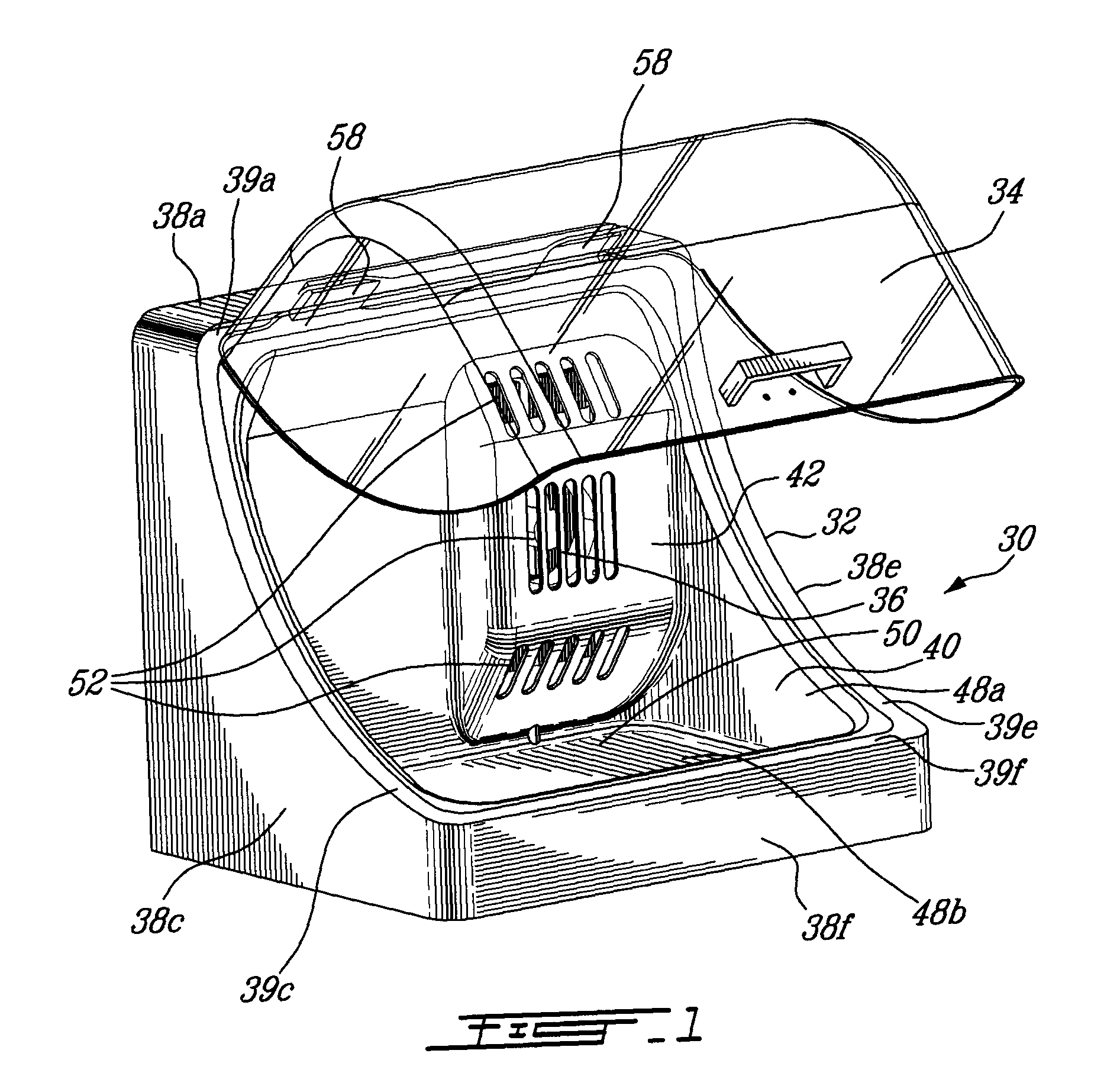

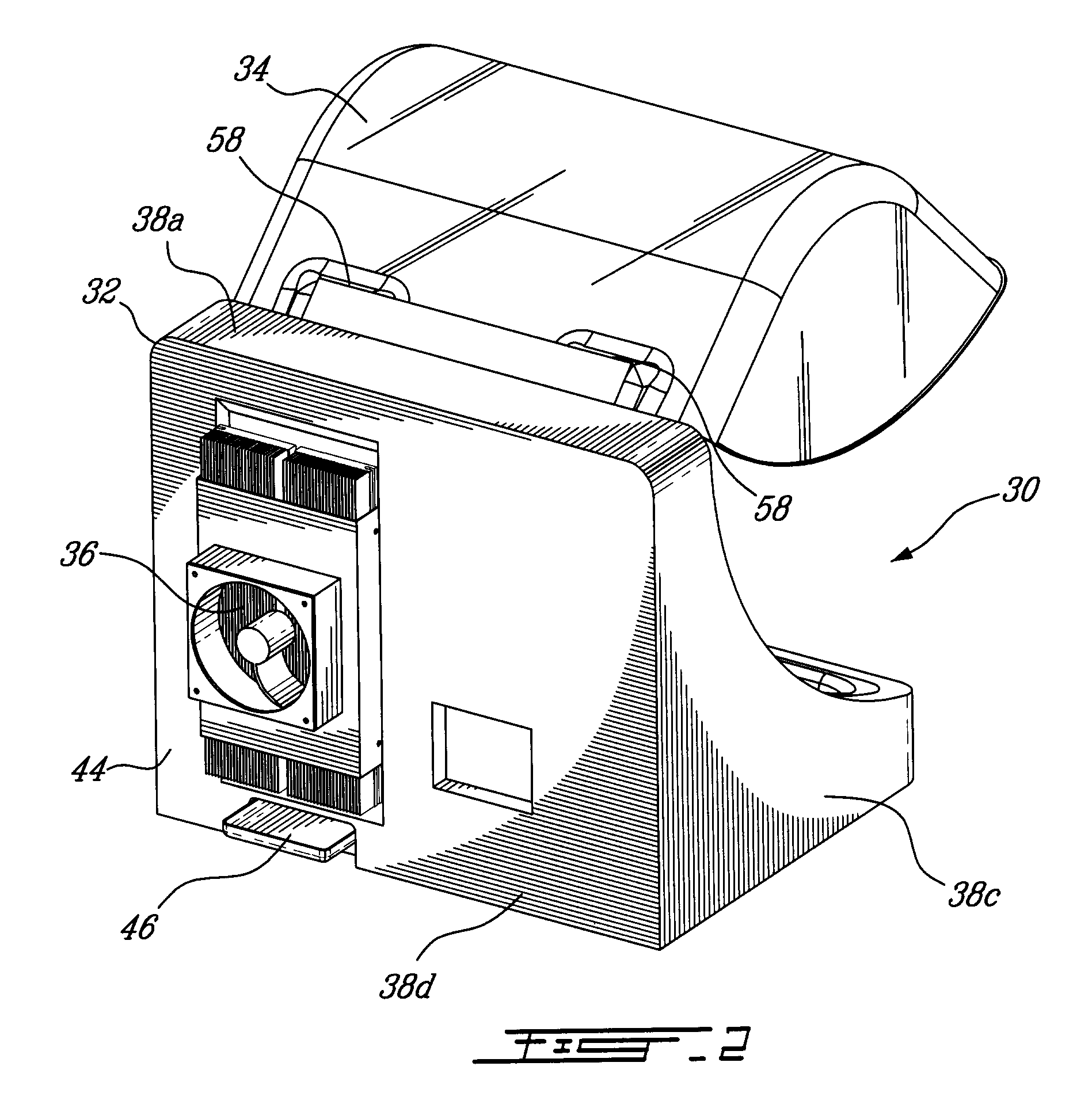

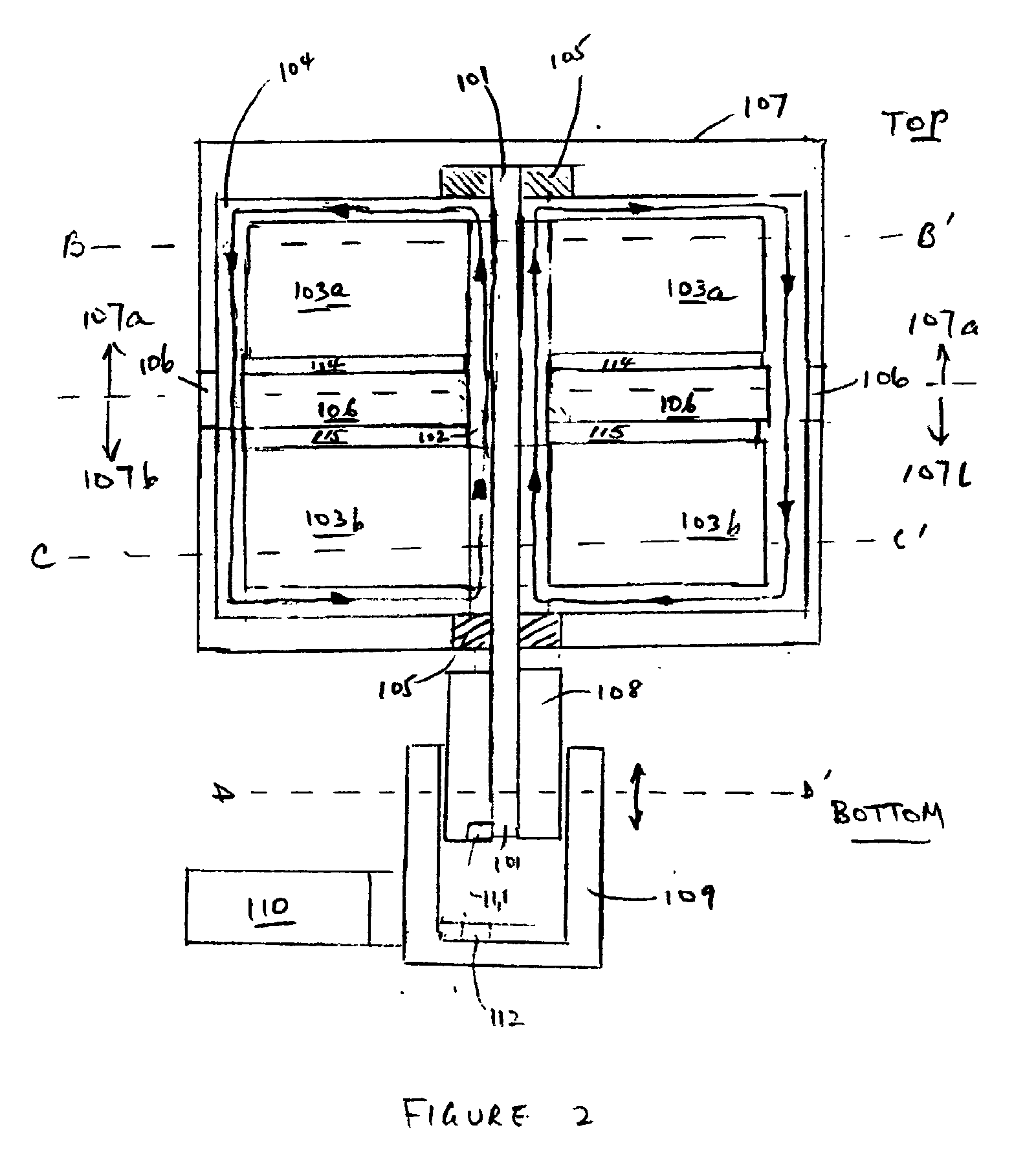

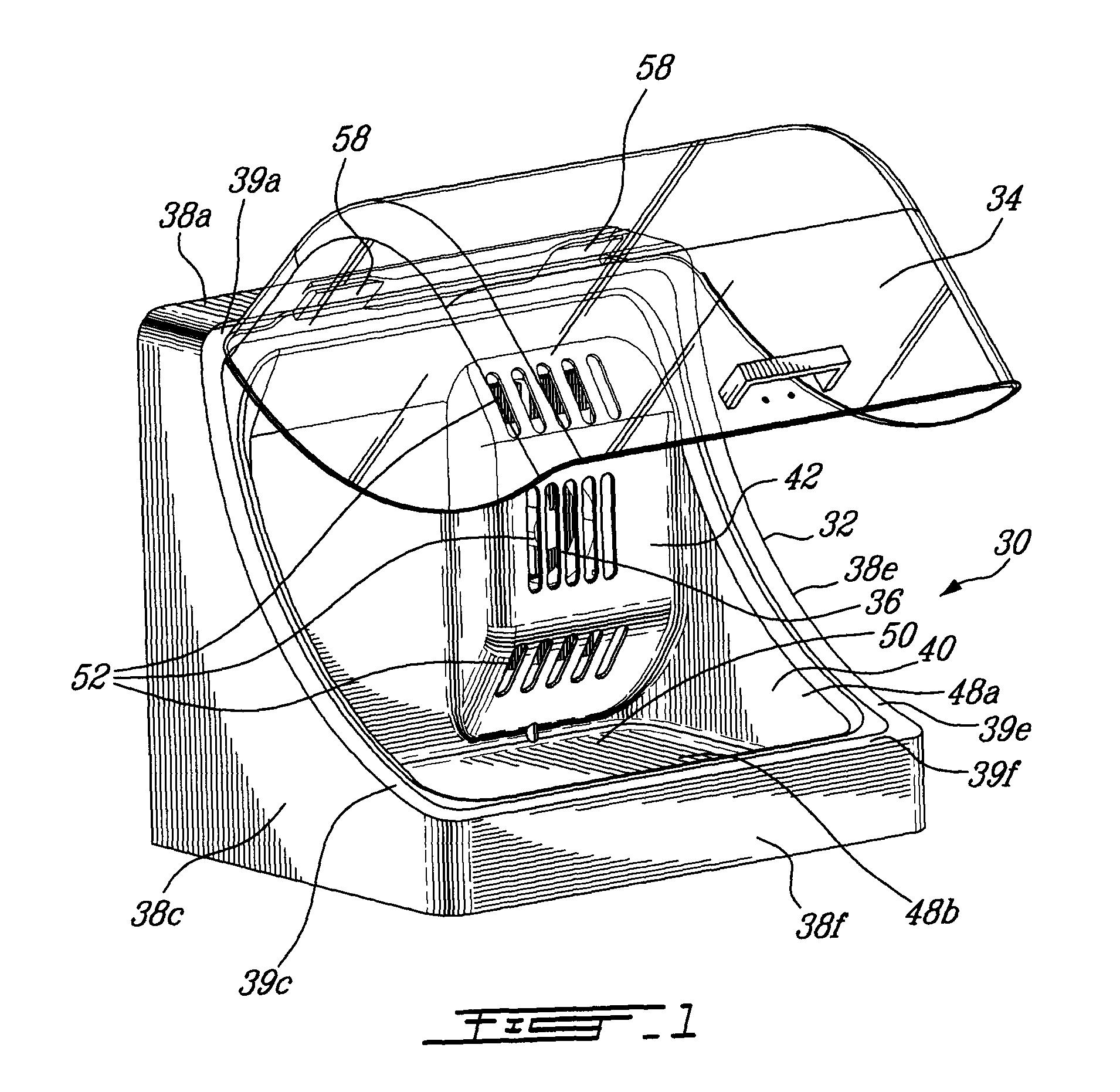

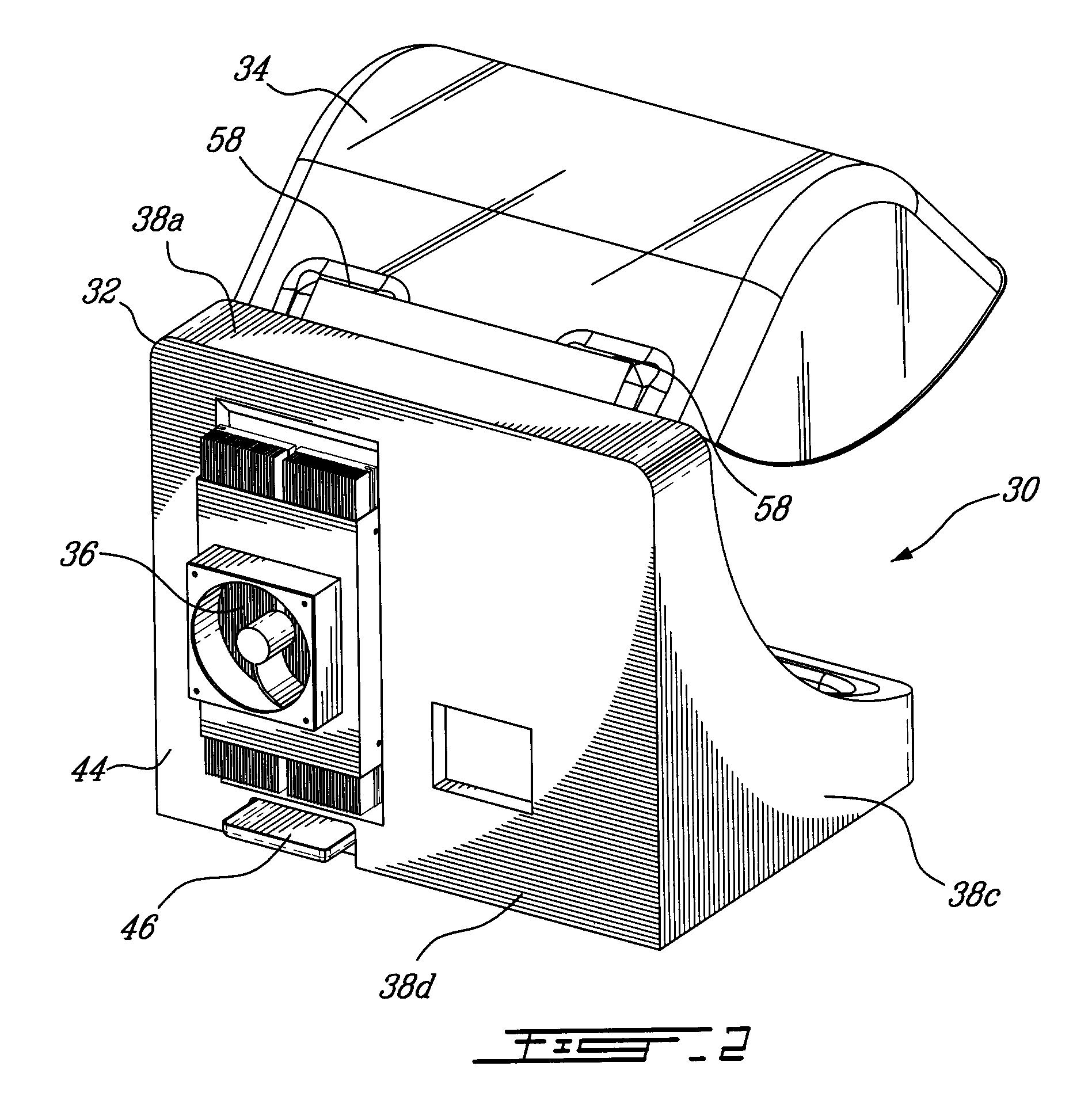

Portable temperature-controlled container

InactiveUS20090145138A1Easy to storeMinimal noiseShow cabinetsMachines using electric/magnetic effectsCold sideTemperature control

The present invention generally relates to containers and more specifically, to a portable temperature-controlled container. The temperature-controlled container is used for maintaining articles at a controlled temperature. The container includes a housing unit defining a storage chamber for receiving the articles, a cooling system mounted to the housing unit, wherein the cooling system includes a cold side assembly system in heat transfer communication with the interior of the chamber, a hot side assembly system in heat transfer communication with the outside of the storage chamber and a thermoelectric module supplied with an electrical power source.

Owner:SG PRODN

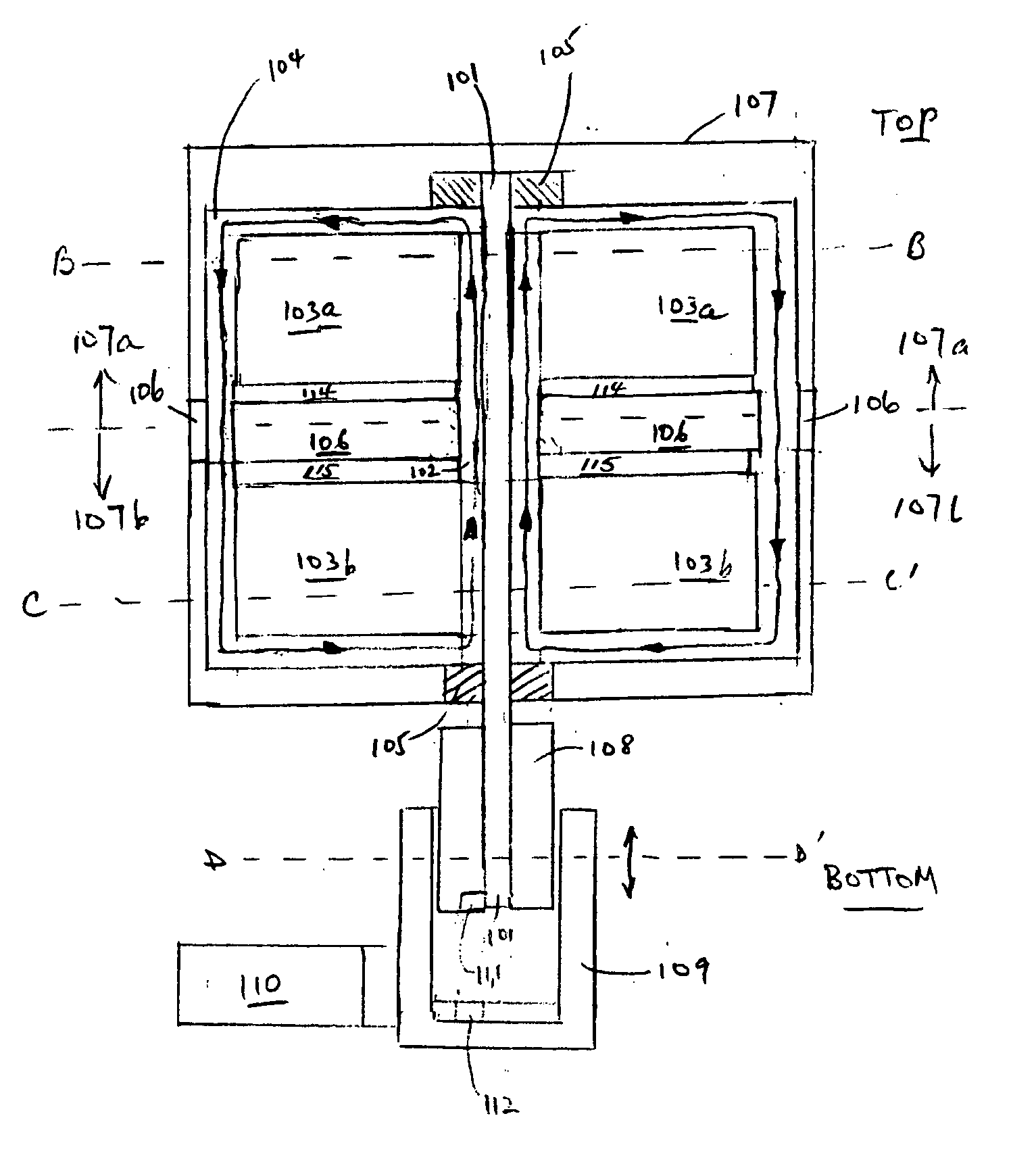

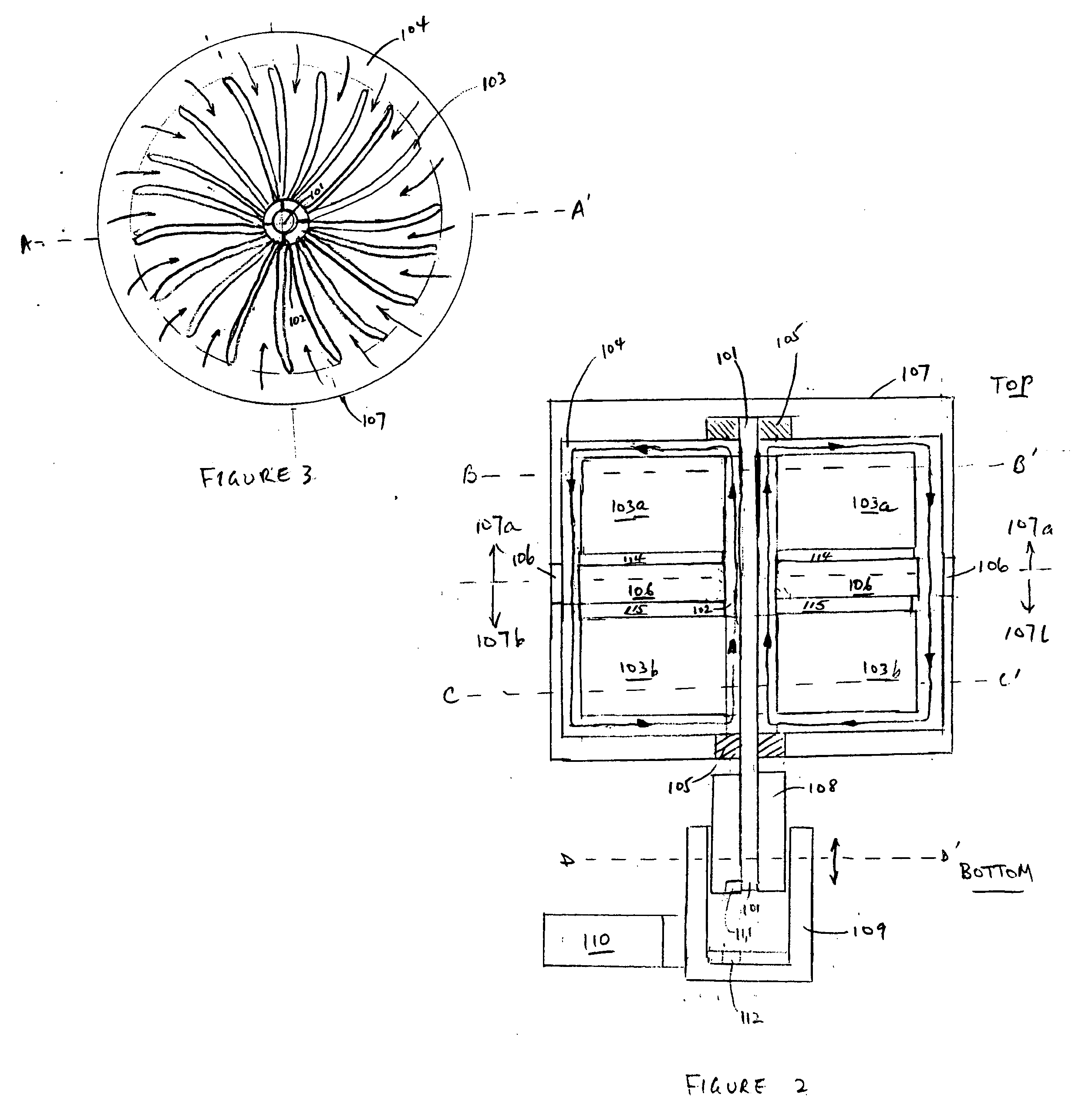

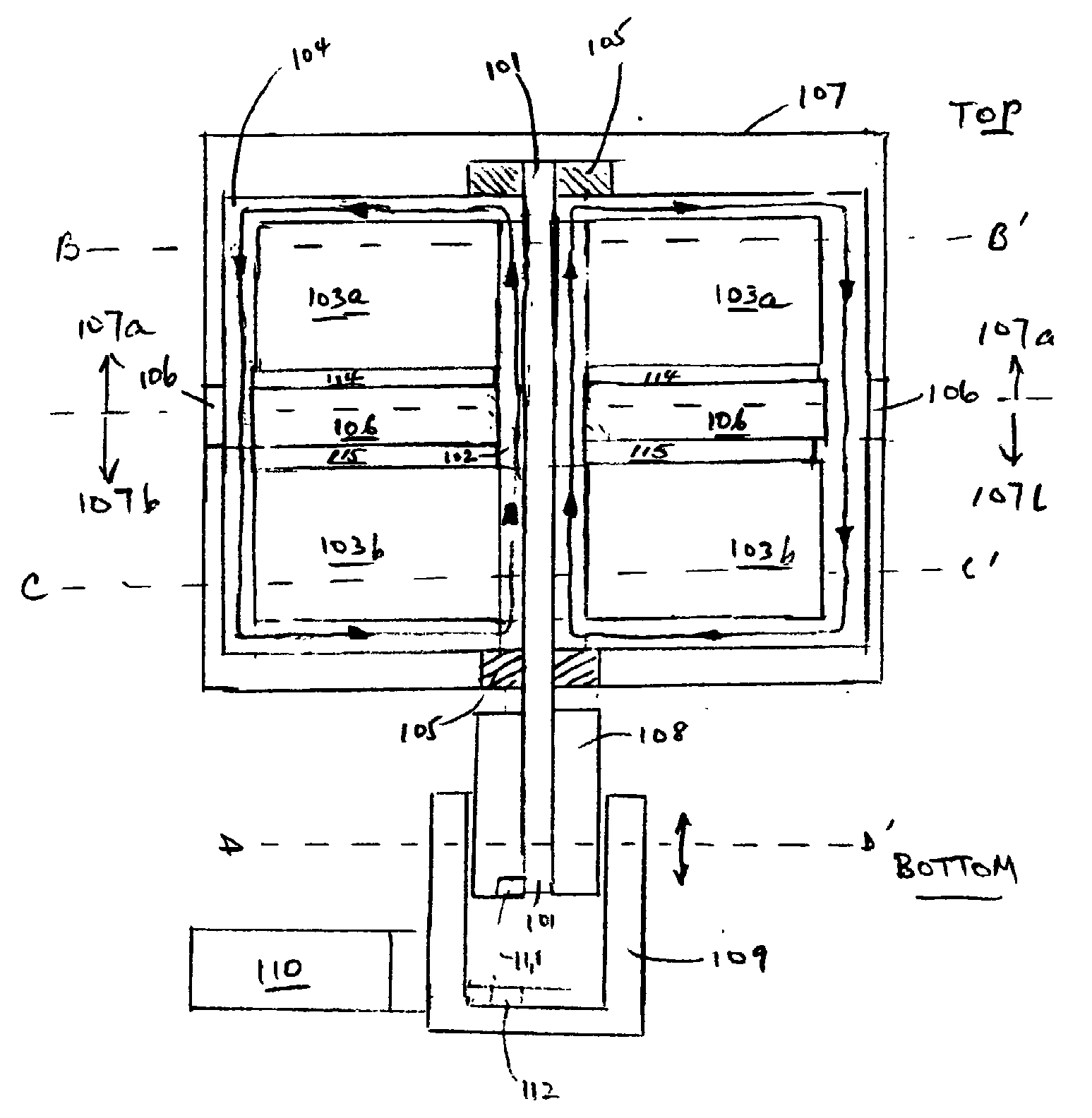

Method and system for electrical and mechanical power generation using Stirling engine principles

InactiveUS20060075752A1Improve efficiencyReduce power consumptionFrom solar energyGas turbine plantsEngineeringTurbine

A heat engine enclosed in a housing has two chambers maintained at different temperatures. The first chamber (“hot chamber”) receives heat energy from an external power source. The second chamber (“cold chamber”) is connected to the hot chamber by two conduits, such that a fluid (e.g., air, water, or any other gas or liquid) filling the two chambers can circulate between the two chambers. The expansion of the fluid in the hot chamber and the compression of the fluid in the cold chamber drive a turbine to provide a power output. The fluid may be pressurized to enhance efficiency. In one embodiment, the turbine propels an axle in a rotational motion to transmit the power output of the heat engine to an electrical generator outside of the heat engine's housing. In one embodiment, the turbine includes a first set of blades and a second set of blades located in the hot chamber and the cold chamber, respectively. The blades may each have a flat profile having two unequal surfaces, such that the turbine rotates in preferentially in one direction.

Owner:SILVER GUY +1

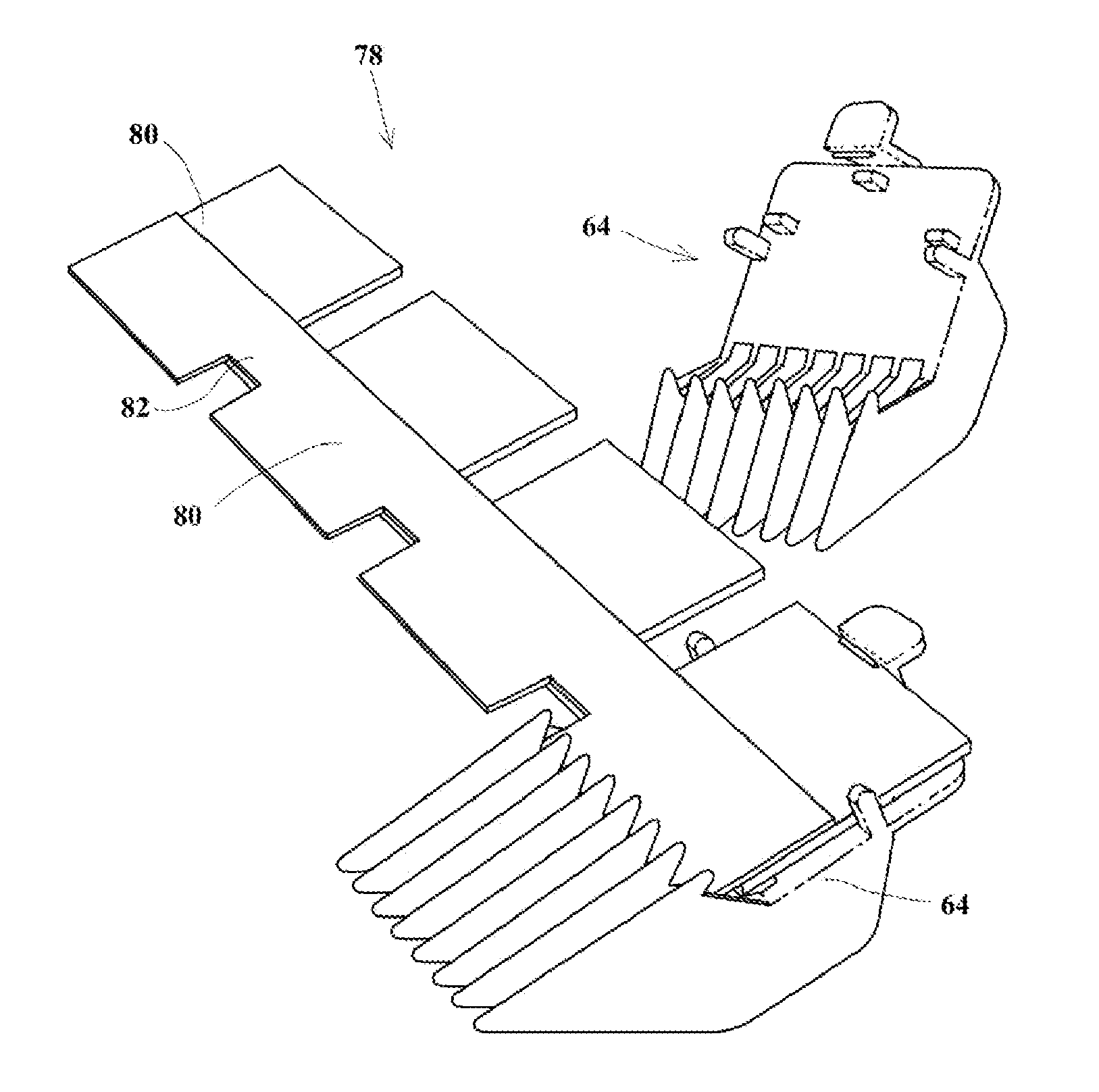

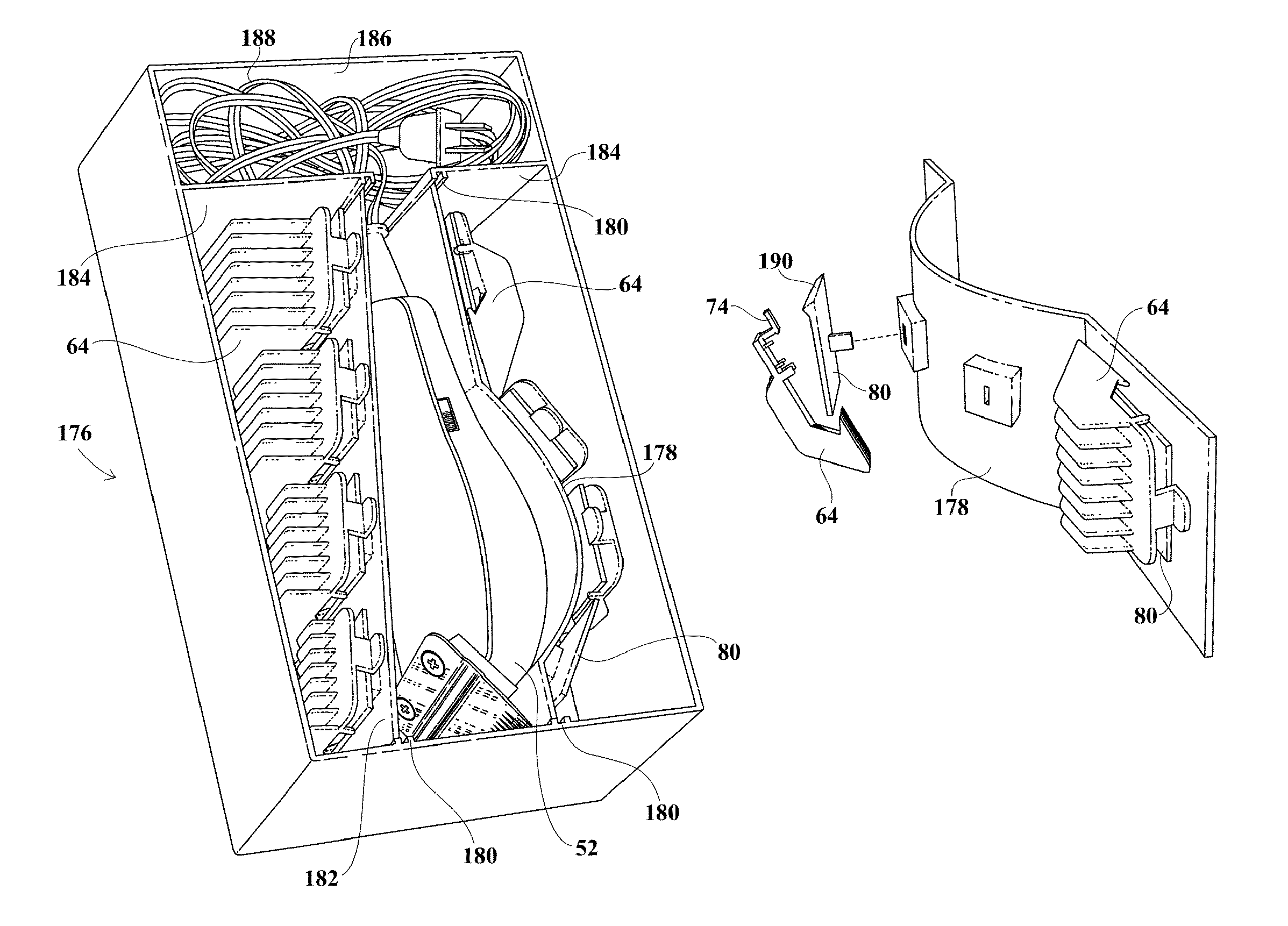

Attachment guide comb organizer

ActiveUS20090218252A1Lack complexitySimple and inexpensive to manufactureHair combsOther accessoriesEngineeringKnife blades

A dummy hair clipper head, or dummy blade, which is a form conforming to those dimensions of a hair clipper's stationary blade which are necessary for its compatibility with attachment guide combs, is employed in an attachment guide comb organizer which comprises a plurality of interconnected forms, whereby a plurality of attachment guide combs can be stored and organized. By interconnecting the forms with either a rigid, contoured or flexible means, with the options of placing them within a container and of making them releasable, the organization and storage of a set of attachment guide combs can be customized. For the purposes of storage the form can be flexible and have a reduced structure from that of the stationary blade. The use of the form also makes possible a variety of new uses for attachment guide combs including a scissor comb, razor comb, and conduit comb.

Owner:MICHEL MATTHEW JUSTIN

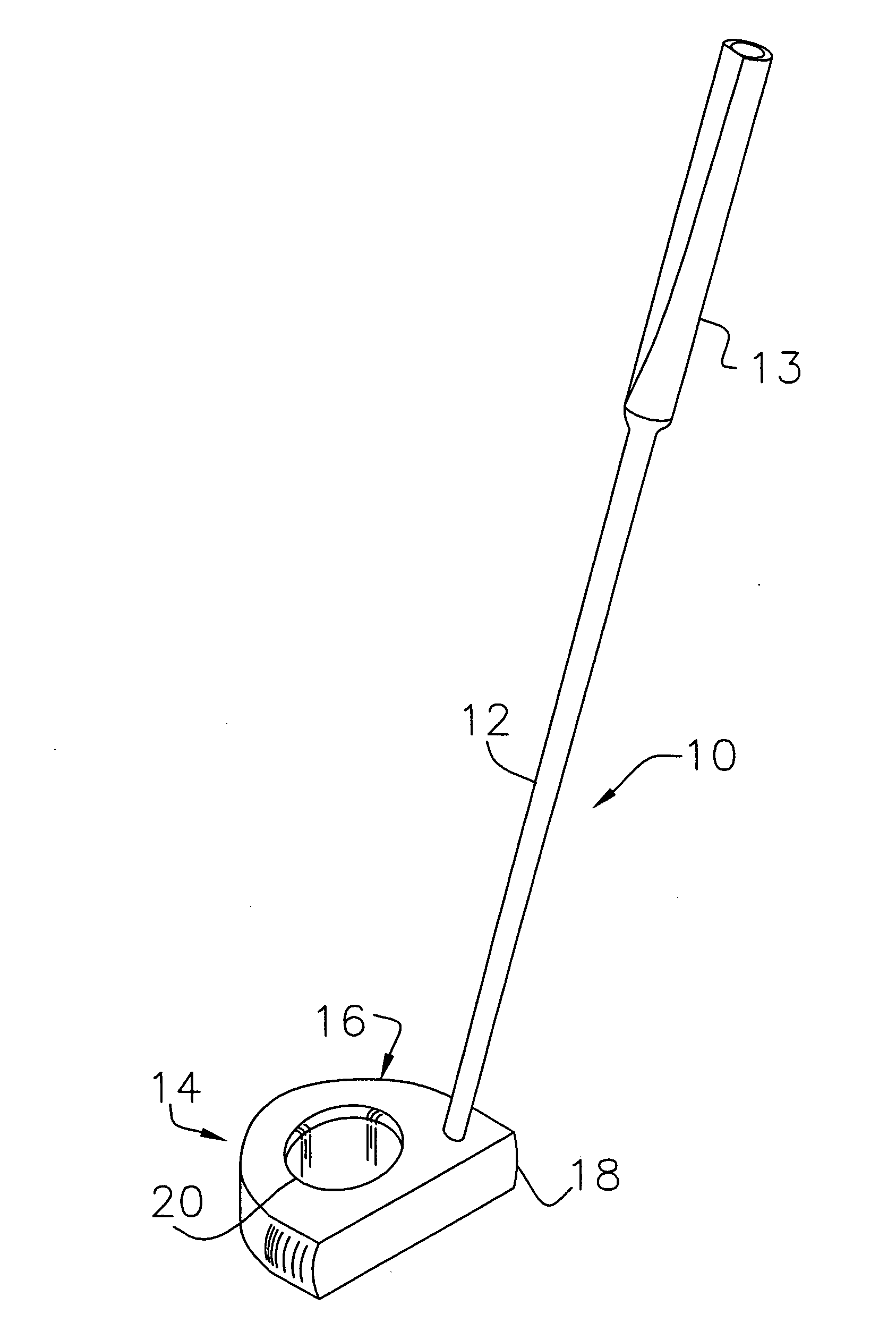

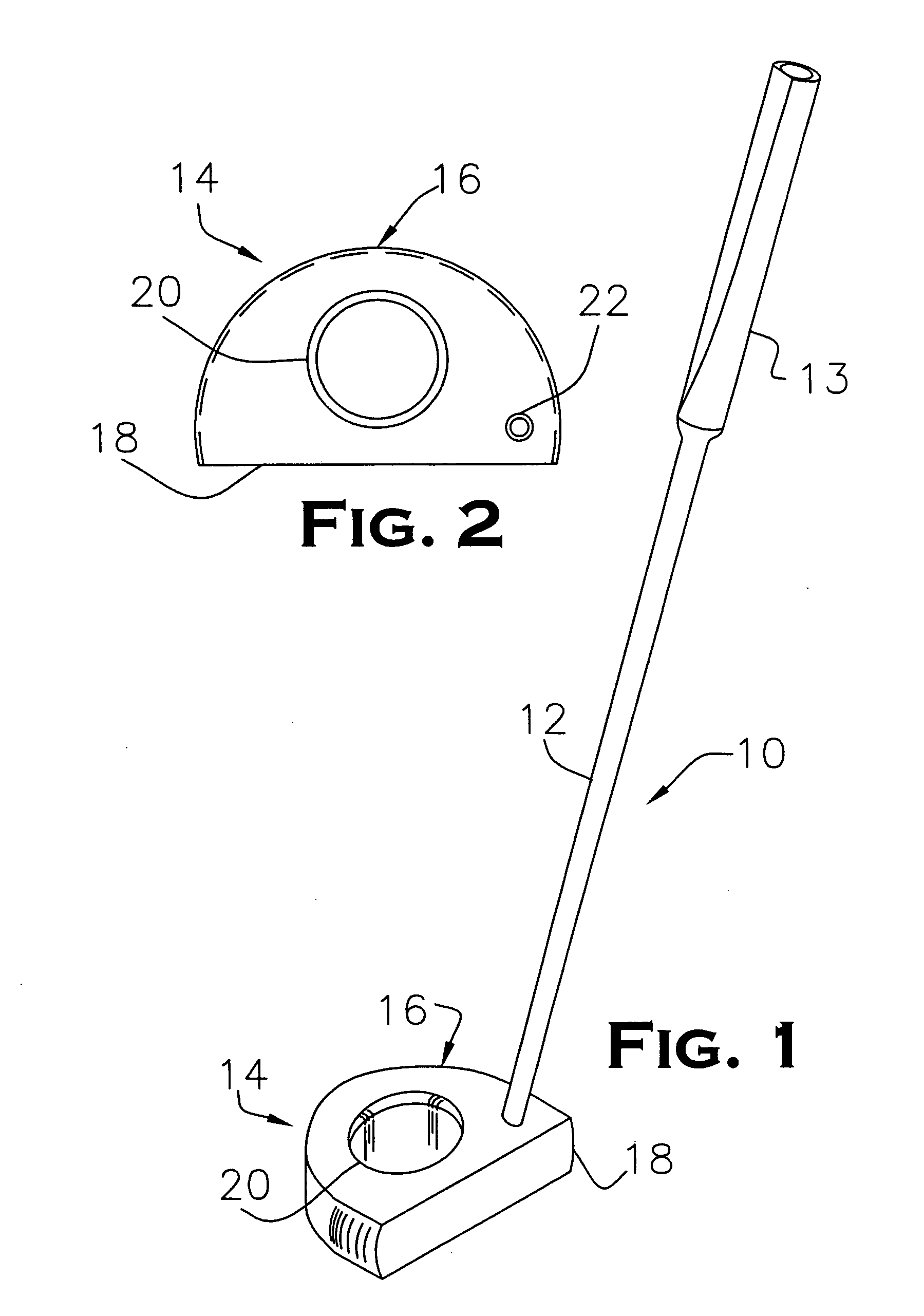

Golf putter with lead glass head

InactiveUS20060063607A1Improve put abilityImprove abilitiesBall sportsGolf clubsOperating temperature rangeWorking range

An improved golf putter is disclosed that is constructed having a head made from a lead glass material containing at least 24% lead oxide in its formulation. The lead glass material formulation is heated to a full melting point of about 2500° F. and maintained at such temperature to remove impurities and bubbles before being reduced to a working temperature range of 1500°-2000° F. While in the working range, the lead glass material is press molded into the desired shape of the putter head or otherwise formed into billets that are milled or machined using conventional glass cutting techniques. Upon formation of the desired shape, the body of the putter head is annealed to remove stress in the lead glass material and thereafter the exterior of the putter head is treated to mechanically strengthen the surface area and prevent chipping of the putter head. The resulting lead glass putter head exhibits a density between about 3.0 to 5.0 grams / cm3 and a Young's modulus between about 50 to 70 GPa that cause the putter head to impart high energy transfer to the ball upon impact with minimal vibration of the head for greater feel of the impact and consistency in putting. The lead glass putter head may be formed into a variety of configurations each adapted to affix to a conventional putter shaft.

Owner:CROSSLEY JOHN W

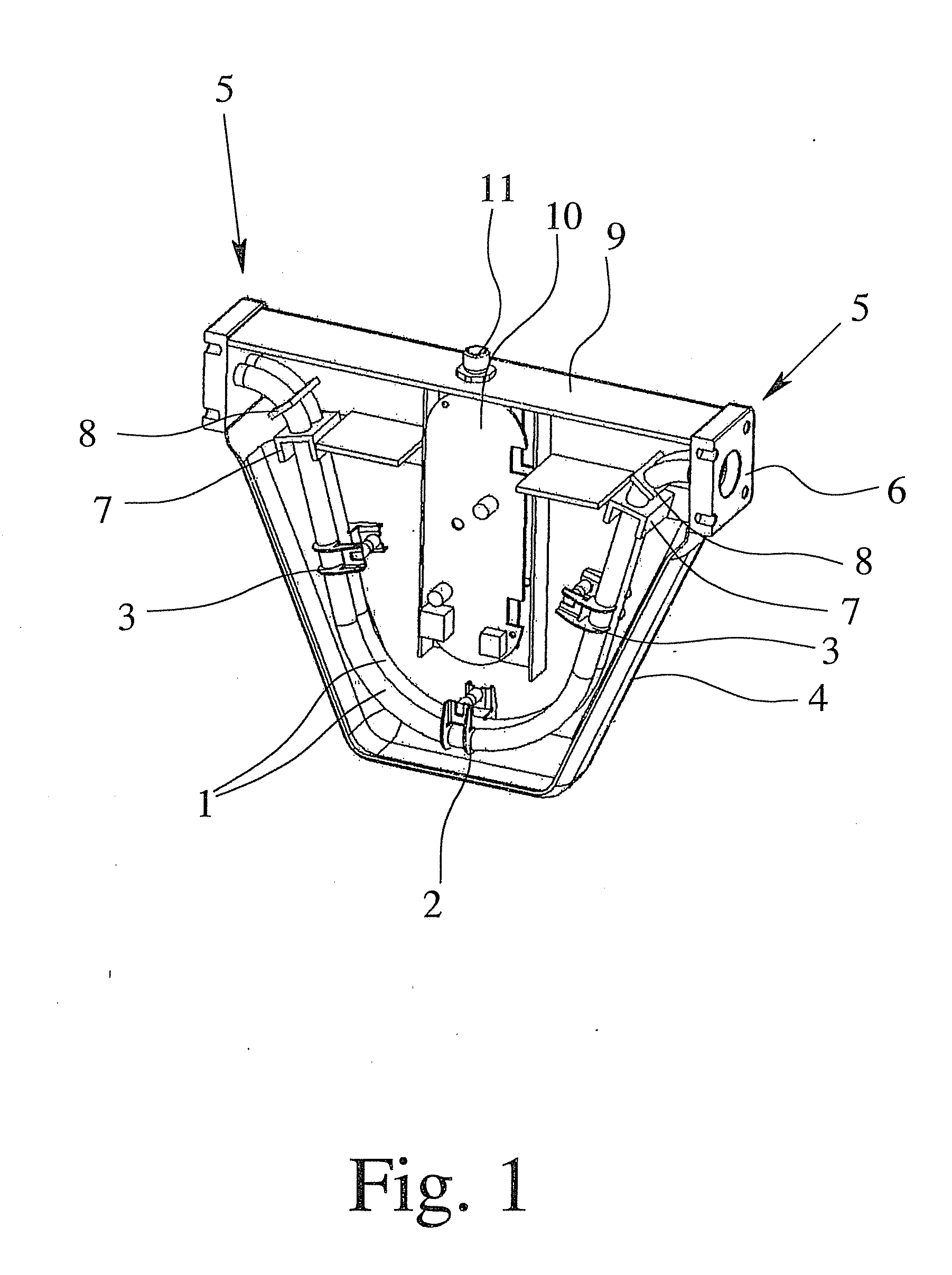

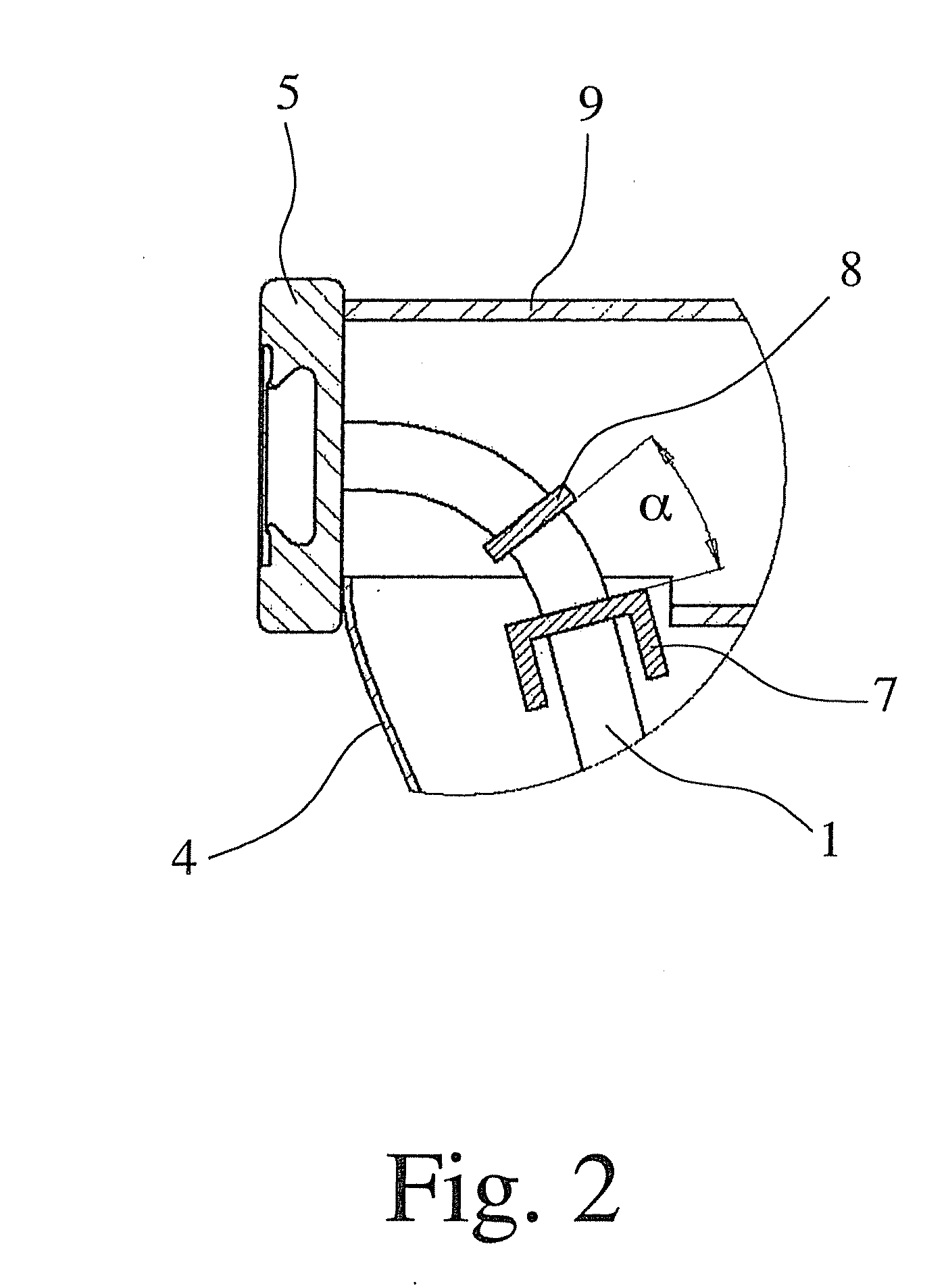

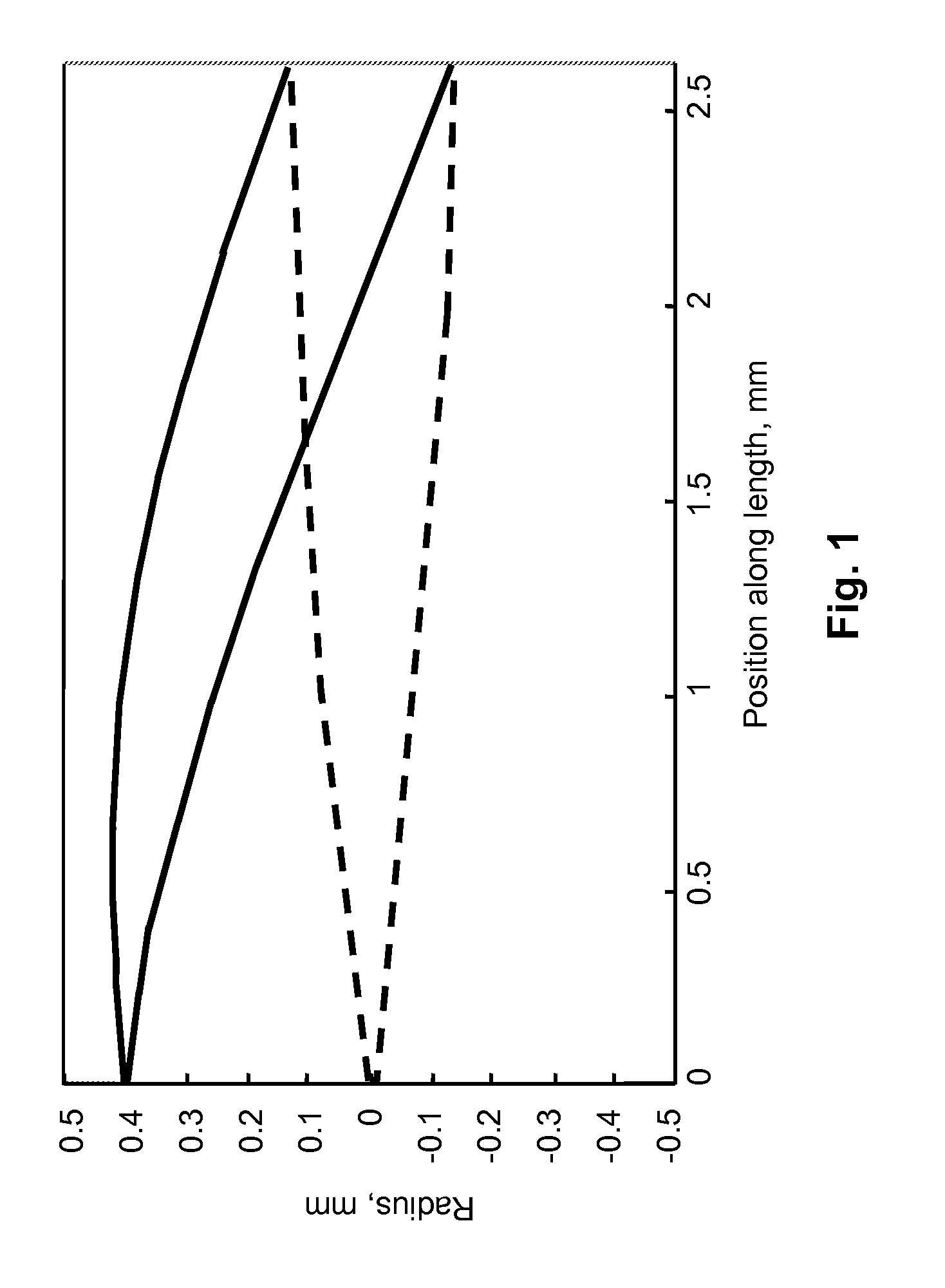

Coriolis mass flowmeter

A Coriolis mass flowmeter having two measuring tubes, wherein two neighboring oscillation node plates are provided on one end of the measuring tube that connect the two measuring tubes to one another and wherein the angle between the planes of both oscillation node plates is determined in such a manner that the vibration of the measuring tubes is minimal up to a predetermined driving force. A method of producing the flowmeter is also disclosed.

Owner:KRONE GMBH

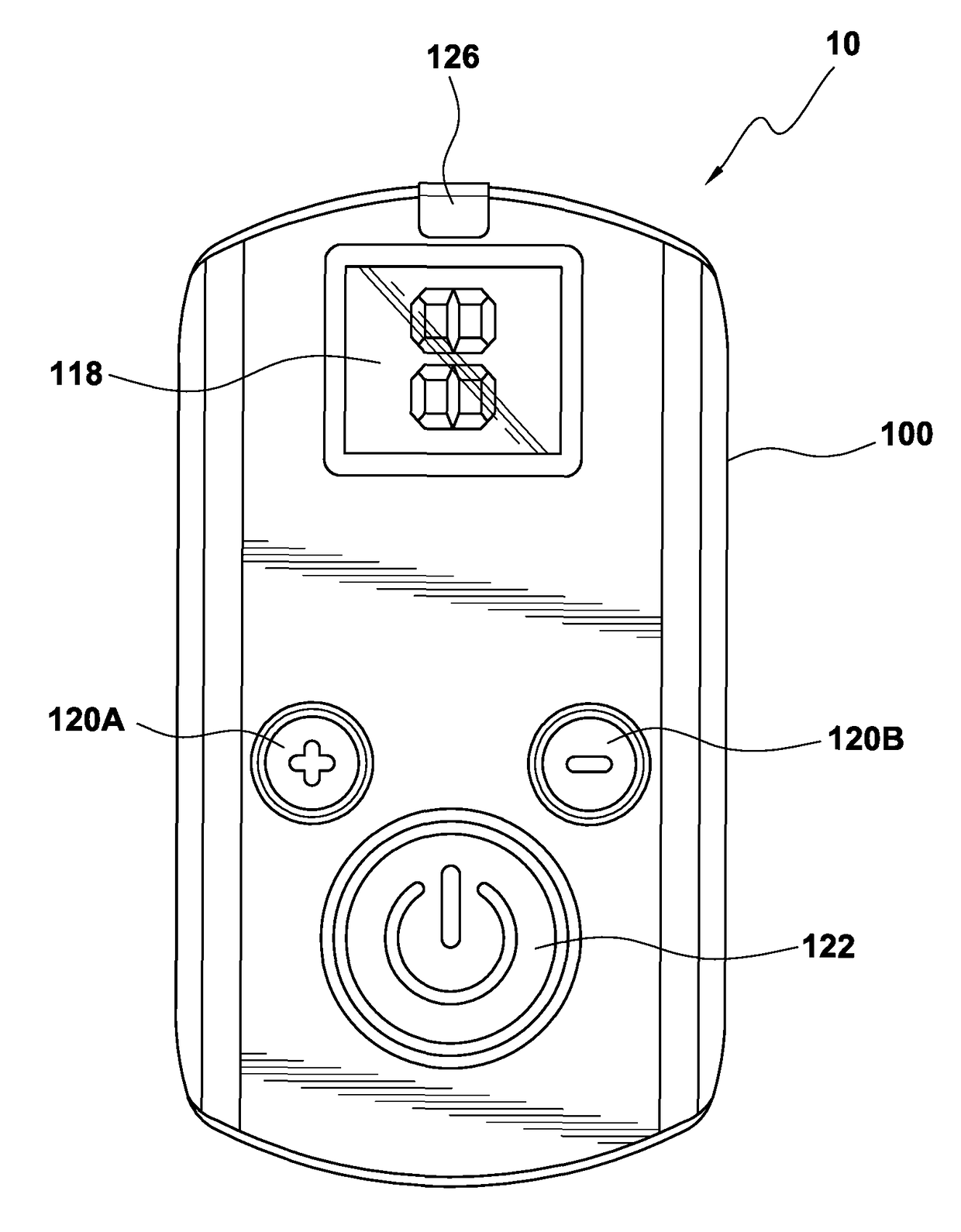

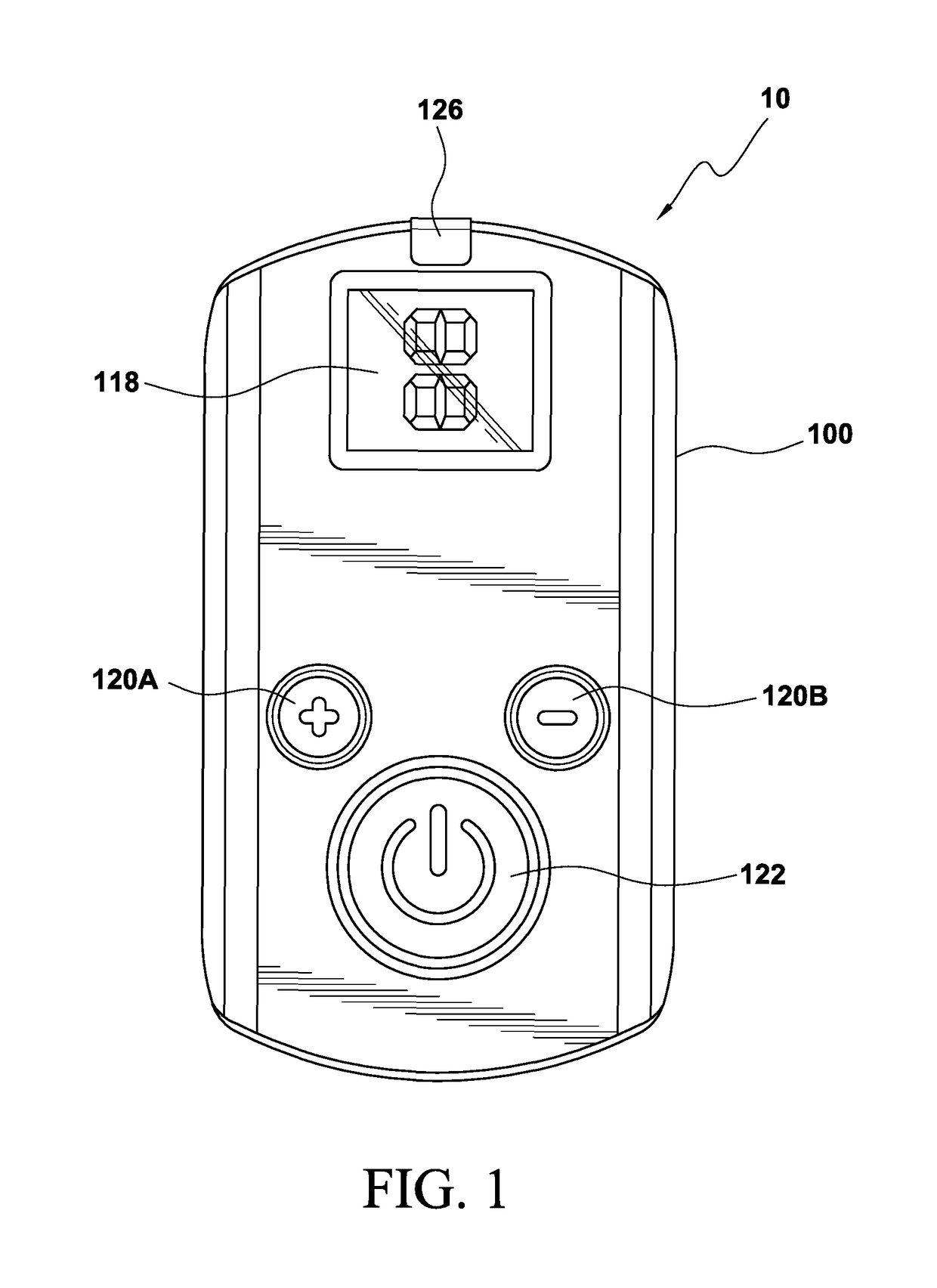

Device and system for drug information detection

An injected dose detection device which includes a housing having a joint surface surrounding an injection device and a through hole formed on the joint surface configured to communicate with an internal part of the housing, a vibration sensor disposed in the internal part of the housing configured to detect at least one vibration signal based on a minimum vibration threshold, a vibration transmitting element positioned directly between the vibration sensor and the injection device and configured to transmit the at least one vibration signal and a processing unit configured to process the at least one vibration signal for generating injected dose information corresponding to the injected dose.

Owner:DIABNEXT LTD

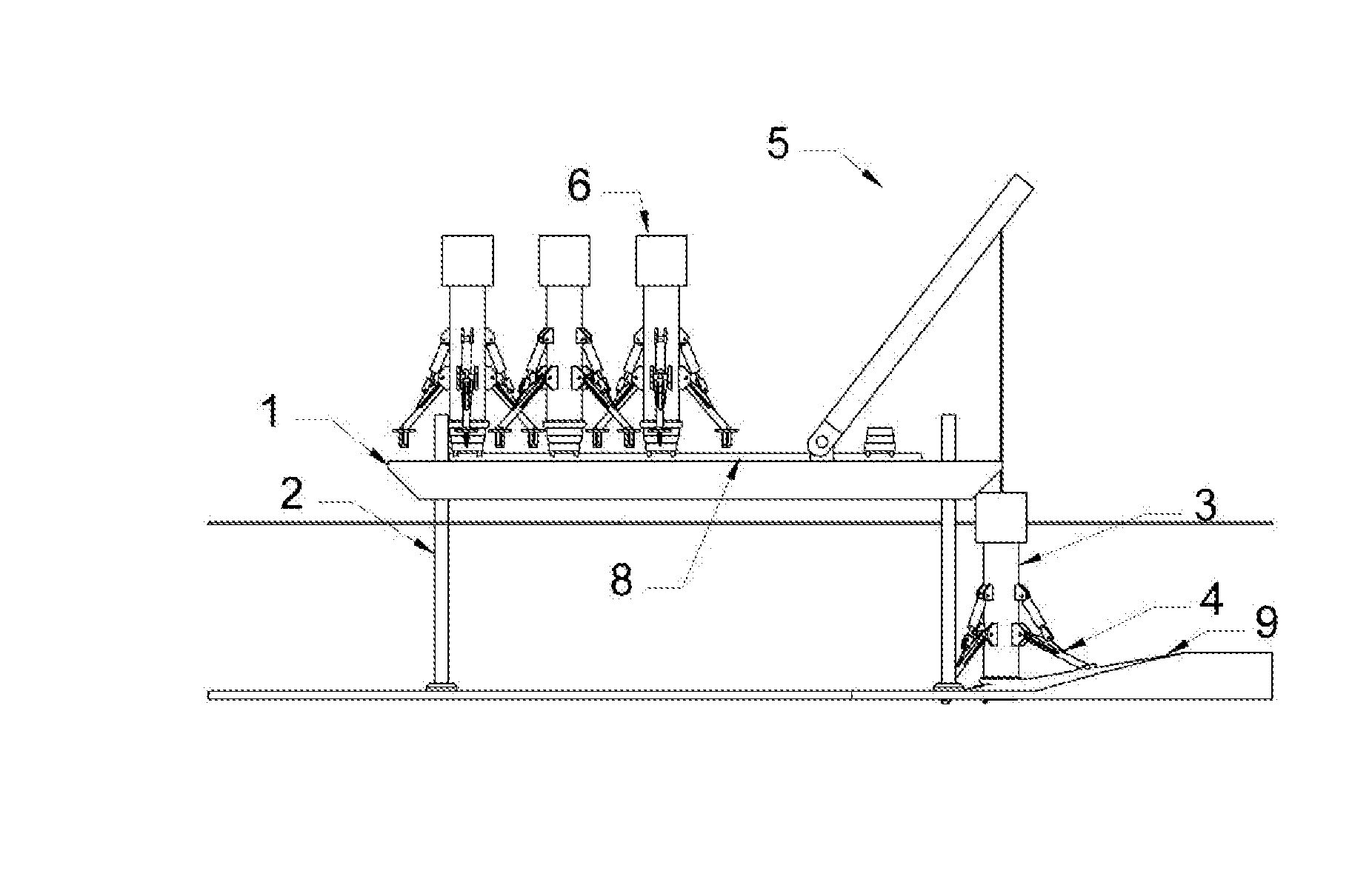

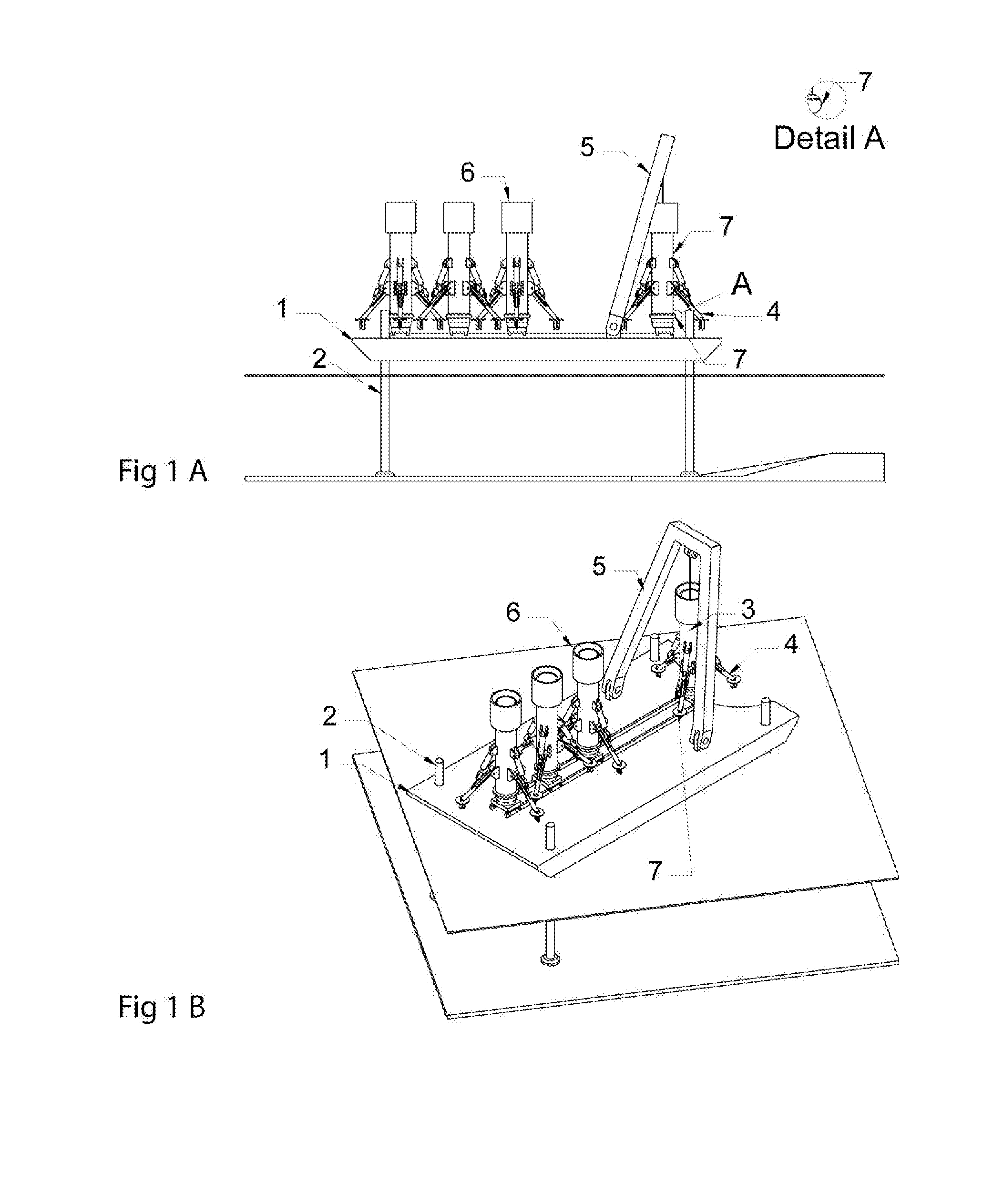

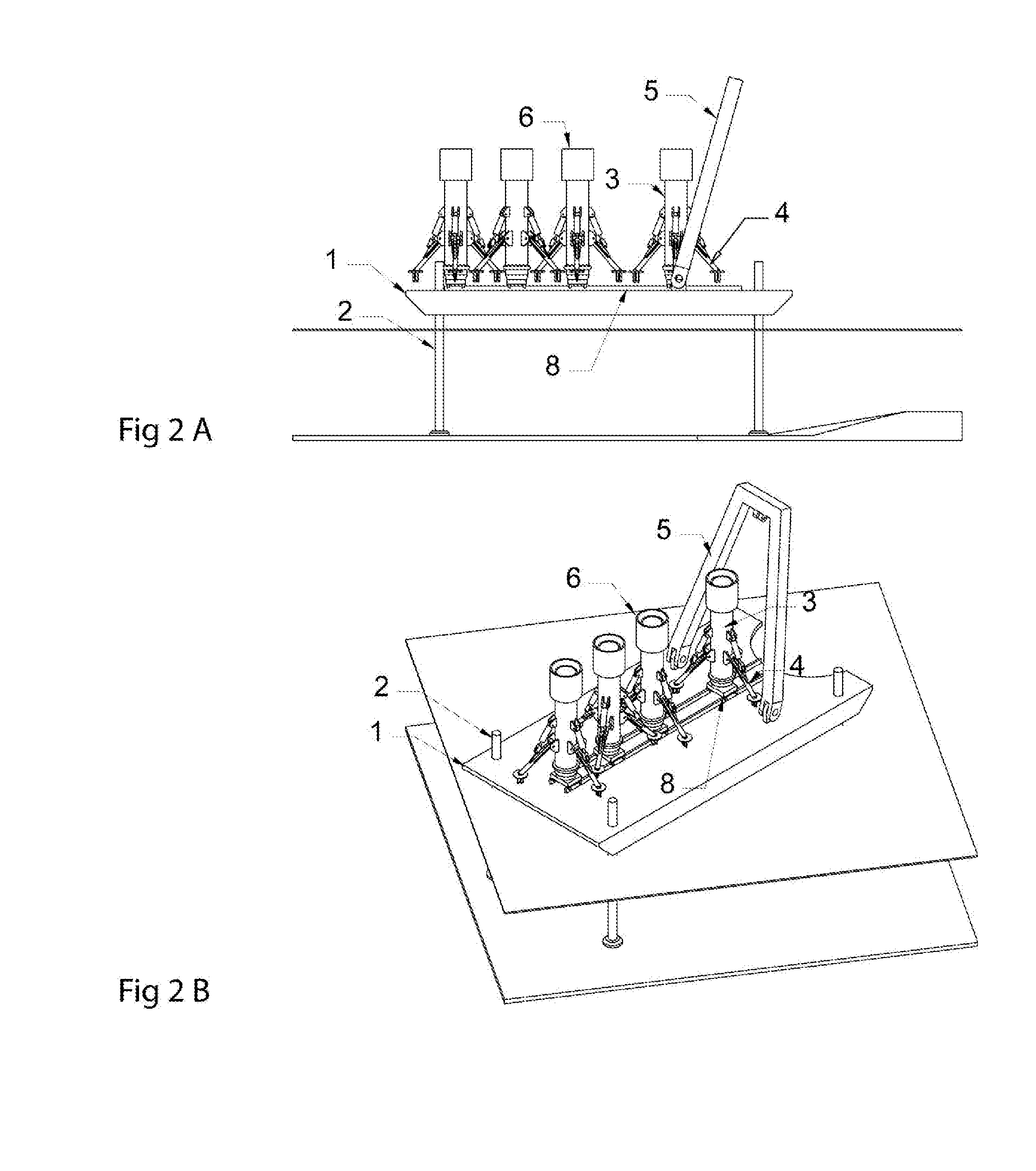

Apparatus and method for reduction of sonic vibrations in a liquid

An apparatus for reduction of sonic vibrations caused when driving a foundation member below the surface of a liquid has a tube structure which is lowered below the surface of the liquid, and which receives the foundation member. A seal is in contact with the tube structure and creates a contained volume around the foundation member, which may be pumped dry so as to minimize the communication of sonic vibrations into the liquid.

Owner:LO NOISE APS

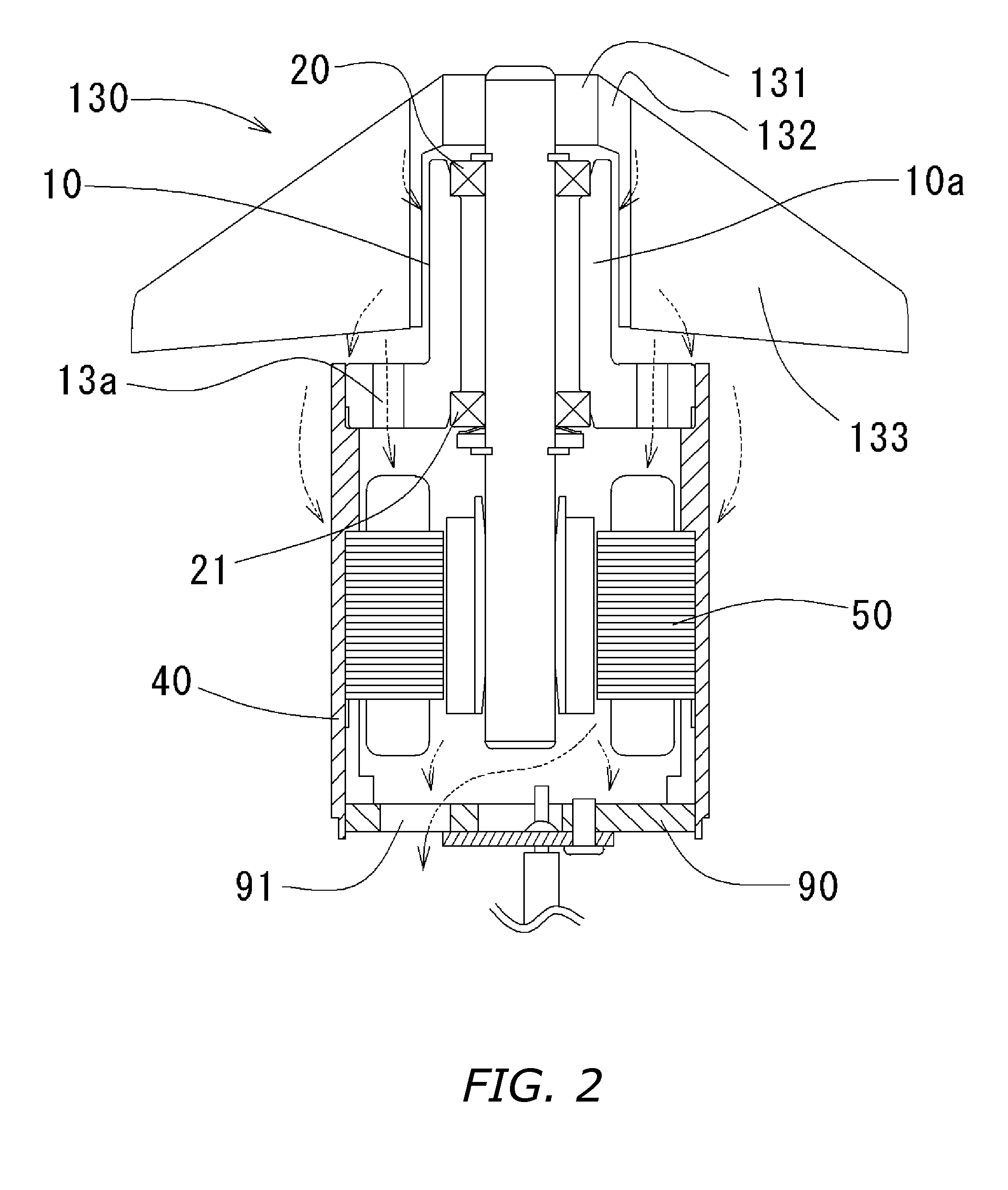

Ventilation fan

In a ventilation fan of inner rotor type in which a shaft is fixed to a motor supporting portion, the shaft is held by a shaft holding portion preferably provided by, for example, a metal member. The shaft holding portion includes a cylindrical portion which is fixed to a resin of the motor supporting portion preferably by being embedded through insert molding and into which the shaft is inserted, and a shaft holding flange portion extending outwards in the radial direction from either one of an upper end or a lower end of the cylindrical portion.

Owner:NIDEC CORP

Method and system for electrical and mechanical power generation using stirling engine principles

InactiveUS20090019846A1Improve efficiencyReduce power consumptionFrom solar energyGas turbine plantsStirling engineHot zone

Owner:SILVER GUY +1

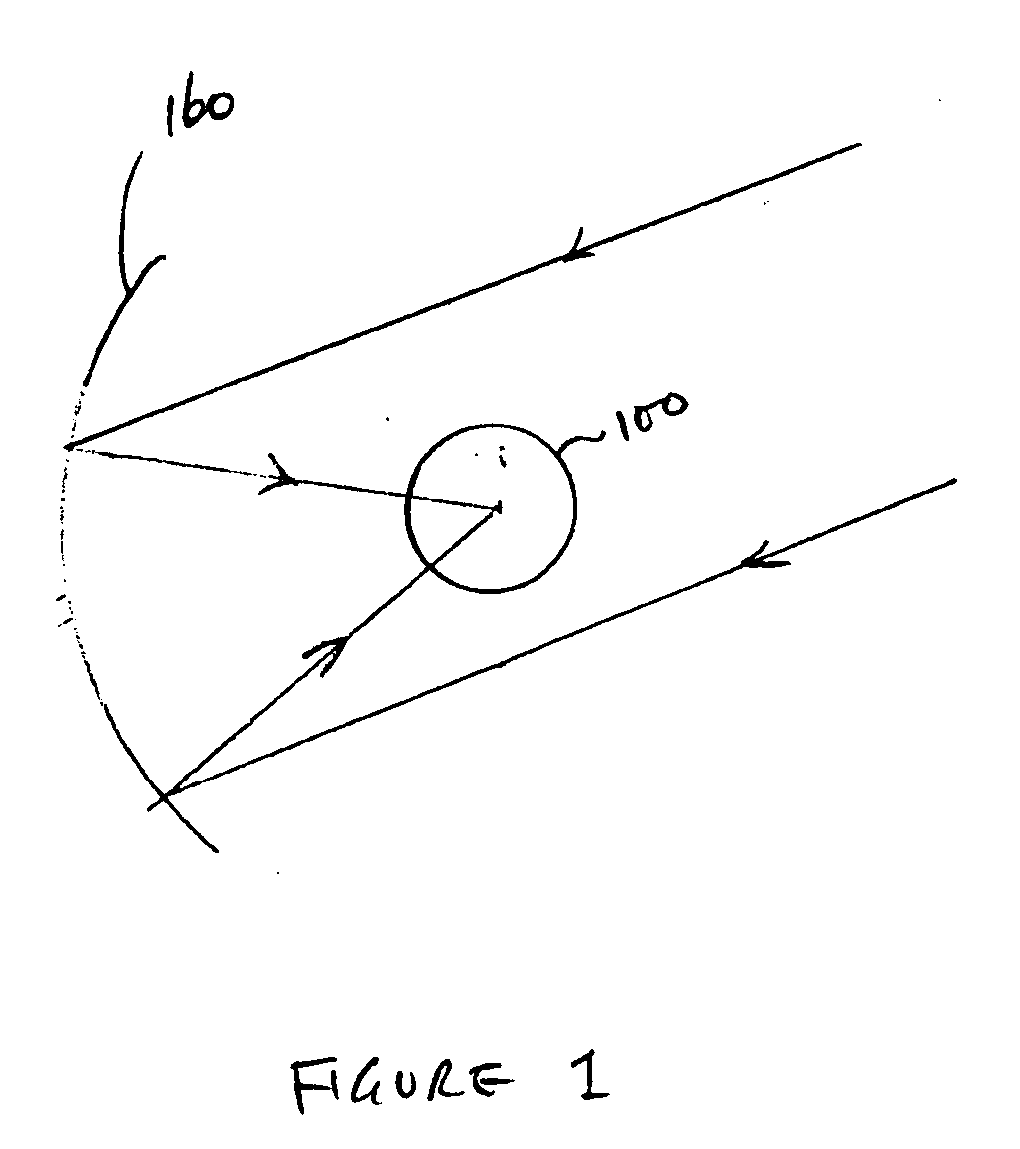

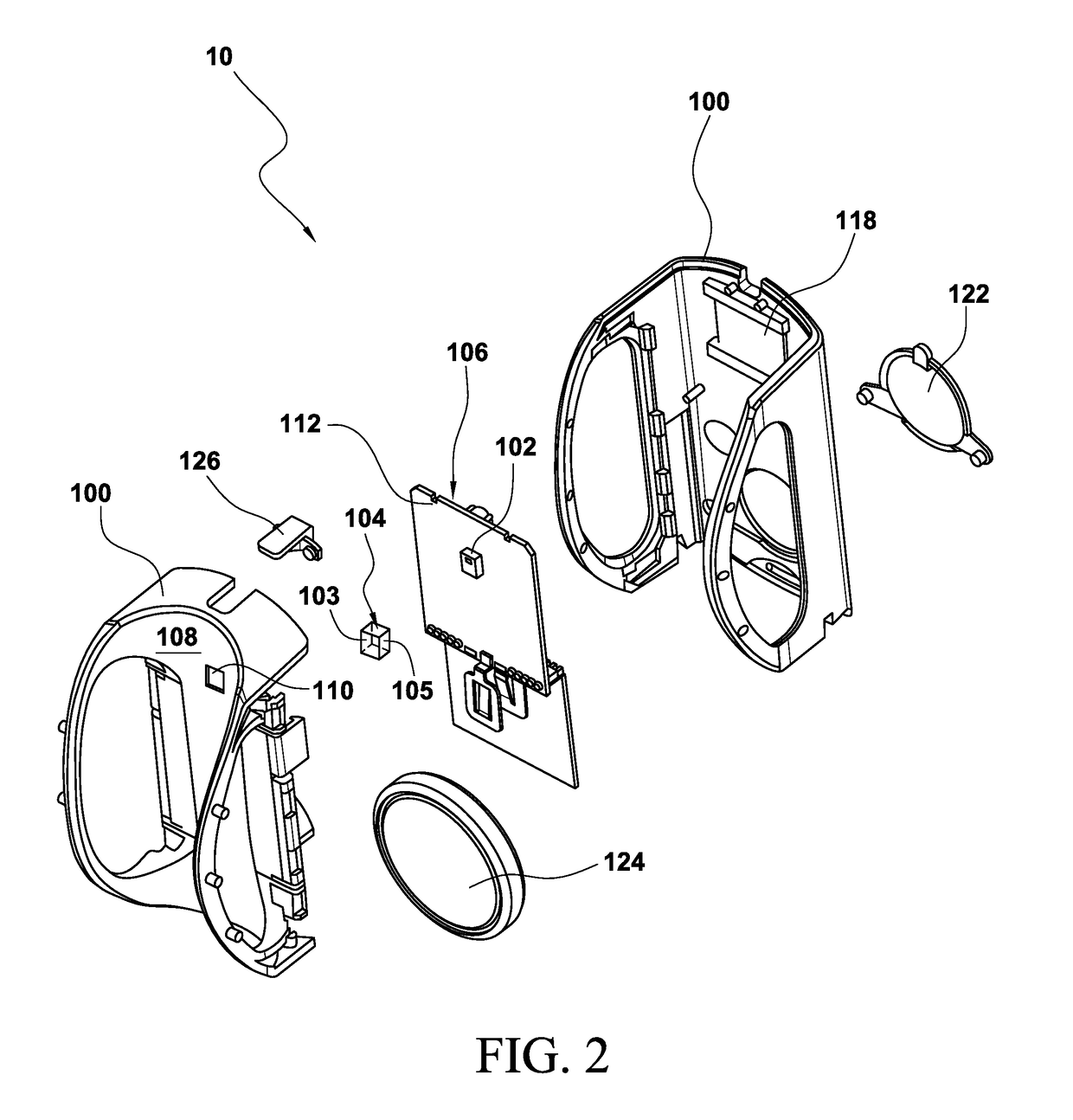

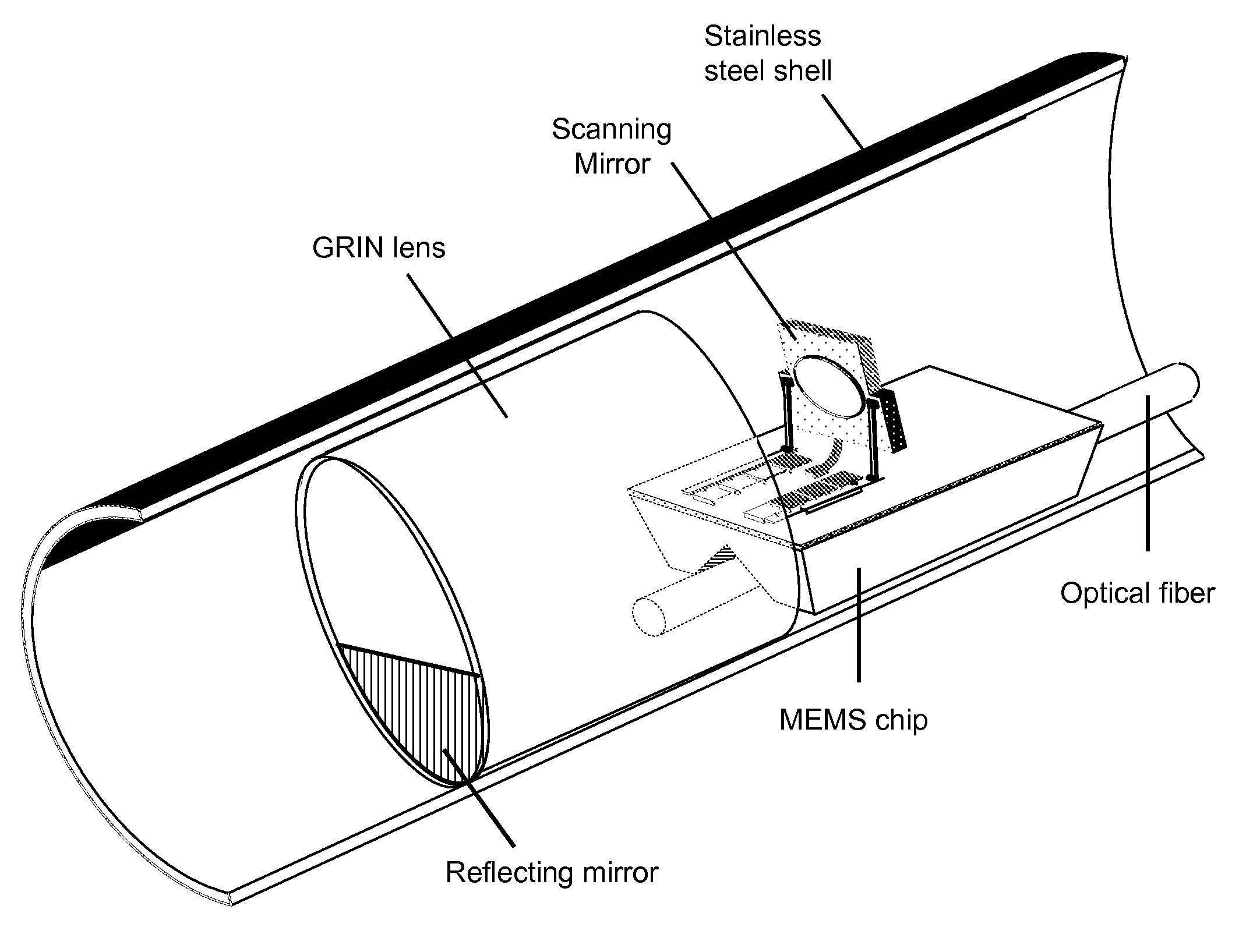

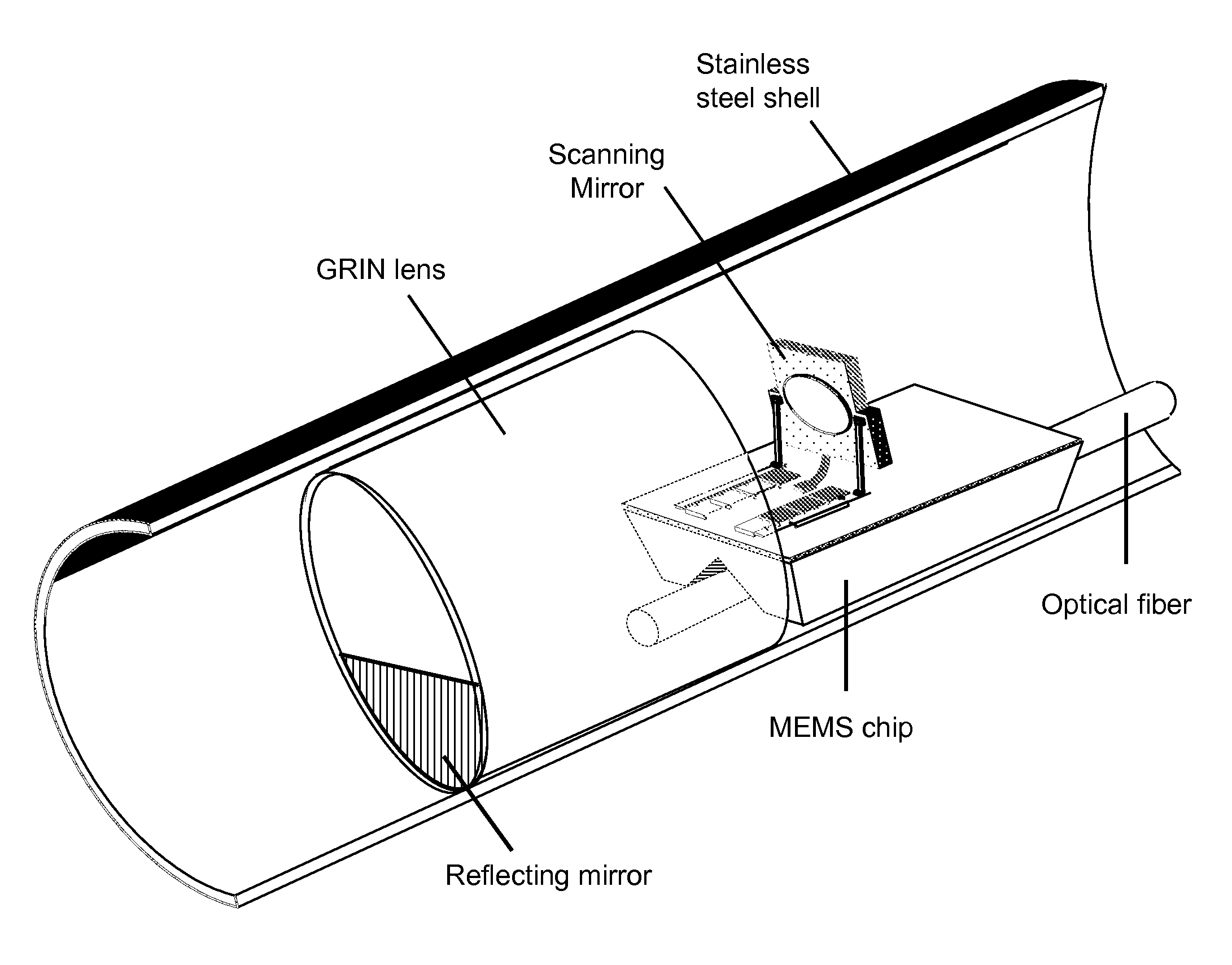

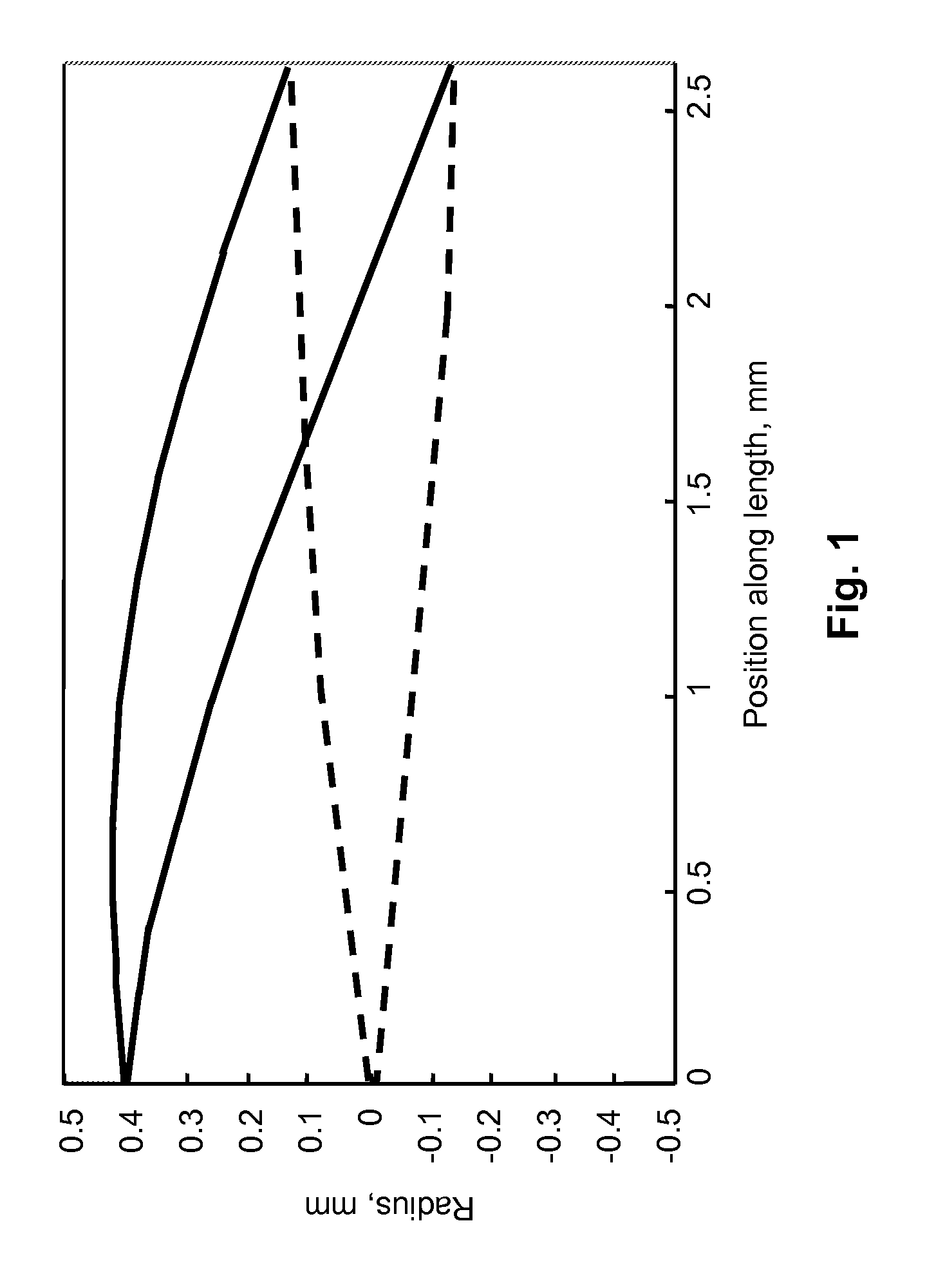

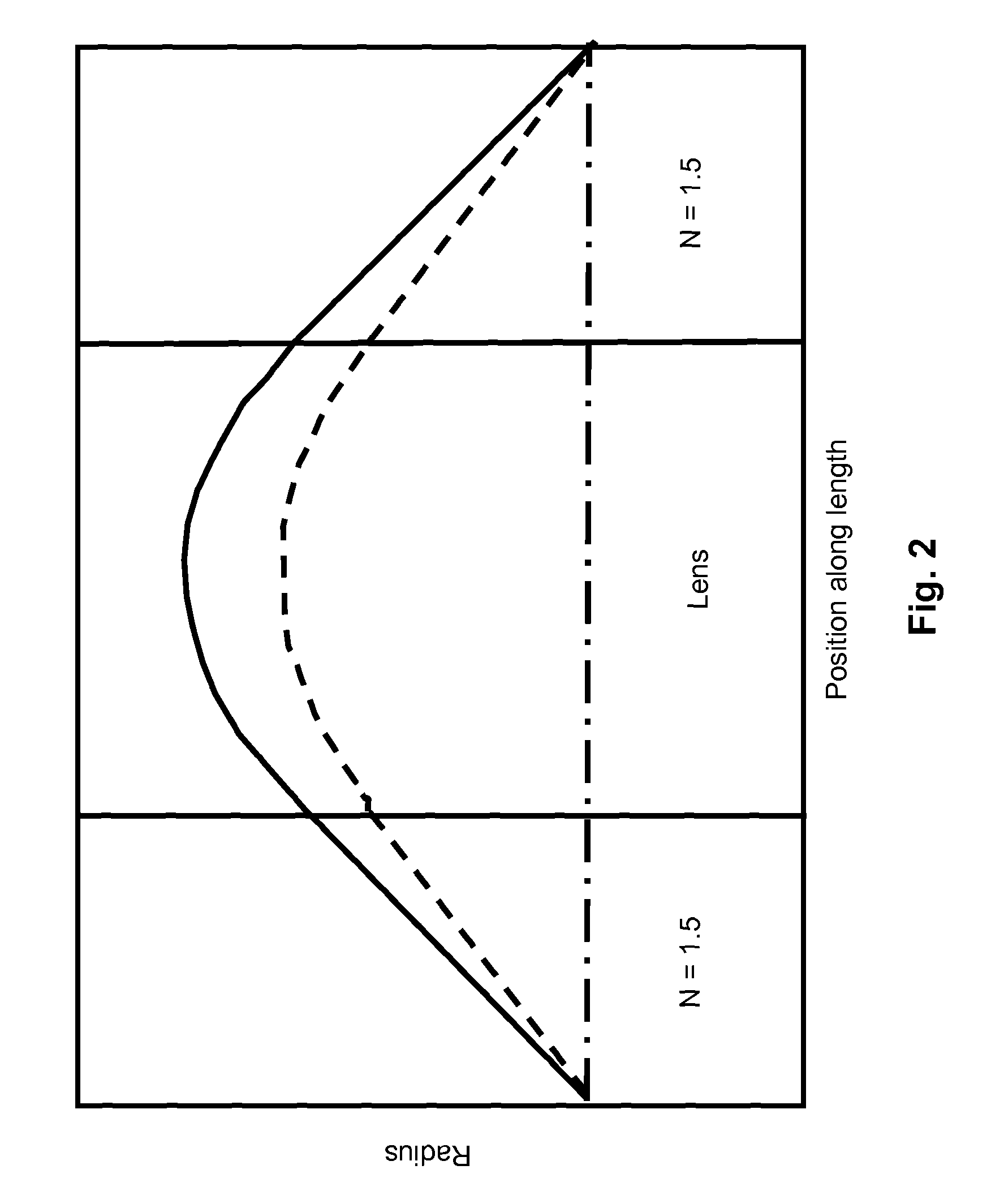

Forward-Looking Optical Coherence Tomography Endoscope

A forward-looking, optical coherence tomography, endoscopic probe is disclosed capable of high resolution with a small diameter. Light is focused and scanned during three passes through a lens. A light source supplies light to the proximal side of the lens. The light makes a first pass through the lens, and is reflected from a fixed mirror on the distal side. The reflected light makes a second pass from the distal side to the proximal side, and exits the lens at the proximal side, and is reflected by a scanning mirror. The light makes a third pass through the lens from the proximal side to the distal side to a sample to be imaged. The light is focused during each of the three passes through the lens. Light reflected from the sample passes back through and is focused by the same system.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Attachment guide comb organizer

A dummy hair clipper head, or dummy blade, which is a form conforming to those dimensions of a hair clipper's stationary blade which are necessary for its compatibility with attachment guide combs, is employed in an attachment guide comb organizer which comprises a plurality of interconnected forms, whereby a plurality of attachment guide combs can be stored and organized. By interconnecting the forms with either a rigid, contoured or flexible means, with the options of placing them within a container and of making them releasable, the organization and storage of a set of attachment guide combs can be customized. For the purposes of storage the form can be flexible and have a reduced structure from that of the stationary blade. The use of the form also makes possible a variety of new uses for attachment guide combs including a scissor comb, razor comb, and conduit comb.

Owner:MICHEL MATTHEW JUSTIN

Ventilation fan

InactiveUS9028223B2Hold steadySmall sizeMagnetic circuit rotating partsBlade accessoriesEngineeringFlange

In a ventilation fan of inner rotor type in which a shaft is fixed to a motor supporting portion, the shaft is held by a shaft holding portion preferably provided by, for example, a metal member. The shaft holding portion includes a cylindrical portion which is fixed to a resin of the motor supporting portion preferably by being embedded through insert molding and into which the shaft is inserted, and a shaft holding flange portion extending outwards in the radial direction from either one of an upper end or a lower end of the cylindrical portion.

Owner:NIDEC CORP

Portable temperature-controlled container

InactiveUS8061148B2Easy to storeMinimal noiseShow cabinetsMachines using electric/magnetic effectsTemperature controlCold side

The present invention generally relates to containers and more specifically, to a portable temperature-controlled container. The temperature-controlled container is used for maintaining articles at a controlled temperature. The container includes a housing unit defining a storage chamber for receiving the articles, a cooling system mounted to the housing unit, wherein the cooling system includes a cold side assembly system in heat transfer communication with the interior of the chamber, a hot side assembly system in heat transfer communication with the outside of the storage chamber and a thermoelectric module supplied with an electrical power source.

Owner:SG PRODN

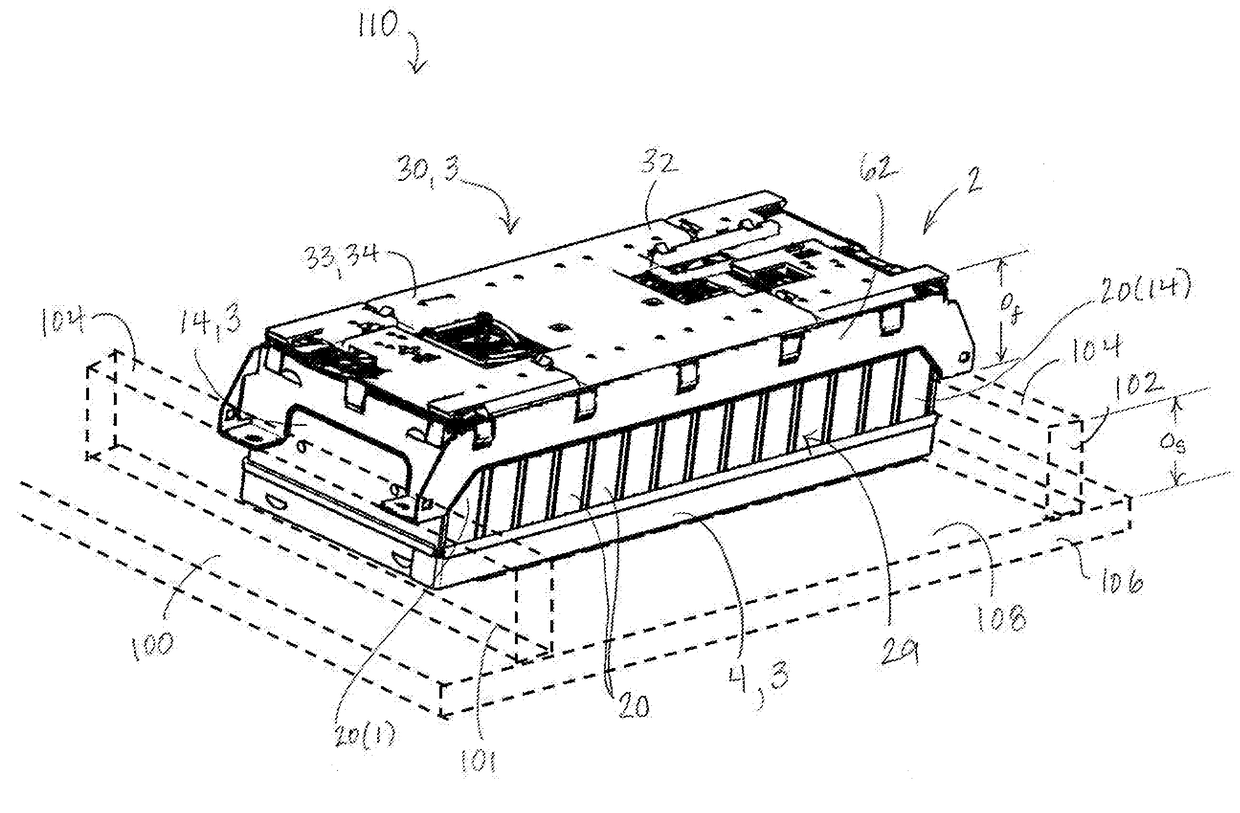

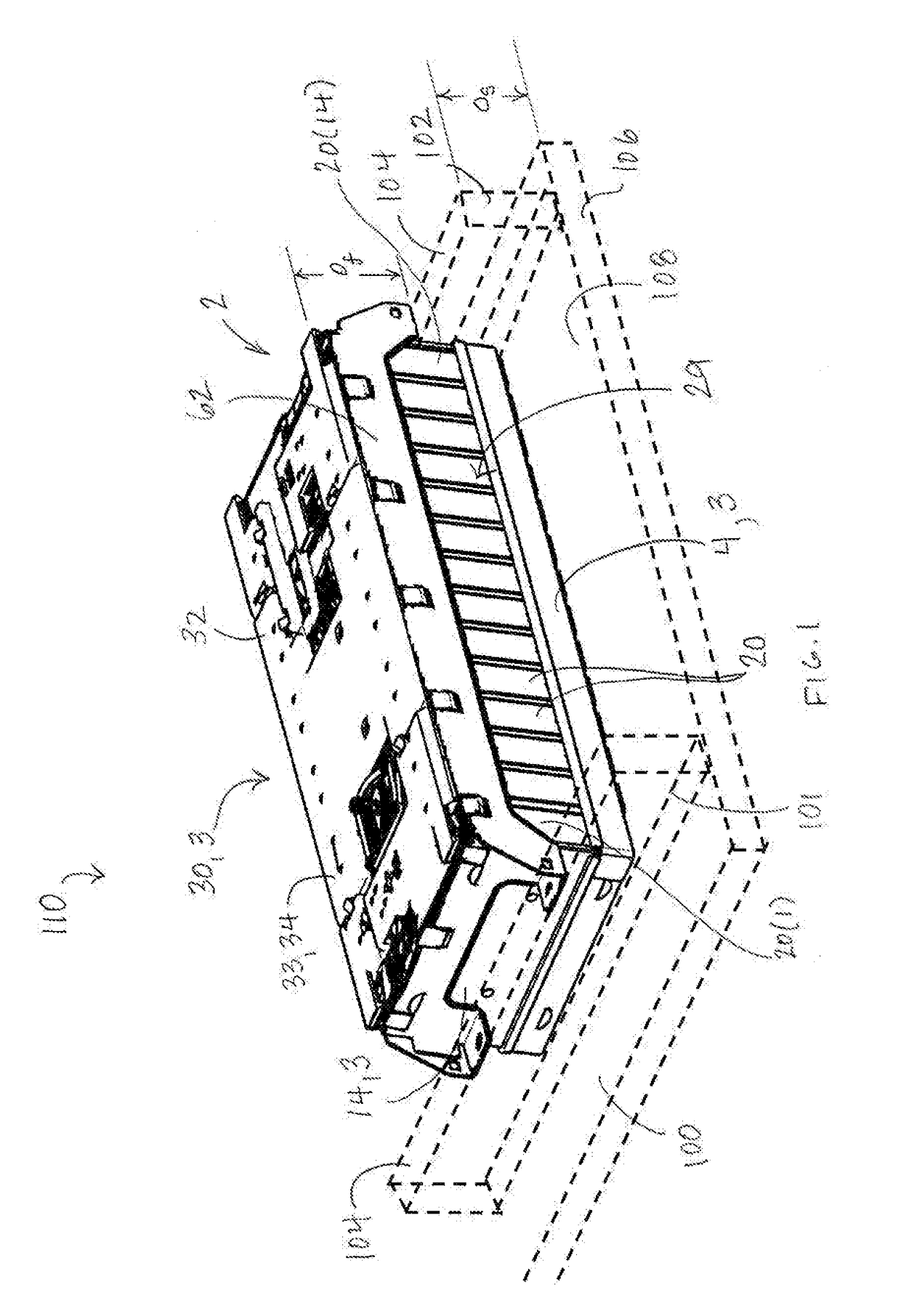

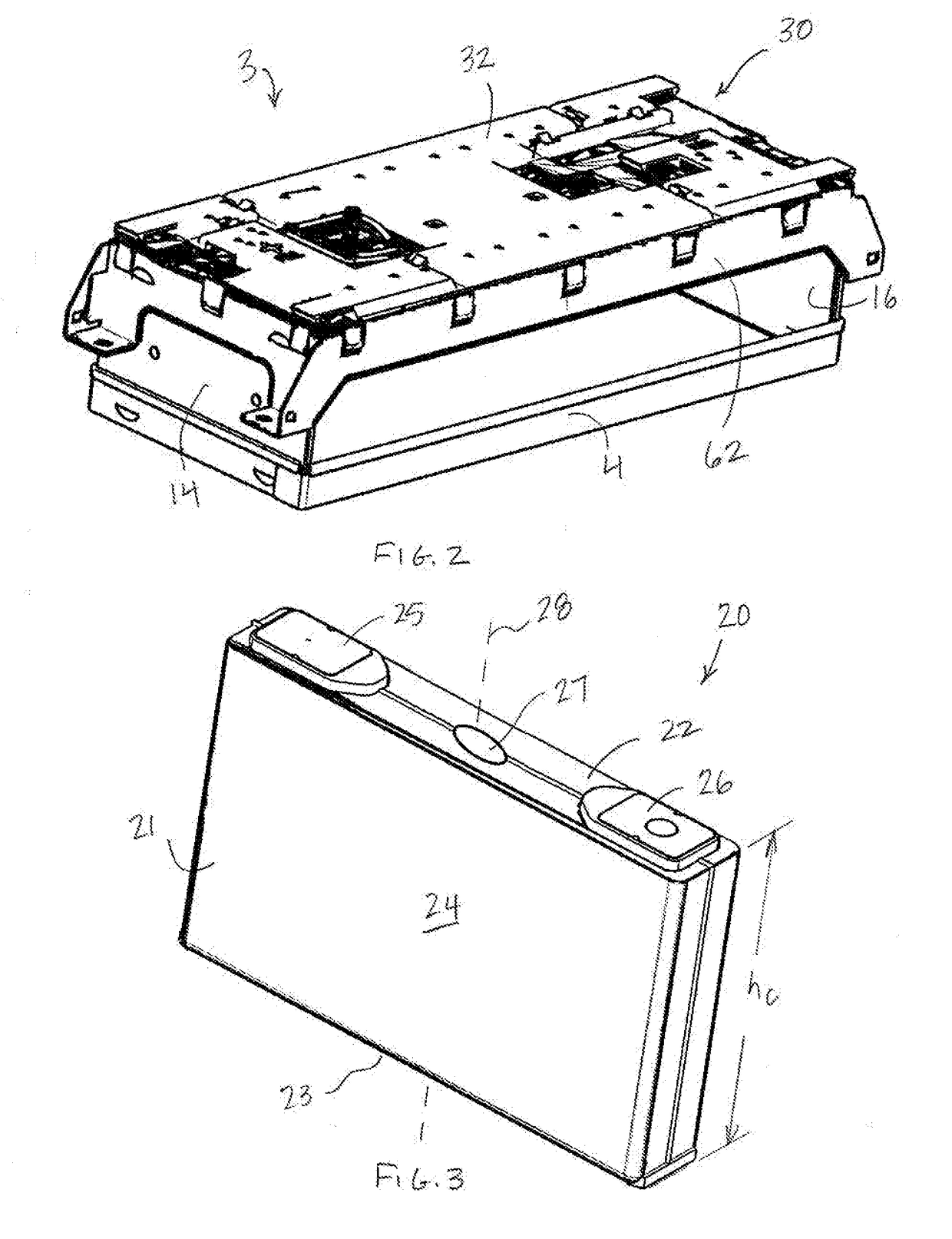

Battery Module Including Cover Assembly

ActiveUS20170338454A1Accurate locationFirm supportSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsComputer moduleEngineering

The present invention relates to a battery module for storage of electrochemical cells, including a cover assembly including an inner frame that encloses an end of the cells and applies a compressive force thereto, an intermediate frame that is snap fit to an outer surface of the inner frame and supports ancillary structures of the battery system, and an outer cover that is snap fit to an outer surface of the intermediate frame.

Owner:BOSCH BATTERY SYST GMBH +1

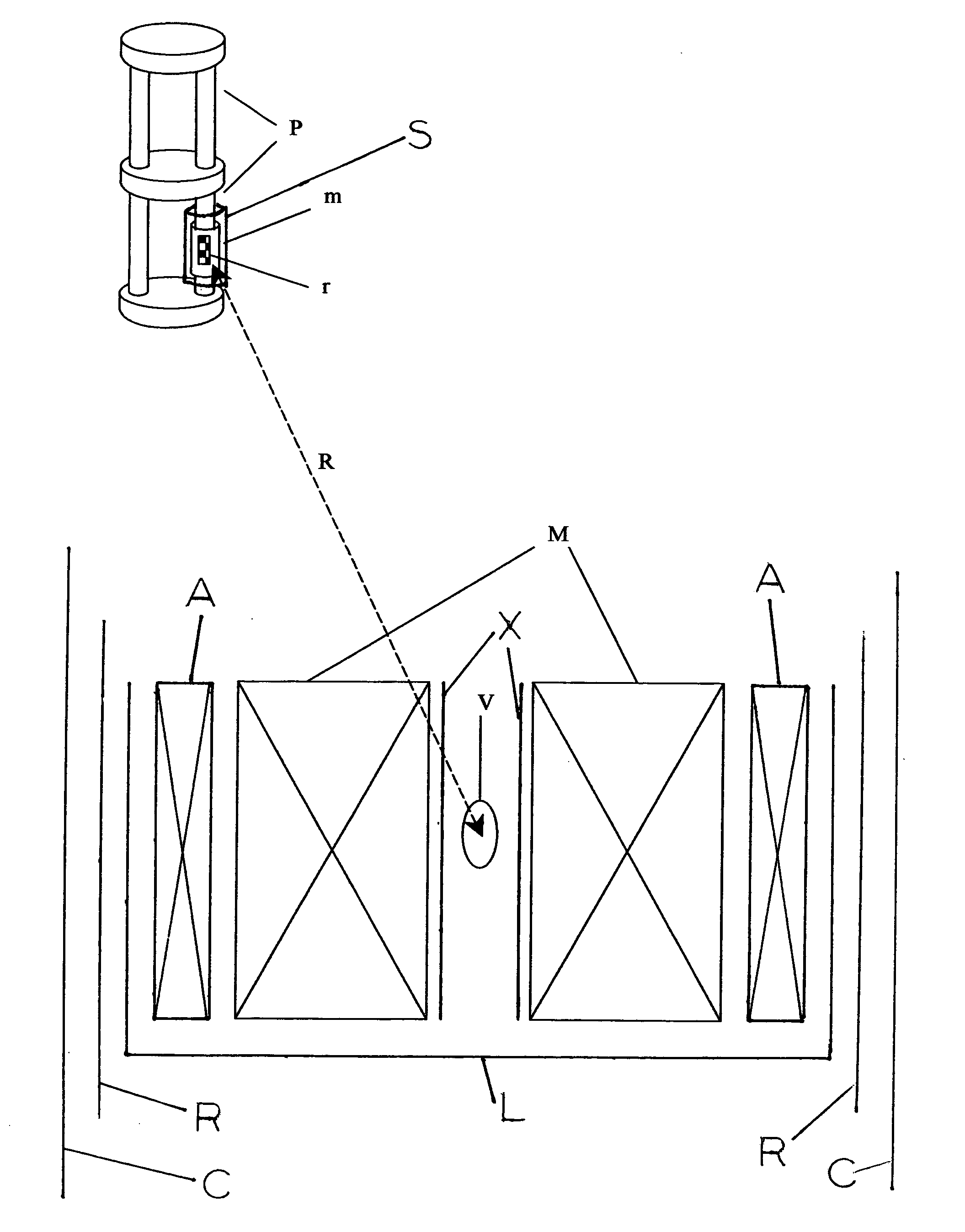

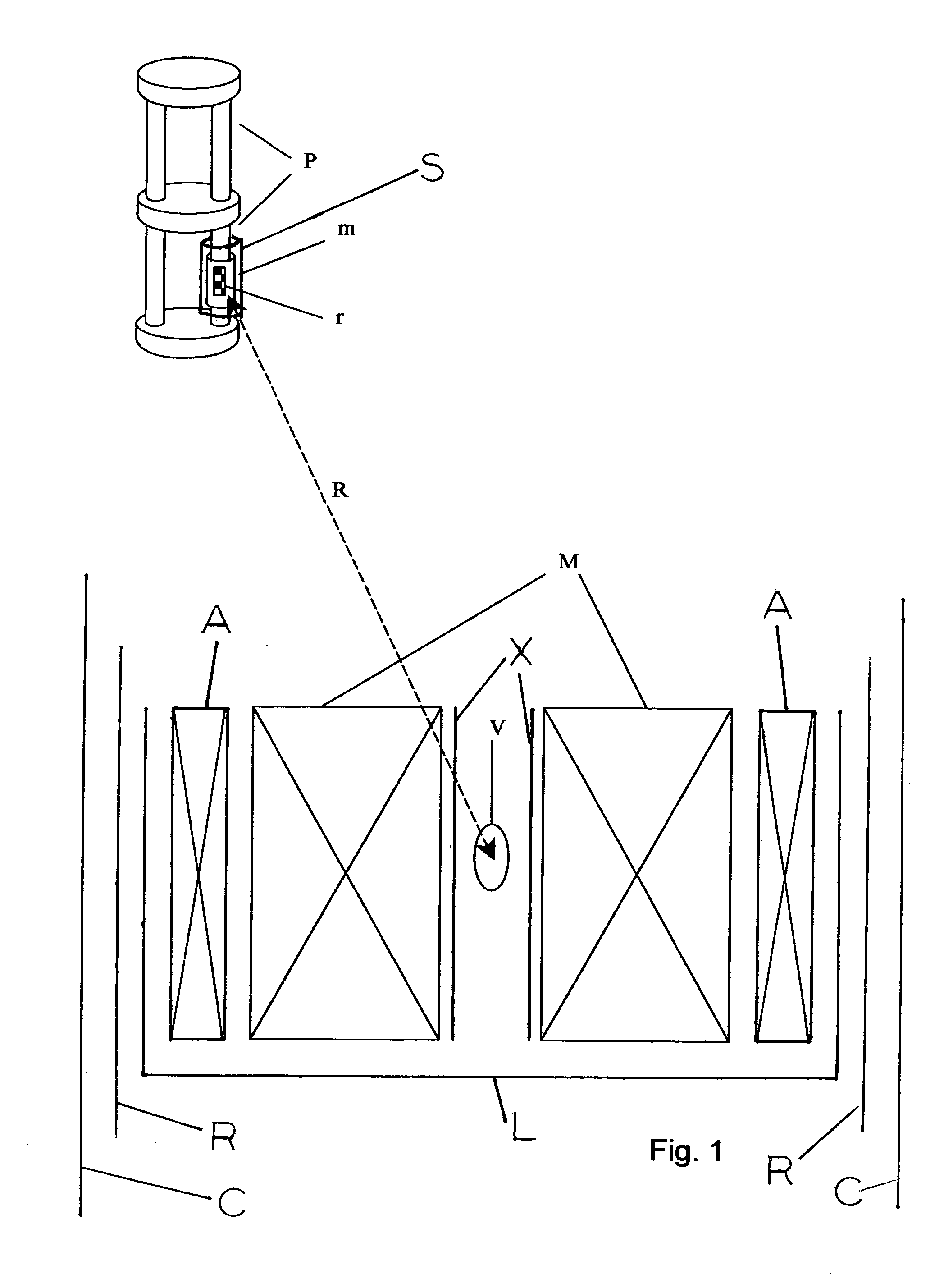

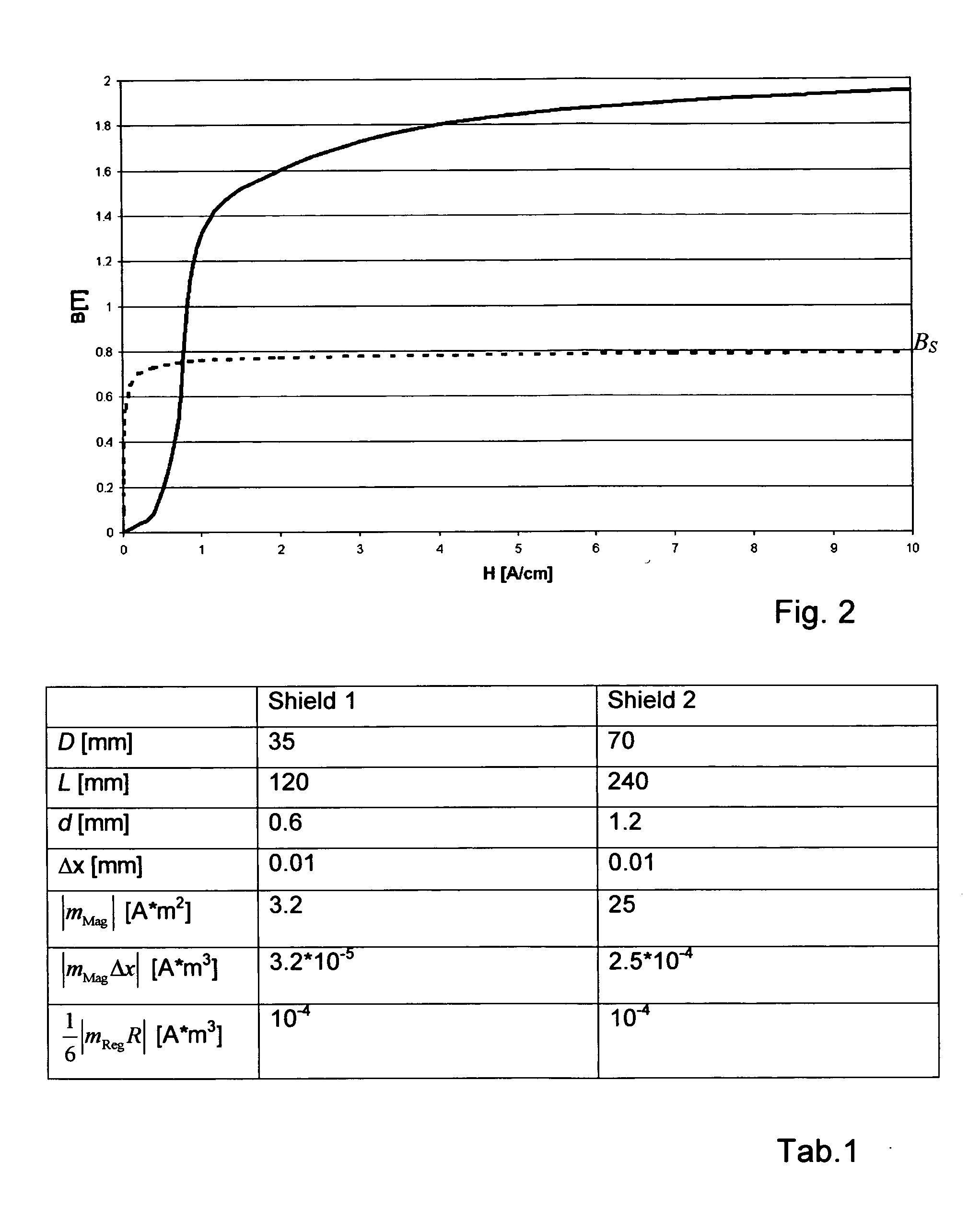

Magnet system with shielded regenerator material

ActiveUS20050253676A1Reduce materialReduce volatilityElectromagnets without armaturesMagnetic measurementsVibration amplitudeMagnet

A magnet system with a magnet arrangement (M), a working volume (V) and a pulse tube cooler (P) with magnetic regenerator material (r) is characterized in that a shielding (m) of magnetic material is provided which reduces the stray field of the magnet arrangement at the location of the magnetic regenerator material (r) and is characterized in that 13m~RegR+mMagΔ x<16mRegR,wherein mMag is the dipole moment of the magnetic material of the shielding (m), Δχ is the vibration amplitude of the magnetic material of the shielding (m), mReg is the amplitude of the dipole fluctuations of the magnetic regenerator material (r) in one cycle without magnetic shielding (m), {tilde over (m)}Reg is the amplitude of the dipole fluctuations of the magnetic regenerator material (r) in one cycle with magnetic shielding (m), and R is the average separation of the magnetic regenerator material (r) from the working volume (V). A magnet system of this type has an optimum stable, temporally constant magnetic field in the working volume (V).

Owner:BRUKER SWITZERLAND AG

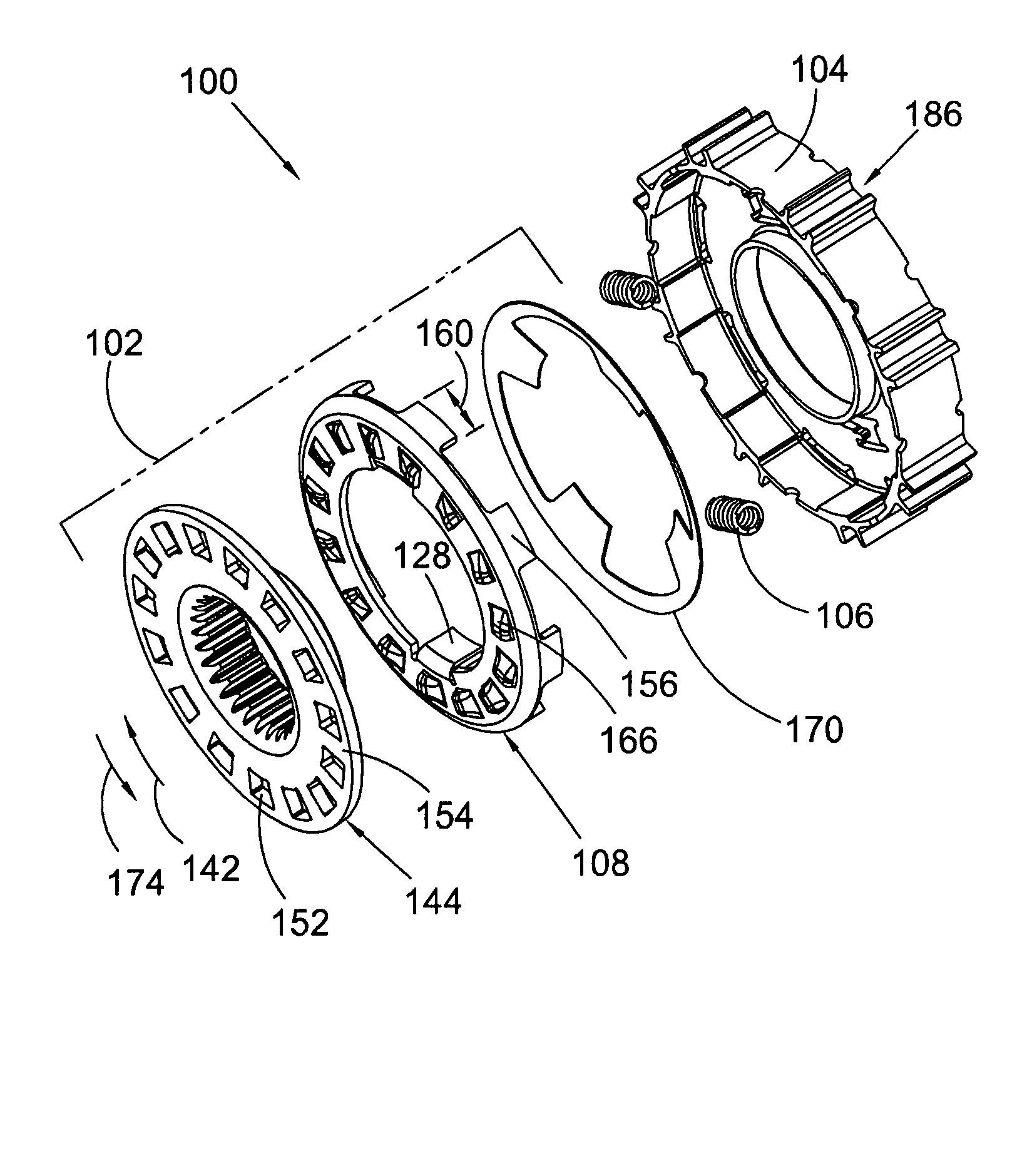

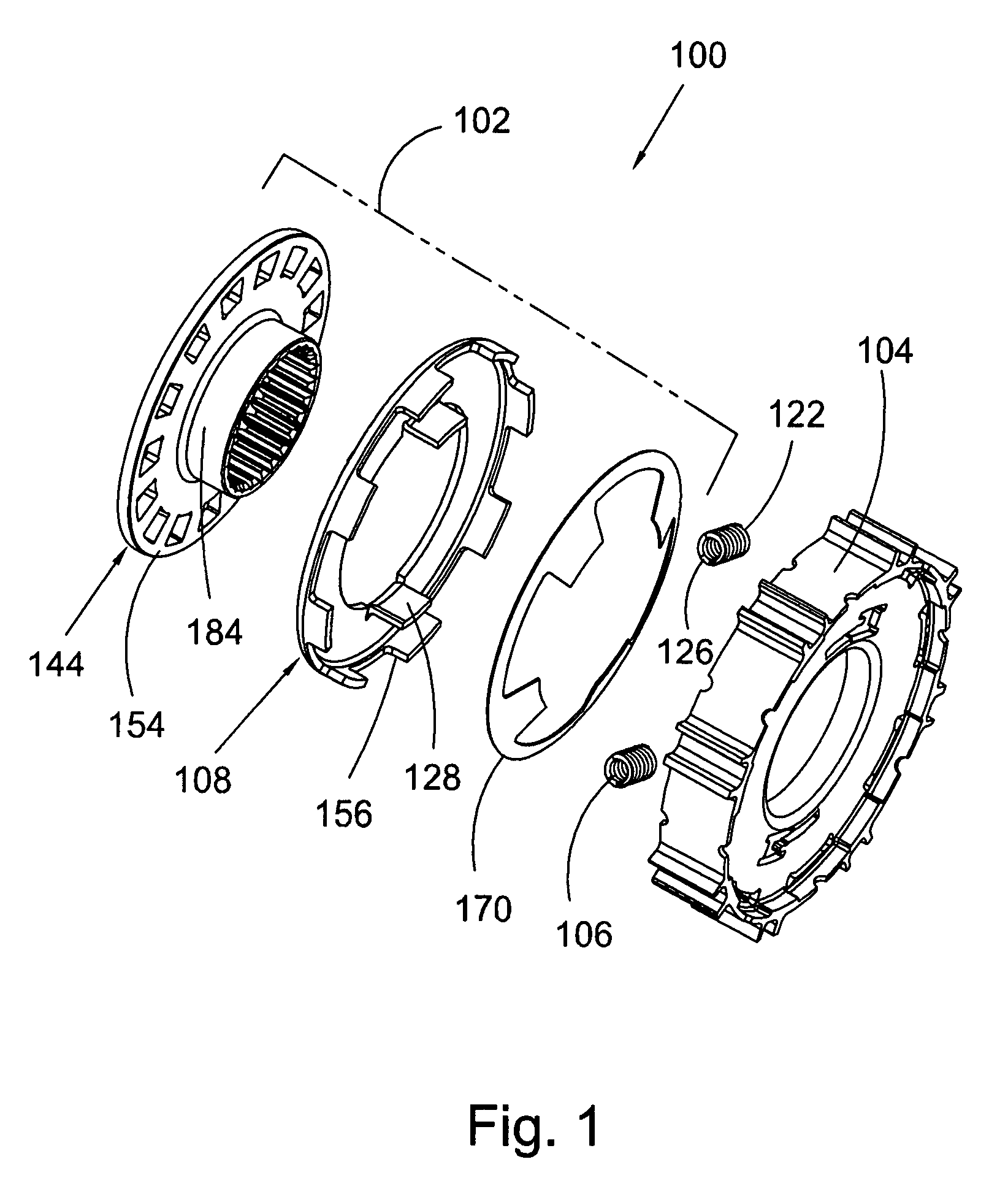

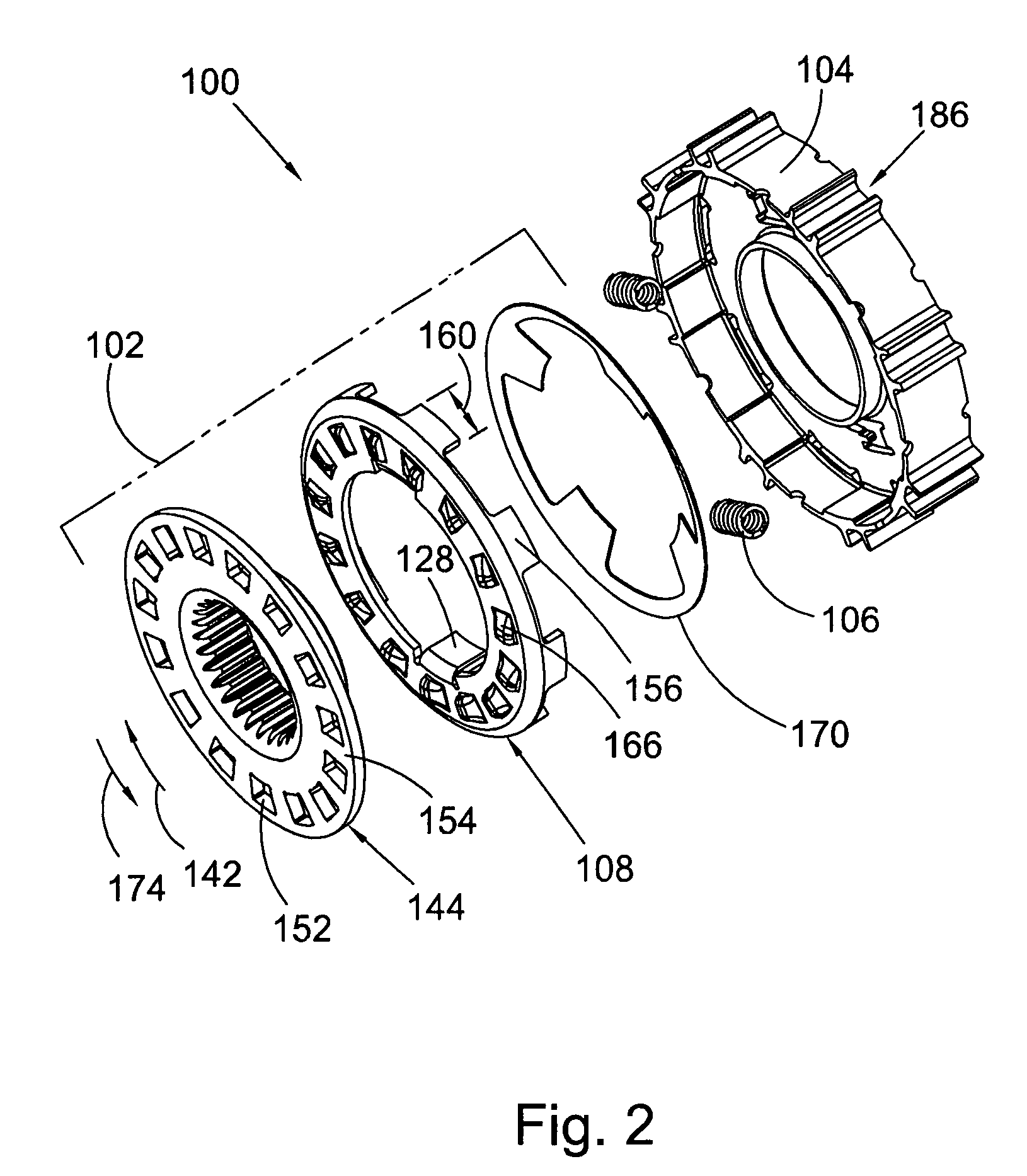

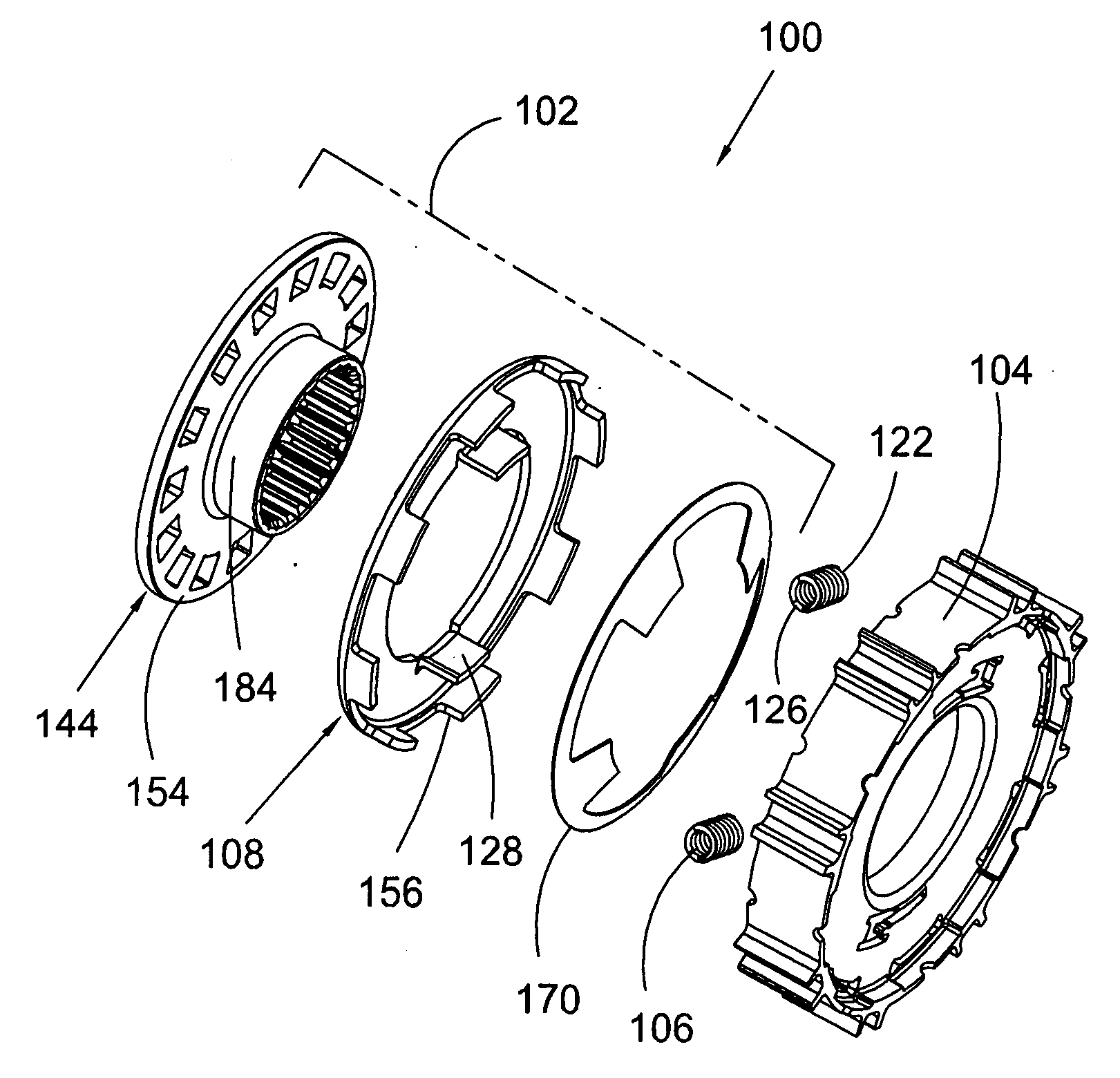

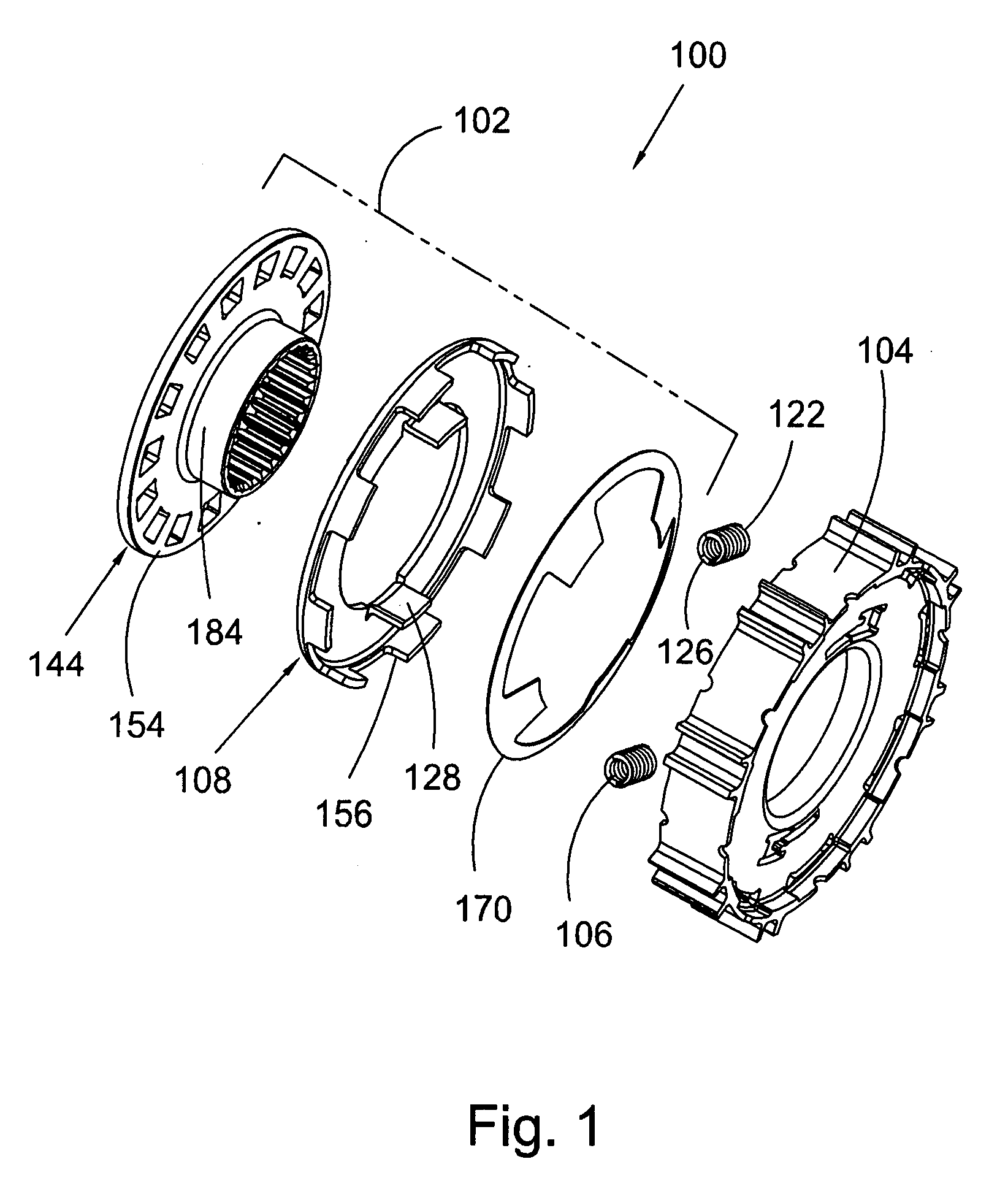

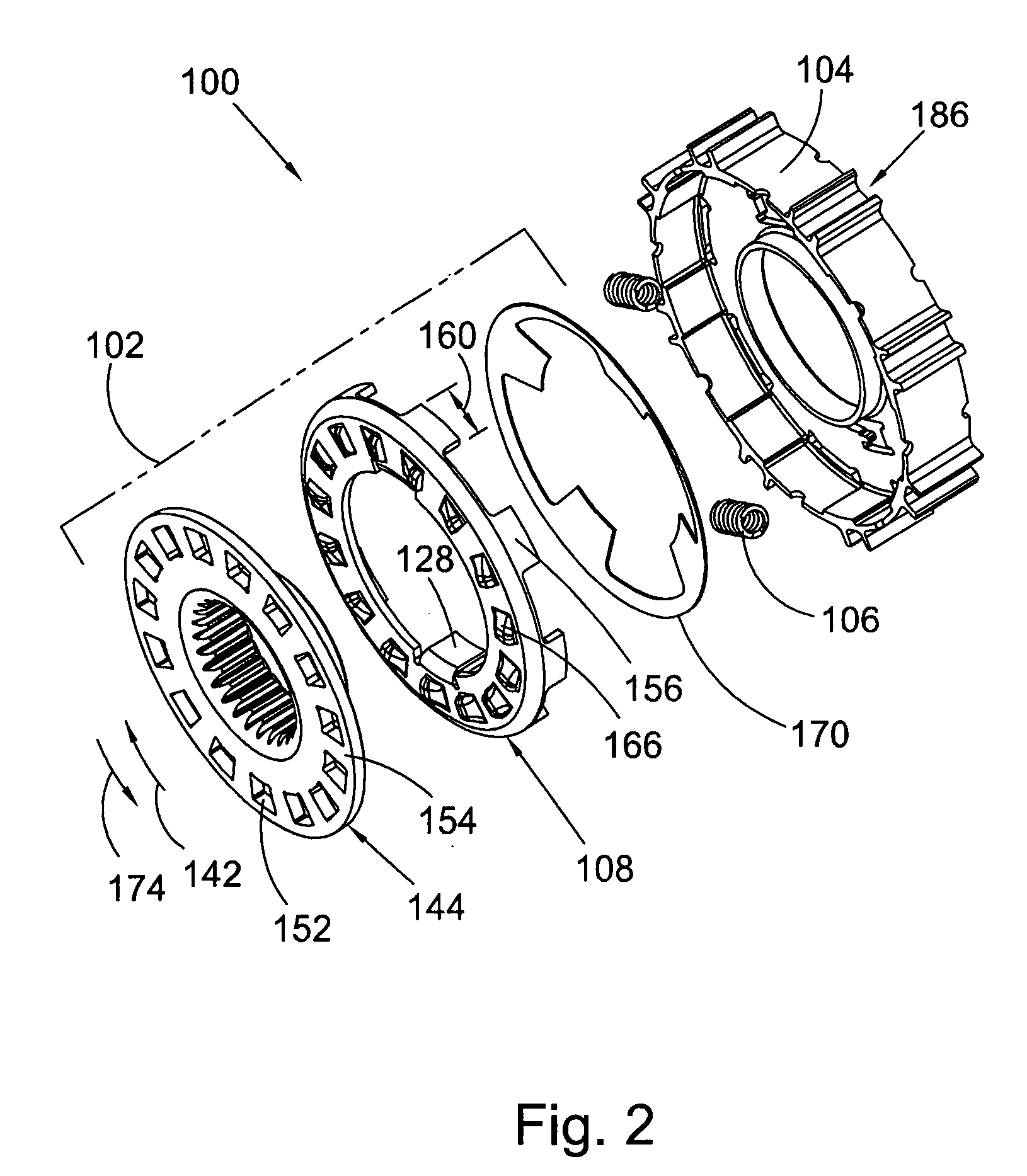

Ratchet one-way clutch with vibration dampening

Owner:SCHAEFFLER TECH AG & CO KG

Forward looking optical coherence tomography endoscope

InactiveUS8323183B2High resolutionSmall diameterInterferometersSurgeryScanning mirrorForward looking

A forward-looking, optical coherence tomography, endoscopic probe is disclosed capable of high resolution with a small diameter. Light is focused and scanned during three passes through a lens. A light source supplies light to the proximal side of the lens. The light makes a first pass through the lens, and is reflected from a fixed mirror on the distal side. The reflected light makes a second pass from the distal side to the proximal side, and exits the lens at the proximal side, and is reflected by a scanning mirror. The light makes a third pass through the lens from the proximal side to the distal side to a sample to be imaged. The light is focused during each of the three passes through the lens. Light reflected from the sample passes back through and is focused by the same system.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Offset track

An offset track forms a pattern perpendicular to the centerline of the track which enables tracks to be formed with even or odd number of metal inserts and thus accommodate virtually any tracked vehicle. The offset track uses variations in body thickness and lug width to provide a high performance offset track with improved ride, minimum vibration and longer wear. Use of full size and mini-inserts in a single track minimizes the weight and further enhances the performance of an offset track.

Owner:MCLAREN GRP HLDG PTE LTD

Attachment guide comb conduit

A dummy hair clipper head, or dummy blade, which is a form conforming to those dimensions of a hair clipper's stationary blade which are necessary for its compatibility with attachment guide combs, is employed in a conduit comb which comprises a form configured to allow air or liquid to pass through the form and between the teeth of the attachment guide comb, whereby an attachment guide comb can be employed in vacuuming, drying, washing and treating hair. The form can be connected in turn to a bottle, air hose, or faucet to allow for the transmission of air or liquid through the comb. The use of the form also makes possible a variety of new uses for attachment guide combs including a scissor comb, razor comb, and comb organizer.

Owner:MICHEL MATTHEW JUSTIN

Coriolis mass flowmeter having a pair of oscillation node plates fixably mounted to measuring tubes

A Coriolis mass flowmeter having two measuring tubes, wherein two neighboring oscillation node plates are provided on one end of the measuring tube that connect the two measuring tubes to one another and wherein the angle between the planes of both oscillation node plates is determined in such a manner that the vibration of the measuring tubes is minimal up to a predetermined driving force. A method of producing the flowmeter is also disclosed.

Owner:KRONE GMBH

Ratchet one-way clutch with vibration dampening

The present invention broadly comprises a stator and one-way clutch assembly including a segment of a stator, a one-way clutch engaged with the segment, and at least one elastically deformable element engaged with the segment and the clutch and arranged to dampen transfer of torque from the stator to the clutch. In some aspects, the clutch includes a first plate and the deformable element is engaged with the segment and the plate. The segment urges the deformable element against the first plate. The first plate is arranged to rotate in response to the urging. The segment and the first plate are arranged to rotationally lock. The first plate and a second plate, connected to a clutch hub, rotationally lock in response to the urging, and the segment and the first plate are arranged to rotationally lock following the locking of the first and second plates.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com